Detecting a defect in any product is a very common occurrence these days. And if the purchase of low-quality haberdashery goods can only result in a waste of money, then a violation of the manufacturing technology of machinery and equipment will entail much more serious and negative consequences, including the death of people. This article provides a general classification of defects, describes the causes of their occurrence, as well as methods of elimination (when possible). Particular attention is paid to violations of the internal structure of metals and poor-quality welded joints, as defects that pose the greatest danger to society. Often the causes of large-scale disasters are defects in welds.

Basic provisions

There are many definitions and concepts of defect. In general, a defect is any non-compliance of a specific product with design documentation, industry standards and norms, as well as GOST. They can be hidden (impossible to detect with the naked eye) or obvious. The latter are also called surface defects.

Types of defects can also be classified according to the degree of impact on the ability of the product to perform its intended functions: minor, significant, and critical. There is no single recipe for assigning a particular defect to a specific class. This, one might say, is a collective examination of a group of specialists. It is necessary to take into account the load diagram of the product, the presence (absence) of stress concentrators, and the location of the defect.

The types of defects can be completely identical, but the impact on the performance of a given specific product can vary, and quite significantly. So, say, the development of temper brittleness of the second type in the steel from which the poker is made will not in any way affect its performance characteristics and service life. But if such a defect occurs in the material of a highly loaded high-speed shaft, it will simply shatter into small fragments when significant fatigue accumulates from high-frequency alternating dynamic loads.

Corrosion damage

As a result of chemical or electrochemical exposure to the environment, the surfaces of equipment parts receive corrosion damage (Fig. 3). A clean metal surface is easily exposed to chemical influences from the environment. However, if, during the process of corrosion, its products form a film firmly bound to the metal, isolating the surface from the corrosive environment, then the metal becomes passive in relation to it.

| (A) | (b) | (V) | |||

| (G) | (d) | ||||

Figure 3 – Examples of corrosion damage:a) atmospheric corrosion; b) electrochemical corrosion; c) corrosion of the impeller blades, accompanied by erosion; d) stress corrosion cracking; e) corrosion of the outer ring of the bearing | |||||

The following types of corrosion are distinguished:

a) atmospheric corrosion (Fig. 3.a):

– wet, which occurs at a relative air humidity of less than 100% under an invisible film formed on the metal surface due to moisture condensation; – wet, which occurs when the metal surface is directly wetted by precipitation or industrial emissions.

The average rate of such corrosion is 0.1 mm/year;

b) chemical corrosion occurs when metals interact with dry gases, vapors and liquid non-electrolytes. Its variety is gas corrosion, which manifests itself in the form of a film of oxides at a temperature of 200...300 °C. With an increase in temperature to 600 °C, when cracks form in the protective film under the influence of internal stresses, the corrosion rate increases and scale forms;

c) electrochemical corrosion (Fig. 3.b) is caused by the heterogeneity of the metal in contact with the electrolyte. A type of electrochemical corrosion is soil corrosion - destruction of underground metal structures by the soil environment.

The rate of corrosion is affected by the speed of mutual movement of the surface and the medium, at high values of which corrosion intensifies under the influence of erosion (Fig. 3.c). In addition, temperature has an effect: at high temperatures the rate of chemical oxidation processes increases, and at low temperatures the fragility of the metal increases, which is especially important in the case of exposure to variable or dynamic loads. Loading conditions also have a significant impact on the nature and rate of the corrosion process:

1) corrosion fatigue is a process of destruction of metals and alloys under the simultaneous action of a corrosive environment and cyclic stresses. The process of crack development proceeds more intensively, since the bottom and walls of the crack are exposed to a corrosive environment; 2) corrosion cracking (Fig. 3.d) occurs under the influence of stress and an aggressive corrosive environment. It is a consequence of reduced corrosion resistance of grain boundaries, the presence of a structural component in the alloy that is susceptible to corrosion, and a decrease in intercrystalline strength; 3) fretting corrosion occurs during sliding friction with very small reciprocating movements under conditions of exposure to a corrosive environment and dynamic loads. The dynamic nature of loading causes a sharp increase in the deformation gradient and temperatures, oxidation and setting of surfaces. Wear during fretting corrosion is observed in the seating surfaces of bearings, axles, gears, bolted and riveted joints, and similar cases.

Corrosion of the working surfaces of parts of idle machines (Fig. 3.e) also reduces their wear resistance. For idle friction pairs, the quality of the surface deteriorates and after the equipment is started up, the running-in process begins again. In this case, corrosion products act as an abrasive. The activation of corrosion products, which occurs in a short time, is associated with a rapid change in the linear dimensions of parts and an increase in gaps.

In crevice corrosion, corrosion damage is concentrated in the gap between surfaces. The gap can be gaps between sheets, gaps in mates and joints, areas of cracks in the metal, as well as gaps between foreign substances that have settled or adhered to the surface. Even metals that are resistant to other types of corrosion are susceptible to crevice corrosion due to the formation of films on their surfaces that have high protective properties.

The consequences of corrosion are local weakening of the sections of working elements and nodal connections of equipment, which leads to stress concentration and subsequent destruction of the structure.

Prevention and prevention of defects

To minimize the likelihood of defects occurring, it is necessary to approach the pre-production stage very carefully and responsibly, as well as comply with all the requirements of technological and design documentation:

- before you start welding surfaces, you need to make sure that the latter have the correct geometry;

- the process itself must be carried out in compliance with all processing regime standards; the lack of proper qualifications on the part of the performer is the cause of marriage in most cases; a solution may be the use of special welding machines and robots, which make it possible to obtain a high-quality and uniform seam along all lengths;

- Each weld after completion of work must be checked by specialists from the quality control department for the presence of hidden and obvious defects; This measure allows you to timely identify and take measures to eliminate defects.

Significant defects

Significant defects include defects whose presence has a significant impact on the operation of the product and its useful life, but which are not considered critical. In other words, in the presence of this type of defect, the characteristics of the product deteriorate somewhat, but it can still be used directly for its intended purpose. An example of such a discrepancy with design documentation is the presence of minor pores on the surface of steel products.

Critical types of defects

A defect, the occurrence of which makes it impossible to use a specific product for its intended purpose (for safety reasons and due to the lack of physical capabilities), is called critical. There is no need to invent examples of such defects for a long time. A classic critical defect is steel burnout (a metal defect in which grain boundaries, as a result of significantly exceeding the permissible heat treatment temperature, oxidize and the material becomes brittle). The production of components and products from such steel is strictly prohibited. This type of defect belongs to the category of irreparable defects. There is only one way out - remelting the steel and obtaining, after annealing, an equilibrium metal structure with the original mechanical and physical properties.

Defects in welded seams of loaded elements are also considered critical. Welding is generally a very serious and responsible occupation, strictly regulated by many laws and regulations. Quality control of welded joints is carried out by highly qualified specialists using complex and very expensive highly specialized equipment for detecting hidden defects. The type of defect, as well as its significance, must be determined with pinpoint accuracy.

Preparation and assembly defects

Typical types are incorrect bevel angle of edges in seams with V-, X- and U-shaped grooves, too large or small blunting along the length of the joined edges; inconsistency of the gap between the edges; mismatch of joining planes leading to displacement of the edges, too large a gap between the edges, delamination and contamination of the edges.

The shape and dimensions of welds are usually specified by technical specifications, indicated on drawings and regulated by standards: structural elements b - weld width, reinforcement height C and penetration depth h.

Main defects

– uneven width and height of reinforcement, local mounds and saddles. These types of defects are most common in manual electric arc welding.

Such defects reduce the strength of the connection and indirectly indicate the possibility of the formation of internal defects.

Defects in welded joints are characterized as both unacceptable and acceptable. Unacceptable defects are digested again.

Finished welded joints are first of all subjected to external inspection to identify external defects (cracks, weakening of the seam, sagging, undercuts, burns, local weariness, porosity, etc.).

Cracks:

hot (technological) and cold. Hot - in rigidly fixed structures of alloy steels (especially with insufficient quality - Smax). Cold – quenching theory (Cmax) Seq = 6.25 and hydrogen.

Surges

are formed as a result of the flow of molten metal onto unmolten metal.

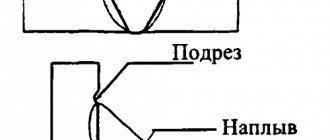

Undercuts

are formed along the edges of the weld in the base metal (depth from tenths to several mm). Burn-throughs are defects in the form of a through hole in the weld (the first root layer or thin metal, or flow through a large gap).

The presence of hidden internal defects in welded joints is monitored by various physical methods: X-ray scanning, scanning with rays of radioactive isotopes (cobalt - 60, cesium - 137), magnetographic method, magnetic powder method and ultrasonic flaw detection, leak detection testing.

Each of these methods has its own specific features that determine its sensitivity and scope of application.

Figure 3.15 – Types of weld defects and causes of their occurrence

Testing products for tightness (limiting the penetration of liquid or gas), or leak detection testing, is carried out using easily penetrating media (liquids or gases), which are clearly distinguishable visually or using instruments.

Internal defects include pores, slag inclusions, lack of penetration, lack of fusion and cracks. Pores are formed due to contamination, moisture in the flux or electrode coating, or insufficient protection in a protective gas environment. Lack of penetration due to poor cleaning of edges from scale, rust, slag, arc wandering due to magnetic blast; incorrect choice of welding mode (current and arc voltage, welding speed), etc.

In addition to quality control, external inspection and the use of various physical methods check the compliance of the mechanical properties and chemical composition of welded joints with the requirements of technical specifications and technological instructions for welding on witness samples.

Defect detection methods

The presence of defects indicates serious violations of the technological process. And the sooner they are detected, the faster measures will be taken to eliminate them. This directly affects the economic performance of an industrial enterprise, and in some cases can prevent a disaster and loss of life.

The main methods for identifying defects are as follows: visual (magnification up to 30 times, possibly using a magnifying glass), checking mechanical properties (impact strength, tensile strength, cold brittleness, red brittleness and others), control using microanalysis (using optical and electron metallographic microscopes), control using x-rays, ultrasonic testing, corrosion resistance tests (usually special equipment is used - salt fog baths).

Non-destructive testing methods

Material defects accompany the part throughout its entire lifespan. They may appear at the stage:

- receipt of the workpiece

(casting defects, forging or rolling defects); - manufacturing

(defects in processing, hardening); - operation

(fatigue cracks, brittle and ductile fracture).

At the same time, manufacturing defects that are not detected in a timely manner are often realized during the operation stage, leading to sudden failures, shutdowns and equipment downtime.

Numerous studies have established that parts subject to cyclic loads operate 90-97% of their service life in the presence and development of defects [9]. Even brittle fracture does not occur instantly, but takes a certain period of time from the moment the defect arises to complete destruction.

This gradual accumulation of damage in the material of the part allows you to monitor its condition using non-destructive testing methods

. The use of these methods allows not only to detect defects, but also to assess the risk of damage and determine the cause of the defect. Knowing the cause allows, by changing production technology, to eliminate the possibility of such defects occurring.

Non-destructive testing methods ensure the detection of defects in the material of a product (object) without destruction through the interaction of a physical field or substance with the test object. The object most often used in non-destructive testing is a part or a connection of parts (welding seam, coating, adhesive joint). From the point of view of physical phenomena, there are nine main types of non-destructive testing:

- Magnetic non-destructive testing

is based on the analysis of the interaction of the magnetic field with the test object. The method is used to control objects made of ferromagnetic materials. The properties that need to be controlled (chemical composition, structure, presence of discontinuities, etc.) are usually associated with the parameters of the magnetization process and the hysteresis loop. - Electrical non-destructive testing

is based on recording the parameters of the electric field interacting with the controlled object (electrical method itself), or the field arising in the test object as a result of external influence (thermoelectric and triboelectric methods). The primary information parameters are electrical capacitance or potential. - Eddy current non-destructive testing

is based on the analysis of the interaction of the electromagnetic field of an eddy current transducer with the electromagnetic field of eddy currents induced in the test object. The method is used to control objects made of electrically conductive materials. Eddy currents are excited in the object by a converter in the form of an inductive coil powered by alternating or pulsed current. The receiving transducer (meter) is the same or another coil. The exciting and receiving coils are located either on one side or on opposite sides of the test object. The intensity and distribution of eddy currents in an object depend on its size, the electrical and magnetic properties of the material, the presence of discontinuities in the material, the relative position of the transducer and the test object, that is, on many parameters. - Radio wave non-destructive testing

is based on recording changes in the parameters of electromagnetic waves of the radio range interacting with the test object. Usually, ultra-high-frequency waves are used and products made from materials where radio waves are not greatly attenuated are monitored:- dielectrics (plastics, ceramics, fiberglass);

- magnetodielectrics (ferrites);

- semiconductors;

- thin-walled metal objects.

Based on the nature of interaction with the control object, the following methods are distinguished:

- transmitted radiation;

- reflected radiation;

- scattered radiation;

- resonant.

- Thermal non-destructive testing

is based on recording changes in the thermal or temperature fields of the test object. The method is applicable to objects made of any materials. Based on the nature of the interaction of the field with the control object, the following methods are distinguished: - passive

or self-radiation (the object is not affected by an external source of energy);

active

(the object is heated or cooled from an external source).

The measured information parameter is temperature or heat flow.

is based on observation or registration of parameters of optical radiation interacting with the test object. Depending on the nature of the interaction, the following methods are distinguished:

- transmitted radiation;

reflected radiation;

Optical methods are widely used due to the wide variety of methods for obtaining primary information. The possibility of their use for external control does not depend on the material of the object. The simplest method is organoleptic visual control, with the help of which visible defects, deviations from specified shapes, colors, and so on are found.

is based on the registration and analysis of penetrating ionizing radiation after interaction with the test object. The most widely used for monitoring are X-ray and gamma radiation.

is based on recording the parameters of elastic waves arising or excited in an object.

Most often, elastic waves in the ultrasonic range are used (with an oscillation frequency above 20 kHz); this method is called ultrasonic

. In contrast to the methods considered, here they use and record not electromagnetic, but elastic waves, the parameters of which are closely related to such properties of materials as elasticity, density, anisotropy (unevenness of properties in different directions) and others.

is based on the penetration of test substances into the defect cavity of the test object. There are different methods:

- capillary

- based on capillary penetration of an indicator liquid (kerosene, turpentine) into the defect cavity, which well wets the object material; they are used to detect surface defects that are faintly visible to the naked eye;

Internal defects in the weld area

Defects in welds are in most cases hidden and can only be seen using special equipment. Therefore, this type of marriage is especially dangerous. The process of welding products is very complex. In some cases, the welding zone is preheated to a certain temperature to ensure maximum weld quality.

The following types of internal defects can occur in a weld: pores, metal oxides and non-metallic inclusions, lack of weld penetration, cracking, overheating, burnout.

Pores are cavities in which gases (hydrogen, carbon dioxide and others) accumulate under high pressure. Such defects can cause a brittle fracture in the weld area. The reason for the occurrence of defects of this type is poor-quality and damp welding electrodes, the presence of metal oxides on the welded surface.

If a defect such as internal lack of penetration occurs, then all the blame can be placed on the welder. Most likely, the work was carried out by an inexperienced worker who had only recently received a profession. Lack of penetration is the absence of a weld in a certain (usually small) area. In addition to low qualifications of personnel, this defect can occur when there is a small gap between the surfaces being welded, an accelerated working feed, or the presence of oxides and other foreign non-metallic inclusions in the electrode melting zone. In the case of electric arc welding, lack of penetration can be caused by incorrectly selected modes (primarily current strength).

Cracks can occur in both longitudinal and cross sections. This defect is especially dangerous, since the propagation of cracks is not limited only to the surfacing zone, but often also affects the welded products.

Overheating occurs due to secondary recrystallization of the metal (accelerated grain growth due to the absorption of neighboring grains). This structure causes the weld area to become brittle. Outwardly, such a defect does not make itself felt. To be able to compare the metal’s score with the standard scale, you need to cut out a control sample, grind it, polish it, and then etch the smooth surface with a special reagent (4-6% solution of nitric acid in alcohol) in order to identify grain boundaries. And only after this set of measures will the structure of the steel be visible through the lens of a metallographic microscope. If destruction of the structure is unacceptable, then you can polish and pickle the weld area, and then attach a special mobile microscope to the structure.

Classification by geometry [ edit | edit code ]

The classification of defects is set out in GOST 30242-97 “Defects in joints during fusion welding of metals. Classification, designation and definitions" [2], as well as in GOST R ISO 6520-1-2012 "Classification of defects in geometry and continuity in metallic materials. Part 1: Fusion welding" [3], which comply with the ISO 6520 standard [4].

Defects in welding joints are divided into six groups:

- Cracks

are discontinuities caused by local rupture of the seam, which may occur as a result of cooling or stress. - Cavities and pores

are discontinuities of arbitrary shape formed by gases trapped in molten metal, which has no corners. - Solid inclusions

are solid foreign substances of metallic or non-metallic origin in the weld metal. - Lack of fusion and lack of fusion

- lack of connection between the weld metal and the base metal or between individual weld beads. - Violation of the weld shape

is a deviation of the shape of the outer surfaces of the weld or the geometry of the connection from the specified value. - Other defects

- all defects that cannot be included in the groups listed above.

Cracks [edit | edit code ]

Cracks that occur in joints during welding can be located in the weld metal, in the heat-affected zone, or in the base metal.

Depending on the orientation, cracks are divided into:

- longitudinal (oriented parallel to the axis of the weld). Mainly caused by high shrinkage stresses [5].

- transverse (oriented transverse to the axis of the weld). As a rule, they are formed as a result of longitudinal shrinkage of metal with low ductility and are usually shallow.

- radial (radially diverging from one point)

In addition, the following types of cracks are distinguished separately:

- placed in the weld crater

- group and separate

- group branched

- microcracks detected by physical methods at at least 50x magnification.

Methods for reducing crack formation during welding are:

- calcination of fluxes before welding;

- preheating of workpieces from 250 to 450 °C;

- welding in a mode with optimal parameters;

- slow cooling of the metal after welding;

- Carrying out soft annealing after welding to relieve residual stresses.

Cavities and pores [edit | edit code ]

The occurrence of these defects is mainly caused by gases trapped in the molten metal. By location they are divided into:

- evenly distributed along the weld;

- located in a cluster;

- arranged in a chain.

Cavities also include fistulas - elongated tubular cavities caused by the release of gas, and shrinkage cavities - cavities that are formed due to shrinkage during solidification. A special case of a shrinkage hole is a crater - an unwelded shrinkage hole at the end of the weld bead.

Solid inclusions [edit | edit code ]

The following types of solid inclusions are distinguished:

- slag inclusions - linear, isolated, others;

- flux inclusions - linear, isolated, others;

- oxide inclusions;

- metal inclusions - tungsten, copper, other metal.

Lack of fusion and lack of penetration [edit | edit code ]

The following types of non-fusion or lack of connection between the weld metal and the base metal or between individual weld beads are distinguished [6]:

- along the side surface;

- between the rollers;

- at the root of the weld.

The term lack of penetration or incomplete penetration refers to the lack of fusion of the base metal in a section or along the entire length of the seam, which appears due to the inability of the molten metal to penetrate into the root of the joint, filling the gap between the parts.

Violation of the shape of the seam [edit | edit code ]

Violations of the seam shape according to GOST 30242-97 include:

- undercuts are longitudinal indentations on the outer surface of the seam bead.

- shrinkage grooves - undercuts from the root side of a one-sided seam due to shrinkage along its border.

- excess convexity of butt and fillet welds

- Excess penetration - excess deposited metal on the back side of a butt weld.

- incorrect weld profile - the angle between the surface of the base metal and the plane tangent to the surface of the weld is less than the normal value.

- overlay - excess deposited weld metal that has flowed onto the surface of the base metal.

- linear and angular displacements of welded elements - displacement between welded elements when they are parallel located at different levels (linear) or the location of the edges of elements at an angle (angular).

- sagging - weld metal that does not have fusion with the surface being connected and is formed as a result of redistribution of the deposited weld metal under the influence of gravity. Sagging often occurs when welding fillet welds or butt welds in a horizontal position.

- burn-through - leakage of metal from the weld pool, leading to the formation of a through hole in the seam.

- not completely filled edge groove

- excessive asymmetry of the fillet weld - a significant excess in the size of one leg over the other.

- uneven seam width

- uneven surface

- weld root concavity - a shallow groove on the root side of the weld caused by shrinkage.

Read also: Automatic switching to backup power from the generator

In welding production, it is customary to distinguish the following types of defects (Figure 3.15):

- Defects in the preparation and assembly of products for welding.

- Seam shape defects.

- External and internal defects.

Elimination of internal defects

Classification of defects can also be made on the basis of the possibility of eliminating the negative consequences of the defect and restoring the functionality of the mechanism. Welding defects, for the most part, are irreparable. And this imposes great responsibility on the performers of the work and the engineers developing the technological process.

But some types of inconsistencies with the technological process can still be eliminated if desired. In particular, defects can be corrected when so-called overheating occurs. To do this, the entire structure is placed in a furnace, kept in it for some time at a given temperature (above the PSC line on the iron-carbon diagram), and then cools down along with the furnace. It is clear that not all designs can fit into a small oven space. Thus, restoring normal grain sizes is not always possible due to the lack of the necessary material and technical base.

Classification of weld defects

When exposed to various factors during work, some unacceptable seam inconsistencies are formed. Welding defects are divided into several groups, the tolerances of which are described in detail in GOST:

- External defects have an uneven shape of the structure, a consequence of non-compliance with the formation technology.

- According to GOST-23055, non-metallic or slag deposits, lack of fusion and lack of penetration of metal products are accepted for internal defective parts. Welding production monitoring devices are used to identify this category of defects.

There are also through burns and cracks, which are unacceptable when using the material. The main shortcomings in the production of seams are considered to be low-quality metal or equipment, as well as untrained personnel who neglected process technology.

Cracks

The most dangerous weld defects are cracks. The appearance of these inconsistencies contributes to the destruction of the structure; they are detected on the line and in nearby areas. Defects in welded seams are formed with a small opening after the connection is made; subsequently, as a result of stress, the dimensions increase.

Cracks are classified into:

- Cold, occurring after cooling, at temperatures below 320 °C. Illnesses appear both immediately and during operation of the device. The reason may be a violation of welding technology and joint formation.

- Hot, formed during metal crystallization at high temperatures, due to a sharp drop in the plastic characteristics of the metal. The presence of an unacceptable amount of silicon, hydrogen, nickel, and carbon contributes to the defect. Propagation occurs along the joint or transversely, classified into macroscopic and microscopic cracks.

Longitudinal crack on the seam

The correction is made by drilling through the entire cavity, in order to prevent development, the defect is removed and a new connection is welded.

Cavities

An arbitrary shape that appears as a result of exposure to gases is called a cavity. Occurs when the metal melts, the cycle of expulsion of excess gases is not complete, or the weld pool is not formed correctly. Discontinuities are formed in the form of oblong cavities; this category includes craters and shells. The main type of welding rejection is fistulas that arise due to the following circumstances:

- the plasticity of the metal does not meet the requirements;

- hardening structures;

- uneven heating.

Defects differ in shape, depth and location, which can be located both on the inside and on the outside of the seam. Fistulas have an oblong tubular shape and are caused by gases. Failure to comply with technical regulations, namely the presence of oil, oxidation and other contaminants at the welding site, leads to a design defect.

Read also: Disassembly and assembly of the dewalt d25123 rotary hammer

Weld cavity

A low-quality tool can cause irreparable damage, as well as the use of auxiliary materials in the form of fluxes. Increased production speed and non-standard flow of protective gases adversely affect the characteristics of the seam. Pores are formed due to the use of faulty tools, wire, or an excessively ventilated room.

When the arc breaks, or the final section is performed incorrectly, craters are formed. The appearance is determined by the type of funnel that needs to be welded upon detection. Modern welding machines can eliminate the discrepancy by reducing the current at the end of the connection.

Solid inclusions

Foreign substances of any origin are a serious problem in the welding process. The main mistakes are high welding speed, low current, and dirty edges. Weld defects are caused by:

- flux residues;

- slag or oxide inclusions.

Oxide ones are formed as a result of the lack of metal stripping and chemical exposure. The slag, if the technology is followed, floats to the surface, but in some situations remains inside the seam. Protective gases create an environment in which it is impossible to include a foreign body. Metallic inclusions can be dangerous because... have dimensions up to several tens of millimeters.

Various types of inclusions in welds

Conditions for occurrence depend on the type of formation:

- disunited;

- linear;

- other education.

The area of welding operations in which the content of slag additives is exceeded is digested. Often, inclusions appear at the junction of a static and an added seam when making multilayer products.

Lack of fusion and lack of penetration

The lack of joining of the base metal, or between individual elements, is called non-fusion. They are distinguished into superficial ones, consisting between the forks, located at the base of the seam. The main reasons for non-fusion are determined:

- increased arc length;

- inadequate edge cleaning;

- reduced welding current;

- increased welding speed.

The presence of a defect using static connections can be compensated for by additional welding. As a result, strength decreases and stress concentration occurs in the non-fusion zone.

Lack of penetration on the seam

Insufficient fusion of the joint during the welding zone is called lack of fusion. The main reasons are residues of rust, oxidation, scale, and other adverse effects. As a result of a decrease in concentration, the possibility of stresses that negatively affect the structure as a whole increases. In case of deviations from the tolerances, areas with an unwelded seam are cleaned down to the base, and the welding operation is repeated.

Violation of the seam shape

Deviation from the specified parameters of the shape of the weld surface and the geometric state of the connection is caused by a violation of the shape.

There are various disorders, each of which occurs due to certain conditions.

- Undercuts - a defect in the form of indentations is formed along the edges of the weld when positioned longitudinally. It is often formed at an increased welding speed, as a result of which the weld pool hardens faster than expected. The increased arc distance promotes the spread of the weld width across the metal, because with this scheme, the heat transfer of the arc remains at the same level, the power is not enough to melt the entire metal cavity.

- Excess deposited material found on the inside of the weld is excess penetration. Linear displacement defects are a condition in which the parts being connected are located at different levels, and there is a difference in height between the joints. There is an angular type of defect, in situations where the angle is asymmetrical to the butt element.

- Overlay is an excess amount of material formed during the process of joining a seam. The defect is formed due to an excessively long arc, incorrect tilt of the electrode, or increased welding current.

- A burn-through is a through hole formed as a result of the leakage of the metal component of the weld pool. Defects are formed as a result of using a high current at a low speed of movement of the electrode, poor lining or incorrect edge clearance.

Violation of the seam shape

There are also other problems associated with the shape, for example, concave edges of the seam formed on the root side of the joint. Other nonconformities include surface-type scuffing, accidental arcing, metal spatter, and others.

External defects in the weld area and methods for eliminating them

Such defects are detected by visual inspection of the weld. The main types of defects of this kind include deviation from the specified geometric dimensions, the occurrence of so-called sagging and undercuts, lack of penetration and burns.

Violation of the geometric dimensions of the weld occurs, as a rule, due to the fault of an inexperienced welder. In addition to the purely external side, the presence of such a defect also negatively affects the mechanical properties of all welded structures. It is almost impossible to eliminate such a defect. And the work will be very expensive. Therefore, it is not recommended to entrust welding of critical products to newcomers to the profession.

Sagging is also a “disease” of many inexperienced welders. They arise as a result of excessive melting of the metal of the electrodes at a slow working feed. Such defects are classified as minor and only affect the appearance of the weld. Eliminated by mechanical processing by cutting the seam (milling, grinding, planing, chiselling, etc.).

Unlike sagging, so-called undercuts are characterized by insufficient fusion of the material. The defect consists of the formation of unfilled areas at the junction of the welded products. An undercut, depending on specific technical conditions, can be classified as either a correctable or an irreparable defect. So, if such a defect was made when welding very critical surfaces (reactors of nuclear power plants, the hull of a submarine, etc.), then it cannot be corrected. Any intervention in this case with the aim of correcting the weld is a gross violation that can lead to very serious consequences. But if the future design is not an integral part of a very important unit or mechanism, then it is possible to correct the undercut by repeating the weld.

External lack of penetration, like internal one, is characterized by a lack of fusion between the electrode material and the surfaces being welded. Eliminating such a defect is not economically feasible, since it requires removing the molten electrode material from the gap between the surfaces being welded.

Cracks on the surface of a weld are classified as surface defects. They can form along the weld along the contact line of the products being welded, and in the cross section. Most often, such defects arise as a result of uneven heating of areas of welded products in the metal melting zone. Therefore, when carrying out work with critical products, preliminary thermal heating of the products is carried out in the welded fusion zone.

Burn-through occurs as a result of significant local overheating of the metal and the formation of a through hole through which the liquid melt flows. Such a defect can be eliminated only with a patch welded directly above such a hole. But, for obvious reasons, this solution is not suitable for every case.

Part defects.

A defect is each individual failure of a product to meet established requirements.

If the product in question has a defect, this means that at least one of its quality indicators or parameters has gone beyond the limit value or one of the requirements of regulatory documentation for product features is not met (not satisfied).

Defects are divided into:

| Structural defects | Manufacturing defects. |

| This is a non-compliance with the requirements of the technical specifications or established rules for the development (modernization) of products. | This is a non-compliance with the requirements of regulatory documentation for the manufacture or supply of products. |

| -insignificant, - significant and -critical. | -Obvious defect -Hidden defect -Removable defect -Fatal defect |

Non-compliance with the requirements of the technical specifications or established rules for the development (modernization) of products refers to

design defects.

Non-compliance with the requirements of regulatory documentation for the manufacture or supply of products refers to

manufacturing defects.

Many defects are detected during external examination (visually) and are called obvious.

Obvious defect

is

a defect for which the regulatory documentation required for this type of control provides for the appropriate rules, methods and means to identify it.

If the regulatory documentation provides for checking the absence of any defect with a tool, device or disassembly of the controlled product, then such a defect is classified as obvious, despite the impossibility of its visual detection.

A latent defect

is a defect for which the regulatory documentation required for this type of control does not provide for the appropriate rules, methods and means to identify it.

Hidden defects, as a rule, are identified after the product reaches the consumer or during additional, previously unforeseen checks in connection with the discovery of other (obvious) defects.

Rice. 8.1.1 The simplest classification of defects.

When developing regulatory documentation (mainly when establishing methods for monitoring manufactured or repaired products), all possible defects are divided into:

- insignificant,

- significant and

- critical.

This division is based on an assessment of the degree of influence of each defect under consideration on the efficiency and safety of use of the product, taking into account its purpose, design, quality indicators, modes and operating conditions.

The specified separation of defects is carried out for the subsequent selection of the type of product quality control (selective or continuous) and for the assignment of such characteristics of selective control as the risk of the consumer (customer).

A minor defect

is a defect that does not significantly affect the intended use of the product or its durability.

The absence of a minor defect can be controlled selectively at a relatively high consumer risk value.

A significant defect

is a defect that significantly affects the intended use of the product and/or its durability, but is not critical.

Monitoring the absence of a significant defect may be carried out selectively only if the consumer risk is sufficiently low.

Critical defect

is

a defect in the presence of which the use of the product for its intended purpose is practically impossible or unacceptable.

In order not to miss a critical defect, product control must be continuous and, in some cases, repeated.

A removable defect

is a defect the elimination of which is technically possible and economically feasible.

Fatal defect

is

a defect, the elimination of which is technically impossible or economically impractical.

The removability and irreparability of a defect is determined in relation to the specific production and repair conditions under consideration, taking into account the necessary costs and other factors.

The same defect can be classified as removable or irreparable, depending on whether it was detected at the early or final stages of the production (repair) process.

Fatal defects may become removable due to improvements in production (repair) technology and a reduction in the cost of correcting defects.

The product defect rate

is the weighted average number of defects per unit of product.

The main purpose of defect detection is to identify non-compliance of a part with the requirements of regulatory and technical documentation.

The most common defects in car parts and units supplied to the Kyrgyz Republic are:

- Changing the size of working surfaces;

- Mechanical damage;

- Violation of the accuracy of the relative position of the working surfaces;

- Corrosion damage;

- Changes in the physical and mechanical properties of the material.

Changes in the size of parts are a consequence of their wear. When wear is uneven, a violation of the geometric shape of the working surfaces of the part occurs in the form of ovality or taper.

A part is considered suitable for further use if its wear does not exceed the permissible values specified in the technical specifications for inspection and sorting.

In practice, usually, the permissible size without repair is taken to be equal to the upper limit size for the hole and the lower limit size for the shaft indicated on the working drawing.

A necessary condition for the use of parts with acceptable wear without restoration during CR is to ensure the required accuracy when assembling mates using regulatory methods, individual or group selection.

A part cannot be reused without refurbishment if it has reached its wear limit.

Establishing wear limits presents certain difficulties. To substantiate them, static data on the wear of parts, analysis of the work of repair enterprises, data on the wear of prototype parts or the results of special studies are used.

Mechanical damage in parts occurs under the influence of loads exceeding permissible values, as well as due to fatigue of materials. The most typical mechanical damages are;

- cracks,

-holes,

- kinks,

-deformations (bending, warping, twisting).

Cracks

most often occur in parts operating under cyclic alternating loads. Fatigue cracks are typical for frame parts, body parts, crankshafts, etc. Cracks in blocks and cylinder heads can be caused by high temperature stresses. The sizes of cracks vary widely, from visible to the naked eye to microscopic, detectable only with the help of special instruments.

Holes and breaks

are a consequence of metal fatigue and large shock loads.

Deformations

Parts that experience significant dynamic loads are usually affected. These are crankshafts, cardan shafts, connecting rods, front axle beams, springs.

Violation of the accuracy of relative position

working surfaces is a very common defect in automotive parts. The causes of these defects are; uneven wear of working surfaces, internal stress arising in parts during their manufacture, residual deformations. These defects appear especially often in body parts. Thus, in engine cylinder blocks, there is a misalignment of the main supports of the crankshaft, non-perpendicularity of the axis of these supports to the axis of the holes in the seating belts for the cylinder liners.

Violation of the accuracy of the relative position of the working surfaces leads to disruption of the normal operation of the unit, causes increased wear and reduces service life.

Corrosion damage

inherent in many details. The damage to body parts of passenger cars and buses is especially significant. They appear as a result of chemical and electrochemical interaction of metal with an aggressive environment.

Changing the physical and mechanical properties of the material

parts most often manifests itself in a decrease in hardness and elastic properties. The decrease in hardness is a consequence of wear of the hardened surface layer during operation to a temperature that affects heat treatment.

Elastic properties

parts are reduced due to fatigue of the metal from which they are made. This defect is most often observed on valve springs and springs.

Sending vehicles and their components for repair.

The dispatch of vehicles and their components to the Kyrgyz Republic is carried out on the basis of an analysis of the results of the technical condition using control (diagnostic) means, taking into account the mileage and the total cost of consumed parts from the start of operation.

Table 4.2.1 Parameters and characteristics of the technical condition of the telephone exchange

| N p/p | Physical characteristics of the ATE state | Condition assessment | Wear coefficient, % |

| 1 | A new motor vehicle, not registered with the traffic police, in excellent condition, after pre-sale preparation, without signs of use | New | 0 — 10 |

| 2 | Practically new vehicle within the warranty period of operation, with the scope of maintenance performed and not requiring repair or replacement of any parts | Very good | 10 — 20 |

| 3 | The vehicle is in the post-warranty period of operation, with the scope of maintenance performed and not requiring routine repairs or replacement of any parts. Automatic telephone exchange after major repairs | good | 20 — 40 |

| 4 | Used vehicle, with completed maintenance, requiring routine repairs or replacement of some parts, with minor damage to the paintwork | Satisfactory | 40 — 60 |

| 5 | Used vehicle, in a condition suitable for further operation after performing routine repairs (replacement) of units, repairs (external painting) of the body (cabin) | Conditionally suitable | 60 — 75 |

| 6 | Used vehicle requiring major repairs or replacement of numbered units (engine, body, frame), full painting | Unsatisfactory | up to 80 |

| 7 | A previously used vehicle requiring repairs in an amount exceeding the economic feasibility of its implementation; lack of technical ability to do so; unsuitable for use and repair | Limit | 80 or more |

The customer submits for repair vehicles and units that have exhausted their specified life, have reached their limit state and have emergency damage that can only be repaired at the ARP.

Buses and cars are sent to the Kyrgyz Republic, if necessary, the body of the Kyrgyz Republic.

If necessary, trucks are sent to the Kyrgyz Republic for frames, cabins, as well as at least 3 other units in any combination.

The unit is sent to the Kyrgyz Republic if the basic and main parts require repair with complete disassembly of the unit.

If there is an appropriate certificate, cars and units must be complete and have only those faults that arose as a result of wear and tear.

For vehicles and units, the first and second complete sets are installed.

A first complete vehicle

is a vehicle with all its components including spare wheels.

The car is of the second completeness

- it is handed over for major repairs without a platform, metal body, and special equipment.

The engine of the first complete set

is

an engine assembled with all components installed on it, including clutch, compressor, fan, power steering pump, fuel equipment, cooling system and lubrication system devices, air cleaner, electrical equipment.

Engine of the second complete set

- This is an engine assembled with a clutch.

first and second complete sets are installed for trucks and their units

-For buses and cars only the first one.

-Power units – the first.

-For diesel engines - the first,

-For carburetor engines first and second.

The Kyrgyz Republic does not accept trucks if their cabs and frames are subject to write-off. Buses and cars, if their bodies cannot be restored. Units and assemblies whose basic or main parts are subject to write-off.

Cars and units must be: cleaned of dirt and must not have parts that have been repaired in ways that exclude the possibility of subsequent repairs. All assembly units, parts and devices must be secured to the machine in accordance with the design.

The technical condition of cars delivered to the Kyrgyz Republic should, as a rule, ensure the ability to start the engine and test with a mileage of up to 3 km.

Cars that have accidental damage or malfunctions that make it impossible to start the engine and move, or may lead to further destruction of parts, are handed over to the Kyrgyz Republic not driving.

Assembly units handed over for repair must have a certificate confirming the need for a control system drawn up by the customer. The engine and other units must be equipped with the parts provided for by the design. The absence of individual fasteners on the engine and assembly units is allowed.

Engines and their assembly units should not have parts repaired in this way, precluding their further use. They must be cleaned and washed, grease and water drained. All openings through which precipitation and dirt can penetrate must be closed with lids or plugs.

Containers and vehicles used to transport the engine and components must ensure their safety. Each engine and separately sold fuel pump is accompanied by a passport and certificate.

Cars and their components received for repair are called repair stock.

Basic methods for preventing the appearance of defects

After operations to correct defects, it is necessary to carry out even more careful quality control of the weld. Indeed, often attempts to eliminate marriage only worsen the situation. If defects are identified again, it is recommended that such products no longer be sent for revision, but written off as a manufacturing defect. The fact is that repeated heating and cooling of metals can lead to undesirable structural changes in steel, as well as the occurrence of many defects in the crystalline structure of the metal.

Neither technology nor good wages for engineering and working personnel can completely guarantee the absence of defects. A good and experienced welder is capable of producing amazing results even with old and far from the best equipment. Therefore, the main direction in preventing welding defects is the constant improvement of qualifications and motivation of working personnel. It is necessary in every possible way to improve the production culture, increase the collective responsibility of the team of workers, and establish good relationships in the team.

Quality control of raw materials, technology and qualifications of welders

To ensure high quality welded joints, control of source materials (base metal, electrodes, welding wire, fluxes, shielding gases, etc.) is necessary. The quality of source materials is established on the basis of certificate data, for which compliance with the requirements of a given technological process for welding products is determined. In the presence of external defects, as well as in the absence of certificates, starting materials are allowed only after chemical analysis, mechanical tests and weldability tests.

When inspecting the base metal, special attention is paid to the areas to be welded - they must be cleaned of dirt, oil, paint, and rust.

Read also: Files are divided into types

The rolled products are checked for the presence of delamination, scale, uniformity of sheet thickness, etc.

Electrodes and welding wire are checked by performing test welding to establish the quality of materials in terms of the nature of melting, ease of slag separation and quality of weld formation. They must meet the requirements of current GOSTs.

Weldability is the property of a metal to form, with the established welding technology, a connection that meets the requirements determined by the design and operating conditions of the product. Weldability is usually controlled in two cases: when selecting materials and developing welding technology, for example, at the project stage or during technological preparation of production. The second check is related to possible deviations of the properties of the base metal, wire, batch of electrodes and fluxes from the certified values.

Control during the welding process is of great importance for quality assurance. This includes the control methods noted above, including monitoring the serviceability of welding equipment and welding fixtures and compliance with established welding modes (current, voltage and welding speed). Such control is carried out by technologists, foremen and other engineering and technical workers responsible for the work of a given site, workshop, or enterprise.

Careful systematic control of the preparation of products for welding and the welding process will not be effective without checking the level of preparedness of welders. For example, when welding pipes during installation, more than 70% of defects occur due to the fault of the welders.

To check the qualifications of welders, the enterprise administration organizes a qualification commission with the participation of an inspector from Gosgortekhnadzor. Tests must be carried out periodically. At the same time, tests are carried out on the theory and practice of welding work, including welding of samples of the corresponding product. Samples are welded under the same conditions and spatial positions as the real product (for example, pipes - rotary and non-rotary joints). After external inspection, the welded samples are checked using the provided non-destructive testing methods and are also subjected to mechanical tests.

The number of samples for testing is regulated by the “Rules for Certification of Welders”.

The reliability of the structure depends on the quality of the work performed. Defects in welded fasteners are not allowed, otherwise the product may fail at the most inopportune moment. Negligence during work and low qualifications of the master can lead to various problems; work technologies and equipment must be used in accordance with GOST standards. The values of the welds may be within tolerance or, on the contrary, in the latter case, it is necessary to redo the work until the required result is achieved.