To improve the technical characteristics of metals and alloys, a technological process called alloying is carried out. It implies the introduction of additional additives into the composition of the material compound, which change its properties. Depending on the percentage of additional components added, three groups of resulting materials are distinguished. Any metalworking master should know low-alloy steels and their grades.

Low alloy steel and its grades

Compound

Before you start understanding the properties, you need to know the composition of low-alloy steels. The amount of alloying additives should not exceed 5% (some sources indicate the maximum amount of additional components - up to 2.5%). Carbon is not considered an alloying component.

The most popular, inexpensive additional additives include:

- Vanadium is responsible for the uniform structure.

- Molybdenum - increases the resistance of the compound to high temperatures.

- Niobium - increases strength.

- Tungsten - increases heat resistance.

- Titanium - increases wear resistance.

- Nickel, silicon - increase shock resistance and current resistance.

Classification of alloy steels

With the development of new technologies and the emergence of different alloy steels, they needed to be classified.

Division by the amount of carbon contained in the alloy:

- High carbon - more than 0.65%.

- Medium carbon - from 0.25% to 0.65%.

- Low carbon - less than 0.25%.

Separation by percentage of alloying additives:

- Low alloyed - up to 5% (according to some sources up to 2.5%).

- Medium alloyed - up to 10%.

- Highly alloyed - 10–50%.

According to their internal structure, alloy steels are:

- Eutectoid - pearlite structure.

- Ledeburite - the presence of primary carbides in the structure.

- Hypoeutectoid - the presence of excess ferrites saturating the composition.

- Hypereutectoid - the presence of secondary carbides in the alloy.

Based on their purpose, these materials can be divided into two large groups:

- Construction - for the manufacture of metal structures that will not be exposed to critical temperatures during subsequent operation.

- Mechanical engineering - used in the manufacture of parts for various mechanisms and housings.

Engineering steels are:

- Cemented - during manufacturing they undergo a process of carburization and then hardening.

- Heat-resistant - medium-carbon steels. They are used in the manufacture of products used in the energy sector.

- Improved - materials that undergo additional hardening. They are used to make parts that are subject to heavy loads.

High carbon alloy steel

Classification

It is worth noting a wide range of low-alloy alloys. With a variety of chemical composition and processing options, they are quite broadly classified:

- and by chemical composition;

- and according to the heat treatment option;

- and according to the degree of weldability.

It is convenient for buyers to navigate based on the formation of alloys into 4 fairly large groups. This:

- so-called low-alloy martensitic steels;

- medium carbon high strength;

- heat-resistant (chromolybdenum);

- ball bearing.

The most popular today are low-alloy steel grades such as: 09G2, 09G2S, 17G1S, 0HSND, 16G2AF. Steels 10KhNDP, 15KhNDP, 15KhSND, 0KhSND are known as atmospheric corrosion-resistant (AKS). There are also substitutes. For example, instead of 09G2S they use 09G2, 09G2T or 09G2DT, instead of 10G2S, 10HSND - 16GAF).

Alloying elements and their influence on the properties of steels

Several alloying additives that are most often added to compounds have been described above. To understand how all the additional components affect the technical characteristics of the alloy, you need to understand them individually in more detail:

- Titanium - the granularity of the structure decreases, density and strength indicators increase.

- Sulfur - this component should not be more than 0.65% in the composition. Otherwise, corrosion resistance, ductility, and impact strength will decrease.

- Carbon - content no more than 1.2% increases strength and hardness. If the quantity is increased, the technical parameters will decrease.

- Phosphorus is not suitable as an alloying additive. An increase in its quantity in the composition leads to a sharp decrease in technical parameters.

- Aluminum - to increase scale resistance, this component is added.

- Nickel - helps to increase corrosion resistance, viscosity, and ductility.

- Chromium - increases hardness, strength, and corrosion resistance.

- Silicon - the content of this component should not exceed 15%. Increases electrical resistance and magnetic permeability.

- Manganese - content up to 0.8% is considered one of the technological impurities. Reduces the negative impact of sulfur on the alloy.

- Oxygen, nitrogen - a large number of gas bubbles in the composition makes the metal more fragile.

- Hydrogen - metallurgists are trying to reduce the amount of this component in the composition to make the material more durable.

Carbon quality structural steel

Regulatory document: high-quality structural carbon steel is manufactured in accordance with GOST 1050-88, GOST 1051-73.

Carbon steel is a steel that does not contain alloying elements, but contains carbon in varying concentrations: up to 0.25% - low-carbon steel, 0.24-0.6% medium-carbon steel, more than 0.6 - high-carbon steel.

Classification of carbon steels

By quality

- ordinary quality;

- improved quality;

- high quality.

By purpose, ordinary quality steel:

- A - supplied according to mechanical properties, used in products subjected to hot processing (welding, forging, etc.), which can change the regulated mechanical properties;

- B - supplied by chemical composition, used for parts subjected to processing that can change the regulated mechanical properties, while their level, in addition to the processing conditions, is determined by the chemical. composition;

- B - supplied according to mechanical properties and chemical composition for parts to be welded.

According to the degree of deoxidation:

- boiling - kp;

- semi-calm - ps;

- mild steel without heat treatment - sp.

According to the chemical composition for high-quality steel:

- I - with normal manganese content (Mn 0.80%);

- II - with a high content of manganese (Mn 1.2%) - G.

Grades of quality structural carbon steel

Carbon steel of ordinary quality: St0, St1kp, St1ps, St1sp, St2kp, St2ps, St2sp, StZkp, StZps, StZsp, StZGps, StZGsp, St4kp, St4ps, St4sp, St5ps, St5sp, St5Gps, Stbps, Stbsp.

Carbon quality steel: 08, 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 58, 60 - machine steel; A12, A20, A30 - automatic steel.

Designation of the steel grade: “St” - steel, the numbers following it are the conditional number of the grade depending on the chemical composition, then the degree of deoxidation (“kp”, “ps”, “sp”) is indicated.

Substitutes for some grades of steel:

- St20 - St15, 25;

- St35 - St30, 40, 35G;

- St45 - 40X, St50, 50G2.

Use of high-quality structural carbon steel

| steel grade | Application area |

| 08kp, 10 | Parts produced by cold stamping and cold heading, tubes, gaskets, fasteners. Cemented and cyanidated parts that do not require high core strength. |

| 15, 20 | Lightly loaded parts: rollers, pins, stops, copiers, axles, gears. Thin parts subject to abrasion: levers, hooks, traverses, liners, bolts, couplers, etc. |

| 30, 35 | Parts experiencing low stress: axles, spindles, sprockets, rods, shafts, etc. |

| 20k | Boiler steel. |

| 40, 45 | Parts with increased strength: crankshafts, connecting rods, ring gears, camshafts, flywheels, gears, studs, ratchets, etc. |

| 50, 55 | Gears, rolling rolls, rods, bandages, shafts, lightly loaded springs, etc. |

| 60 | Parts with high strength and elastic properties: rolling rolls, eccentrics, spindles, spring rings, clutch springs and discs, shock absorber springs. |

| A12, A20, A30 | Irrelevant mass-produced parts produced on automatic machines. |

Weldability: good for boiler steels and steel grades St08-St35; difficult for steel St45; automatic steels are not used for welding.

Marking

Metal marking carries a lot of information for buyers and people working with products. Low-alloy steel grades are indicated in accordance with GOST 4543-71. The marking is a set of letters and numbers, each of which has a specific meaning. Standard transcript:

- The letter comes first. It determines the properties of the metal and assigns it to a certain subgroup. For example, the letter “F” indicates a stainless steel base.

- The number following the first letter indicates the percentage of carbon in the composition. For example, 5 - 0.05%.

- Next, alloying additives are designated according to the periodic table.

- After the designations of additional components, numbers are indicated indicating their percentage in the compound.

Low-alloy structural steel for welded structures

Low alloy steels are...

Low-alloy steels contain from 0.2% C and up to 2-3% of mostly non-deficient alloying elements. They are not much more expensive than carbon ones, but have a number of important advantages: a higher yield strength, which allows reducing metal consumption by 15-30%; reduced susceptibility to mechanical aging; increased cold resistance, better corrosion resistance and wear resistance; the ability to significantly increase, after quenching and tempering, strength, toughness, wear resistance and notch sensitivity. All this, combined with good weldability, has led to the widespread use of these steels in the manufacture of pipelines and apparatus, all kinds of welded structures in carriage building, automotive industry, agricultural engineering, etc.

The steels are not flake-sensitive and are not prone or have little tendency to temper brittleness. When using high-strength non-pearlite and low-pearlite steels with a very low content of carbon, sulfur and phosphorus, which results in very good weldability, high impact strength and a low cold brittleness threshold. The high strength of steels in this case is achieved through microalloying with niobium, vanadium and titanium and the use of controlled rolling during production.

As the experience of factories has shown, the use of low-alloy steel in apparatus construction makes it possible to improve the technical and economic indicators of production and achieve significant savings in metal due to the higher yield strength of a number of grades of low-alloy steel compared to conventional carbon steel.

The use of low-alloy steel in petroleum apparatus construction allows reducing the weight of structures by up to 25%, the labor intensity of manufacturing lightweight structures by 16%, the complexity of installation work by 15% and the cost by 20%.

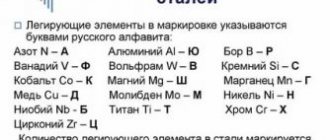

An alphanumeric code is used to designate grades of low-alloy steel. The numbers at the beginning of the marking indicate the carbon content in hundredths of a percent (average content), and the letters indicate what alloying element is contained in the steel. When marking steel for various alloying elements, the following designations are used:

- N - nickel

- X - chrome

- G - manganese

- M - molybdenum

- C - silicon

- B - tungsten

- F - vanadium

- T - titanium

- K - cobalt

- Yu - aluminum

- D - copper

The numbers appearing in the brand after the letters indicate the approximate content of the corresponding alloying element, if the amount of this element exceeds 1.5%.

Below is a list of grades of low-alloy structural steel:

List of low alloy steel grades

- Steel 09G2

- Steel 14G2

- Steel 12GS

- Steel 16GS

- Steel 17GS

- Steel 17G1S

- Steel 09G2S

- Steel 10G2S1

- Steel 10G2BD

- Steel 15G2SFD

- Steel 14G2AF

- Steel 16G2AF

- Steel 18G2AFps

- Steel 14ХГС

- Steel 15G2AFDps

- Steel 20ХГ2Ц

- Steel 10HSND

- Steel 10KhNDP

- Steel 15HSND

- Steel 35GS

- Steel 25G2S

Find out more

Steel 15HSND low-alloy structural...

St2ps steel is carbon steel of ordinary quality...

Steel grade 20: explanation, characteristics, chemical...

Steel 110G13L (Hadfield steel)…

Application of metal

Low alloy steels are used in various industries. Application area:

- Manufacturing of lightweight metal structures.

- Housings for household appliances.

- Parts for industrial equipment.

- Cutting tools.

Due to the high price of such materials, they are used in cases where analogues cannot cope with the tasks.

Metal construction

Welding

To connect parts made of low-alloy steel using welding, you need to take into account several nuances:

- Make vertical, ceiling seams.

- The welding rod must have a cross-section of at least 4 mm.

- To reduce the cooling rate of the metal, it is necessary to make butt or side welds.

- When welding workpieces with a thickness not exceeding 6 mm, only one pass is required.

- To give the connection high ductility, you need to use E42A electrodes.

- If the metal contains a small amount of carbon, it is necessary to use electrodes coated with fluorine and calcium.

To carry out welding work, it is necessary to use a special additive Sv-10G2.

Low-alloy steels have increased technical parameters due to the addition of additional components to the composition. They are used in those areas of industry where it is necessary to use parts and metal structures of high strength and wear resistance. To connect individual parts, you need to take into account a number of nuances of using welding equipment.