Those who plan to permanently live outside the city have to think not only about the interior of the house, but also about the arrangement of engineering systems. Including the construction of an autonomous sewer system, since in suburban villages it is still rare to see centralized systems for the removal and disposal of wastewater. Therefore, the homeowner will have to choose whether to use outdated, environmentally unsafe, but cheap solutions, such as a cesspool, which requires regular pumping, or prefer a more expensive modern wastewater treatment plant. An example of such an installation is the Tver septic tank. Let's look at how the installation works.

Today, manufacturers produce various wastewater treatment plants. Those who value comfort and care about the environment should purchase a Tver septic tank - the operating instructions for this equipment are quite simple and understandable, and servicing the stations will not require much time.

Regular pumping of such an installation is not required, since the wastewater in the installation does not heat up, but is cleaned. Moreover, the manufacturer guarantees the highest level of cleaning. By choosing a Tver septic tank, home owners do not have to worry about the ecology of the site; the stations effectively clean the wastewater, completely removing harmful pollutants.

In addition, if the capacity is chosen correctly, then water in the house can be used without restrictions all year round, without stopping the installation for the winter and without fear that the septic tank will overflow.

Device

Tver septic tanks are a monolithic polypropylene container with one or more (depending on modification) necks in the upper part and inlet and outlet pipes in the end walls.

The bottom of the installation has a rounded shape, eliminating the possibility of the tank floating up during a strong rise in groundwater. The shape of the container is clearly visible in the photo.

Photo: general appearance of the original shape of the Tver septic tank

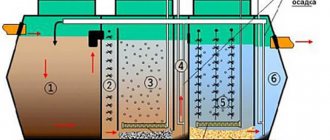

The internal part of the tank is divided by partitions into 6 compartments, each of which is used for a specific technological process of wastewater treatment. In addition to the partitions, the cavity of the container contains a network of pipelines to ensure aeration, as well as special fillers (brush, expanded clay, limestone loading).

Photo: internal loading of a working septic tank

A video will help you see clearly what a Tver septic tank is.

Principle of operation

Tver is a septic tank, the design and principle of operation of which involves the use of several different methods of wastewater treatment simultaneously. This allows you to get 98% purified water at the output. All processes take place inside the container, without the use of soil post-treatment.

Diagram of the internal structure and operating principle

Wastewater processing occurs in the following sequence:

- Wastewater, passing through the sewer pipeline, enters through the inlet pipe into the first compartment of the tank - the septic tank (1). Segregation of wastewater occurs in it. Large particles settle to the bottom of the chamber, fats collect on the surface, and the settled liquid ends up in the middle part.

- At the next stage, the settled water from the first compartment flows through the overflow into the anaerobic bioreactor (2), filled with a brush load. In this compartment, purification occurs due to the work of anaerobic bacteria that enter the drains along with human waste products. Colonies of microorganisms settle on the surface of the brush load and contribute to the transformation of difficult-to-oxidize particles from wastewater into easily oxidized ones.

- The clarified liquid enters a compartment called the aeration tank (3), where the process of mixing it with activated sludge occurs. This compartment is filled with expanded clay loading. At the bottom of the chamber there is a pipeline with holes (aerator), through which air is pumped using a compressor. Air supply is necessary for aerobic bacteria covering the surface of expanded clay. This type of microorganisms for the septic tank is loaded into the device simultaneously with the expanded clay loading.

- In the fourth compartment, the secondary settling tank (4), activated sludge is separated from the liquid. Activated sludge returns along the inclined wall to the third chamber, and clarified water flows into the next compartment.

- The fifth compartment - an aerobic bioreactor (5) serves to oxidize and sorb remaining contaminants. At the bottom of the chamber there is a load of crushed limestone, which, when dissolved, binds and neutralizes phosphates. Processes in an aerobic bioreactor occur with the active supply of oxygen through aerators.

- The sixth compartment, the tertiary settling tank (6), collects purified liquid flowing from the container through the outlet pipe. In this compartment it is possible to install a special float with chlorine tablets for additional water purification.

Advantages of the Tver septic tank:

- Large working volume.

- The drain is purified up to 98%, odorless and safe for the environment.

- Purified water is discharged to the ground without further treatment. This saves space on the site, as well as time and money for maintaining a well or filtration field.

- The body is made of homogeneous polypropylene, reinforced with stiffening ribs, and equipped with loading wings to protect against floating.

- Overflows from chamber to chamber are gravity-fed. There is no risk of blockages and maintenance is simplified due to the absence of airlifts.

- The compressor is installed and connected in the house. There is no risk of flooding of electrical appliances when the septic tank overflows. The compressor pumps warm air from the room into the septic tank, which promotes the development of microflora and good wastewater treatment.

The lineup

Tver - septic tanks are represented by a large number of models, differing in tank volume, daily productivity (from 0.35 to 25 cubic meters per day), type of drainage (gravity-flow and equipped with drainage pumps) and other parameters.

These installations can be used for a summer house or a country house, and also serve: bathhouses, small cottage villages, boarding houses, shopping centers. In addition, they can be installed at industrial facilities: garages, boiler rooms, warehouses, gas stations, etc.

Photo: various models of septic tanks Tver

Containers of the same volume have several modification options designed for specific operating conditions.

For example, the Tver 1 biological treatment station is presented by the manufacturer in the following versions:

- Septic tank Tver 1P is the basic model of the installation. The letter P in the marking means that the container is made of polypropylene. The type of water drainage is gravity. The depth of the inlet pipe is 0.1-0.3 meters.

- Septic tank Tver 1PN - installation with forced drainage (letter N in the marking). The tank has an additional capacity in which a drainage pump is installed to pump out treated wastewater.

- The Tver 1PM septic tank has the height of the tank walls increased by 30 cm. The depth of the inlet pipe due to the change in the height of the walls is 0.6 meters. At the same time, the air supply valves remain at the same depth (unlike models with increased neck heights), which makes them easier to access during maintenance.

- Septic tank Tver 1PNM - combines the advantages of two previous models: it is equipped with an additional chamber with a drainage pump for forced drainage and has increased body walls.

- The Tver 1NP septic tank is equipped with an additional chamber with a fecal pump installed in it. Only, unlike the PN model, the additional chamber is located on the side of the inlet pipe. In this case, the pump serves to pump wastewater into the container if the inlet sewer pipeline is too deep (more than 0.7 m). Purified water leaves the installation by gravity.

- The Tver 1NPN septic tank is equipped with two additional chambers. One contains a fecal pump for forced supply of wastewater to the installation. In the second, a drainage pump is installed for forced removal of purified water.

- The Tver 1NPM septic tank has an additional chamber for forced supply of wastewater into the container. In addition, the height of the container has been increased by 30 cm. It is advisable to use this unit if the supply sewer pipeline is located at a depth of more than 1.4 meters. The purified water is discharged by gravity.

- The Tver 1NPNM septic tank has two additional chambers (for drainage and fecal pumps) and an increased height of the tank walls.

- Septic tank Tver 1P-0.1m (0.2, 0.3, 0.4m) has a neck height of 0.1 (0.2, 0.3, 0.4) meters.

Note! The absence of the letter P in the septic tank marking means that the container is made not of polypropylene, but of metal.

Photo: industrial septic tank Tver for large objects

In total, the manufacturer offers more than 280 options for various modifications of Tver septic tanks. Its catalog contains cleaning plants of 13 capacities in various configurations, designed to serve from 1 to 36 people.

The technical parameters of the most popular models of septic tanks in Tver can be viewed in the tables.

Installations designed to serve from 1 to 5 people.

Installations for 5-10 people.

Installations for 10 or more people.

Which is better: “Tver” or “Topas”?

Our clients often ask us to explain how Tver differs from Topas and which sewage system is better. Topas is a station with a receiving chamber-averaging chamber, and Tver - with a receiving chamber-settling chamber, like in a simple septic tank. Compared to the Topas septic tank, in which wastewater is pumped by airlifts, in Tver all overflows are gravity-fed. This reduces the likelihood of blockages and makes drain maintenance easier. In Topas, when servicing, you need to disconnect the airlifts and wash them with a high-pressure washer.

The compressor in Topas is located under the station cover, in the instrument compartment. If the septic tank floods, you will have to change the electrical equipment. In Tver, the compressor is installed in the house. On the one hand, this prevents damage to the devices in the event of an accident, but on the other, as already mentioned, the compressor will make noise, and the air duct may become clogged with frozen condensate in winter. At the same time, Topas is equipped with an alarm system that notifies the owner about the overflow of the septic tank, so the likelihood of flooding is significantly reduced.

If you compare the price, then Tver is more expensive than Topas. For example, the Topas 5 model with a capacity of 1000 l/day costs about 93,000 rubles, and the Tver 1P model with the same capacity costs about 105,000 rubles. The difference is significant.

Criterias of choice

The Tver septic tank modification should be selected based on the following parameters:

- The number of people living in the house. Each family member should have a capacity of approximately 0.2 cubic meters. per day. That is, if the capacity of the septic tank is 1 cubic meter. per day, then this installation can easily serve 5 people (1:0.2=5).

- Groundwater level. For wetlands or areas with high groundwater levels, only models with forced drainage should be selected.

- The depth of the sewer pipeline leaving the house.

Attention! How correctly the choice of modification is made will determine not only the efficiency of the installation, but also how convenient it will be to maintain the Tver septic tank during operation.

Diagram of an option for placing a septic tank on the site

Septic tank body "Tver"

Until 2000, the septic tank was produced in a metal casing. Since 2000, monolithic polypropylene with a sheet thickness of 5 mm has been used to make the body. The sheets are joined using automated welding, the sidewalls are welded manually using an extruder. There are horizontal stiffening ribs on the sides of the body. They strengthen the body and reduce the risk of deformation under pressure. The edges of the body protruding at the ends (loading wings) serve as lugs and prevent the septic tank from floating in high groundwater.

Installation

Before starting installation work, you should read the recommendations contained in the operating instructions and study the installation diagram. Installation of a septic tank in Tver is carried out in the following sequence:

- A pit is being prepared, the dimensions of which can be seen in the installation diagram (the manufacturer includes a Tver septic tank with each model). Please note that it is recommended to leave a space of no more than 20 centimeters from the walls of the pit to the tank body.

- The bottom of the pit is filled with sand and compacted. The thickness of the sand layer should be at least 10 centimeters. It is recommended to ensure that the bottom of the container is not buried more than 2 meters from the ground surface. Otherwise, there is a need to construct retaining walls.

- A septic tank is being installed.

- The space around the edges of the rounded bottom is filled with sand and compacted.

- At the same time, the space between the body and the walls of the pit is gradually filled with sand and filled with water. At each stage of filling, the horizontal level of the container should be monitored.

- A supply sewer pipeline is laid with a slope of at least 2 cm per 1 linear meter. A sand cushion with a thickness of at least 10 centimeters is installed under the pipeline. It is recommended to lay pipes at a depth of at least 20 cm with mandatory insulation.

- The outlet pipeline is laid in the same way. Its slope should be at least 0.5 cm (for gravity models) and at least 1 cm (for models with forced drainage) per linear meter.

- A drain pump with a float switch is installed in the appropriate compartment (for models marked H).

- The compressor is installed in a dry, heated room. The air duct from the compressor to the installation is laid in a trench along with the supply sewer pipeline.

- An electrical cable in a protective casing is also laid in the trenches.

- Expanded clay and limestone loading is poured into the appropriate compartments of the container, a brush filler is suspended, and aerobic bacteria are introduced for biological wastewater treatment.

- The aeration system is being adjusted. In aeration tank 1, active seething should occur, and in the second aeration tank, individual air bubbles should rise to the surface.

- A ventilation riser connected to the sewage system in the house is being installed.

- The biological treatment station is put into operation.

Photo: the final stage of installation - backfilling the septic tank in the pit

Disadvantages of the Tver septic tank:

- Installing the compressor in the house or in a remote box near the septic tank. The compressor in the house takes up space and creates noise. It should also be taken into account that there is usually less oxygen in a living room. If installed incorrectly, condensation may freeze in the air duct in winter.

- The pump is connected to the cable through a heat-shrink sleeve. Problems may arise with such a connection, and manufacturers do not provide a warranty on a pump with a cut plug.

- The alarm is not provided by the manufacturer. The owner does not receive notification of an accident and needs to check the septic tank more often.

- The loading wings are thin (5mm) and look flimsy. There is a risk that they will break under the weight of the soil. Although in our practice such problems did not arise, probably due to the stiffening ribs on the septic tank body.

- The station is horizontal, voluminous and requires space on the site.

- A sewer truck is called in to pump out the sludge; this is a waste of time, money, and often nerves (there are different types of sewer trucks). In addition, the owner must understand a little about the structure of the septic tank. Before pumping, special taps are opened and sludge is pumped from the settling tanks into the receiving chamber. During maintenance, it is also necessary to regulate aeration using valves on the air pipes.

- Tver is noticeably more expensive than other SBOs in the middle price category, such as Eurolos BIO, Unilos Astra, BioDeka.

Service

Maintenance of a Tver septic tank involves periodic external inspections in order to identify deficiencies in the functioning of the station. To do this, you need to remove the caps from the necks. If upon inspection it is discovered that a crust has formed in the septic chamber, then it should be broken without stirring. This is done to ensure normal gas separation. Crusting is considered normal.

When inspecting and servicing the Tver septic tank, you should check whether there is a need for pumping. To do this, a probe (long stick) is lowered into the septic chamber. The appearance of resistance to the movement of the probe at a distance of more than 40-50 cm from the bottom means that there is a need to pump out the container with a sewer truck or fecal pump. If a large amount of activated sludge accumulates in the installation, it is recommended that it also be moved to a septic chamber before pumping.

Maintenance work on a Tver septic tank includes removing dead biofilm from the brush load. It is recommended to do this 1-2 times a year. The film is removed by short-term intensive air supply into the bioreactor. The film that has settled to the bottom is pumped into the septic chamber using airlifts (they are put into operation by alternately opening the corresponding taps). Details of servicing Tver septic tanks of various modifications are described in the manufacturer’s instructions.

If the brush load is heavily clogged, it must be rinsed with a strong stream of water. It is more convenient to carry out these actions after pumping the sludge from the storage tank.

As it dissolves (once every 2-3 years), the amount of dolomite (limestone) load should be replenished - this is also a mandatory condition for maintaining the Tver septic tank.

Reviews

The device we have considered is a serious and well-thought-out engineering structure for wastewater treatment. It is not surprising that owner reviews about the Tver septic tank are positive.

However, you can sometimes find negative reviews about this device on the Internet.

Note that the shortcomings of the Tver septic tank indicated in them are directly related to violations of installation rules: the mandatory ventilation fan riser has not been installed. In addition, the review states that on weekends the device experiences a load that is twice the permissible load.