Total information

| Substitute |

| Steel 15, Steel 25 |

| Type of delivery |

| Long products, including shaped steel: GOST 1050-74, GOST 2590-71, GOST 2591-71, GOST 2879-69, GOST 8509-86, GOST 8510-86, GOST 8240-72, GOST 8239-72. Calibrated rod GOST 7417-75, GOST 8559-75, GOST 8560-78, GOST 10702-78. Polished rod and silver steel GOST 14955-77, GOST 10702-78. Thick sheet GOST 1577-81, GOST 19903-74. Thin sheet GOST 16523-70. Tape GOST 6009-74, GOST 10234-77. Strip GOST 1577-81, GOST 103-76, GOST 82-70. Wire GOST 5663-79, GOST 17305-71. Forgings and forged blanks GOST 8479-70. Pipes GOST 10704-76, GOST 10705-80, GOST 8731-87, GOST 8732-78, GOST 8733-87, GOST 5654-76, GOST 550-75. |

| Purpose |

| After normalization or without heat treatment, crane hooks, couplings, bearing shells and other parts operating at temperatures from -40 to 450 ° C under pressure, after chemical treatment - gears, worms and other parts that require high surface hardness with low core strength . |

Description

Steel 20GL is used : for the manufacture of disks, sprockets, gear rims, drums and other parts that are subject to requirements for strength and toughness, operating under static and dynamic loads; for the manufacture of the 3rd group of castings of pipeline fittings parts in the northern version with impact strength testing KCU-60≥300 kJ/m2 (3.0 kgf m/cm2), operating at operating medium temperatures from -60 to +350 °C without restrictions on nominal operating pressure; critical cast parts of automatic couplers and bogies of freight and passenger cars, electric and diesel trains and locomotives.

Note

Cold resistant steel.

Advantages of steel and its disadvantages

Steel grade 20 has the main advantage - this high-quality alloy with good technological characteristics can be purchased at a reasonable price. When using metal to produce products, its advantages are noted:

- is both plastic and durable, resistant to abrasion;

- retains the necessary qualities when operating in the temperature range (-40 - +450 °C);

- has low flake sensitivity;

- resistant to high pressure environments (gas, steam);

- practically no cracks form in the alloy structure after pressure treatment;

- the metal has high weldability (before heat treatment);

- after welding work, the seams do not need to be hardened;

When using metal, it is necessary to take into account its main disadvantage - the appearance of signs of corrosion on the surface. To prevent such a process, it is necessary to coat it with a special protective chemical composition (plating).

Composition and structure

The basis is iron. Additional components:

- Carbon (0.2%). The strength and hardness of the alloy depends on this component. The more it is, the higher these indicators, but at the same time the plasticity decreases.

- Manganese (0.6%). This is a strong deoxidizer. When it is added, the amount of sulfur in the composition is reduced. Increases strength and wear resistance at the surface of the alloy structure. Improves forging and metal welding.

- Silicon (0.35%). Strong deoxidizing agent. Added to reduce the content of nitrogen, oxygen, hydrogen. This reduces the number of pores and gas pockets, which negatively affect strength.

- Copper (0.3%), chromium (0.2%), nickel (0.3%). These components are needed to increase resistance to rust formation and increase mechanical resistance.

- Sulfur (0.04%), phosphorus (0.035%). Harmful components that worsen its technical characteristics and properties.

The properties and parameters of the finished product depend on the number of additional components. To change them, the composition can be saturated with various alloying additives.

Copper wire

Mass fraction of steel elements 20 according to GOST 1050-2013

| C (Carbon) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulphur) | Cr (Chrome) | Ni (Nickel) | Cu (Copper) | Fe (Iron) |

| 0,17 – 0,24 | 0,17 – 0,37 | 0,35 – 0,65 | < 0,03 | < 0,035 | < 0,25 | < 0,30 | < 0,30 | rest |

If the mass fraction of aluminum is not less than 0.02 or Ti, V, Nb, Al are introduced separately or in any combination (Ti + V + Nb + Al < 0.015), then the nitrogen content is not standardized. It is allowed to reduce the level of silicon when using other deoxidizers, for example, Al, Ti, V, Nb. It is allowed to reduce the level of manganese if all requirements for mechanical properties are met.

20GL Yekaterinburg

| Brand: | 20GL |

| Classification: | Alloy casting steel |

| Application: | disks, sprockets, ring gears and other parts that are subject to requirements for strength and toughness, operating under static and dynamic loads |

| Foreign analogues: | Known |

Chemical composition in % of material 20GL

GOST 977-88, also included in GOST 21357-87

| C | Si | Mn | S | P |

| 0.15- 0.25 | 0.2- 0.4 | 1.2- 1.6 | up to 0.04 | up to 0.04 |

| Note: ??? Material 20GL is also included in GOST 21357-87, where it has a different chemical. composition and properties??? |

Heat treatment modes for 20GL material

| Normalization 880-900 ° C, Vacation 600-650 ° C |

| Quenching 870-890 ° C, Tempering 620-650 ° C |

Mechanical properties at T=20oC of 20GL material.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Castings, K25, GOST 977-88 | 540 | 275 | 18 | 25 | 491 | Normalization 880-900 ° C, Vacation 600-650 ° C | ||

| Castings, KT30, GOST 977-88 | 530 | 334 | 14 | 25 | 383 | Quenching 870-890 ° C, Tempering 620-650 ° C | ||

| Castings, GOST 21357-87 | 500 | 300 | 20 | 35 | Normalization | |||

| Castings, GOST 21357-87 | 550 | 400 | 15 | 30 | Quenching and tempering |

| Hardness 20GL, | HB 10 -1 = 143-187 MPa |

Foreign analogues of material 20GL

Attention!

Both exact and closest analogues are indicated. 1.1120

| USA | Germany | Japan | European Union | Italy | Bulgaria | Hungary | Poland | Romania | Czech | Austria |

| — | DIN,WNr | JIS | EN | UNI | BDS | MSZ | PN | STAS | CSN | ONORM |

A352GrLCC

| ||||||||||

| 1.1133 | ||||||||||

| G17Mn5 | ||||||||||

| GS20Mn5 |

| SCMn1 |

Designations:

| Mechanical properties : | |

| sв | -Short-term strength limit, [MPa] |

| sT | - Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | -Elongation at break, [%] |

| y | -Relative narrowing, [%] |

| KCU | -Impact strength, [kJ/m2] |

| HB | -Brinell hardness, [MPa] |

| Physical properties: | |

| T | -Temperature at which these properties were obtained, [Deg] |

| E | -Elastic modulus of the first kind, [MPa] |

| a | -Coefficient of thermal (linear) expansion (range 20o-T), [1/degree] |

| l | -Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | -Material density, [kg/m3] |

| C | -Specific heat capacity of the material (range 20o-T), [J/(kg deg)] |

| R | -Specific electrical resistivity, [Ohm m] |

20GL-Alloyed steel for castings 20GL-chemical composition, mechanical, physical and technological properties, density, hardness, application

Affordable metal products

20GL

Characteristics and properties

Physical properties:

- Density indicator - 7850 kg/m3.

- The melting of the alloy begins at 1500 °C.

- Thermal conductivity of the finished product without an increased amount of alloying additives is 48 W/m*K.

- Heat capacity - 490 J/kg*K.

- Linear expansion - 11.6*10-6 1/deg.

- Electrical resistance - 220 Mohm*mm.

Chemical properties:

- Low resistance to alkalis and acids.

- Rapid formation of rust with prolonged exposure to moisture.

To make steel resistant to corrosion processes, manufacturers apply a galvanic coating based on chromium and zinc.

Mechanical parameters:

- Easy machining.

- Average hardness and strength.

- Modulus of elasticity - 200 MPa.

- Elongation at break - 26%.

- The maximum narrowing of the structure is 55%.

- The endurance limit of the metal is 14 kg/mm2.

- Impact strength of metal surfaces - 780 kJ/m2.

- The tensile strength of the structure is up to 46 kg/mm2.

The metal conducts electricity well and is paramagnetic.

Steel coils

Mechanical properties

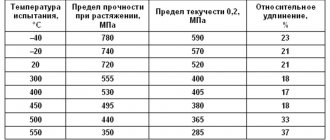

Mechanical properties at elevated temperatures

| test t, °C | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 |

| 410 | 25 | 55 | |||

| 490 | 7 | 40 | |||

| 390 | 21 | 50 | |||

| 390-490 | 50 | 163 | |||

| 340-440 | 50 | 163 | |||

| 490 | 7 | 40 | 207 | ||

| 410 | 25 | 55 | |||

| 340-490 | 28 | 127 | |||

| 20 | 280 | 430 | 34 | 67 | 218 |

| 200 | 230 | 405 | 28 | 67 | 186 |

| 300 | 170 | 415 | 29 | 64 | 188 |

| 400 | 150 | 340 | 39 | 81 | 100 |

| 500 | 140 | 245 | 40 | 86 | 88 |

| 700 | 130 | 39 | 94 | ||

| 800 | 89 | 51 | 96 | ||

| 900 | 75 | 55 | 100 | ||

| 1000 | 47 | 63 | 100 | ||

| 1100 | 30 | 59 | 100 | ||

| 1200 | 20 | 64 | 100 |

Mechanical properties of rolled products

| Heat treatment, delivery condition | σB, MPa | δ5, % | ψ, % | KCU, J/m2 |

| Calibrated hot-rolled, forged and silver steel of the 2nd category after normalization | 410 | 25 | 55 | |

| Calibrated steel of the 5th category after hardening | 490 | 7 | 40 | |

| Calibrated steel of category 5 after annealing or high tempering | 390 | 21 | 50 | |

| Steel, calibrated and calibrated with a special finish after tempering or annealing | 390-490 | 50 | 163 | |

| Steel calibrated and calibrated with special finishing after spheroidizing annealing | 340-440 | 50 | 163 | |

| Calibrated and calibrated steel with a special finish, cold-worked without heat treatment | 490 | 7 | 40 | 207 |

| Normalized or hot rolled strips | 410 | 25 | 55 | |

| Heat-treated sheet of category 1-2 | 340-490 | 28 | 127 | |

| 430 | 34 | 67 | 218 | |

| 405 | 28 | 67 | 186 | |

| 415 | 29 | 64 | 188 | |

| 340 | 39 | 81 | 100 | |

| 245 | 40 | 86 | 88 | |

| 130 | 39 | 94 | ||

| 89 | 51 | 96 | ||

| 75 | 55 | 100 | ||

| 47 | 63 | 100 | ||

| 30 | 59 | 100 | ||

| 20 | 64 | 100 |

Mechanical properties of forgings

| Heat treatment, delivery condition | Section, mm | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 | HB |

| Normalization | |||||||

| KP 175 | <100 | 175 | 350 | 28 | 55 | 64 | 101-143 |

| KP 175 | 100-300 | 175 | 350 | 24 | 50 | 59 | 101-143 |

| KP 175 | 300-500 | 175 | 350 | 22 | 45 | 54 | 101-143 |

| KP 175 | 500-800 | 175 | 350 | 20 | 40 | 49 | 101-143 |

| KP 195 | <100 | 195 | 390 | 26 | 55 | 59 | 111-156 |

| KP 195 | 100-300 | 195 | 390 | 23 | 50 | 54 | 111-156 |

| KP 215 | <100 | 215 | 430 | 24 | 53 | 54 | 123-167 |

| KP 215 | 100-300 | 215 | 430 | 20 | 48 | 49 | 123-167 |

| Hardening. Vacation. | |||||||

| KP 245 | 100-300 | 245 | 470 | 19 | 42 | 39 | 143-179 |

Mechanical properties of steel after chemical treatment

| Section, mm | σ0.2, MPa | σB, MPa | δ5, % | ψ, % | KCU, J/m2 | HB | HRСе |

| Cementation 920-950 °C, air. Quenching 800-820 °C, water. Vacation 180-200 °C, air. | |||||||

| 50 | 290-340 | 490-590 | 18 | 45 | 54 | 156 | 55-63 |

Properties according to GOST 1050-2013 standard

| Yield strength, σ0.2, MPa | Tensile strength, σв, MPa | Elongation at break, δ5, % | Relative narrowing, ψ, % |

| > 245 | > 410 | > 25 | > 55 |

Properties according to GOST 2284-79 standard

| Assortment | Yield strength, σ0.2, MPa | Tensile strength, σв, MPa | Elongation at break, δ5, % |

| Annealed tape | – | 310-540 | 18 |

| Cold-worked tape | – | 490-830 | – |

Technological properties

| Forging temperature |

| Start 1280, end 750. Air cooling. |

| Weldability |

| Weldable without restrictions, except for parts after chemical-thermal treatment. Methods of welding RDS, ADS submerged arc and gas shield, KTS. |

| Machinability |

| In the hot-rolled state at HB 126-131 and sB = 450-490 MPa, Ku tv.alloy. = 1.7 and Ku b.st. = 1.6. |

| Tendency to release ability |

| Not inclined. |

| Flock sensitivity |

| Not sensitive. |

Critical point temperature

| Critical point | °C |

| Ac1 | 735 |

| Ac3 | 850 |

| Ar3 | 835 |

| Ar1 | 680 |

Impact strength

Impact strength, KCU, J/cm2

| Delivery condition, heat treatment | +20 | -20 | -40 | -60 |

| Annealing | 110 | 68 | 47 | 10 |

| Normalization | 157 | 109 | 86 | 15-38 |

Endurance limit

| σ-1, MPa | τ-1, MPa | n | σB, MPa | σ0.2, MPa | Heat treatment, steel condition |

| 206 | 1E+7 | 500 | 320 | ||

| 245 | 520 | 310 | |||

| 225 | 490 | 280 | |||

| 205 | 127 | Normalization 910 C, release 620 C. | |||

| 193 | 420 | 280 | |||

| 255 | 451 | Cementation 930 C, hardening 810 C, tempering 190 C. |

Chemical properties

The material has low chemical resistance to most acidic compounds. If moisture gets on the surface, rust will remain on it. Because of it, the appearance and strength are greatly deteriorated.

To protect the material from corrosion, galvanic coatings (chrome, zinc, and other similar compounds) should be applied.

Physical properties

| Test temperature, °C | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| Modulus of normal elasticity, E, GPa | 212 | 208 | 203 | 197 | 189 | 177 | 163 | 140 | ||

| Modulus of elasticity under torsional shear G, GPa | 78 | 77 | 76 | 73 | 69 | 66 | 59 | |||

| Density, pn, kg/cm3 | 7859 | 7834 | 7803 | 7770 | 7736 | 7699 | 7659 | 7917 | 7624 | 7600 |

| Thermal conductivity coefficient W/(m °C) | 51 | 49 | 44 | 43 | 39 | 36 | 32 | 26 | 26 | |

| Ud. electrical resistance (p, NΩ m) | 219 | 292 | 381 | 487 | 601 | 758 | 925 | 1094 | 1135 | |

| Test temperature, °C | 20- 100 | 20- 200 | 20- 300 | 20- 400 | 20- 500 | 20- 600 | 20- 700 | 20- 800 | 20- 900 | 20- 1000 |

| Linear expansion coefficient (a, 10-6 1/°С) | 12.3 | 13.1 | 13.8 | 14.3 | 14.8 | 15.1 | 15.2 | |||

| Specific heat capacity (C, J/(kg °C)) | 486 | 498 | 514 | 533 | 555 | 584 | 636 | 703 | 703 | 695 |

Deoxidation level

- Calm steel 20. Due to the introduction of silicon and manganese, oxygen is completely absent. Iron oxides are also in very small quantities. This ensures “quiet” solidification of the metal in the ladle. The homogeneity and density of ST20 at the outlet are excellent, only a gas shell is formed on top.

- Boiling steel. It is formed by the deoxidation of manganese, which leads to an increase in the content of ferrous oxide. The compound forms carbon dioxide. As a result, gas bubbles form, looking like a boiling mass. Such a metal is very porous, chemical elements are distributed unevenly, which causes deterioration in mechanical characteristics, increases the risk of cracks, and impairs weldability. But there are also advantages - low price, absence of unsafe waste.

- Semi-quiet ST20. Something in between the previous varieties of the alloy.

Steel grade 20: explanation, characteristics, chemical composition

Description

Steel 20 belongs to structural carbon quality steels. It is used for the manufacture of parts that require high viscosity and are not subject to stress during operation. In particular, this steel is used for the manufacture of non-fire equipment of oil refineries: reaction chambers, evaporators, distillation columns, gas separators, heat exchanger bodies and other vessels, as well as welded flanges. In petroleum engineering, piston cores for mud pumps, cracked forged drill keys, axles, couplings, crosshead pins and compressor pump drive gears, various bolts, nuts, screws, studs, forks, levers, washers, etc. are manufactured.

After normalization or without heat treatment, crane hooks, couplings, bearing shells and other parts operating at temperatures from -40 to 450 ° C under pressure are made from steel 20; after chemical treatment - gears, worms and other parts that require high surface hardness with low core strength.

Decoding steel 20

The number 20 indicates the average carbon content in hundredths of a percent, i.e. The carbon content in steel 20 is 0.2%.

If the steel is designated 20A, then the letter “A” at the end of the mark indicates that the steel belongs to the high-quality category

Substitutes and analogues

Steel substitutes:

- steel 15

- steel 25

Foreign analogues:

- C22 - Germany DIN

- 1.0402 - Euronorms (EN)

- 1020 - USA (AISI, ASTM)

- XC18, AF 40 C20, AF 42 - France (AFNOR)

- 050A20- UK BS

- S 20 - Japan JIS

- 12024 - Czech Republic (CSN)

- 20 – Poland(PN/H)

Chemical composition, % (GOST 19281-2014)

| C, carbon | Mn, manganese | Si, silicon | P, phosphorus | S, sulfur | Cr, chromium | Ni, nickel | Cu, copper | As, arsenic |

| no more | ||||||||

| 0,17-0,24 | 0,17-0,37 | 0,35-0,65 | 0,25 | 0,04 | 0,035 | 0,25 | 0,25 | 0,08 |

Heat treatment of Steel 20

To increase surface hardness and, therefore, increase resistance to wear, parts made of steel 20 are in some cases carburized or cyanidated (for example, crosshead pins, gears, axles).

Cementation is carried out at a temperature of 910-930 ° C; cemented products are hardened at a temperature of 780-800 ° C in water and tempered at 150-180 ° C. They are cyanidated, as a rule, in baths of molten salts containing 20-25% sodium cyanide at a temperature of 820-850 ° C for 20-40 minutes. With this cyanidation mode, it is possible to obtain cyanidation with a depth of 0.2-0.3 mm. After cyanidation and hardening with tempering at 150-180 °C, the products have a surface hardness of HRC 62-64.

Mechanical properties

| GOST | Delivery status | σв, MPa, | δ5, % | Ψ, % | Hardness HB , no more |

| no less | |||||

| GOST 1050-88 | Calibrated steel: | ||||

| hot-rolled, forged and silver steel of the 2nd category after normalization | 410 | 25 | 55 | — | |

| 5th category after hardening | 490 | 7 | 40 | — | |

| 5th category after annealing or high tempering | 390 | 21 | 50 | — | |

| GOST 10702-78 | Steel calibrated and calibrated with special finishing: | ||||

| after holiday or annealing | 390-490 | — | 50 | 163 | |

| after spheroidizing annealing | 340-440 | — | 50 | 163 | |

| cold-worked without heat treatment | 490 | 7 | 40 | 207 | |

| GOST 1577-93 | Normalized or hot rolled strip | 410 | 25 | 55 | — |

| GOST 4041-71 (transverse samples) | Heat-treated sheet of category 1 and 2 | 340-490 | 28 | — | 127 |

Mechanical properties of forgings (GOST 8479-70)

| Heat treatment | Section, mm | KP | σ0.2, MPa, | σв, MPa, | δ5, % | Ψ, % | KCU , J/cm2 | Hardness HB , no more |

| no more | ||||||||

| Normalization | Up to 100 | 175 | 175 | 350 | 28 | 55 | 64 | 101-143 |

| 100-300 | 350 | 24 | 50 | 59 | 101-143 | |||

| 300-500 | 350 | 22 | 45 | 54 | 101-143 | |||

| 500-800 | 350 | 20 | 40 | 49 | 101-143 | |||

| Up to 100 | 195 | 195 | 390 | 26 | 55 | 59 | 111-156 | |

| 100-300 | 390 | 23 | 50 | 54 | 111-156 | |||

| Up to 100 | 215 | 215 | 430 | 24 | 53 | 54 | 123-167 | |

| 100-300 | 430 | 20 | 48 | 49 | 123-167 | |||

| Hardening + tempering | 100-300 | 245 | 245 | 470 | 19 | 42 | 39 | 143-179 |

Mechanical properties of steel after chemical treatment

| HTO mode | Section, mm | σ0.2, MPa, | σв, MPa, | δ5, % | Ψ, % | KCU , J/cm2 | Hardness HB , no more |

| no more | |||||||

| Cementation at 920-950 °C, cooling. on air; hardening from 800-820 °C in water; holiday at 180-200 “C, cool. on air | 50 | 290-340 | 490-590 | 18 | 45 | 54 | HRC e 156 - cores; HB 55-63 - surfaces |

Endurance limit (n = 107)

| Strength characteristics | σ-1, MPa | τ-1, MPa |

| σ0.2 = 320 MPa, σв = 500 MPa, | 206 | — |

| σ0.2 = 310 MPa, σв = 520 MPa, | 245 | — |

| σ0.2 = 280 MPa, σв = 490 MPa, | 225 | — |

| — | 127*1 | — |

| σ0.2 = 280 MPa, σв = 420 MPa, | 193 | — |

| — | 255 | 127*2 |

*1 - Normalization at 910 °C, tempering at 620 °C. *2 - Cementation at 930 °C, tempering at 190 °C.

Mechanical properties at elevated temperatures

| t isp, °С | σ0.2, MPa | σв, MPa | δ5, % | ψ, % | KCU , J/cm2 |

| 20 | 280 | 430 | 34 | 67 | 218 |

| 200 | 230 | 405 | 28 | 67 | 186 |

| 300 | 170 | 415 | 29 | 64 | 188 |

| 400 | 150 | 340 | 39 | 81 | 100 |

| 500 | 140 | 245 | 40 | 86 | 88 |

| 700 | — | 130 | 39 | 94 | — |

| 800 | — | 89 | 51 | 96 | — |

| 900 | — | 75 | 55 | 100 | — |

| 1000 | — | 47 | 3 | 100 | — |

| 1100 | — | 30 | 59 | 100 | — |

| 1200 | — | 20 | 64 | 100 | — |

Impact strength KCU

| Heat treatment | KCU , J/cm2, at temperature, °C | |||

| +20 | -20 | -40 | -60 | |

| Annealing | 110 | 68 | 47 | 10 |

| Normalization | 157 | 109 | 86 | 15-38 |

Note. σ4001/10000 = 98 MPa; σ4751/100000 = 35 MPa; σ4501/10000 = 120 MPa; σ4751/1000000 = 78 MPa; σ4501/1000 = 59 MPa;

Technological properties

Forging temperature, °C: beginning 1280, end 750. Cooling in air. Weldability - weldable without restrictions, except for parts after chemical treatment. Welding methods: RDS, ADS submerged arc and gas shield, KTS. Cutting ability - K v

tv.sp = 1.7 and

K v

b.st = 1.6 in the hot-rolled state at

HB

126-131 and σw = 450-490 MPa. Flock sensitivity - not sensitive. Tendency to temper brittleness - not prone.

Temperature of critical points, °C

| Ac1 | Ac3 | Ar3 | Ar1 |

| 735 | 850 | 835 | 680 |

Find out more

Steel 15HSND low-alloy structural...

Steel 15

U10, U10A carbon tool steel…

High-quality carbon structural steel…

Heat treatment features

The material is subject to heat treatment - hardening, tempering, annealing. After their implementation, the ferrite-pearlite structure changes, which transforms into martensite. There is a decrease in the plasticity of the material with a simultaneous increase in its strength.

When heating workpieces, two types of furnaces are used - induction and blast furnaces. For hardening, the temperature range is from 790 to 820°C. The time spent in the oven may vary depending on the technology. Cooling is performed in air, oil or water. For annealing, the workpieces are heated to 160–200°C.

Kinds

Depending on the degree of deoxidation, three types of steel can be distinguished:

- Boiling. Manganese is used for deoxidation. The composition increases the amount of iron. When interacting with carbon, a large amount of carbon dioxide is released. The peculiarity of this type of steel is its high porosity. The main components of the metal are distributed unevenly throughout the structure. Because of this, the strength indicator decreases.

- Calm. It is formed in the process of removing oxygen from the metal composition. To do this, manganese and silicon are introduced into the alloy. It contains a minimal amount of iron oxide inside. The structure is homogeneous and ordered. The steel turns out to be high-strength. Gas pockets that form near surfaces are removed mechanically.

The third type is a semi-resistant alloy. It is a combination of two options.

Chemical composition of steel 20-KHS

| Standard | C | S | P | Mn | Cr | Si | Ni | Cu | N | As | Al | Nb |

| TU 14-1-5433-2005 | 0.14-0.2 | up to 0.009 | up to 0.02 | 0.4-0.8 | 0.1-0.3 | 0.17-0.37 | 0.1-0.3 | up to 0.3 | up to 0.008 | up to 0.08 | 0.02-0.05 | 0.03-0.06 |

| TU 14-1-5491-2004 | 0.18-0.22 | up to 0.009 | up to 0.02 | 0.4-0.8 | up to 0.25 | 0.17-0.37 | up to 0.3 | up to 0.3 | up to 0.008 | up to 0.08 | 0.02-0.05 | 0.03-0.06 |

According to TU 14-1-5491-2004, deviations from the chemical composition are allowed: for carbon ±0.010%, for manganese ±0.050%, for sulfur +0.0010%, for phosphorus +0.0030%, for nitrogen +0.0030% , for silicon ±0.020%, for chromium +0.020%, for vanadium +0.020%, for aluminum +0.010%, for niobium +0.010%. The carbon equivalent of SEQ is calculated by the formula and should not exceed 0.43%: SEQ = C + Mn/6 + (Cr + Nb)/5 + (Ni + Cu)/15, where C, Mn, Cr, Nb, Ni, Cu is the mass fraction of the main elements that make up the steel.

According to TU 14-1-5433-2005, deviations from the chemical composition are allowed: for carbon ±0.010%, for manganese ±0.050%, for sulfur +0.0010%, for phosphorus +0.0030%, for nitrogen +0.0030% , for niobium +0.010%.

Types of rolled profiles

A rolled profile from ST 20 is obtained in one of two ways:

- Hot deformation. This method is used only for products of a certain thickness, which should not be higher than 4 mm.

- Cold deformation. For small thickness products. As a result of the procedure, the alloy thickens.

The following types of rolled products are obtained using these methods:

- Cold-rolled pipes made of entirely welded steel. The sheets must be joined along the edges of the seams, which protrude in a straight line. This is done after preliminary convolution of them along the radius. The results are solid products with increased hardness.

- Seamless pipes. The method of hot and cold drawing is used, which gives the product maximum strength and sets a fairly high price.

- Profiles of all types: sheets, channels, wires, rods. You can make any length and width of the product.

Mechanical properties of steel 20-KHS

| Type of delivery | Section, mm | sТ|s0.2, MPa | σB, MPa | d5, % | KCU, kJ/m2 |

| Heat-treated pipes in delivery condition according to TU 14-1-5433-2005. The impact strength column shows the values KCU-60/KCV-20 | ≥335 | ≥470 | ≥20 | ≥294/294 | |

| ≥355 | ≥510 | ≥20 | ≥294/294 | ||

| Heat-treated pipes, as delivered according to TU 14-1-5491-2004 | ≥350 | 510-630 | ≥20 | ≥392 |

Manufacturing

Production methods:

- Converter. The molten metal is blown through with a stream of air.

- Martenovsky. Melting scrap metal in special furnaces.

- Using electric ovens. Allows you to control the work process.

The material is used for the manufacture of various types of rolled products:

- Cold deformation. Used for rolling workpieces with a thickness of no more than 4 mm. When cold hardening increases the strength of the alloy.

- Hot deformation. Used for rolling workpieces with a thickness of over 4 mm.

Hot deformation is a popular metal rolling technology, but scale forms on the surfaces, which reduces the strength of the material.

Open hearth furnaces

The main differences between Steel 20 and Steel 20A

The addition of the letter “A” at the end of the designation of Steel 20 indicates that Steel 20A belongs to the category of high-quality steel. The main differences in the chemical composition are more stringent requirements for the Sulfur (S) content and broader requirements for the Carbon (C) content (see table).

| Chemical element | % | |

| Steel 20 | Steel 20A | |

| Carbon (C) | 0.17-0.24 | 0.15-0.25 |

| Sulfur (S), no more | 0.04 | 0.035 |

Therefore, Steel 20A is less susceptible to embrittlement.

Chemical composition

| Standard | C | S | P | Mn | Cr | Si | Ni | Fe | Cu |

| GOST 977-88 | 0.15-0.25 | ≤0.04 | ≤0.04 | 1.2-1.6 | — | 0.2-0.4 | — | Remainder | — |

| TU 24.05.486-82 | 0.17-0.25 | ≤0.04 | ≤0.04 | 1.1-1.4 | ≤0.3 | 0.3-0.5 | ≤0.3 | Remainder | ≤0.3 |

| GOST 21357-87 | 0.17-0.25 | ≤0.02 | ≤0.02 | 1.1-1.4 | ≤0.3 | 0.3-0.5 | ≤0.3 | Remainder | ≤0.3 |

Fe is the basis.

Areas of application

Certain technical characteristics of steel 20 explain its use in different areas of industry:

- Production of pipe fittings (sleeve nuts, fittings, flanges, crosses, nipples).

- Manufacturing of building materials.

- Assembly of various metal structures, machines, ships, industrial equipment.

This metal is used to produce:

- Seamless pipes. Manufactured by cold or hot drawing. Their feature is high strength.

- All-welded cold-rolled pipes.

- Various profiles (wire, I-beams, channels, metal corners, sheets of different thicknesses, rods).

Products from this alloy are manufactured according to certain state standards:

- GOST 17305-91—production of wire of different sections.

- GOST 82-70 - production of metal strips of different widths.

- GOST 16523-97 - production of light sheets of small thickness.

- GOST 10704-9 - pipe manufacturing.

- GOST 8479-70 - production of forged parts, forgings.

- GOST 1577-93 - production of metal sheets of large thickness.

- GOST 14955-77 - production of silver and grinding rods.

- GOST 7417-75 - production of calibrated rods.

- GOST 8240-97, GOST 1050-88 - production of shaped and long products.

GOSTs indicate the basic requirements for finished products and their testing for admission to sale.

Steel sheets

GOST

Standards for the production of products from grade 20:

- long products, including shaped steel - GOST 1050-88, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006, GOST 8509-93, GOST 8510-86, GOST 8240-97, GOST 8239-89;

- calibrated rod - GOST 7417-75, GOST 8559-75, GOST 8560-78, GOST 10702-78;

- polished rod and silver - GOST 14955-77;

- thick sheet - GOST 1577-93, GOST 19903-74;

- thin sheet - GOST 16523-97;

- tape - GOST 6009-74, GOST 10234-77, GOST 103-2006, GOST 82-70;

- wire - GOST 5663-79, GOST 17305-91;

- forgings and forged blanks - GOST 8479-70;

- pipes - GOST 10704-91, GOST 10705-80, GOST 8731-74, GOST 8732-78, GOST 8733-74, GOST 5654-76, GOST 550-75.

Analogs of material

For some products, it is possible to replace the material with steel having similar qualities. Products of Russian manufacturers are steel 40Х, 30, 25, 15. Substitute metal can be supplied from abroad - 20 (China), S20C (Japan), 1020, 1023 (USA), C22R (Germany).

Foreign analogues of Steel 20

| A country | USA | Germany | Japan | France | England | European Union | Italy | Belgium | Spain |

| Standard | — | DIN,WNr | JIS | AFNOR | B.S. | EN | UNI | NBN | UNE |

| Brand | 1020 | 1,0402 | S20C | 1C22 | 050A20 | 1,0402 | C18 | C25-1 | 1C22 |

| 1023 | 1,0405 | S20CK | 2C22 | 055M15 | 1,1151 | C20 | C25-2 | C22 | |

| 1024 | 1,1151 | S22C | AF42 | 070M20 | 1,1152 | C21 | C25k | ||

| G10200 | C22 | STB410 | AF42C20 | 070M26 | 2C22 | C22 | F.112 | ||

| G10230 | C22E | STKM12A | C20 | 1449-22CS | C20E2C | C22E | F.1120 | ||

| H10200 | C22R | STKM12A-S | C22 | 1449-22HS | C22 | C22R | |||

| M1020 | Ck22 | STKM13B | C22E | 1C22 | C22E | C25 | |||

| M1023 | Cm22 | STKM13B-W | C25E | 22HS | C25E | ||||

| Cq22 | XC15 | 430 | |||||||

| St35 | XC18 | C22 | |||||||

| St45-8 | XC25 | C22E | |||||||

| A country | China | Sweden | Bulgaria | Hungary | Poland | Romania | Czech | Switzerland | South Korea |

| Standard | G.B. | SS | BDS | MSZ | PN | STAS | CSN | SNV | KS |

| Brand | 20 | 1450 | 20 | A45.47 | 20 | OLC20 | 12022 | Ck22 | SM20C |

| 20G | C22 | C22E | K18 | OLC20X | 12024 | SM20CK | |||

| 20R | C22E | SM22C | |||||||

| 20Z |

Legend

| Mechanical properties | |

| σB | temporary tensile strength (tensile strength), MPa |

| σ0.2 | conditional yield strength, MPa |

| σcom | compressive strength, MPa |

| σco0.2 | compressive yield strength, MPa |

| σ0.05 | elastic limit, MPa |

| σben | bending strength, MPa |

| σ-1 | endurance limit during bending test with a symmetrical loading cycle, MPa |

| δ5, δ4, δ10 | relative elongation after rupture, % |

| ψ | relative narrowing, % |

| ν | relative shift, % |

| ε | relative settlement at the appearance of the first crack, % |

| τK | ultimate torsional strength, maximum shear stress, MPa |

| τ-1 | endurance limit during torsion testing with a symmetrical loading cycle, MPa |

| KCU and KCV | impact strength, determined on a sample with concentrators of the U and V types, J/cm2 |

| HRСе and HRB | Rockwell hardness (scale C and B respectively) |

| HB | Brinell hardness |

| H.V. | Vickers hardness |

| HSD | Shore hardness |

| Physical properties | |

| E | normal modulus of elasticity, GPa |

| G | modulus of elasticity in torsional shear, GPa |

| ρn | density, kg/m3 |

| λ | thermal conductivity coefficient, W/(m∙°C) |

| ρ | electrical resistivity, Ohm∙m |

| α | linear thermal expansion coefficient, 10-61/°С |

| With | specific heat capacity, J/(kg∙°С) |

Sources

- https://vse-stali.ru/stal-konstruktsionnaya/uglerodistaya-kachestvennaya/stal-20-stal-20a/

- https://punktpriema.ru/articles/tehnicheskie-harakteristiki-uglerodistoy-stali-20.html

- https://metalloy.ru/stal/marka-20

- https://metal.place/ru/wiki/20/

- https://MetallolomResurs.ru/svoystva-stali-20.html

- https://nzmetallspb.ru/benzoinstrument/stal-20-harakteristiki-svojstva-oblast-primeneniya.html

- https://xlom.ru/spravochnik/marka-stali-st-20

20GL Chelyabinsk

| Brand: | 20GL |

| Classification: | Alloy casting steel |

| Application: | disks, sprockets, ring gears and other parts that are subject to requirements for strength and toughness, operating under static and dynamic loads |

| Foreign analogues: | Known |

Chemical composition in % of material 20GL

GOST 977-88, also included in GOST 21357-87

| C | Si | Mn | S | P |

| 0.15- 0.25 | 0.2- 0.4 | 1.2- 1.6 | up to 0.04 | up to 0.04 |

| Note: ??? Material 20GL is also included in GOST 21357-87, where it has a different chemical. composition and properties??? |

Heat treatment modes for 20GL material

| Normalization 880-900 ° C, Vacation 600-650 ° C |

| Quenching 870-890 ° C, Tempering 620-650 ° C |

Mechanical properties at T=20oC of 20GL material.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Castings, K25, GOST 977-88 | 540 | 275 | 18 | 25 | 491 | Normalization 880-900 ° C, Vacation 600-650 ° C | ||

| Castings, KT30, GOST 977-88 | 530 | 334 | 14 | 25 | 383 | Quenching 870-890 ° C, Tempering 620-650 ° C | ||

| Castings, GOST 21357-87 | 500 | 300 | 20 | 35 | Normalization | |||

| Castings, GOST 21357-87 | 550 | 400 | 15 | 30 | Quenching and tempering |

| Hardness 20GL, | HB 10 -1 = 143-187 MPa |

Foreign analogues of material 20GL

Attention!

Both exact and closest analogues are indicated. 1.1120

| USA | Germany | Japan | European Union | Italy | Bulgaria | Hungary | Poland | Romania | Czech | Austria |

| — | DIN,WNr | JIS | EN | UNI | BDS | MSZ | PN | STAS | CSN | ONORM |

A352GrLCC

| ||||||||||

| 1.1133 | ||||||||||

| G17Mn5 | ||||||||||

| GS20Mn5 |

| SCMn1 |

Designations:

| Mechanical properties : | |

| sв | -Short-term strength limit, [MPa] |

| sT | - Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | -Elongation at break, [%] |

| y | -Relative narrowing, [%] |

| KCU | -Impact strength, [kJ/m2] |

| HB | -Brinell hardness, [MPa] |

| Physical properties: | |

| T | -Temperature at which these properties were obtained, [Deg] |

| E | -Elastic modulus of the first kind, [MPa] |

| a | -Coefficient of thermal (linear) expansion (range 20o-T), [1/degree] |

| l | -Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | -Material density, [kg/m3] |

| C | -Specific heat capacity of the material (range 20o-T), [J/(kg deg)] |

| R | -Specific electrical resistivity, [Ohm m] |

20GL-Alloyed steel for castings 20GL-chemical composition, mechanical, physical and technological properties, density, hardness, application

Affordable metal products

20GL