Bosch GWS 9-125 S angle grinder with speed control. Photo VseInstruments.ru

The need to perform work with one type of power tool that requires changing the established basic characteristics leads to equipping it with additional devices. For example, an angle grinder with a speed controller significantly increases its functionality. You will find more detailed information about the features of operating an angle grinder with a speed controller in this section.

What is rotation speed adjustment, how does it work, is it needed and why?

In the simplest version, the rotation speed can be changed using a power control device, which is based on the principle of variable resistance . That is, by and large it is an ordinary rheostat . Many users use it on household grinders when carrying out polishing and grinding work with soft materials, where at low speeds they can achieve high-quality results.

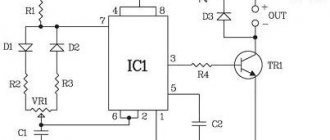

Typical electrical circuit diagram of the speed controller. Photo source here

However , the use of such a device increases the risk of the angle grinder overheating , as overloads occur at low speeds. For this reason, the feasibility of equipping household angle grinders with a power regulator is highly questionable.

Professional, powerful angle grinders are equipped with a more complex technical device for adjusting speed, which is based on an electronic circuit . The presence of a function to support rotation speed when the load changes is its distinctive feature. The prices for such grinders are much higher than for ordinary household ones.

Useful video

With feedback

The system for maintaining the speed of professional angle grinders during regulation includes a sensor that reads the rotation speed . The magnet included in the sensor design sends a signal to an electronic control device, which reports data on the rotation speed. The electronic unit reacts accordingly, increasing the current in the electric drive windings as the load increases (reduces speed). This feedback from the tachometer and the electronic unit occurs continuously and maintains a stable rotation speed in different operating modes of the angle grinder.

What is an angle grinder intended for?

An angle grinder was invented specifically for grinding, therefore, unlike a sawing tool, it works at a very high speed. The material is cut by grinding it. When cutting wood or plywood with a metal disc, high-speed friction leads to smoldering or even combustion of the workpiece. The plastic or soft metal under such a disk will simply melt. Soft materials can only be processed with a grinder when using special discs.

Cutting profiled sheets using an angle grinder using an abrasive cutting wheel.

For cutting stone, brick and tile, discs coated with diamond chips and several cooling slots along the edge are used. The use of circular saw blades, as well as Chinese saw blades with a “grinder” fit, is a gross violation of safety rules and is therefore strictly prohibited.

Contrary to popular belief, an angle grinder is not a universal tool, and trying to do all the work with it is wishful thinking. Seeing the desire of craftsmen to saw various materials with a grinder, BOSH has developed a universal carbide disc Multi Wheell 2608623013. This is an abrasive disc with slots for cooling, thanks to which it does not burn the material being cut. Please note that neither BOSH nor other reputable companies produce saw blades for angle grinders.

Universal carbide disc Multi Wheell from BOCH

When purchasing any blade, it is important to make sure that the speed (rpm) indicated on the label is not less than the spindle speed of your angle grinder. A disc designed for 8,000 rpm may shatter when operated at 10,000 rpm.

This is especially important if the angle grinder does not have a speed control function.

Device, electrical circuit of an angle grinder with a rotation speed controller

The factory speed controller is located inside the angle grinder body and is built into the electrical circuit as follows:

Regulator connection diagram. Source here

The connection diagram is quite simple : the red wire is connected to one of the contacts of the switch, the blue wire is connected through the second contact of the starting device to one of the two stator windings, and the black wire is directly connected to the other winding.

When connecting a regulator, made by yourself or ready-made, purchased in a store, to an angle grinder where it is not provided by the manufacturer, it is not always possible to fit it inside the case . Practice shows examples of implementing a regulator as a separate unit into a network cable break. Users perform it in the form of a mobile universal device , which is applicable for other types of power tools (drill, hammer drill).

Other functions: soft start and more

Angle grinder (grinder) MAKITA 9565CVK with soft start and speed control. Photo 220Volt

In addition to the speed control device and electronic stabilization, which increase the range of work performed, the angle grinder can be equipped with other useful options .

- The soft starter allows you to reduce additional effort on the part of the user, since dynamic loads arising from a sharp increase in spindle speed greatly contribute to this. Installing a soft start is especially important for powerful angle grinders with large inertial mass. Increasing comfort during work, reducing the risk of injury, increasing the reliability of components and parts is ensured by this option.

- The automatic balancing mechanism reduces vibration and runout that occurs due to uneven wear of the working tool.

- Anti-jamming protection , which cuts off the current supply to the windings of the angle grinder during an unexpected forced stop of the electric drive. Prevents motor overheating and failure.

- In order to reduce injuries, for example, in the event of a sudden power outage, then the same unexpected switching on, restart protection . After shutdown, the grinder will re-enter operating mode only after the user presses the protection lock.

- If the nature of the work does not allow you to wait a long time for the rotating spindle to stop, then an additional braking option will help stop it as quickly as possible.

- Problems that arise when replacing a working tool, even when using a special wrench, are solved by using a special quick-release nut . It allows you to change equipment in the shortest possible time.

Tips for choosing a grinder with soft start

To work away from power sources, you should choose a battery-powered tool. This increases the cost and limits the operating time, but allows the angle grinder to be used even in field conditions.

There are also gasoline and pneumatic grinders, which are used primarily in industrial enterprises. Devices with internal combustion engines do an excellent job of cutting large workpieces with a diameter of up to 400 mm. Models powered by compressed air require a compressor with a capacity of 200–400 l/min.

Let's consider other parameters that influence the choice of an angle grinder.

Size of used disks

All discs for grinders, including devices with a speed control function, are divided into two types: cutting and stripping. The diameter of the circles varies from 100 to 500 mm. The most common sizes are:

- 125 mm;

- 180 mm;

- 230 mm;

- 360 mm.

On larger models it is allowed to install disks of smaller diameter, provided that the mounting hole matches.

Please remember: the larger the disk size, the more massive the device will be. This will affect the cycle time.

Engine power

The power of household models does not exceed 1 kW. For professional devices this parameter can reach 5 kW.

The cutting depth directly depends on the value of this parameter.

Availability of manual and electronic protection

Biting the disc during operation is the biggest nuisance. The grinder can break out of your hands and cause serious damage. Possible reasons:

- contact of the circle with a foreign object;

- working with an object that is too strong;

- weak spindle nut tightening;

- exceeding the maximum number of rotations of the nozzle;

- operation of a disc whose material does not match the surface being processed.

All this leads to the fact that the working nozzle breaks or falls into pieces. In the latter case, fragments flying at high speed pose a danger to human health.

To reduce the risk of injury, manufacturers equip the tool with anti-jamming mechanisms.

All inexpensive models have a special casing to protect against disk fragments in case of jamming. These are international safety requirements.

Protection systems can be divided into two types:

- Mechanical. On professional models with a speed control function, special clutches are installed. If the disk is overloaded or jammed during the transmission of torque, it begins to slip, preventing damage to the nozzle.

- Electronic. In this case, a special safety unit is responsible for the emergency stop. Its operating principle is based on reading electrical parameters during operation. An abrupt cessation of rotation is accompanied by a jump in current, to which the sensors instantly react, de-energizing the tool.

Other functions

- Protection against accidental activation. Two start buttons are installed on the angle grinder. Switching on occurs only when pressed simultaneously.

- Load stabilizer. When cutting particularly dense materials, the electronic system automatically maintains the specified number of revolutions. The function will be useful for craftsmen who work with large workpieces made of stone, marble or concrete.

Advantages of universal angle grinders

Angle grinder (grinder) METABO WEV 10-125 Quick 600388000 (in box). Photo 220Volt

It is not always possible to solve the problem of processing certain types of materials with an ordinary angle grinder without additional options; the working tool is not suitable for effective work at the speeds produced by an angle grinder without a speed regulator. The problem of choosing the right modes is especially acute for users involved in grinding, cleaning, and polishing various materials. To complete the job, sometimes you have to find another tool with suitable characteristics.

The versatility of angle grinders with variable speed control lies precisely in the ability to independently set the rotation speed , for example, of cord brushes when stripping. When performing grinding operations, the contact patch between the working tool and the surface being processed increases, which requires the use of high-power grinders. Such grinders with additional options installed on them perform almost any type of work with various materials.

Criteria for choosing an angle grinder with an electronic speed controller

A grinder with an electronic speed controller is far from a cheap purchase option. You should clearly understand the amount of work that will require changing the rotation speed of the working tool. Having made sure that the purchase of an angle grinder with such an option is justified, the technical characteristics of the angle grinder are selected in combination with the capabilities of the electronic control unit to influence the selection of the operating mode.

Detailed information about the selection criteria can be found at the link “Choosing an angle grinder with speed control.”

Rating of the best angle grinders with speed control

| Nomination | Place | Name | Price |

| The best network angle grinders with speed control | 1 | DeWALT DWE4357-QS, 1700 W, 125 mm | 17 590 ₽ |

| 2 | BOSCH GWX 19-125 S, 1900 W, 125 mm | 13 250 ₽ | |

| 3 | AEG WS 15-125 SXE DMS, 1500 W, 125 mm | 18 590 ₽ | |

| 4 | Metabo WEV 17-125 Quick Inox RT box, 1750 W, 125 mm | 13 275 ₽ | |

| 5 | Hitachi G15VA, 1500 W, 150 mm | 24 335 ₽ | |

| 6 | Makita 9565CVR, 1400 W, 125 mm | 9 079 ₽ | |

| 7 | AEG WS 13-125 XE, 1300 W, 125 mm | 6 659 ₽ | |

| 8 | BOSCH GWS 9-125 S, 900 W, 125 mm | 6 232 ₽ | |

| 9 | Sturm! AG9012TE, 1100 W, 125 mm | 3 680 ₽ | |

| The best cordless angle grinders with speed control | 1 | DeWALT DCG412M2 4.0Ah x2 case, 18 V, 125 mm | 30 924 ₽ |

| 2 | Makita DGA517Z, 18 V, 125 mm | 14 050 ₽ | |

| 3 | Bort BWS-18Li-125, 18 V, 125 mm | 14 190 ₽ |

Make your own external regulator without losing power

Users of angle grinders that do not have a speed controller installed are faced with work, the quality of which can be improved by processing at lower speeds than those provided by the technical data. You can expand the functionality of the grinder by installing this option yourself , with your own hands.

Depending on the nature of the work being performed, you can install a simpler power regulator or a complex electronic device with feedback, which will ensure support of the selected speed without loss of power. Information on installation methods can be found in the article at the link “Do-it-yourself speed controller for an angle grinder.” If malfunctions occur in the mechanism, you should familiarize yourself with the information presented in the article “Do-it-yourself repair of grinder speeds.”

On a VTA-16-200 triac and a thyristor

The main elements of power regulators are semiconductor devices - triacs and thyristors . They are easy to buy in specialized stores, as well as other elements included in the circuit - resistors and capacitors . A user who has skills in making electronic boards can make a regulator with his own hands. The option of purchasing a ready-made regulator is also popular among those who want to install it on an angle grinder.

Regulator circuit on the U2010B chip. Photo source here

Some microcircuits that act as the main component of the electronic speed control unit, working in conjunction with a sensor that reads the speed, ensure that the desired speed is maintained without loss of power. It is quite difficult to make such a circuit with your own hands without knowledge of electronics. However, there are microcircuits, for example, U2010B , where a tachometer is not required for operation.

Such a device can be found in a store and inserting it into the electrical circuit of an angle grinder will not be difficult.

Speed controller circuit

To install this system, variable resistance alone is not enough. If you simply lower the voltage in the circuit, the power and speed of the device will decrease. Having dropped to minimum values, such voltage will not turn the angle grinder shaft. Therefore, it is necessary to develop a complete scheme.

The most modern regulators are manufactured using integrated circuits. The electrical circuit of the simplest tool includes a motor and a start button. These are reliable components that often outlive the device itself. Therefore, you should not be afraid of including electronic components in the form of a tuning module and a soft start system.

The wide distribution of products with such devices in the mass sector is hampered by the high price. However, very often they make homemade devices or purchase a ready-made product.