General characteristics of steel grade 40ХН2МА

Grade 40ХН2МА is a high-quality structural high-alloy chromium-nickel-molybdenum steel . It is flake-sensitive and difficult to weld, so additional operations must be carried out to obtain welded fasteners; in addition, 40ХН2МА is not sensitive to temper brittleness. It should be noted that products made from this steel are very corrosion-resistant.

The scope of application of 40ХН2МА is very wide

| Substitute: | 40HGT, 40HGR, 30H3MF, 45HN2MFA |

| GOST standards: | GOST 8479-70, GOST 1133-71, GOST 8319.0-75, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006, GOST 103-2006, GOST 1051-73, GOST 4543-71, GOST 7417-75, GOST 8559-75, GOST 8560-78, GOST 10702-78, GOST 14955-77 |

| Application: | crankshafts, valves, connecting rods, connecting rod caps, critical bolts, gears, claw couplings, discs and other heavily loaded parts. Rolls for cold rolling of metals. |

Application in production

Steel 40ХНМА and St 40ХН2МА are in most cases used to produce solid-rolled rings, valves or crankshafts, bolts and other fastening materials. The resulting products can be operated at temperatures up to 500 degrees Celsius. It can be supplied to production in the form of the following blanks:

- Calibrated rod.

- Long products.

- Forgings.

- Valka.

Forgings made of steel 40ХН2МА

Steel circle

As a rule, steel 40ХН2МА and 40ХНМА is used to produce parts that are used in harsh conditions. An example is the elements of an internal combustion engine that are exposed to elevated temperature, pressure and constant or variable load. Hardening and tempering significantly increase the surface's resistance to abrasion and deformation. The alloy is also used in the manufacture of the main elements of various other critical mechanisms, for example, gearboxes.

see stock and prices >>

Chemical composition in % of material 40ХН2МА

| C | Si | Mn | Ni | S | P | Cr | Mo | Cu |

| 0.37 — 0.44 | 0.17 — 0.37 | 0.5 — 0.8 | 1.25 — 1.65 | up to 0.025 | up to 0.025 | 0.6 — 0.9 | 0.15 — 0.25 | up to 0.3 |

Temperature of critical points of material 40ХН2МА.

| Ac1 = 730, Ac3(Acm) = 820, Ar3(Arcm) = 550, Ar1 = 380, Mn = 320 |

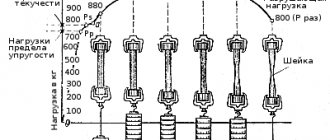

Mechanical properties at T=20oC of the material 40ХН2МА.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Bar | F 25 | 1080 | 930 | 12 | 50 | 780 | Quenching and tempering |

| The hardness of the material is 40ХН2МА after annealing, | HB 10 -1 = 269 MPa |

Physical properties of the material 40ХН2МА.

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.15 | 39 | 7850 | 331 | ||

| 100 | 2.11 | 11.6 | 38 | 490 | ||

| 200 | 2.01 | 12.1 | 37 | 506 | ||

| 300 | 1.9 | 12.7 | 37 | 522 | ||

| 400 | 1.77 | 13.2 | 35 | 536 | ||

| 500 | 1.73 | 13.6 | 33 | 565 | ||

| 600 | 13.9 | 31 | ||||

| 700 | 29 | |||||

| 800 | 27 | |||||

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

Technological properties of material 40ХН2МА.

| Weldability: | difficult to weld. |

| Flock Sensitivity: | sensitive. |

| Tendency to temper brittleness: | not inclined. |

Remaining metal steel 40ХН2МА for April 2021.

| Name | brand | size | remainder | price |

| Square | 40ХН2МА | 100mm | 0,2 | 174000 |

| Circle | 40ХН2МА | 110mm | 15,195 | 95000 |

| Sheet | 40ХН2МА | 110mm | 1,22 | 180000 |

| Circle | 40ХН2МА | 115mm | 16,378 | 95000 |

| Round forging | 40ХН2МА | 120×2300mm | 0,22 | 123000 |

| Pipe | 40ХН2МА | 121×24mm | 0,49 | 106000 |

| Circle | 40ХН2МА | 1300mm | 1,48 | 175000 |

| Circle | 40ХН2МА | 130mm | 3,335 | 95000 |

| Circle | 40ХН2МА | 142mm | 0,286 | 103000 |

| Pipe | 40ХН2МА | 146×22mm | 0,62 | 106000 |

| Circle | 40ХН2МА | 150mm | 6,24 | 95000 |

| Square | 40ХН2МА | 160mm | 2 | 174000 |

| Circle | 40ХН2МА | 160mm | 14,698 | 95000 |

| Circle | 40ХН2МА | 16mm | 0,229 | 124000 |

| Square | 40ХН2МА | 170mm | 2,13 | 174000 |

| Circle | 40ХН2МА | 170mm | 2,867 | 99000 |

| Circle | 40ХН2МА | 175mm | 0,81 | 123000 |

| Hexagon | 40ХН2МА | 17mm | 0,936 | 118000 |

| Circle | 40ХН2МА | 18.5mm | 1,153 | 124000 |

| Square | 40ХН2МА | 180mm | 0,44 | 174000 |

| Circle | 40ХН2МА | 180mm | 2,73 | 99000 |

| Round forging | 40ХН2МА | 180mm | 0,215 | 133000 |

| Circle | 40ХН2МА | 185mm | 0,213 | 111000 |

| Round forging | 40ХН2МА | 185mm | 0,207 | 170000 |

| Square | 40ХН2МА | 190mm | 1,34 | 174000 |

| Circle | 40ХН2МА | 190mm | 4,94 | 95000 |

| Round forging | 40ХН2МА | 190mm | 0,738 | 170000 |

| Square | 40ХН2МА | 200mm | 0,715 | 174000 |

| Circle | 40ХН2МА | 200mm | 6,806 | 95000 |

| Round forging | 40ХН2МА | 200mm | 0,205 | 150600 |

| Circle | 40ХН2МА | 203mm | 2,286 | 198500 |

| Round forging | 40ХН2МА | 210×600mm | 1,06 | 165000 |

| Square | 40ХН2МА | 210mm | 1,06 | 118000 |

| Circle | 40ХН2МА | 210mm | 0,844 | 95000 |

| Round forging | 40ХН2МА | 210mm | 0,498 | 170000 |

| Square | 40ХН2МА | 220mm | 3,355 | 174000 |

| Circle | 40ХН2МА | 230mm | 0,497 | 109500 |

| Pipe | 40ХН2МА | 237×16mm | 13,2 | 108500 |

| Circle | 40ХН2МА | 240mm | 2,745 | 111000 |

| Round forging | 40ХН2МА | 240mm | 1,105 | 211000 |

| Round forging | 40ХН2МА | 245mm | 0,998 | 211000 |

| Round forging | 40ХН2МА | 250mm | 0,304 | 118000 |

| Circle | 40ХН2МА | 254mm | 0,547 | 160000 |

| Circle | 40ХН2МА | 260mm | 11,126 | 107000 |

| Circle | 40ХН2МА | 270mm | 3,161 | 118560 |

| Square | 40ХН2МА | 280mm | 0,546 | 155000 |

| Round forging | 40ХН2МА | 285mm | 0,22 | 211000 |

| Circle | 40ХН2МА | 28mm | 1,52 | 92000 |

| Round forging | 40ХН2МА | 300mm | 5,89 | 180000 |

| Circle | 40ХН2МА | 30mm | 2,614 | 92000 |

| Circle | 40ХН2МА | 310mm | 7,354 | 107000 |

| Round forging | 40ХН2МА | 310mm | 3,31 | 180000 |

| Circle | 40ХН2МА | 320mm | 2,776 | 119000 |

| Round forging | 40ХН2МА | 320mm | 2,62 | 180000 |

| Circle | 40ХН2МА | 330mm | 1,155 | 133000 |

| Round forging | 40ХН2МА | 330mm | 0,46 | 183000 |

| Circle | 40ХН2МА | 340mm | 5,544 | 143500 |

| Round forging | 40ХН2МА | 340mm | 16,09 | 180000 |

| Round forging | 40ХН2МА | 345mm | 0,811 | 247000 |

| Circle | 40ХН2МА | 34mm | 2,49 | 99000 |

| Round forging | 40ХН2МА | 350×715mm | 0,606 | 126000 |

| Round forging | 40ХН2МА | 350mm | 0,57 | 180000 |

| Circle | 40ХН2МА | 360mm | 4,66 | 174000 |

| Round forging | 40ХН2МА | 360mm | 6,35 | 180000 |

| Circle | 40ХН2МА | 370mm | 0,525 | 155000 |

| Round forging | 40ХН2МА | 370mm | 4,96 | 180000 |

| Round forging | 40ХН2МА | 380mm | 2,735 | 183000 |

| Round forging | 40ХН2МА | 385mm | 1,786 | 211000 |

| Circle | 40ХН2МА | 38mm | 0,204 | 124000 |

| Circle | 40ХН2МА | 390mm | 0,74 | 179000 |

| Round forging | 40ХН2МА | 390mm | 2,005 | 211000 |

| Round forging | 40ХН2МА | 400×800mm | 9,92 | 175000 |

| Round forging | 40ХН2МА | 400×840mm | 4,9 | 138000 |

| Round forging | 40ХН2МА | 400mm | 4,7 | 180000 |

| Round forging | 40ХН2МА | 405mm | 4,52 | 180000 |

| Circle | 40ХН2МА | 40mm | 0,49 | 84000 |

| Round forging | 40ХН2МА | 410mm | 3,63 | 180000 |

| Round forging | 40ХН2МА | 420mm | 6,09 | 180000 |

| Circle | 40ХН2МА | 42mm | 2,568 | 98000 |

| Round forging | 40ХН2МА | 430mm | 4,83 | 180000 |

| Round forging | 40ХН2МА | 440×100mm | 9,92 | 138000 |

| Circle | 40ХН2МА | 440mm | 0,225 | 177000 |

| Round forging | 40ХН2МА | 440mm | 6,11 | 137000 |

| Square | 40ХН2МА | 450mm | 1 | 138000 |

| Round forging | 40ХН2МА | 450mm | 5,02 | 180000 |

| Circle | 40ХН2МА | 45mm | 0,228 | 92000 |

| Circle | 40ХН2МА | 460mm | 7,05 | 174000 |

| Round forging | 40ХН2МА | 460mm | 13,16 | 180000 |

| Pipe | 40ХН2МА | 465×21mm | 2,805 | 289000 |

| Circle | 40ХН2МА | 470mm | 0,335 | 160000 |

| Round forging | 40ХН2МА | 470mm | 4,95 | 180000 |

| Round forging | 40ХН2МА | 475×290mm | 0,426 | 103000 |

| Round forging | 40ХН2МА | 480×480mm | 1,094 | 106000 |

| Circle | 40ХН2МА | 480mm | 0,72 | 122500 |

| Round forging | 40ХН2МА | 480mm | 7,33 | 180000 |

| Circle | 40ХН2МА | 48mm | 0,318 | 124000 |

| Round forging | 40ХН2МА | 490×195mm | 0,296 | 138000 |

| Round forging | 40ХН2МА | 490mm | 11,77 | 180000 |

| Round forging | 40ХН2МА | 500mm | 7,35 | 180000 |

| Circle | 40ХН2МА | 50mm | 8,422 | 92000 |

| Circle | 40ХН2МА | 520mm | 0,4 | 174000 |

| Round forging | 40ХН2МА | 520mm | 6,79 | 180000 |

| Round forging | 40ХН2МА | 525×220mm | 0,372 | 138000 |

| Round forging | 40ХН2МА | 525mm | 0,54 | 211000 |

| Circle | 40ХН2МА | 52mm | 3,515 | 99000 |

| Pipe | 40ХН2МА | 530×25mm | 0,436 | 99000 |

| Round forging | 40ХН2МА | 530mm | 16,7 | 180000 |

| Circle | 40ХН2МА | 540mm | 8,06 | 174000 |

| Circle | 40ХН2МА | 550mm | 0,32 | 111000 |

| Round forging | 40ХН2МА | 550mm | 7,4 | 180000 |

| Circle | 40ХН2МА | 555mm | 0,37 | 182000 |

| Circle | 40ХН2МА | 55mm | 0,242 | 103000 |

| Circle | 40ХН2МА | 560mm | 8,98 | 174000 |

| Round forging | 40ХН2МА | 560mm | 6,87 | 180000 |

| Round forging | 40ХН2МА | 570×2100mm | 1 | 138000 |

| Round forging | 40ХН2МА | 580×1020mm | 8,555 | 138000 |

| Circle | 40ХН2МА | 580mm | 8,77 | 174000 |

| Round forging | 40ХН2МА | 580mm | 7,64 | 180000 |

| Circle | 40ХН2МА | 590mm | 2,9 | 165000 |

| Round forging | 40ХН2МА | 590mm | 3,302 | 225000 |

| Round forging | 40ХН2МА | 595mm | 3,274 | 225000 |

| Round forging | 40ХН2МА | 600mm | 6,01 | 180000 |

| Round forging | 40ХН2МА | 605mm | 0,2 | 185000 |

| Round forging | 40ХН2МА | 610×1380mm | 10,2 | 138000 |

| Round forging | 40ХН2МА | 610mm | 6,61 | 180000 |

| Round forging | 40ХН2МА | 620mm | 0,45 | 185000 |

| Round forging | 40ХН2МА | 640mm | 8 | 180000 |

| Circle | 40ХН2МА | 65mm | 1,997 | 94000 |

| Round forging | 40ХН2МА | 660mm | 6,93 | 180000 |

| Round forging | 40ХН2МА | 670mm | 3,965 | 180000 |

| Round forging | 40ХН2МА | 680mm | 8,05 | 180000 |

| Round forging | 40ХН2МА | 690mm | 1,327 | 225000 |

| Round forging | 40ХН2МА | 700mm | 8,58 | 180000 |

| Round forging | 40ХН2МА | 708mm | 1,545 | 211000 |

| Round forging | 40ХН2МА | 720mm | 8 | 180000 |

| Circle | 40ХН2МА | 750mm | 1,59 | 122500 |

| Round forging | 40ХН2МА | 800×730mm | 1 | 138000 |

| Circle | 40ХН2МА | 800mm | 0,98 | 103000 |

| Round forging | 40ХН2МА | 800mm | 8,7 | 180000 |

| Circle | 40ХН2МА | 80mm | 1,855 | 92000 |

| Round forging | 40ХН2МА | 850mm | 1,594 | 155000 |

| Circle | 40ХН2МА | 85mm | 0,976 | 108500 |

| Round forging | 40ХН2МА | 870mm | 7,07 | 225000 |

| Round forging | 40ХН2МА | 900mm | 3,47 | 221000 |

| Circle | 40ХН2МА | 90mm | 2,386 | 95000 |

| Round forging | 40ХН2МА | 910mm | 1,8 | 221000 |

| Round forging | 40ХН2МА | 930mm | 2,01 | 221000 |

| Round forging | 40ХН2МА | 950mm | 1,26 | 221000 |

| Pipe | 40ХН2МА | 95×9.5mm | 4,395 | 106000 |

| Circle | 40ХН2МА | 95mm | 5,515 | 95000 |

| Circle | 40ХН2МА | 980mm | 1,296 | 148500 |

Characteristics and chemical composition of materials

Adding certain substances to the composition can significantly change the basic properties of the metal. The considered steels 40ХН2МА and 40ХНМА have the following chemical composition:

- I took carbon as the main element, since even a slight change in its concentration can lead to an increase or decrease in strength, ductility and other qualities. Steel 40ХН2МА and 40ХНМА are characterized by an increased carbon concentration, the indicator ranges from 0.37% to 0.44%.

- Alloying is carried out with chromium and molybdenum. The concentration of the first substance is 0.6-0.9%. Steel 40ХН2МА, the characteristics of which determine resistance to heat, has 0.15-0.25% molybdenum. Steel 40ХНМА, the characteristics of which are almost identical, has molybdenum less than 0.1%.

- The composition also includes silicon (0.17-0.37%), manganese (0.5-0.8%) and some other substances in small composition.

Physical properties of steel 40

As previously noted, mechanical properties are largely determined by the amount of carbon. Too much concentration of this element leads to increased hardness and strength, but reduces the degree of weldability.

If it is necessary to weld such metals, the workpiece is preheated; the work is carried out only when using RND technology. The resulting part is subjected to heat treatment, since the resulting seams are fragile and not resistant to vibration loads. Hardness without heat treatment is 269 MPa. Forging, hardening and tempering can be carried out. The addition of molybdenum determines resistance to high temperatures, so heating at the time of heat treatment is carried out to 1000 degrees Celsius and higher.

Analogues of steel 40ХН2МА

41.Composition, purpose and heat treatment of steels being improved.

Contain from 0.3 to 0.5% carbon. Used after improvement (hardening + high drop). Structure: leave sorbitol. They must have a high yield strength, low sensitivity to stress concentrations under cyclic load conditions, a high endurance limit, and a sufficient viscosity reserve. The main feature of improved steels is hardenability. The more severe the operating conditions of the part, the greater the hardenability should be, the more complex the steel composition should be. For shafts with a cross section of less than 20 mm: unalloyed steels 35, 40, 45, 50. The introduction of chromium or manganese increases the hardenability to 25 mm: 40Х, 40Г2, 45Г2. simultaneous alloying with chromium and manganese increases the hardenability to 10 mm (40ХГ). The introduction of boron increases the hardenability to 600 mm. The addition of titanium helps to obtain a fine-grained structure (prevents the growth of austenitic grains) (30ХР, 30ХГТ, 40ХГТР). Chromansil (30ХГСА) also belongs to this group.

Highly loaded parts are made from steels alloyed with nickel or nickel with molybdenum. Hardenability of 75-100 mm is provided in steels 40ХН, 30ХН3А, 40ХН2МА. A further increase in hardenability is achieved by introducing vanadium (38ХН3МФА).

Other brands in this category:

- Brand 10G2

- Brand 10Х2М

- Brand 12G2

- Brand 12Х2Н4А

- Brand 12X2NVFA

- Brand 12Х2НВФМА

- Brand 12Х2НМ1FA

- Brand 12X2NMFA

- Brand 12ХН

- Brand 12ХН2

- Brand 12ХН2А

- Brand 12ХН3А

- Brand 14Х2ГМР

- Brand 14Х2Н3МА

- Brand 14ХГН

- Brand 15G

- Brand 15Н2М (15НМ)

- Brand 15X

- Brand 15ХА

- Brand 15KhGN2TA (15KhGNTA)

- Brand 15ХГНМ

- Brand 15HF

- Brand 16G2

- Brand 16ХСН

- Brand 18Х2Н4ВА

- Brand 18Х2Н4МА

- Brand 18ХГ

- Brand 18ХГТ

- Brand 19X2NVFA

- Brand 19X2NMFA

- Brand 19ХГН

- Brand 20G

- Brand 20G2

- Brand 20Н2М (20НМ)

- Brand 20X

- Brand 20Х12Н12Г6

- Brand 20Х14

- Brand 20Х17Н3М

- Brand 20Х2Н4А

- Brand 20ХГНМ

- Brand 20ХГНР

- Brand 20ХГНТР

- Brand 20ХГР

- Brand 20ХГСА

- Brand 20ХМ

- Brand 20ХН

- Brand 20ХН2М (20ХНМ)

- Brand 20ХН3А

- Brand 20HN4FA

- Brand 20ХНР

- Brand 20HF

- Brand 21X2NVFA

- Brand 21X2NMFA

- Brand 23X2NVFA

- Brand 23X2NMFA

- Brand 25G

- Brand 25Х2ГНТА

- Brand 25Х2Н4ВА

- Brand 25Х2Н4МА

- Brand 25ХГМ

- Brand 25ХГНМТ

- Brand 25ХГСА

- Brand 25ХГТ

- Brand 27ХГР

- Brand 30G

- Brand 30G2

- Brand 30X

- Brand 30Х10Г10Т

- Brand 30Х3МФ

- Brand 30Х5

- Brand 30ХГС

- Brand 30ХГСА

- Brand 30KhGSN2A (30KhGSNA)

- Brand 30ХГСНМА

- Brand 30ХГТ

- Brand 30ХН2ВА

- Brand 30HN2VFA

- Brand 30ХН2МА (30ХНМА)

- Brand 30HN2MFA

- Brand 30ХН3А

- Brand 30HN3M2FA

- Brand 30XPA

- Brand 33ХС

- Brand 34ХН1М

- Brand 34ХН1МА

- Brand 34ХН3М

- Brand 34ХН3МА

- Brand 35G

- Brand 35G2

- Brand 35X

- Brand 35ХГ2

- Brand 35ХГН2

- Brand 35ХГСА

- Brand 35ХГФ

- Brand 35HN1M2FA

- Brand 36G2S

- Brand 36H2N2MFA (36HN1MFA)

- Brand 38Х2Н2ВА

- Brand 38Х2Н2МА (38ХНМА)

- Brand 38Х2Н3М

- Brand 38Х2НМ

- Brand 38Х2НМФ

- Brand 38Х2У (38ХУ)

- Brand 38ХА

- Brand 38ХВ

- Brand 38ХГМ

- Brand 38ХГН

- Brand 38ХГНМ

- Brand 38ХМ

- Brand 38ХМА

- Brand 38ХН3ВА

- Brand 38ХН3МА

- Brand 38ХН3МФА

- Brand 38ХС

- Brand 40G

- Brand 40G2

- Brand 40GR

- Brand 40X

- Brand 40Х2Г2М

- Brand 40Х2Н2ВА

- Brand 40Х2Н2МА (40Х1НВА)

- Brand 40Х3Г2МФ

- Brand 40ХГНМ

- Brand 40HGTR

- Brand 40ХН

- Brand 40ХН2МА (40ХНМА)

- Brand 40ХС

- Brand 40ХСН2МА

- Brand 40HFA

- Brand 45G

- Brand 45G2

- Brand 45X

- Brand 45Х4В3ГФ

- Brand 45ХН

- Brand 45HN2MFA (45HNMFA)

- Brand 47GT

- Brand 50G

- Brand 50G2

- Brand 50X

- Brand 50Х3В10Ф

- Brand 50X6FMS

- Brand 50ХН

- Brand 50ХНМ

- Brand G13A

- Brand Х6Ф1

Catalytic gas nitriding

This type of chemical treatment involves creating a special atmosphere in the stove. Dissociated ammonia is pre-treated on a special catalytic element, which significantly increases the number of ionized radicals. Features of the technology include the following points:

- Preliminary preparation of ammonia makes it possible to increase the proportion of solid solution diffusion, which reduces the proportion of reaction chemical processes during the transition of the active substance from the environment to iron.

- Provides for the use of special equipment that provides the most favorable conditions for chemical processing.

Steel nitriding process

This method has been used for several decades and allows changing the properties of not only metals, but also titanium alloys. The high costs of installing equipment and preparing the environment determine the applicability of the technology to the production of critical parts that must have precise dimensions and increased wear resistance.

Material 40ХН2МА Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells 40ХН2МА material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, 40ХН2МА material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.