In this article we will tell you how to choose the right tungsten electrode for argon arc welding, what types of tungsten there are, their distinctive properties, and how the composition affects the quality of the weld.

But at the very beginning, we would like to draw your attention to the fact that tungsten electrodes of the WL-15, WL-20, WC-20, WY-20 and WZ-8 brands have appeared in the range of PTK branded products.

Our tungsten electrodes have undergone X-ray microanalysis of elemental composition at the National Research Institute. We conducted this paid study on our own initiative in order to demonstrate to dealers and consumers the highest quality of our products.

The analysis was carried out on a Tescan Vega II scanning electron microscope, which allows you to obtain SEM images and analyze the elemental composition in real time, which is necessary for quality control of products and materials.

You can familiarize yourself with the research protocols and the results of the elemental composition of tungsten electrodes produced by PTK in the reporting documents.

What is a tungsten electrode and where is it used?

A tungsten electrode is a round rod made of pure tungsten or tungsten with the addition of additives (alloying additives). Tungsten is used in TIG welding with a non-consumable electrode.

If you have a question, why “non-melting”, then the answer is very simple. Tungsten has the highest melting point among pure metals (3422°C). Therefore, argon arc welding is performed with straight polarity, because the temperature of the cathode spot (-) reaches 3000 °C, and the temperature of the anode spot (+) reaches 4000 °C. Because of this, the electrode is not consumed during welding, but burns out.

Electrodes can have a clean or polished surface. A distinctive feature of clean electrodes is that they are chemically cleaned, i.e. The workpieces are etched to remove oxides and contaminants from the surface.

This is the most labor-intensive and costly procedure, therefore it is used much less frequently in industrial production. The ground surface of the electrodes suggests that the electrodes may have been processed by forging, broaching, or centerless grinding. The latter method is the most popular; as a result of this manufacturing, the thermal conductivity of the electrodes improves.

The diameter and length of tungsten electrodes can vary. Standard electrodes have a length from 50 to 175 mm, and a nominal diameter from 0.5 to 10 mm. In Russia, electrodes are manufactured according to GOST 23949-80, TU 48-19-27-91, TU 48-19-39-85, 48-19-221-83 and TU 48-19-527-83 from pure tungsten and tungsten with activating alloying additives of rare earth metals.

Tungsten electrodes are used exclusively in TIG welding, due to the prevention of oxides on the surface of the connecting seam. Welding occurs in a shielding gas environment, which protects the welding zone from exposure to oxygen.

This type of welding uses a chemically inert gas (noble gas). These gases include helium, argon and special welding mixtures. A distinctive feature of these gases is that they have very low chemical reactivity, in other words, they do not interact with the metal of the weld. These gases are also colorless and odorless.

general information

Tungsten electrodes are metal rods with an average length of 175 millimeters. They can be made of pure tungsten or with admixtures of other metals. Used only for semi-automatic or fully automatic argon welding. Instead of argon, you can use any other protective gas, for example, helium.

The characteristics of tungsten electrodes are as follows. The melting point reaches 3400 degrees Celsius, which is a very high value. Therefore, during the welding process, the electrode practically does not change in size, although slight evaporation of the metal is possible. Therefore, such rods are called non-melting.

We wrote above that tungsten electrodes can be made not only from pure tungsten, but also with the addition of other metals. This is necessary to improve the properties of the electrode. For example, to stabilize the arc or for welding refractory materials.

Tungsten electrodes have their own markings. Typically, the marking of tungsten electrodes consists of two Latin letters and a number. In order to better remember a brand, it is not necessary to look at the name. You can just remember the color. Each brand has its own color, which is used to color the end of the electrode. All brands can be divided into three categories: for working with direct current, with alternating current and universal. Let's take a closer look at them. We will tell you about the most popular brands.

Alphanumeric marking of tungsten electrodes

In Russia, 2 types of marking of tungsten electrodes can be used and applied - this is the classification according to GOST, TU and the international classification according to ISO 6848. Let us briefly consider these types of markings.

Marking of domestic electrodes according to GOST and TU

Products that are manufactured in Russia and comply with the established GOST and TU contain the letters “E” and “B” in their name; they come first in the name and mean “tungsten electrode.” Further, the name indicates the chemical composition of the additives and their mass fraction.

- EHF - “H” - pure (tungsten not less than 99.92%);

- EVL - “L” - lanthanum (mass fraction of lanthanum oxide from 1.1 to 1.4%);

- EVL-2 - “L” - lanthanum (mass fraction of lanthanum oxide from 1.4 to 1.6%)

- EVI-1 - “I” - yttrium (mass fraction of yttrium oxide from 1.5 to 2.3%)

- EVI-2 - “I” - yttrium (mass fraction of yttrium oxide from 2.0 to 3.0% and tantalum 0.1%)

- EVI-3 - “I” - yttrium (mass fraction of yttrium oxide from 2.5 to 3.5% and tantalum 0.1%);

- EVT-15 - “T” - thorium (mass fraction of thorium dioxide from 1.5 to 2.0%).

International marking according to ISO 6848 standards

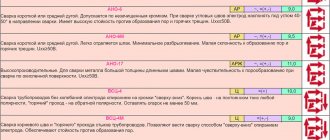

Most tungsten alloys have been standardized by the International Organization for Standardization in ISO 6848. The table below shows the alphanumeric designations and percentage composition of alloying additives.

| Letter designation | Color code | Mass fraction of alloying additives |

| W.P. | Green | – |

| WC-20 | Grey | ~2% |

| WL-10 | Black | ~1% La₂O₃ |

| WL-15 | Gold | ~1.5% La₂O₃ |

| WL-20 | Blue | ~2% La₂O₃ |

| WT-10 | Yellow | ~1% ThO₂ |

| WT-20 | Red | ~2% ThO₂ |

| WT-30 | Violet | ~3% ThO₂ |

| WT-40 | Orange | ~4% ThO₂ |

| WY-20 | Blue | ~2% Y₂O₃ |

| WZ-3 | Brown | ~0.3% ZrO₂ |

| WZ-8 | White | ~0.8% ZrO₂ |

Know what material is to be welded

Regardless of the welding method, special attention must be paid to the brand and characteristics of the parts being welded. It is also important to know the conditions under which the weld and the structure as a whole will be used.

First of all, this factor influences the choice of the right brand of welding consumables that are best suited for given conditions.

For example, if high demands are placed on the structural homogeneity of the weld with the base metal, it is necessary to select welding materials that fully satisfy all requirements.

Before you start welding aluminum or welding stainless steel, you need to know the grade of metal in order to select the right welding materials. because Depending on the chemical composition, different alloys exhibit a tendency to increased deformation and crack formation. Some metals and their alloys require preheating or heat treatment, which affects the selection of the correct welding material.

When welding products made of steel 20 with a thickness of up to 100 mm, no preheating is required, and for steel 12Kh1MF, starting with a thickness of 6 mm, preheating of products to a minimum temperature of 200°C and subsequent heat treatment of the weld are required.

Before TIG welding aluminum alloys with a non-consumable electrode, you always need to know what grade of aluminum is to be welded in order to choose the right welding material. Typically, manufacturers indicate on the packaging what grades of alloys these welding materials are intended for.

What are alloying additives and rare earth metals?

We have looked at the alphanumeric designations of tungsten electrodes, now it’s time to talk about the rare earth metals (elements) that are part of the electrodes, or rather, alloying additives (additives).

Rare earth metals are a group of 17 elements that include scandium, yttrium, lanthanum and lanthanides. All these metals are silvery-white in color, similar in chemical and physical properties, and form refractory oxides that are practically insoluble in water.

These metals received the name “rare earth” due to the fact that they are rarely found in the earth’s crust, and these metals are also difficult to mine and industrially produce.

The most commonly used additives in tungsten welding electrodes are lanthanum, cerium, yttrium, zirconium and thorium.

Advantages and disadvantages

Welding using tungsten electrodes guarantees a slag-free weld.

There are no pores in such a seam. Welding of this type makes it possible to connect most known alloys and metals with each other. In addition, the use of welding of this type allows you to create connections with walls of different thicknesses. Welding with tungsten electrodes is performed without sparks or spatter. No slag is formed on the seam and no smoke is emitted, unlike coated electrodes. All these factors allow welding to be performed at high speed.

At the same time, welding with such a material implies that before performing the work it is necessary to thoroughly clean the surface of the parts. Otherwise, the resulting seam will have certain defects (lack of penetration, pores, etc.).

Properties of filler metals and their influence on the quality of the weld

Tungsten Electrode WP (Green)

Pure tungsten electrodes are classified as WP and have a green color code. The tungsten content in them is at least 99.5%.

- Features: Electrodes marked WP provide high arc stability, but have poor heat resistance and electronic emission. Due to this limited thermal load, the working end of the electrode must be sharpened into a round shape (ball).

- Current type: Designed for welding with sinusoidal current (AC) in argon or helium.

- Metal: This type of electrode is designed for welding aluminum, magnesium, nickel and their alloys.

Due to the fact that WP electrodes were used on transformer equipment, and now most welding equipment is inverter, the need for such electrodes has decreased significantly, so these electrodes are not in the PTK range.

Tungsten electrodes WL-10 (black), WL-15 (gold) and WL-20 (blue)

WL-10 is a lanthanum oxide (La₂O₃) electrode, color code black. The mass fraction of lanthanum oxide reaches up to 1%.

WL-15 is a lanthanum oxide (La₂O₃) electrode, gold color code. The mass fraction of lanthanum oxide varies from 1.4 to 1.6%.

WL-20 is an electrode containing lanthanum oxide (La₂O₃), the mass fraction of which reaches up to 2.2%. The electrode color code is blue.

- Features: These are universal electrodes that can withstand high current loads, improve arc stability and ease of starting while reducing burnout. Lanthanum electrodes are less likely to contaminate the seam with tungsten, which is especially important during finishing work. They also retain the sharpness of the working end for a long time.

- Current type: Electrodes can be used for direct and alternating current (AC/DC) welding.

- Metal: Used for welding carbon and alloy steels, aluminum, titanium, nickel, copper and magnesium alloys.

The range of PTK branded products includes tungsten electrodes WL-15 with a diameter from 1.6 to 4.0 mm and WL-20 with a diameter from 1.0 to 4.0 mm.

Composition and technical characteristics

Electrodes containing tungsten as the main material are very refractory. They are designed to melt the edges of the welded products and filler material. In most cases they are used in an argon protective environment.

According to international standards, the marking of tungsten electrodes contains information not only about the manufacturer and type, but also about the chemical composition of the products.

Electrodes of this type may have the following chemical composition:

- Tungsten is actually the basis of all electrodes of this kind. It is very difficult to use such electrodes in their pure form, so various impurities are added to them to improve or change their qualities.

- Cerium - allows you to give the arc greater stability. Among the main requirements when working with electrodes containing cerium is a clean tip. During welding, cerium oxide collects at the end of the rod and if there are foreign elements on it, the quality of the weld can be greatly deteriorated.

- Thorium - used in rods intended for welding non-ferrous metals and stainless steel. When working with such electrodes, you must pay close attention to safety. The workplace must be provided with good ventilation. Thorium is radioactive and can cause great harm to health.

- Zirconium - this “additive” allows you to cook at high currents, while having a stable and powerful arc. Electrodes containing zirconium are intended for welding copper and aluminum. The main requirement when working is the cleanliness of the weld pool.

- Yttrium - electrodes with this component are the most durable among tungsten ones. They are used in the assembly and repair of structures designed for heavy loads. They are suitable for welding copper, titanium and other steels.

- Lanthanum - when welding products with this element in the composition, you will get a stable arc and easy ignition (including re-ignition). Electrodes with lanthanum are more durable and resistant to high temperatures.

Tungsten electrode PTK WL-20

Tungsten electrodes WC-10 (pink) and WC-20 (gray)

WC-10 is a cerium oxide (CeO₂) electrode, pink color code. The mass fraction of cerium oxide reaches up to 1%.

WC-20 is an electrode containing cerium oxide (CeO₂), the mass fraction of which varies from 1.8 to 2.2%. Has a gray color code.

- Features: Cerium as an alloying element improves arc stability and ease of starting while reducing burnout. Tungsten grade WC-10/20 is recommended for use in short welding cycles at low current values.

- Current type: Cerium electrodes are designed for welding with direct and alternating current (AC/DC).

- Metal: Electrodes are designed for welding aluminum, all types of steels and their alloys, especially thin sheets.

Only branded tungsten electrodes PTK WC-20 with a diameter of 1.6 to 3.2 mm are on sale.

Tungsten electrode WY-20 (blue)

This is a tungsten electrode containing yttrium oxide (Y₂O₃), which is color coded blue. The mass fraction of the alloying additive varies from 1.8 to 2.2%.

- Features: Yttrium tungsten electrodes can withstand high currents and, subject to welding technology, provide a high-quality and reliable seam, therefore they are especially suitable for welding particularly critical structures.

- Current type: Designed for direct current (DC) welding only.

- Metal: This type of electrode is suitable for welding all types of steels, titanium, copper and their alloys.

The range of WY-20 electrodes is presented in diameters of 1.6 / 2.0 / 2.4 and 3.2 mm.

Tungsten electrodes WZ-3 (brown) and WZ-8 (white)

WZ-3 is a zirconium oxide (ZrO₂) electrode, color code brown. The mass fraction of cerium oxide reaches up to 0.3%.

WZ-8 is an electrode containing zirconium oxide (ZrO₂), the mass fraction of which varies from 0.7 to 0.9%. Has a white color code.

- Features: This type of electrodes can be used when welding at high currents. They have poor arc stability and are very demanding on the cleanliness of the weld pool. It is recommended to sharpen the working end of these electrodes in the shape of a hemisphere.

- Current type: Designed for welding on alternating current (AC) only.

- Metal: Electrodes are designed for welding aluminum, magnesium, nickel, bronze and their alloys.

Only branded tungsten electrodes PTK WZ-8 with diameters of 1.6 / 2.0 / 2.4 and 3.2 mm are on sale.

Tungsten electrodes WT

WT brand electrodes are doped with thorium oxide (ThO₂) and include the following varieties:

- WT-10 - yellow color code, thorium dioxide content up to 1%;

- WT-20 - red color code, thorium dioxide content up to 2%;

- WT-30 - purple color code, thorium dioxide content up to 3%;

- WT-40 - orange color code, thorium dioxide content up to 4%.

Tungsten electrodes made of thorium oxide alloy are used in direct current (DC) welding of stainless steel, copper, nickel, titanium and their alloys.

An important and distinctive feature of thorium is its radioactivity. Thorium is considered a radioactive metal, making inhalation of fumes and dust a health risk to the welder and disposal an environmental risk. Based on these considerations, there are no WT thorium tungsten electrodes in the range of PTK branded products.

TIG welding with consumable electrode

The electrode in this case is a metal rod. It is covered with a layer of rutile. The welding arc is ignited by molten metal vapors, which give ionization in argon. The oscillator is not used in this case.

Prices for electrodes in these categories depend not only on the country of origin, but also on the pricing policy of the enterprises that produce them. Currently, tungsten electrodes have the following cost:

- WP brand electrodes – from RUB 3,657/kg;

- WZ brand electrodes – from 5000 rub/kg;

- WT brand electrodes – from 5000 rub/kg;

- electrodes brand WY – from 5000 rub/kg;

- electrodes brand WL – from 5000 rub/kg;

- WC brand electrodes – from 4730 rub/kg.

Recommendations for selecting electrode diameter and welding current

The quality of the weld directly depends on the correctly selected diameter of the welding electrode and the set current. Therefore, we have prepared special recommendations for you that will help you achieve the highest quality results in the welding process.

| Electrode diameter, mm | Recommended current for welding in argon (AC), A | Recommended current for welding in helium (AC), A | Recommended current for welding in argon (DC), A | Recommended current when welding in helium (DC), A |

| 1,0 | up to 60 | up to 50 | up to 70 | up to 50 |

| 1,6 | 60–120 | 50–110 | 70–120 | 50–100 |

| 2,0 | 70–130 | 60–120 | 90–150 | 70–130 |

| 2,4 | 100–180 | 90–160 | 110–180 | 90–150 |

| 3,0 | 140–230 | 120–200 | 150–220 | 120–200 |

| 3,2 | 160–250 | 150–220 | 180–270 | 160–250 |

| 4,0 | 200–320 | 180–300 | 200–350 | 180–320 |

Features of working with metal

You should know that welding can be carried out in manual, automatic or semi-automatic mode. The work is done without using an additive, using only molten metal from the tips of the elements for welds, which significantly reduces operating costs. There are a number of points to consider:

- tungsten soldering is possible even in cases where the thickness of the elements is less than 0.1 mm;

- during operation, air masses must be removed from the operating zone; gas consumption depends on the thickness of the product, soldering speed, and type of connections;

- the arc can be ignited without touching the metal, in which case an oscillator will be needed;

- you need to carefully monitor the choice of current polarity, which will reduce the waste of electrodes by reducing the heating of the metal;

- Argon creates a protective bubble, preventing oxidation and reducing material usage.

There are a number of job requirements. They must be adhered to to maintain high quality products, in particular:

- ensure precise adherence to dimensions to obtain seams of the highest quality;

- use certain devices that simplify assembly;

- degrease the tips of the electrodes and the surfaces to be treated;

- correctly select the current strength to save electrodes and preserve the shape of their sharpening;

- do not forget to displace air from the work area;

- if inert shielding gases are used, you must constantly ensure that the gas cloud covers not only the weld pool, but also the electrode with the tip of the heated wire;

- as welding accelerates, the rate of supply of inert gases should also increase.

The manual technique has a number of features. Work is performed from right to left. If the thinnest components are welded, then the torch should be held at an angle of 60 degrees, if thicker ones - 90 degrees. When choosing a method for installing additives, take into account the thickness of the products.

Automatic and semi-automatic modes also have their own features. So, the direction of work should help move the filler rod in the front part of the arc. The electrodes are placed in a perpendicular position to the welding surfaces, and the additive and wire are placed at an angle of 90 degrees.

Welding with tungsten electrodes

Transformers are the main power sources when alternating current is used, generators and rectifiers when direct current is used.

All sources must have a steeply falling characteristic, which will maintain a constant voltage value if the arc length is disrupted due to changes. Regarding what is cooked with tungsten electrodes. This type of welding is used when working with molybdenum, nickel, titanium and high-alloy steels. The source of high temperature is current.

The components are a special electrode and argon gas, that is, the process takes place in a protected environment, which leads to improved characteristics of welding seams, simplifying the work itself and making it more efficient.

Welding calculator for TIG welding

We remind you that we have developed a specialized TIG welding calculator that will be useful to dealers and welders who are just learning the basics of argon arc welding. The calculator will “give” recommendations for welding work with aluminum, steel and stainless steel, possibly with the choice of torches and components. The choice of thickness of the welded metal is from 1 to 12 mm. Also, the calculator will tell you which areas need to be welded, depending on the type of connection.

Follow the link and use the TIG calculator.

Welding Features

In addition to the correct selection of electrodes, you also need to know exactly how welding is performed. There are several features of argon welding that any welder needs to know:

- Connecting stainless steel and other materials, the tip of the electrode is a current conductor.

- Proper sharpening affects the stability of the arc. If sharpened incorrectly, the quality of welding suffers.

- In addition to the composition of the metal being welded, the composition of the tungsten electrodes must also be taken into account.

This type of welding is not easy and has many nuances. This is what the welding process looks like:

Tungsten electrodes should only be used when necessary. Conventional welding is best done with simple consumables.

This is what welding looks like:

Adviсe

The best option for tungsten electrodes for argon arc welding is to operate on direct current of straight polarity. Particular attention must be paid to sharpening the tip of the rod. It is recommended to pay attention to other points:

- There is no need to be overzealous during the sharpening process. The material may overheat and become brittle. Its further use will hardly be possible, it will simply crumble;

- It is important to monitor the quality of the gas supplied. The volume fraction of high-quality argon reaches 99.9%. If its quality is low, it will immediately become noticeable by the darkened seam. It will be necessary to make adjustments using equipment on the cylinder;

- It is important to set the optimum amperage to avoid erosion of the rod tip. Blunting or the formation of a large drop will lead to the fragility of the electrode, skipping melting areas, and through burns of the material;

- To obtain a high-quality seam, welding is carried out from right to left. The torch is held in the right hand and the filler wire in the left.

In some cases, alternating current may be used. Argon welding with alternating current is not so demanding on the shape of the rod tip. Here it is important to simply prepare the electrode for welding by giving the tip a semicircular shape. But AC welding is very sensitive to the surfaces that need to be welded. This is especially true for aluminum. The main condition for obtaining smooth welds without uncooked areas is cleaning and thorough removal of fatty traces from the surface.

Literature and sources used:

- GOST 23949-80 Non-consumable tungsten welding electrodes. Specifications

- Cary, Howard B. & Helzer, Scott C. (2005), Modern welding technology, Upper Saddle River, New Jersey: Pearson Education

- Watkins, Arthur D. & Mizia, Ronald E, Optimizing long-term stainless steel closure weld integrity in DOE standard spent nuclear canisters, ASM International

Which brands are the best?

Tungsten electrodes are presented by both foreign and domestic manufacturers.

The most popular were:

- products of the Swedish company ESAB, manufactured not only in Europe, but also at Russian factories;

- the high price of Fubag rods from Germany corresponds to their quality;

- the entire range of tungsten electrodes is in the catalog of the Italian brand BlueWeld;

- lanthanum wire EVL from Ecotek plant.

In addition to products from large factories, trading enterprises offer products from many Chinese manufacturers. The most popular were Shaanxi Yuheng Tungsten Molybdenum Industrial Co., Ltd, which has been producing tungsten electrodes for over 15 years, Hangzhou Linan Dayang Welding Material Co., Ltd, etc.