Every welding inverter requires electrical power. But sometimes situations arise when the work area is located far from fixed networks. However, there are no hopeless situations, and one of the ways to solve the problem is a portable generator. It is the most optimal device that provides autonomy to any electrical equipment. However, a gas generator for a welding inverter is not suitable for everyone, since there are certain requirements and technical conditions. The parameters of each unit must correspond to each other; only in this case is their productive collaboration possible.

Is it possible to connect a welding machine to a gas generator?

Welding machines are used in many areas of human activity.

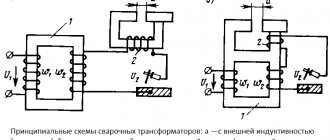

They help solve problems in everyday life in a country house, in small manufacturing enterprises, in auto repair shops, and in large industrial facilities. Welding is especially in demand on construction sites, where until recently heavy transformer welding machines were used. They are large in size, such a unit must be transported by road. Transformer welding is problematic to move around the construction site. Welding process

Structure of the apparatus

The design of the inverter welding machine is much lighter and more compact.

Structure of a large-sized welding transformer

Purpose of transformer welding machine elements:

The inverter apparatus consists of three main small-sized elements:

Design of an inverter welding machine

On the outside of the case and control panel are located:

With the development of modern welding technologies, inverter machines are gradually replacing transformer machines. This topic is well covered by a forum on the Internet, where the advantages and disadvantages of inverter devices are discussed. They are better than transformer welding, have low weight and dimensions, are more functional, easy to operate, and can be easily carried by hand.

An example of transporting an inverter device

Operating principle of the inverter

The alternating current arriving at the input (220 V with a frequency of 50 Hz) is converted into direct current at the input rectifier. Filters, consisting of a set of electrolytic capacitors, additionally smooth out its fluctuations, making the current better and more stable.

Next, the semiconductor modulator again converts the DC voltage into AC voltage, with a higher oscillation frequency of up to 100 kHz. The secondary rectifier makes it constant again, the step-down transformer reduces the voltage to the level of 70 V. The welding current can be regulated by the control board from 10 to 160A, this is quite enough for welding metals.

Electronic board of inverter welding machine

The problem with the operation of inverter-type welding machines is unstable power sources. Questions about emerging malfunctions and how to fix them are well covered on the Internet forum, where experts give practical advice to amateurs and share their experiences with each other. Semiconductor devices, modulator transistors and inverter rectifier diodes become very hot during operation. To reduce the temperature, they are installed on duralumin radiators. At high temperatures and surges in supply voltage, these elements may fail.

Which generator is best for a welding machine?

Problems with the welding inverter if incompatible with the generator

- The source does not turn on (the red indicator lights up)

- Either the power supply or the power board is burning out

Generator malfunctions due to incompatibility with the welding machine

There are several possible malfunctions and incorrect operation of the generator:

- Engine stalls

- The circuit breaker is triggered

- The inverter unit burns out on digital power plants or AVR on traditional ones

Since welding equipment belongs to inductively loaded consumers, therefore, during operation and welding work, starting loads constantly arise that affect the internal combustion engine of the generator and its electrical part.

Any inverter welding machine can operate in a certain extended range of supply voltage. However, when operating from a generator, when the welding arc is ignited, voltage dips occur. This mode of operation, with a constantly changing generator voltage, can negatively affect the welding inverter and can even lead to its failure.

If, when deciding which electric generator to choose for welding, a model without an appropriate power reserve is purchased, then either the engine stops or the electrical protection is triggered.

The inverter digital generator is more applicable for connecting electronics, measuring equipment and ohmic consumers. Inverter power plants are not recommended for working with inductively loaded consumers, such as welding.

Very often, reviews, articles, and videos tell and show the operation of a welding source when connected to a generator at extreme conditions, and surprisingly, the generator works, but with a significant overload. And this is promoted as an idea and an opportunity to save on a purchase without overpaying for an additional reserve of generator power. If this is a one-time and short-term job, then you can agree. For regular and time-intensive work, a power reserve is simply necessary. Service department statistics show that working without a power reserve will soon lead to failure of the AVR.

Selecting a Power Source

Which autonomous power source to choose for an inverter welding machine? When powering an inverter welding machine from an industrial network, there is no need to worry too much about the stability of the power source. But in the field, on construction sites, it is not always possible to connect to power grids. To do this, you need to choose autonomous power supplies. The most common and popular type is a small-sized gasoline generator.

But this raises a number of questions:

The topic of in what cases and which generator to connect to is widely discussed by a forum of specialists on the Internet. It tells you which welding equipment is best to use on construction sites.

Using an inverter with a gas generator

Power calculation

First of all, you need to familiarize yourself with the parameters of the welding machine, they are in the product passport, or you can find them on the Internet. For example, a welding machine produces a maximum current of 160A, it is necessary to calculate what maximum power the welding machine can consume. The formula used is:

P St = Is x Ud efficiency, where

R St = (160 x 25) 0.85 = 4.7 kW or 4700 W.

During the welding process, maximum power mode is never used constantly. Welders operate within an adjustable range of medium to maximum current, depending on the material they are dealing with.

We need to calculate the average power consumption of the welding machine over the period of welding work. The passport indicates such a parameter as PV, this is a temporary adjustment in percentage for the use of maximum power during operation. Typically, PV is 40%; to calculate the average power, you need to multiply the maximum by PV100, you get 4700 x 0.4 = 1.88 kW.

In some passports for inverter devices and generators, power is indicated not in kW (kilowatts), but in kVA (kilovolt-amperes). This difference must be taken into account. Both units measure power consumption, kW - shows active power consumption, kVA - total.

Ideally, when using heating devices as a load, all power is active, the current is converted into heat kVA = kW. But with a different load, with inverter devices, electric motors and other consumers, only part of the power will be active, which will be used to spin up the rotor of the electric motor or heat up the electrode of the welding machine. A reactive component appears, which is spent on heating the wire and semiconductor elements of electrical circuits. As a result, the total expended power will be greater than the active power.

To estimate the ratio of active and reactive power, taking into account the appearance of linear and nonlinear interference in a network with various loads, a power factor (PF) cos-ϕ was introduced. Its optimal value is 1, when the load is a heating element; for KM inverter devices, approximately 0.8 is indicated in the data sheets. To convert kVA to kW, you need to multiply kVA by cos-ϕ (KM); to convert kW to kVA, you need to multiply kWcos-ϕ (KM). In this case:

Best Cheap Generators

To make it easier for you to choose a generator for your welding machine, we will additionally tell you about four high-quality models for your home and garage. This is not a rating, but rather a list of excellent generators that have performed well in a variety of conditions.

Huter DY6500L

The Huter DY6500L generator is an excellent helper in the household. Its power is 5 kW, which is enough to power a low-power inverter delivering up to 150 Amps. This is a synchronous generator running on gasoline fuel. For full operation, it is recommended to use gasoline of a grade not lower than AI-92. This model can also run on propane. Tank with a capacity of 22 liters.

Huter DY6500L is started using a recoil starter. There is a built-in forced cooling system, it is of the air type. The weight of the generator is about 80 kg, which is quite a lot. But two or three people can move it to the right place without any problems.

BRIMA LT 8000 B

We also recommend the LT 8000 B model from the famous German brand BRIMA for inverter welding. Its power is slightly more than that of the previous generator - 6 kW. But this is its rated power. And the maximum is 6.5 kW. However, remember that we do not recommend constantly using the generator beyond its capabilities. The LT 8000 B model is useful for those whose machine produces up to 180 Amps of welding current.

This is also a gasoline generator. Tank capacity - 25 liters. Powered by a reliable 190F engine. It is four-stroke, equipped with forced air cooling. Starting is carried out using built-in electronics. The generator can work without a break for up to 8 hours, then it needs a break to avoid overheating.

Generator types

Manufacturers make generators for various purposes. The best option is to choose an inverter-type gasoline generator, especially for welding machines. Preferably from the same manufacturer as the welding machine.

A gasoline generator using inverters produces a very stable high-frequency voltage and current. This ensures high quality welding and a long service life of the welding machine.

Generators are divided into three types:

Model of industrial inverter gas generator

Professional inverter gas generator

Depending on the tasks performed and operating conditions, it is necessary to select a generator taking into account the following factors:

Small-sized, lightweight, portable, gasoline inverter generators are in great demand among household consumers. The forum of the portal about welding equipment on the Internet reveals questions about which country and manufacturer of generators are better.

Video. Generator welding.

From the above information it is clear that for short-term household work it is enough to take a gasoline inverter generator slightly higher than the calculated average power consumption of the inverter welding machine. By setting the welding current on the panel to medium or slightly higher power, you can carry out high-quality welding work with electrodes up to 3 mm Ø. This will save money on purchasing a generator. In other cases, it is better to choose an industrial or professional inverter gas generator.

When choosing generators of this group, the power is calculated based on the maximum power consumed by the welding machine plus 30–40%.

Only such conditions will ensure high-quality welding and long-term operation of the equipment.

Both in the garage and in the country, welding is always needed from time to time... IMHO.

But the problem was that the generator with built-in welding weighs at least 70 kg. It is very difficult to carry, lift and generally transport alone.

Movik

non-professional builder

The generator was purchased to work with power tools. The idea to use welding came a little later, since there was no great need. They give a lot of theoretical advice, but unfortunately there is no feedback from practitioners.

The generator was purchased to work with power tools. The idea to use welding came a little later, since there was no great need. They give a lot of theoretical advice, but unfortunately there is no feedback from practitioners.

What device, parameters according to the passport?

A gasoline generator is an indispensable technical tool used to automate the operation of electrical appliances and other equipment when there is simply no possibility of power supply from the central power grid. Naturally, the use of a gasoline generator for welding is not limited to electric welding alone - it is possible to connect any electrical appliances in production and construction sites, in suburban areas, etc. Next, we will talk about the key operational features, characteristics and nuances of choosing this equipment.

What power generator is needed for welding with an inverter?

Reading time: 7 minutes

There is nothing impossible for inverter welding in everyday life and in the garage. Need your gate repaired? Weld the gate? Build a greenhouse? Weld reinforcement when building a house? No problem. The inverter will cope with all tasks. It is compact and easy to use; it can be used by both a beginner and an old-school master accustomed to bulky transformer devices.

Naturally, any inverter needs power. To do this, just plug the device into a power outlet using a network cable. Nothing complicated. But what to do if the electricity in your area is turned off or there is no electricity at all? In such situations, you need a generator for the welding inverter. We have previously told you about what a welding generator is and how it differs from a regular generator. Today we will tell you what kind of generator is needed for a welding inverter or how to choose a generator for a welding machine so as not to make a mistake.

Criterias of choice

For many users, it is enough to know that when operating a fuel generator it is possible to generate electrical energy. Professionals distinguish for themselves separate categories of such devices, among which gas generators for welding and their diesel analogues are in the same row. However, it is inappropriate to consider these generators as a separate type of device that generates electricity from a fuel resource.

The principle of operation of a welding gas generator is not much different from conventional household analogues used on the farm. The key essence of its action is that when started, a welding arc is ignited, through the winding of which an electric current flows, sufficient to maintain the arc burning process.

The process of generating current is quite simple. An internal combustion engine is hidden inside the generator. This mechanism involves rotation of the internal crankshaft with the transformation of mechanical energy into electrical energy.

However, the technical simplicity of the process of generating energy for welding is not all that you need to know about such equipment. When choosing a high-quality gas generator for welding, you should rely on more significant criteria.

The most important parameter of the gas generator to which the welding machine will be connected is the maximum level of power generated. It should not be confused with consumption. You should look for this value in the user manual or data sheet.

Naturally, the generated power of the generator should be selected in comparison with the consumption of the existing welding machine. If the latter value is not in the technical documentation, then consumption can be calculated by multiplying the maximum welding current with the arc voltage and dividing this value by the efficiency of the welding inverter.

Important! The output of the generator should have a power value higher than the consumption of the welding machine (by about 30%), which will allow it to work without overload.

It is also worth noting that there are more nuances in the combination “welding unit - generator” than just “buy with a reserve”, and therefore when selecting one device for another, you should have a detailed consultation with a specialist.

Read other articles from our experts:

Advantages and disadvantages of Japanese gas generators, examples of devices and selection criteria, what should you pay attention to?

What to look for when buying Vepr gas generators, what advantages the company’s devices have, as well as examples of models and customer reviews.

Will the generator pull the welding machine?

You can cook using a generator, the main thing is that it is of sufficient quality and suitable power. At the same time, the main thing to understand is this: the generator must be 25% more powerful than the welding machine. This will ensure that the generator will pull the inverter and will not turn off when overloads occur.

If you don’t know what power your welding machine has, it can be easily found using the following formula: the maximum current must be multiplied by the arc voltage. As a result of simple mathematical operations, you can calculate the maximum power of the welding machine.

For this calculation, you only need to know the current strength. All other components are almost the same: the arc voltage of the welding inverter is 25 Volts, and its efficiency is at least 85%. For example, 180A*25V/0.85=5294 W. In this case, the generator power must be at least 5.3 kW. However, taking into account the 25% power reserve, the best option would be a 6.5 kW generator.

Gasoline generators with welding function

Gasoline generators with a welding function are multifunctional devices characterized by their ability to withstand heavy loads. The design of this device is an anchor that rotates due to an external drive.

A welding generator is also a power plant, but with a wider range of loads to bear. It is primarily used to start arc type welding. However, the above-mentioned versatility of such an installation is manifested precisely in the fact that in addition to power for welding, it can also be used to electrify ordinary household objects.

Among the professional areas of operation of such installations, the following stand out:

Portable welding generators are distinguished by their compactness, mobility, optimal weight and relative “silence” during operation. These qualities make it possible to use such installations in field conditions (welding, metal cutting).

Various models of such devices are distinguished by certain physical and technical characteristics and operational features:

Welding generators dominate over simple power plants, since their performance under load is many times higher, and they perform better under instantaneous overload conditions. In general, the functionality of these installations is more flexible compared to simple “household” analogues.

Model examples

Welding generator Eisemann S6401:

Excellent for welding in places located away from the central electrical network. It is characterized by optimal dimensions, operational reliability and unpretentiousness in terms of service. The systems of this installation are perfectly protected from possible failures, which ensures an extremely long and stable operating period even at sites with increased pollution and high labor intensity (construction sites).

Power station Eisemann S6400:

Can work in two formats:

The installation starter is manual. The design and mechanisms are perfectly protected from destructive factors, which implies an extremely long operating period of the station without the need for additional service.

Attention! Among other advantages, the described Eisemann generators are equipped with folding handles, which greatly simplify the transportation process.

Operating rules

When operating a gasoline generator for welding machines, you should strictly adhere to the recommendations from the user manual and advice from professional welders. After purchase, you should carry out a run-through check - approximately the first 20 hours of active use allow the parts to fit together.

It is best not to run the device at a power higher than 50% of the rated documented value at this time. If we are talking about working at heights, then it is worth requiring/selecting a device with a modified carburetor capable of operating in conditions of oxygen-enriched air.

It is also worth familiarizing yourself with the rules for the following operating procedures:

Competent action in any situation, both normal and emergency, will allow you to maintain the functionality of the installation for the entire operational period without the need for unscheduled repairs.

Will the generator pull the welding machine?

Sometimes you have to cook in the absence of electricity and there is nothing you can do about it. Accordingly, there is a need to choose a generator for welding, which is not so easy to do.

First of all, this is a high cost, since special generators for welding are more expensive. However, even if we do not look at this factor, a number of difficult questions still arise.

For example, will a generator be able to power a welding machine? How to correctly calculate the power of a generator for welding? Which brand of generator is best to choose? These are the most pressing questions concerning this moment.

Communities › Do It Yourself › Blog › Tell Spark a gas generator - a welding tool!

Good day everyone! Gentlemen, please tell me how to pair a gasoline generator with a welding tool. You have to cook in the country where there is no electricity. I saw people like that working, but there was a big gas generator there that couldn’t be lifted by one. But I need something smaller, lighter, cheaper, for electrode 2 or 3, not professional, since it will rarely be used. Thank you all in advance for your smart advice!

Comments 79

So you need to go to the store and ask for the spark plug to check on the spot

I was walking here this week, saw men making fences and remembered the topic.

WELDING INVERTER AURORA MINIONE 1600 and Gasoline generator SPECIAL SB-6500E2 I bought the generator from Maxidom about a month and a half ago at a discount and cost 23,000 rubles with electric start. I took the Aurora in the winter for about six thousand, it also seems to be new. I have already welded the fence, I am pleased with the work of both.

Yamaha generator 7.5 kW Tesla inverter 5.6 kW at maximum speed without problems. there should be a reserve on the generator

Is it possible to connect inverter welding to a Scat generator set?

You have a question! Is it possible to connect an inverter welding machine to the generator? Theoretically, why not? If you look in more detail when calculating the load, you should take into account several important points. The inverter welding machine in its design has many capacitors, coils and electronic circuits and for the generator set it is a reactive consumer with a real power factor (COS φ)

0.7. Apparent power is calculated as the active power declared by the manufacturer and indicated in the technical specification, divided by the power factor (COS φ).

For example, let’s select generators for Arco inverter welding machines (link to the page with welding machines) with a maximum welding current of 160A, 180A, 200A.

| Welding machine power | Suitable Generator Model |

| No more than 160 amps | UGB-6000 Basic, UGB-6000, UGB-6000 E, UGB-6000E AUTO, UGB-6000 ET/6 kW |

| No more than 180 amps | UGB-7500, UGB-7500 Basic UGB-7500E, UGB-7500E AUTO |

| No more than 200 amperes | UGD-11500E |

160 A is the welding current, which is only sufficient to work with an electrode with a maximum diameter of 4.0 mm. The maximum active power consumption of such a device is 3.8 kW. Accordingly, the total power of the generating set, taking into account the coefficient of 0.7, will be 5.0-5.5 kW. Considering the recommended stock

180 A – the device will allow you to carry out welding work with an electrode with a diameter of up to 5 mm.

The maximum active power consumption is 4.8 kW. When calculating the total power, we get 7.5 kW. The power of the generating set when connecting such an inverter, taking into account the 20% reserve, should be no less than 8.0-8.5 kW.

200 A - a serious device, powered by a three-phase network and will allow you to cook with an electrode with a diameter of up to 6 mm. The power consumption, taking into account the coefficient, will be 11.5 kW of three-phase current. The generator set for connecting a welding machine with such a current must be three-phase and with a power of at least 15 kW.

What if you buy a 250A welding inverter, but don’t use it at full power? Is it possible in this case to connect it to a generator of lower power? Advice: don't take risks. Only an electromechanical specialist will be able to determine at what welding current and how many watts the machine consumes.

The options for inverter welding machines should be taken into account. Functions such as “anti-stick” and “hot start” will require at least a little additional power for a short time.

Based on the above, we can conclude:

In order to preserve the life of the SKAT ® generator and simply not harm it, take a more serious approach to your choice. Carefully select the energy source for the device. Check all technical parameters, paying attention to indicators such as maximum power consumption and power factor. Be sure to leave a 20% power reserve for the generator.

Without any particular concerns, you can connect a welding machine with a current of 140-160 A to SKAT ® gasoline generators: UGB-6000, UGB-6000 Basic, UGB-6000E, UGB-6000T Basic, UGB-6000ET/ 6 kW, UGB-6000E/AUTO , UGB-7000, UGB-7000 Basic, UGB-7000E, UGB-7000E/AUTO, UGB-7500E, UGB-8500E, UGB-8500ET, UGB-11500E, UGB-10000ET ,

for diesel generators SKAT ® UGD-6000E, UGD-6000ET, UGD-6000EK, UGD-10000E, UGD-10000ET

Is it possible to connect welding transformers to generators?

There are three types of welders: transformers, semi-automatic machines and inverters.

You cannot connect a transformer to a brush generator - it will not withstand the load. A welder is a very powerful inductive consumer. A 130 A transformer (3 mm electrode) consumes about 7 kW at nominal value, and twice as much when igniting the arc. There is a high risk of burning the generator winding and being left without a generator and warranty repairs.

Inverter welding machines with a power of 160–200 A when welding with an electrode of 3–4 mm at a welding current of 120 amperes can be connected to gasoline generators UGB-5000, UGB-6000 or diesel generators UGD-6000E or UGD-6000EK.

Source

Types of gasoline generators and their characteristics

Manufacturers present to your attention a huge number of gasoline generators for household use; they are equipped with both two-stroke and four-stroke internal combustion engines. The two-stroke version is slightly cheaper, but such engines need to be filled with gasoline with added oil. Four-stroke engines are more durable, stable in operation and are fueled with pure gasoline. The capacity of the gas tank, as a rule, allows uninterrupted operation from 8 to 12 hours.

It is important to know that at peak loads the inverter can consume a current of 20 A or more, so the generator must be equipped with a power outlet and an automatic fuse designed for this current.

To organize electrical power supply for a welding inverter from a gas generator, you need to know the parameters of the generated current and voltage. We will look at them using the example of the Daewoo GDA 3500 power plant, namely:

- a gas generator using a four-stroke engine produces a voltage of 220 V to two sockets with a maximum current of 14.54 A;

- rated power 2.8 kW, maximum 3.2 kW and total power 4 kVA;

- engine power 7.5 hp, AI-92 gasoline, tank capacity 18 liters, which allows the gas generator to operate from 12 to 18 hours depending on the load.

All generators in this price group produce about 4-5 kVA and allow welding work with electrodes with a diameter of 1.6 mm to 3 mm. If it is necessary to carry out work with large-diameter electrodes, stations with higher parameters are needed. This greatly increases their cost, but also significantly expands the welding capabilities. It is also worth noting that the weight of a gas generator increases with increasing power, which affects its mobility.