Characteristics

The most characteristic properties of a material appear depending on the percentage of carbon content. Alloys with a relatively small proportion of carbon (0.6-0.7%) have a troostite structure, alloys with a high proportion (1% and above) have a martensitic structure.

Secondary properties (for example, a tendency to increased brittleness with temperature changes) appear with increasing concentration of some additional elements in the alloy and are the same for the entire line of tool steels.

pros

- low cost;

- good resistance to plastic deformation;

- lack of brittleness upon cooling after annealing;

- optimal viscosity and hardness for the rapid production of many tools.

Minuses

- The U7 alloy has low wear and heat resistance: when the finished tool is heated to a temperature above 200 °C, the hardness of the material is lost;

- Due to the large grain, the strength is slightly lower than that of fast-cutting types.

U8 – classic knife steel

Grade U8 is classified as eutectoid steel. That is, the presence of pure carbon is equal to that found in perlite cementite. This means that the steel contains no secondary carbides. This led to the emergence of a number of subtleties that arise when working with U8 steel and its analogues.

For example, in the composition of U8, their absence guarantees the presence of a homogeneous structure; steels of this type are well processed by forging welding. That is why these alloys are included in Damascus steels. But it is also necessary to remember that the absence of carbides complicates the heat treatment process. In particular, a change in the optimal hardening temperature by several degrees leads to a decrease in mechanical properties, namely strength and toughness.

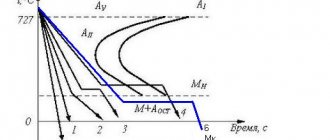

Preliminary heat treatment is also important. Its task is to optimize the structure immediately before hardening. It should be noted that steel grade U8 and its analogues have low hardenability and, as a result, are very sensitive to the length of the cooling delay time.

In 1997, GOST R 51015-97 was developed and put into effect in our country. He divides all knives into two large groups:

The first group includes products that are used to work with bread and vegetables. The second group includes knives intended for processing meat. This group also includes products intended for tourists, etc.

The same document defines the material from which knife products are made - this is U8A or U10A. Index “A” means that these are steels of improved quality; they have a reduced content of phosphorus and sulfur. Rods and strips made of U8A steel are used as workpieces.

GOST specifies that the surface hardness should be at the level of 49 HRC, but at the same time, the production of knives with a surface hardness of 41.5 HRC is also allowed.

Steel group U8 allows you to maintain the parameters defined in GOST R 51015-97.

Undoubtedly, in addition to the described material, the use of other steel alloys, for example, 40X13 or 65X13, is also permissible. The use of these alloys makes it possible to obtain knives with high strength and corrosion resistance. But the use of steels of this kind makes it possible to obtain products that have high strength and resistance to dullness, of course, when using knives for their intended purpose. But with a sharp impact, it is possible to get chips or cracks on the body of the blade. The presence of a large number of alloying elements can lead to increased fragility of the blade.

Read also: Melting furnaces for metal

Knives made from the U8 family have virtually no alloying components; GOST specifies that the presence of chromium should not exceed 0.2%, nickel and copper should not exceed 0.25%

pros

The advantages of steel grade U8, which is defined by GOST R 51015-97 as the main one for the production of utility and household knives, include the following - after heat treatment, it acquires sufficient strength and surface hardness sufficient to ensure the sharpness of the knife for a long service life. The blade tip can be refilled relatively easily, that is, ordinary abrasive stones can be used for this. Such a knife is difficult to break upon impact.

Minuses

But the undoubted disadvantage is low resistance to corrosion. In other words, knives made from U8 require constant care. That is, after work, the blade must be wiped dry, or it is better to apply a layer of a protective agent, for example, some kind of oil.

98 Forging temperature, °C: beginning 1180, end 800. Sections up to 100 mm are cooled in air, 101-300 mm in a pit. Quenching 780-800 °C, water Interpretation of steel grade U8A: the letter U indicates that this is unalloyed tool steel, and the letter A indicates that this is high-quality steel, which contains carbon in an amount of 0.8%. Tools made of U8A steel and its heat treatment: circular saws are made from steels 85ХФ, 65Х, У8А, ШХ6. All woodworking tools produced by forging or stamping are annealed before machining. To heat the saws, they are loaded into an oven at the required temperature. After heating, they are quenched in oil in a vertical position. When the saw has cooled to approximately 300-400°, it is removed and clamped between two hardening plates until final cooling. Thin saw blades can be hardened between hollow, well-cooled hardening plates. To release the saws, they are compressed with clamps and in this position placed in an oven heated to a temperature of 450-500° and kept for 1.5-3 hours. To better straighten the saw during vacation, tighten the bolts of the clamp by removing it from the oven for a short time. Required hardness Rc = 40-42. For the manufacture of collet chucks, according to GOST instructions, U8A steel is also used. In addition to this steel, factories also use U7A, U10A, 65G, 4ХС, 9ХС steels and, in some cases, low-carbon steel with subsequent carburization. The hardness of the working (clamping) part of the collet chuck is Rc = 58-62, and the spring part (shank) is Rc = 40-45. In cemented collets, the hardness can be increased accordingly by 2-3 units. In collet chucks made of carbon steel, the specified combination of hardness is achieved by hardening the working part in water, followed by cooling the entire chuck in oil. The exposure in water for a collet with an internal diameter of 5-8 mm is 2-3 seconds. Alloy steel collet chucks are completely hardened in oil, and then the spring part is tempered in a salt or lead bath to the required hardness. After this, the collet chucks undergo a general tempering in an oil or nitrate bath at a temperature of 200-300°, depending on the technical conditions specified in the drawing. For the convenience of subsequent grinding and to avoid warping of the hole, the cut in the collet is not made completely, but a bridge is left with a thickness of at least 2-3 mm and without sharp corners. If the jumper cracks during hardening, then after tempering the crack should be welded by electric welding and then cleaned. After final grinding, the bridges are cut and the collets are set or compressed in appropriate fixtures.

Read also: The unit of equipment repair complexity is

97 Forging temperature, °C: beginning 1180, end 800. Sections up to 100 mm are cooled in air, 101-300 mm in a pit. Quenching 770-800 °C, water Section up to 10-12 mm. Quenching 800 °C, oil or molten salts at 190 °C. Tempering 160-200 °C Section up to 8 mm. Quenching 800 °C, oil or molten salts at 190 °C. Tempering 380-480 °C * Section up to 60 mm. Quenching 770 °C, water or 5-10% NaCl solution. Vacation 170 °C. Springs. Isothermal hardening at 800 °C in molten salts and water. Ichotherm temperature is 280-360 °C. Tempering 280-360 °C Surface hardening with induction heating. Vacation 160-200 °C

97 Forging temperature, °C: beginning 1180, end 800. Sections up to 100 mm are cooled in air, 101-300 mm in a pit. Quenching 770-800 °C, water Section up to 10-12 mm. Quenching 800 °C, oil or molten salts at 190 °C. Tempering 160-200 °C Section up to 8 mm. Quenching 800 °C, oil or molten salts at 190 °C. Tempering 380-480 °C * Section up to 60 mm. Quenching 770 °C, water or 5-10% NaCl solution. Vacation 170 °C. Springs. Isothermal hardening at 800 °C in molten salts and water. Ichotherm temperature is 280-360 °C. Tempering 280-360 °C Surface hardening with induction heating. Tempering 160-200 °C Interpretation of steel grade U10A: the letter U indicates that this is an unalloyed tool steel, in which carbon is present in an amount of 1%, and the letter A at the end of the designation indicates that this is a high-quality steel with a minimum of harmful impurities. Tools made of U7 steel and its heat treatment: drills made of U10A carbon steel are cooled in water to a temperature of 150-200° and then transferred to oil. Carbon steel drills with a diameter of up to 8-10 mm are hardened in oil. Release in an oil bath at a temperature of 150-180° for 1.5-2 hours. The hardness of the working part of drills made of alloy and carbon steel with a diameter of up to 10 mm is Rc = 59-63, over 10 mm Rc = 61-64. The legs of the cones in the shanks must be hardened to a hardness of Rc = 30-45. High-carbon steel U10A, U12A is used for the manufacture of simple, small-sized gauges for measuring instruments. Round dies (dies) for thread cutting are made from carbon steels U10A and U12A and from alloy steels 9ХС, ШХ15, ХВГ. The best way to heat dies for hardening is heating in a salt bath with preheating by repeated immersion in the same bath. Heating can also be done in a chamber oven. The holding time at the hardening temperature in all these cases should be minimal. When heated in a chamber furnace, the cutting part is sprinkled with cast iron shavings or coal with soda to protect against decarburization and oxidation, and when heated in a salt bath, the thread is covered with green soap or thick foam made from laundry soap. Alloy steel dies are cooled in hot oil at a temperature of 150-200°. Carbon steel dies with a diameter of less than 6 mm are cooled in oil, and those larger than 6 mm in water (until darkening) with transfer to the oil. Cooling of small dies in oil is carried out by rolling them off a baking sheet on which they are heated in a chamber oven, or by dropping them from a device when heated in baths. Tempering of dies is carried out in an oil bath and electric furnaces PN31, N15 or in laboratory-type furnaces. Tempering temperature: for dies made of 9ХС steel – from 200 to 240°, and for dies made of other steel grades – from 180 to 220°. The holding time during tempering is 3-4 hours. Hardness control is carried out using an RV device. Required hardness Rc = 58-62. The hardness of the jumpers opposite the slot, according to GOST 1679-42, should be within the range Rc = 30-45. Tempering of jumpers is carried out by heating them in a lead bath or on a low-power spot welding machine. However, observation of the operation of dies with unreleased jumpers has established that cases of breakage of dies in these places are very rare. Significantly more scrap is obtained from a decrease in the hardness of the cutting edges when tempering jumpers in small dies. The heating time for round dies made of carbon and alloy steel for hardening is shown in the table below.

Read also: How to connect an electric motor from an Indesit washing machine

Brand: U11A hand taps, rasps, needle files, saws for woodworking, dies for cold stamping, axes, gauges of simple shape and lower accuracy classes C 1.06 – 1.13 Chemical composition diagram of steel U11A Si 0.17 – 0.33 Mn 0.17 – 0.28 Ni up to 0.2 S up to 0.018 P up to 0.025 Cr up to 0.2 Cu up to 0.2 Fe

U8 steel is a carbon tool steel produced in accordance with GOST 1435-99 and 1435-54. It contains carbon (from 0.76 to 0.83%), silicon (from 0.17 to 0.33%), manganese (from 0.17 to 0.33%), nickel (no more than 0.25 %), sulfur (up to 0.028%), phosphorus (no more than 0.03%), chromium (up to 0.2%), copper (up to 0.25%). Analogues of steel u8 in terms of main characteristics are steel grades u7 and u10.

U8 grade steel is used for the manufacture of various tools, during operation of which there is no heating, for example, milling cutters, punches, screwdrivers, side cutters, knurling rollers, flat and coiled springs, combination pliers, parts of watch mechanisms, various plumbing and woodworking tools and etc.

In the marking of carbon tool steel, the letter “y” is always in the first place, meaning that this steel is classified as carbon. In second place is a number showing the amount of carbon, expressed in tenths of a percent. For example, steels y7, y8, y10 will contain 0.7%, 0.8% and 1% carbon, respectively. Since U8 steel does not have the letter “A” at the end of the marking, it is classified as high-quality.

Intermittent hardening is suitable for U8 steel. To implement this, the heated part is placed in water for cooling, and then transferred to oil, where it is finally cooled. By reducing the cooling rate in the region of martensitic transformation, it is possible to reduce structural stresses. U8 steel is hardened at 780 °C, and tempered at a temperature of 400 °C. This produces a material with a hardness of 187 MPa.

U8 steel is produced in the form of forged strips, hot-rolled circles, forged squares, forged circles, sheets, etc. The demand for this grade of steel is explained by its fairly low price combined with the high hardness of the surface layer of the alloy. However, the wear resistance of U8 steel is low. Due to low hardenability (heat resistance), it is not recommended to use steel8 to create tools with a cross-section of more than 20-25 mm, as well as parts of equipment and machines that operate continuously and heat up to temperatures above 200°C. It is logical that weldability with such characteristics will also be extremely low, therefore U8 steel is not intended for creating welded structures.

The positive characteristics of U8 steel also include extremely low flake sensitivity (internal cracks do not form during processing) and easy machinability when heated.

offers a wide range of u8 steel, produced in the form of circles, strips, sheets, tapes, etc. For any questions you may have, you can consult with our online consultants.

Decoding

The name of any steel grade briefly describes its composition, including the amount of foreign impurities. So, for U7A steel:

- the letter “U” indicates that this is carbon (high-strength and non-alloyed) steel;

- number 7 is the carbon percentage coefficient, in this case amounting to 0.7%;

- the letter “A” marks the material as high-quality, with an impurity content (sulfur and phosphorus) of no more than 0.025%.

Knife made of U7 steel.

More rare markings “AA” or “AA” will indicate a particularly pure alloy - up to 0.015% impurities. The permissible amount of impurities in a material without such markings (for example, U7) is 0.035%.

Varieties of non-alloy tool steels with a high manganese content can be additionally marked with the letter G - for example, U8GA.

Steel U7 – steel for an ax

This alloy is often called the best steel for an axe. It received this definition for its excellent combination of hardness and specific gravity: HB 10-1 = 187 MPa with a weight of 7830 kg/m3. As a result, steel grades U7 and U7A are widely in demand in the manufacture of working parts for a wide variety of metalwork tools: axe, cleaver, chisel, hammer, sledgehammer, chisel, chisels, strikers, crimpers, etc. The same alloy is often used to produce wire cutters, pliers and needle nose pliers. In short, grade 7U alloy can be used as the main material for the working surface of a tool that does not heat up during operation.

This unalloyed steel is supplied to the workshops of industrial enterprises in the form of various shaped long products:

- calibrated rods (GOSTs 8559-75, 7417-75, 8560-78, 1435-99)

- silver and polished rods (GOSTs 14955-77, 1435-99)

- tapes (GOST 2283-79)

- stripes (GOST 4405-75, 103-2006)

- forgings (GOST 1133-71, 4405-75, 1435-99)

Chemical composition

Approximate percentage of components for U7 steel:

| C | Mn | P | S | Si | Cr | Ni | Cu | Fe |

| 0,65-0,74 | 0,17-0,33 | 0,17-033 | remainder |

U7A steel contains slightly less impurities:

| C | Mn | P | S | Si | Cr | Ni | Cu | Fe |

| 0,65-0,74 | 0,17-0,28 | 0,17-033 | remainder |

Physical properties

U7/U7A steel is not subject to temper brittleness and is not prone to flocking. Not used for welding. Has good sandability.

Forging of ingots is carried out at a temperature of 1150 °C with a subsequent decrease to 800 °C.

Forging steel.

Some physical properties directly depend on the amount of impurities in the material. For example:

- excess sulfur increases the fragility of the material when hot (red brittleness);

- excess phosphorus – brittleness at low temperatures (cold brittleness);

- the presence of manganese in the alloy has a positive effect on ductility, but its excess also leads to brittleness and cracking.