The high popularity of such a material as stainless steel is explained by its unique characteristics that ordinary carbon steel alloys do not possess. Thanks to the wide variety of stainless steel grades available on the modern market, they can be selected to successfully solve various technological problems.

The appearance of stainless steel structures does not change throughout their entire service life

What is unique about stainless steels?

Stainless steel was patented in England in 1913. The author of this invention, which, without exaggeration, became the most important stage in the development of not only steel, but also other industries, is metallurgist Harry Brearley.

The addition of an element such as chromium to their chemical composition made it possible to endow ordinary steel alloys with unique characteristics and obtain corrosion-resistant steels from them.

It is chromium, which must be at least 10.5% in stainless steel alloys, that provides these materials with such characteristics as:

- exceptionally high corrosion resistance;

- very high strength;

- good weldability;

- ease of processing using cold deformation methods;

- long service life without loss of original characteristics;

- aesthetically attractive appearance of products made from alloys of this category.

Influence of alloying elements on the properties of steels

Stainless steels necessarily contain chromium and iron in their chemical composition. These elements complement each other, which is what gives these materials such unique characteristics. In particular, chromium, combining with oxygen, creates an oxide film on the surface of the stainless alloy, which becomes a reliable obstacle to corrosion processes.

In order to provide stainless steel with additional characteristics and significantly improve existing properties, alloying additives are introduced into its chemical composition - nickel, titanium, molybdenum, niobium, cobalt, etc. This alloying makes it possible to create various types of stainless steel alloys that differ from each other their characteristics and, accordingly, purpose.

We are already so accustomed to corrosion-resistant steel that we don’t even notice how much more comfortable our lives have become due to the presence of stainless steel in it.

Stainless steel contains carbon in its chemical composition, which gives it high hardness and strength. It should be noted that this chemical element is an essential component of any steel alloy and has a serious impact on its properties.

The unique characteristics of stainless steel make it possible to successfully use this metal in a variety of areas related to the operation of products and equipment in conditions of high humidity and constant exposure to aggressive environments. Stainless steels are actively used for the production of products for both industrial and household purposes. In particular, it is from this metal that cutlery and knives are most often made, elements of communications and enclosing structures, equipment parts, etc.

Physical properties

Stainless steel has gained high popularity not only due to its anti-corrosion properties, but also due to its variety of physical properties. Modern corrosion-resistant steels are produced by adding various impurities to the steel.

The physical properties of the finished steel depend on the amount and type of impurity. It should be noted that some grades of stainless steel are susceptible to corrosion after a long period of use. This is due to the composition, that is, the addition of this or that metal. Such an alloy has other advantages that eliminate susceptibility to oxidation.

It is necessary to highlight the main physical properties of stainless steel, which qualitatively distinguish it from a number of other metals. These properties include:

- High strength. Products made from stainless steel are characterized by increased strength in comparison with analogues. Due to its resistance to physical stress, the products are not damaged and do not lose their original shape. High-quality steel remains reliable for more than ten years.

- Resistance to aggressive external environment. Such steel is practically not subject to changes due to environmental conditions. This allows you to maintain the performance properties of the product for a long time.

- Heat resistance. Stainless steel products are resistant to high temperatures, even when exposed to open fire. Also without changing shape, size and properties under significant temperature changes.

- Environmental friendliness. Anti-corrosion properties prevent the oxidation process. In addition, the material does not contain harmful components, therefore it is widely used in the food industry.

- Anti-corrosion properties. The main property that such steel has is that it prevents rust. Moreover, the alloy does not corrode even after exposure to acids or alkalis.

- Appearance. The appearance of stainless steel products is qualitatively different from items made of other materials. Steel has a clean, shiny appearance that does not change after a long period of use.

- Compliance. Such an alloy is easy to process, and making an object of the desired shape from it is not difficult.

The choice of stainless steel with certain physical properties depends on the purpose of its use. Today, a variety of components for the production of stainless steel allows you to create a material with the necessary characteristics.

Classification methods

The characteristics of stainless steels are determined both by the chemical composition of the alloys and by the characteristics of their internal structure. Depending on these parameters, all steels classified as stainless steel are divided into four groups.

Ferritic (chromium)

The chemical composition of steels of this group contains chromium in a volume of 20% (which is why they are called chromium). Due to the significant chromium content, products made from such steels are able to successfully withstand even very aggressive environments. Steel alloys of this group have good magnetic characteristics.

Chemical composition and mechanical properties of ferritic steels

Large consumers of ferritic steels are enterprises of the heavy and chemical industries; elements of heating equipment are produced from stainless alloys of this type, as well as much more. Alloys of the ferritic group occupy a fairly large share of the stainless steel market and, in terms of their level of demand, are only slightly inferior to materials with an austenitic internal structure, but are much cheaper than the latter.

Austenitic

These are stainless steels, a significant proportion of the chemical composition of which (up to 33%) is chromium and nickel. Consumers prefer these alloys due to the fact that such materials are characterized by high strength and exceptional corrosion resistance.

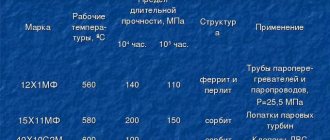

Chemical composition and areas of application of heat-resistant austenitic stainless steels (click to enlarge)

Martensitic and ferritic-martensitic

Due to the peculiarities of the internal structure, such alloys are distinguished by the highest strength among steels. In addition, they are characterized by good wear resistance and a minimal amount of harmful impurities in their composition. It is this category that includes heat-resistant, corrosion-resistant steel, which can not only successfully withstand oxidative processes, but also be operated under conditions of constant exposure to high temperatures, without losing its original properties.

Content of chemical elements in martensitic and ferritic-martensitic steels (click to enlarge)

Combined

This includes steels with a combined internal structure: austenitic-ferritic and austenitic-martensitic. Such innovative materials optimally combine the best properties of all the above types of stainless steels.

Chemical compositions of corrosion-resistant steels of the austenitic-martensitic class

Possession of information about which group a particular grade of stainless steel belongs to allows you to optimally select alloys for solving certain technological problems.

Chemical composition

The chemical composition of stainless steel depends on the type and grade of the alloy. The main features that characterize stainless steel are the presence of at least 10.5% chromium and low carbon content. Carbon is very important in steel making as it gives the required strength. The percentage component of which in the anti-corrosion alloy should not exceed 1.2%.

Stainless steel may also contain Titanium, Phosphorus, Molybdenum, Sulfur, Nickel and Niobium. Depending on the chemical composition, stainless steel is divided into several types.

The most widely used is stainless steel of group A2. Group A2 contains 10% nickel, 18% chromium and 0.05% carbon. Most of it is occupied by the base, namely iron with accompanying components.

The composition of steels in this group includes 0.05% carbon, 2% molybdenum, 12% nickel and 17% chromium. Due to the presence of molybdenum in the composition, the alloy is resistant to acid, so the name “acid-resistant” is often applied to it.

Anti-corrosion steels of group A, due to their chemical composition, are easy to weld. That is why this type is widely used in industry. From such steel it is possible to produce parts of almost any shape, with a strong connection of the component parts.

Particular attention in production is paid to steel for the food industry. In this case, corrosion-resistant steel should not contain foreign components that can negatively affect the taste of products, as well as impurities hazardous to human health.

The resistance of steel to corrosion depends on the amount of chromium. The larger its component, the more stable the alloy. Classic stainless steel used under normal conditions contains no more than 13% chromium. To withstand an aggressive environment, the proportion of chromium must exceed 17%. This corrosion-resistant alloy is suitable for use in acidic environments.

Highly resistant alloys retain their properties even in nitric acid of 50% saturation. For resistance against stronger acids, the percentage of nickel in the composition is increased and other components are added in small quantities.

The most popular brands and areas of their application

To choose the right stainless steel for the manufacture of products for a specific purpose, you can use special reference books that list both all grades of such material and their main characteristics. Meanwhile, in each of these groups there are the most popular brands, which are most often chosen by the consumer. Let's list them.

- 10Х17Н13М2Т and 10Х17Н13М3Т are steels that are characterized by good weldability and excellent corrosion resistance. Thanks to these properties, stainless steel alloys of these grades are successfully used for the production of products that, during their operation, are constantly exposed to high temperatures and aggressive environments. The properties of steels of these grades are formed due to the presence in their chemical composition of the following elements: chromium (16–18%), molybdenum (2–3%), nickel (12–14%), carbon (0.1%), silicon (0 .8%), copper (0.3%), sulfur (0.02%), phosphorus (0.035%), manganese (2%), titanium (0.7%). If there is a need to select stainless steels of these grades, then you should keep in mind that their foreign analogues can also be purchased on the domestic market, namely: SUS316Ti (Japan), 316Ti (USA), OCr18Ni12Mo2Ti (China), Z6CNDN17-12 (France) ).

- 08Х18Н9 and 08Х18Н10 are stainless steel alloys from which pipes of both round and any other cross-section are made. These materials are used for the production of various structures used in the mechanical engineering and chemical industries, as well as for the production of pipeline elements and furnace devices. The chemical composition of these grades of steel contains the following elements: chromium (17–19%), carbon (0.8%), titanium (0.5%), nickel (8–10%).

- 10Х23Н18 - steel of this grade is characterized by a high content of nickel (17–20%) and chromium (22–25%), as well as manganese (2%) and silicon (1%) in its composition. This combination of elements gives the alloy the required characteristics and creates an increased tendency to temper brittleness. It should be noted that the alloy of this grade belongs to stainless steels of the heat-resistant category.

- 08Х18Н10Т - a stainless alloy of this brand is characterized by high resistance to oxidation processes, as well as good weldability, and to obtain a high-quality connection using this technology, the products do not need to be preheated, and they also do not require heat treatment after welding. To improve the strength characteristics of products made from such steel, they must be hardened, as specified in the relevant regulatory document.

- 06ХН28МДТ - an alloy of this grade is optimally suited for creating welded structures that will subsequently be used in aggressive environments. The chemical composition of this steel contains the following elements: chromium (22–25%), nickel (26–29%), copper (2.5–3.5%).

- 12Х18Н10Т – products made from steel of this grade are mainly used to equip enterprises in the chemical, pulp and paper, construction, food and fuel industries. This metal is characterized by thermal resistance, good impact strength and practicality of use.

- 12Х13, 20Х13, 30Х13 and 40Х13 – stainless steel alloys of these grades are practically impossible to weld, but they also have positive properties. The latter lies in the fact that these steels do not have a tendency to temper brittleness, and their internal structure is not affected by defects, which in professional language are called flakes. Cutting and measuring tools, as well as springs and springs for various purposes are made from these grades of stainless steel.

- 08Х13, 08Х17, 08Х18Т1 are stainless steel alloys of the ferritic group, from which products are produced that do not experience shock loads during operation, as well as exposure to low temperatures.

Types of stainless steel surfaces

Application of stainless steel

Initially, stainless steel became widely used in architectural construction, as well as in the design of houses and furniture. Stainless steel was used in the construction of large famous shopping centers - La Defense (Paris), Canary Wharf (London), Sony Center (Berlin) and Petronas Towers (Kuala Lumpur).

Today, stainless steel is increasingly used for the construction of elements such as facades, advertising installations, shop windows, sculptures, fountains and many outdoor structures, because steel does not corrode in air and is not afraid of high humidity.

Due to its good heat-resistant properties, stainless steel is used in the manufacture of bathhouses, saunas, bathrooms, and swimming pools. One of the main advantages of choosing this steel was its high hygienic properties.

Stainless steel is often used in interior design, in the construction of railings, window frames, doors, stairs and elevators.

Since stainless steel goes well with natural stone, wood and glass, for designers it is an excellent material to aesthetically decorate any place or room.

The use of stainless steel has a wide range of applications in many areas of production:

- Architecture and construction;

- Food industry;

- Electric power industry;

- Transport engineering, shipbuilding, aircraft manufacturing;

- Construction of spacecraft;

- Pulp and paper production;

- Chemical and oil refining industry;

- Environmental protection.

How to decipher the markings

Marking of stainless steels, the rules for the formation of which are stipulated by the provisions of regulatory documents, carries the following information:

- the number in first place indicates the quantitative content of such a chemical element as carbon in the alloy composition (for example, in steel grade 08Х17 carbon is contained in an amount of 0.08%, and in 40Х13 - 0.4%);

- after the letters in the marking, each of which indicates the corresponding chemical element (X - chromium, H - nickel, M - manganese), numbers are placed indicating its content in whole percentages.

An example of decoding the designation of stainless steel

In general, if we talk about the rules for marking steel alloys classified as stainless, they are practically no different from those adopted for marking steels of any other type.

Features and Specifications

Before answering the question, it is advisable to understand why this metal is so popular. It's all about its properties and features:

- Resistance to environmental influences, including aggressive ones.

- Good wear resistance. With active use, the products last for more than ten years.

- Lack of response to sudden changes in ambient temperature.

- Lack of predisposition to the appearance and spread of corrosion.

- Not dangerous for people, animals, plants.

- Easy to care for and visually attractive.

Stainless steel AISI 304

A little about the designation. The basis is the classification of the American Institute of Steel and Alloys (which, in fact, in English looks like the American Iron and Steel Institute, AISI), which appeared in the 30s of the last century, due to the need to streamline the technical terminology of the metallurgical industry. Specifically, analyzing the designation of brands according to the AISI classification can tell us little. For the AISI 304 alloy, the first digit “3” indicates that it belongs to the austenitic class, and the subsequent “0” and “4” simply inform about the serial number of the steel in the entire group of austenitic class stainless steel. In a word, melancholy.

If we consider the domestic analogue of the AISI 304 brand, which according to GOST 5632-72 is 08Х18Н10, then deciphering the stainless steel grade will become a much more exciting activity. At its core, the decoding of GOST stainless steel grades is much more informative for us than the AISI classification. Briefly about what this set of letters and numbers is - 08Х18Н10. This is not “zero eight x eighteen ah ten” and not “zero eight x eighteen ah ten”, but I have heard such things from time to time. This is “zero eight ha eighteen en ten.” The marking designation according to the Russian standard uses only numbers and letters of the Russian alphabet, alternating one after another. All stainless steels are called alloyed, and the markings indicate exactly the main alloying components, but we will tell you what this word means a little later. Now let’s see how the marking and decoding of corrosion-resistant steels looks in more detail.

certificate for stainless steel AISI 304 (08Х18Н10)

This is interesting: HSS steels - features, grades, designations, explanation

How to identify food grade stainless steel at home

Analyzers and spectrometers are used to determine the chemical composition of steel. This is sophisticated equipment for professional use.

In order to determine whether metal can be used for storing and transporting food products at home, you can use “folk” methods:

- Using vinegar. To do this, you will have to stock up on a metal sample in advance, place it in 2% vinegar and wait for the reaction. If the surface has not darkened within a few hours, most likely the steel is actually food grade.

- By placing it in a work environment. A fragment of metal is placed in a liquid for storage or transportation of which steel or a product made from it is purchased. After a few hours, the results are assessed.

- Using sandpaper and copper sulfate. This method is suitable for those who are not sure about the metal from which stainless kitchen utensils are made. You should rub the pan with an abrasive material, then apply a solution of copper sulfate to the treated surface. If a red film appears, the steel is not suitable for contact with food.

This is interesting: What is cold welding for metal? Its features, pros and cons

There is a misconception among ordinary people that stainless steel can be determined by a magnet. Unfortunately, this method does not guarantee the correct choice, since among the stainless steels used for the manufacture of equipment for the food industry, there are steels that are magnetic and those that are not.

Magnetic method

Using a magnet, you can determine the structure of the alloy, accordingly its series and purpose.

It is natural for stainless steel to have a dual state regarding magnetism. It can be completely absent, insignificant, or manifest itself fully. The structure, i.e., the arrangement of atoms in the crystal lattice, is responsible for this.

Martensitic-ferritic steels (400 series) have full magnetic properties. While grades with an austenitic structure (300 and 200 series) are completely inert in this regard, and only when martensite or ferrite is separated, weak signs appear.

If stainless steel is magnetic, then it is not intended for heat treatment, long-term storage of products, or use at low temperatures (below -40 ºС). In case of complete inertia or very weak signs appear, you can safely use the dishes for all purposes.

Chemical method

Using copper sulfate. When copper sulfate interacts with the surface, you need to pay attention to the formation of a reddish coating: the more saturated it is, the lower the quality of the stainless steel. These are copper molecules released by the interaction of Fe and SO4. Formed on feritic-martensitic steels (weakly rusting) with low chromium content (up to 17%).

In the presence of nickel and other elements, such a reaction either does not occur or occurs only slightly.

Adhering to the most basic rules, it is not difficult to understand the purpose of stainless steel. Moreover, domestic and European manufacturers very accurately fulfill the purpose of the standards.

Spark test

Testing metal for spark color is a common method of sorting scrap metal, which is used even by specialists. The grade of stainless steel can be determined by the following factors:

- the number of sparks and flashes, which is directly proportional to the volume of carbon in the alloy;

- the color of the sparks, which indicates the composition of the metal (the lighter it is, the higher the likelihood that this is low-carbon steel);

- the presence of shiny white sparks, which indicates a high titanium content in the composition.

To carry out the test, an angle grinder (grinder) is required. Start grinding the surface of the steel and observe the reaction. The color, length and shape of the sparks will help you accurately determine metal or stainless steel.

Why do you need to know the decoding of steel grades?

Anyone whose work is related to metals has had to deal with the concept of “steel grade”. Decoding the markings allows you to find out the chemical composition and physical properties of the alloy. Although at first glance the marking may seem quite complex, it is easy to understand. To do this, you need to understand the principle of its composition.

For such a brief description of the alloy, letters and numbers are used to indicate the chemical elements and their quantities. This means that for competent work with steels, it is important to know the abbreviations themselves and how each element changes the properties of the finished alloy. Then it will be possible to determine with utmost precision what technical characteristics a certain grade of steel has.

Having received an order for a product, designers develop a design and also select the most suitable steel grades for a particular case, based on decoding their properties. The device being created must function under certain conditions, so it is examined during movement - this is how it is possible to understand which parts will experience increased loads.

To establish requirements for the strength of elements, calculations are made. At the next stage, the metal is selected in accordance with steel grades according to GOST, which can withstand repeated loading and friction. The greater the load the product experiences, the more limited the designer is in choosing the material. Next, a prototype of the device is made from the selected metal and tested in accordance with the methods used in a particular area. At this stage, the steel grade can be changed. Let us note that most often steel is used for the manufacture of machines, devices and complex mechanisms.

Recommended reading

- Cutting copper with a laser: advantages and disadvantages of technology

- Types of metal cutting: industrial applications

- Metalworking according to drawings: convenient and profitable

Regardless of the specific area, working with metals requires an understanding of their grades, purposes and other characteristics displayed in the index. Thanks to the numbers and letters used in the code, it is possible to quickly understand the characteristics of the metal without requiring additional clarification. This article outlines the fundamental principle of classification, as well as a simple way to read the markings of the steels most common in production.

This is interesting: Heat-resistant steels: composition and grades of heat-resistant alloys