Basement and basement spaces are often used by people for work: commerce, offices, shoe repair shops, clothing tailoring and for other purposes. And there is a need to install sanitary devices that consume water and, therefore, require sewerage.

But what if the sewerage system is laid at the top, under the ceiling of the basement? The answer is simple - you need to install a fecal pump with a grinder for the toilet. It is also called sololift, after the name of one of the first Sololift models from Grundfos.

Fecal pump with grinder

The purpose of a household sololift is to raise wastewater to the height of the building's gravity sewer and drain it into it. Since the waste can also be feces from the toilet, to make it easier for the pump to pump them, a toilet grinder is built into it, turning soft fractions, toilet paper and small waste into pulp.

Not all sewage pumps are equipped with a grinder; this must be taken into account when choosing one, taking into account the composition of the waste and its formation.

Design and operating principle

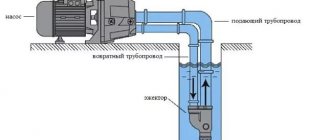

Sololift is a plastic tank the size of a flush cistern, which is connected through a pipe to the drain hole of the toilet. The body may have additional holes for connecting sewerage from a bathtub, sink, bidet and other devices. There is also an outlet for connecting a pressure manifold.

A carbon filter is installed in the lid, providing air outlet when filling the tank and air flow when emptying. Coal is used to neutralize unpleasant odors. The filter is a porous material filled with activated carbon powder. The service life of such a filter is short.

Scheme 1. Design of a fecal pump

A fecal pump with a toilet grinder is installed inside the tank. The chopper blades are mounted on the same shaft as the pump. The pump is placed inside the receiving filter or such a filter is placed in front of it. It has fairly large holes and is designed to protect the pump only from large objects accidentally falling into the toilet. These same holes are indirectly involved in the grinding of feces and soft fractions.

A check valve is installed behind the pump to prevent waste from flowing back into the tank. The outlet pressure manifold has a diameter of 40 mm. It always remains filled with waste up to the check valve.

The pump is controlled by a wastewater level sensor in the tank. When the tank is filled, the level reaches the upper limit and the sensor turns on the pump. When the level shifts to the lower limit, the sensor turns off the pump.

The principle of operation of the pump is to suck in liquid crushed into pulp and supply it under pressure through the sewer into the gravity main sewer of the building, located under the ceiling.

Installation

Before installing the pump in a permanent location, pay attention to the diameter of its inlet pipe. It must match the diameter of the sewer pipe coming out of the toilet. If they do not match, you will not be able to make a tight connection.

A floor sewer pump with a grinder, the installation of which is carried out independently, is mounted in the following sequence:

- supply pipes are inserted into all inlet pipes of the pump (maintaining a slope of 3 centimeters per 1 meter of length) or plugs;

- the pump is installed in a permanent place behind the toilet and attached to the floor using a hammer drill and dowels;

- a sewer pipe is laid from the pump to the drain riser. If several pipes are joined together, the connections between them must be welded, soldered or glued. If it is necessary to vertically remove the pipe from the pump, the pipe should be turned up no further than 30 cm from the pump outlet. In this case, normal pressure will remain in the pipe;

- The drain pipe coming out of the toilet is connected to the pump using a corrugated pipe. In this case, some features are taken into account: the entrance to the pump housing must be located below the level of the pipe exit from the toilet . It is also necessary to tilt the drain pipe to ensure the movement of waste by gravity;

- the toilet grinder pump is connected to the electrical network;

- The operation of the unit is checked and there are no leaks at the joints of the system elements.

Tip: During installation, do not allow the drain pipe to turn at significant angles, as this will place additional stress on the pump components.

We have a separate article on our website about a sewer pump with a grinder for the kitchen. In it you will also find information about popular models and their characteristics.

You can also read what household sewer pumps are and where they are used on our website.

And about the hygienic shower for the toilet there is information on this page https://okanalizacii.ru/santeh_vodoprov/unitaz/gigienicheskij-dush-dlya-unitaza.html. Such equipment brings additional comfort, and its installation is quite simple.

Specifications

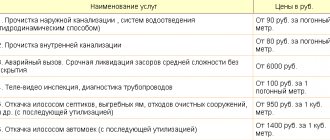

The table shows average data for common models.

| Characteristic | Minimum | Greatest |

| Productivity, l/min. | 60 | 250 |

| Pump power, W | 250 | 900 |

| Lifting height, m | 3,5 | 10 |

| Horizontal range, m | 75 | 120 |

| Number of inlet pipes, pcs. | 1 | 5 |

| Suction fluid temperature, 0C | 35 | 75* |

* - short-term, up to 3 minutes, 900.

A sewage pump is selected taking into account the amount of wastewater, its characteristics, as well as the remoteness of the connection point. Pumps not designed for pumping out hot liquids will quickly fail if used to pump out high-temperature wastewater. Low-power ones will not be able to lift wastewater to great heights.

With low productivity, pumping will take a very long time, and some of the wastewater will begin to stagnate in the pipes. Conversely, a very efficient pump will pump out the tank faster than it fills. Hence the frequent switching on, which will lead to early failure of the electric motor.

Therefore, the choice of pump must be made taking into account knowledge of all the data on the quantity and nature of wastewater and not chasing the most powerful ones.

The most famous pump manufacturers are: Grundfos, SFA, JEMIX, UNIPUMP, Termica, AquaLiv.

DIY installation

- Preparatory stage - choosing a location, reading the instructions, selecting the diameter of the pipe and adapter.

- Installation - drains are connected to all inlet pipes. Their slope should be 3 cm per meter. Plugs are inserted into non-working holes.

- For models without a carbon filter, it is necessary to consider the ventilation system.

- Power connection. For models with a plug, run an extension cord, but without a plug, directly from the mains through a 30 mA RCD

- Start the device and test it in operation.

Types of sololifts

The type of sololift is determined by the type of toilet with which it is installed. Therefore, there are floor-mounted options for floor-standing toilets and wall-mounted options for wall-hung toilets with installation.

In addition, special sololifts are produced for pumping wastewater with high temperatures, up to 90 degrees.

There are also built-in models of toilet grinders, but they come complete with the equipment and can only be used with it.

The same models sometimes differ in the number of inlet pipes.

Equipment operating parameters

The power source for pumping equipment is usually a stationary electrical network. At the household level, the voltage is traditionally 220 V, but in industry and agriculture equipment with a voltage of 380 V can be used.

The following parameters are also important for the future owner:

- power (for domestic use 0.5 - 1.5 kW);

- productivity (150 – 600 l/min);

- height of the liquid column – pressure (10-20 m);

- operating fluid temperature (+1… +40 ºС);

- working environment temperature (+1…+40 ºС);

- degree of density of the pumped medium (up to 1200 kg/m3);

- acidity level of the working environment (Ph – not higher than 10).

Work with pumping equipment must take into account the specified parameters; moreover, for each individual model, the noted indicators can be expressed in specific values that cannot be exceeded.

Features of sololift installation

The sololift is a receiving tank, therefore, it should be the lowest point for the sewerage installation. The reservoir has a certain height, on which its useful capacity depends. Therefore, sewer pipes in the corresponding rooms have to be laid slightly higher than in standard ones, otherwise they can quickly become clogged due to incomplete drainage.

If the pipes are already laid at the usual level and their alteration is not advisable, then the installation of the sololift is carried out with recess into the floor, for which a pit is made.

Usually, a vertical part of the sewer pipe immediately comes out of the tank, which turns into a horizontal section under the ceiling. The latter, if possible, should be performed with a slope towards the point of entry of the pipe into the gravity collector. This will allow the wastewater to drain from the horizontal section, facilitate the operation of the pump and reduce the degree of clogging with fat deposits on the walls of the horizontal section of the collector.

In the section of the vertical collector, immediately after the check valve, a ball valve should be installed, the same cross-section as the collector, to minimize the drainage of wastewater when dismantling the sololift, repairing and servicing the check valve.

What is the device?

The design assumes the presence of a pump that ensures forced supply of wastewater into the pipeline. If there are any large particles, the pump crushes them.

The product is so compact that it can be easily placed behind the cistern or inside. Despite its size, the device is powerful: it pushes wastewater 5-7 meters in a vertical position and 100 meters in a horizontal position.

Sanitary pump design

The pump body is made of durable plastic, inside of which there is an entire system for pumping liquids, equipped with cutting elements for grinding large particles of wastewater.

In order for the pump to function without interruption, it is connected to the sewerage system and electricity supply. The chopper is located in the upper part of the housing. There are models located under the pump, but they are ineffective, because solid inclusions are not processed well enough. The final element of the design is a check valve, which prevents waste from flowing back.

Principle of operation

The operating principle depends on the selected pump model:

- a product with a float switch assumes that the device will start working only when the mass has accumulated to a certain volume;

- in other models, the shredder starts instantly, turning waste into a homogeneous mass that goes into the sewer.

Advantages

This device is a real salvation for those who want to move the toilet away from the riser or install plumbing in a room below the sewer level. In addition, the pump has a number of advantages:

- Preventing possible blockages and traffic jams.

- Possibility of installing pipes of smaller diameter.

- To flush away wastewater, a smaller volume of water is needed, which results in significant savings.

- Plumbing equipment is located anywhere in the room.

- Products with high-quality insulation operate silently.

Disadvantages and limitations in work

The devices depend on electricity, which can be a problem for a country house. Pumps need regular cleaning, but this must be done manually or using special chemicals. If you do not clean it, the device will become clogged, which will affect its operation. There are self-cleaning models, but you have to pay more money for them.

How to use a fecal pump with a grinder

The sewer grinder has steel blades, without sharpening the blades. It is designed to loosen and pulp soft feces. Therefore, its grinding capabilities are very limited. It can handle toilet paper, liquid leftovers from soup or mashed potatoes. But it will fail if harder fractions get in. Even potato peels and a napkin are too much for him.

And, if a hard object gets into the impeller and jams it, the pump may fail. Pieces of rags and cellulose napkins used for kitchen cleaning are especially dangerous. They get wrapped around the blades, after which the shredder cannot even cope with toilet paper.