Connecting pipes using soldering

Let's consider connecting copper tubes with fittings followed by soldering, which can be low- and high-temperature.

In the first method, soldering is carried out at a temperature of 300 ºC. The second method is used when installing systems with high loads for industrial purposes. Couplings are used as connectors for copper pipes; tin-lead solder and flux are additionally needed.

The pipe soldering technology will be as follows:

- First of all, a pipe of a certain size is cut. This process must be carried out carefully, taking into account the size of the existing fittings.

- The ends of the pipes must be inspected - there should be no defects such as chips, cracks or burrs. If they are not eliminated, there will be problems with the tightness of the connection after all the work is completed.

- After making sure that the ends are clean, you can start connecting. Due to the fact that several pipes will be connected, and they can be of different sections, the fittings must be selected accordingly.

- Next, the end of the pipe and the inner walls of the couplings should be treated with flux, which will degrease the surfaces to obtain the highest quality connection.

- Now the end of the pipe is threaded into the copper tube connector and heated. It must be selected so that the cross-section is 1-1.5 cm larger than the cross-section of the pipe. The pipes are heated with a gas burner. The gap between the pipe and the coupling is filled with molten solder. Currently, you can find any type of solder on the market to suit your needs, so there should not be any problems with the choice.

- After the solder is evenly distributed around the circumference, the parts to be joined must be left until it has completely hardened.

At the final stage, you need to check the connectors for the copper pipes and the entire system by running water into it. At this moment, not only the system will be checked, but it will also be cleaned of flux residues, which over time can cause metal corrosion.

What to consider when choosing

Let's look at a few tips to help you choose the right fittings for copper pipes:

- The density of copper is slightly higher than that of steel or cast iron. Therefore, when choosing, pay attention to the weight. When choosing, immediately ask the seller for a similar steel fitting to compare it with the weight of the spare part you want to buy. If the part is light, then it is made of alloys with a high content of alloying impurities. You should refrain from purchasing such a spare part, since its use is fraught with various risks (cracks, breaks, corrosion).

- Examples of reliable brands are Viega, Tiemme, MAJDANPEK, Mueller. Russian companies make quite passable parts that, in terms of price and quality, are suitable for home use. But you shouldn’t trust Chinese and Vietnamese products - they are often made from low-quality “dirty” alloys that contain additives and impurities.

Installation of various types of fittings

Installation of different types of fittings is carried out in different ways. However, before starting to set up the connection, the following work must be done:

- cut the pipe to the required length, according to the developed project. To cut copper pipes, it is more advisable to use a pipe cutter that does not deform the edges;

- clean off any burrs left after cutting. To do this, you can use a bevel remover or sandpaper;

- if necessary, for example when installing a fitting by soldering, widen the end of the pipe by a few millimeters.

Installing compression fittings

To install a compression type fitting, you will need a wrench of the appropriate size. Installation occurs in the following way:

- a fixing nut and a clamping ring are put on the prepared pipe section;

- the pipe is connected to the selected fitting;

- The connection is fixed first with your hands and then with a wrench.

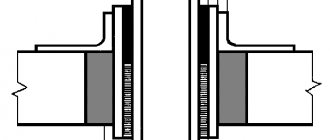

Installation of compression fitting

In the process of smoothly tightening the nut, the clamping ring fits tightly to the pipe, which makes it possible to achieve a tight connection.

Installation of press fittings

To install a press fitting, you will need to prepare special press pliers or a press gun (the equipment is used by professionals. To connect pipes at home, pliers are sufficient).

The installation diagram is as follows:

- a pipe is inserted into the fitting;

- the maximum depth level is noted so as not to completely block the flow in the pipeline;

- the press sleeve is compressed.

Attaching the Compression Fitting to the Pipe

You can watch the video for more information about installing press fittings.

Installing Threaded Fittings

Threaded fittings are installed according to the standard scheme:

- a thread is cut on the pipe using special tools;

Preparing pipe threads

- the threads on the fitting or pipe are sealed with the selected material;

Thread sealing with Tangit Unilok thread

- the fitting is screwed on.

Since copper pipes are quite soft, it is important not to overtighten the threaded connection.

Installing solder fittings

The installation of fittings installed by soldering is completely similar to the process of pipe soldering:

- Flux (a special substance to increase the fusibility of solder) is applied to the prepared section of the pipe;

- the selected connecting element is put on;

- Using a gas torch and solder, the free space in the seam is filled.

Solder fitting installation

When performing work, it is important to strictly follow safety precautions. Soldering is performed in a well-ventilated area

There should be no flammable mixtures or objects nearby.

Thus, you can select and install any type of fittings for copper pipelines yourself.

Features of different connection methods

Installation of units on copper pipelines is carried out in the following ways:

- welded - heated to a temperature close to the melting point,

- capillary – soldering at low temperature,

- threaded - twisting onto a thread,

- crimp - using compression fittings,

- crimping - using press fittings and press pliers.

Note! Welding and capillary methods are only applicable for connecting copper pipes to each other or to copper fittings. Threaded, crimp and press fittings can be used not only in copper, but also in steel or brass.

Each method has nuances of installation work and features of the resulting units. Welding and soldering make it possible to form reliable one-piece units, but their implementation requires welding equipment, and its use is not always possible. Other methods can be used for installing copper pipelines in rooms where finishing work has been carried out, in close proximity to other communications, including near gas pipes.

Welded connection of copper pipes

Welding of copper pipe products is carried out only butt.

The work is performed in the following order:

- Asbestos-cement sheets are laid under the elements to be connected to reduce heat loss and speed up the heating of the pipe and fitting.

- The ends of the fitting and pipe are heated with a gas burner operating at high power.

- The melted sections are joined and pressed tightly against each other, avoiding distortions.

- The cooled seam is forged to reduce the graininess of the resulting burr.

Note! Copper cools easily, so heating and joining should be done as quickly as possible. If thick-walled pipes are welded, connect a second burner, which heats the melted sections without allowing them to cool.

Capillary connection or soldering

A more popular method of installing copper components than welding is soldering. Firstly, this method does not require strong heating of the parts to be joined and subsequent forging of the seam. Secondly, there are no restrictions on the time of work, since it is not the pipes and fittings that need to be heated, but the solder - a thin wire made of technical copper.

We recommend that you read: How to make and install a heat exchanger (economizer) for a chimney with your own hands

The connection is made in several steps:

- Insert the pipe into the socket of the fitting.

- Heat the joint by applying solder to the pipe along the edge of the socket placed on it.

- The molten solder rises along the gap between the copper elements, filling it evenly.

- Allow the formed knot to cool.

- After cooling, clean the outer part of the connection from solder residues using a cleaning agent. For the same purpose, the insides of the pipeline are washed with water immediately or upon completion of installation of all components.

Note! The name of the method comes from the capillary effect - a liquid can overcome gravity and move upward between two surfaces at a certain distance between them. Molten copper is a liquid and therefore rises between the walls of the pipe and fitting. However, this method requires that the pipe network elements being connected have sockets that provide the required clearance.

Using Threaded Fittings

The simplest is a threaded connection, made if you need to form a detachable unit. Most often, steel and brass fittings are used for this method, which can have internal or external threads.

Installation is carried out as follows:

- Wrap FUM tape onto the external thread of the fitting or pipe.

- Screw an element with an external thread into an element with an internal thread manually.

- Screw the fitting all the way in using a wrench.

Note! Threaded units are prone to loosening during operation and require periodic tightening. Therefore, they can be installed only in those sections of the pipeline that are accessible for preventive maintenance.

Compression fittings

Compression fittings consist of a body with external threads on fittings, a ferrule nut and one or two ferrules. The essence of the connection method is that the end part of the pipe is clamped between the fitting fitting and the compression nut. This method is convenient in that it is carried out without heating, without special tools - an adjustable wrench is enough; with the same wrench, if necessary, you can dismantle the unit. At the same time, the reliability of the compression unit is much higher than that of a threaded unit. Compression fittings are made from various materials, but only those with ferrules made of copper are used to connect copper pipes.

We recommend that you read: How to choose and connect a faucet for a washing machine yourself

The connection is made in the following order:

- Remove from the fitting and place the crimp nut on the pipe, moving it away from the edge.

- Perform the same actions with the crimp rings one by one.

- Insert the fitting into the pipe.

- Alternately slide the rings towards the fitting body and screw on the nut.

- Tighten the crimp nut with a wrench.

Note! Applying excessive force when tightening the ferrule nut may deform the pipe or strip the fitting threads.

Features of the use of press fittings

Crimping is similar to the crimp connection method, but to perform the crimping unit, a press fitting and press pliers are required.

The fitting for crimping consists of a body with a smooth or ribbed fitting, a fixing ring and a press ring.

Assembly installation procedure:

- Place a press ring and a fixing ring on the pipe and move them away from the cut.

- Install the fitting into the pipe.

- Slide the rings one by one towards the fitting body.

- Tighten the press ring with press pliers.

The resulting connection is non-separable and is not inferior in reliability to welded and capillary ones.

Types of press fittings for pipes

Types of threaded fittings

Depending on the method of application, two groups of such elements are distinguished:

- Compression (crimp fittings for pipes);

- For soldering.

The first ones are intended for making detachable pipeline connections. They can be made in the form:

- Knee;

- Tee;

- Couplings;

- Crane.

Products in this group are characterized by low cost, the ability to be used several times, and ease of installation, which can be performed without any special devices.

In addition, when press fittings are used repeatedly, their reliability decreases.

Types of Compression Fittings

Soldered models are also available in various designs:

- Transition tees;

- Rotations of 45 and 90°;

- Contours;

- Single- and double-socket couplings;

- Plugs;

- Arcs.

They are fastened by capillary soldering using a coaxial overlap connection. In this case, molten solder is sucked into the installation gap, which cools down and makes the joint airtight.

The advantages of compression fittings include their low cost. They are the cheapest of all existing varieties and are made from Cu DHP grade copper. They can be used with both high and low temperature welding.

Let's watch the video, the nuances of installation, testing:

Installing such parts can significantly reduce installation time, but at the same time ensures high strength and reliability of connections. This is what makes copper pipes and fittings popular despite high prices. Only for low-temperature soldering, special parts with a groove along the inner circumference are produced. Solder is placed into it at the factory, and when such an element is put on a pipe coated with flux and heated, the joint will be soldered.

Three main connection methods

Before connecting sections of copper pipes, they must be cut in accordance with the wiring diagram and prepared. You will need a pipe cutter or hacksaw, a pipe bender and a file. And for cleaning the ends, fine-grained sandpaper will not hurt.

Only having a diagram of the future pipeline system in hand can you calculate the required amount of consumables. It is necessary to decide in advance where and what diameter the pipes will be installed. It is also necessary to clearly understand how many connecting elements are required for this.

Option #1: Welding copper pipes

To perform automated or manual welding of copper pipes, electrodes and gas are required to create a protective environment (nitrogen, argon or helium). You will also need a DC welding machine and, in some cases, a torch. The electrode can be graphite, tungsten, copper or carbon.

The main disadvantage of this installation technology is the significant differences in the characteristics of the resulting seam and the pipe metal. They differ in chemical composition, internal structure, electrical and thermal conductivity. If welding is performed incorrectly, the joint may even separate later.

Due to the alloying of copper as a result of the action of the deoxidizer present in the electrode, the weld seam is in many respects very different from the base metal being welded

Only a qualified craftsman can properly weld copper pipes. This requires certain knowledge and skills.

This installation option has a lot of technological nuances. If you plan to do everything yourself, but have no experience working with a welding machine, then it is better to use a different connection method.

Option #2: Capillary soldering

In domestic conditions, copper pipes are rarely connected by welding plumbing fixtures. It is too complex, requires specialized skills and is time consuming. It is easier to use the capillary soldering method using a gas torch or blowtorch.

The technology of soldering copper pipes with solder is based on the capillary rise (seepage) of the latter after melting along the gap between two pressed metal planes

Soldering of copper pipes happens:

- low temperature - soft solders and a blowtorch are used;

- high temperature - refractory alloys and a propane or acetylene torch are used.

These methods of soldering copper pipes do not make much difference in the final result. The connection in both cases is reliable and tear-resistant. The seam with the high-temperature method is somewhat stronger. However, due to the high temperature of the gas stream from the burner, the risk of burning through the metal of the pipe wall increases.

Solders are used based on tin or lead with the addition of bismuth, selenium, copper and silver. However, if pipes are soldered for a drinking water supply system, then it is better to avoid the lead option due to its toxicity.

Image gallery

To implement low-temperature welding, it is not necessary to have special equipment and special skills of the performer. You can do it yourself

How to connect copper products

- The required section of the product is cut off, as in the previous version;

- The outer and inner parts are cleaned of dirt using a special brush or sponge for copper;

- The pipe is inserted into the capillary fitting as far as possible, flux is applied, the excess of which can be removed with a clean cloth;

- The connection is heated using a gas burner or a special construction hair dryer, and solder is applied. The solder should melt and evenly fill the mounting gap;

- We are waiting for the solder to cool naturally. Remains of flux are removed with a damp and clean cloth.

Now you know how to connect copper pipes in several ways. If anything about copper installation seems unclear to you, you can always study the instructional video. In principle, this work is quite simple and can be done independently, without resorting to the services of professionals.

Even taking into account the fact that polymer pipes are being used more and more often, metal products are still enjoying considerable success. Typically, the metal used is copper, brass and steel. Copper is superior in terms of resistance to corrosion and high temperatures. Actually, the connection of copper pipes will be discussed in this article.

Even though copper pipes are expensive, taking into account all the characteristics of the material, their use is quite justified.

First of all, before connecting copper pipes, you should decide how to connect them, by soldering or another method.

Amateur Radio Technology

| Internal threads are cut using taps. When cutting threads with a diameter of up to 10 mm, a set of three taps is used manually: rough, medium and finishing, which have one, two and three marks on the cylindrical part of the shank, respectively. Two taps can also be used - rough and finishing, respectively, with one and two marks on the tap. The correct choice of hole diameter is of great importance. If the diameter is larger than it should be, the internal threads will not have a full profile and the result will be a weak connection. If the diameter of the hole is smaller, it is difficult for the tap to enter it, which leads to the breaking of the first threads or to jamming and breakage of the tap. The diameter of the hole for a metric thread can be approximately determined by multiplying the thread size by 0.8 (for example, for an M2 thread, the drill should have a diameter of 1.6 mm, for MZ - 2.4-2.5 mm, etc. (see. table). The drill diameter in the table below corresponds to the standard thread pitch. First, the thread is cut with the first tap, then with the second. To break off the chips, the tap is turned half a turn in the opposite direction after each clockwise turn. To cool the tap and reduce the effort when cutting threads, lubricants are used: for aluminum - kerosene, for copper - turpentine, for steel - emulsion or machine oil. Bronze and cast iron are cut without lubrication. When cutting a blind hole, its depth should be 3-4 mm greater than the length of the required thread. In this case, it is necessary to periodically unscrew the tap to remove chips from the hole. External threads on screws, bolts and studs are cut by hand using dies. The diameter of the rods for external metric threads should be selected according to the table. The threaded rod must have a clean surface; You cannot cut threads on rods covered with scale or rust, as in this case the dies will quickly wear out. Before cutting the thread, the rod is clamped in a vice so that its end protrudes above the level of the vice jaws a little more than the length of the part being cut, and a chamfer is removed at the very end of the rod. When starting to thread, make sure that the die cuts into the rod without distortion. When the die is skewed, the thread profile is distorted and the teeth of the die may break. Cool the die in the same way as the tap. Here your opinion matters — give your rating (rated — 4 times) |

|

- Simple New Year's garland

- Simple testers of thyristors and quartz

- Simple analog frequency meter

- Universal transistor voltage indicator

- What you need to know about the operation of a three-phase electric motor in a single-phase network...

- DIY FM transmitter

- Simple 10 W tube amplifier for 6N2P+6P14P

- TPS2530 – controlled switch with current limiter from Texas Instruments

- A simple transformerless low-frequency amplifier

- VEF TA DM

- TAN-76-4

- TAN-70-4

- Scheme TA K-701

- Ohm's law, formula

- Counter - Digital frequency counter on PC

Installation and replacement rules

The use of each type of fitting has its own limitations:

- For gas, only soldering or press connections are permitted.

- The compression connection cannot be poured into a screed with a heated floor system and used for gas pipelines (do not forget - installation of gas pipelines is permitted only to specialized organizations with a license).

- Soldering is used in all cases where the pipeline cannot be observed visually - when laying pipes behind drywall, in walls, floors.

You can only replace the compression fitting - unscrew it and install a new one. If the solder and press connector fails, you will have to cut the structure, build it up using a fitting and pipe, and install a new connector.

Connectors coated with chrome and nickel are not used for aesthetic reasons, but there is no prohibition on the use of such elements.

Installation technology

For any installation method, it is necessary to prepare the workpiece:

- Use a pipe cutter to cut the piece to the required length.

- Clean off any burrs using a file.

- Clear away any shavings.

- Degrease.

- Calibrate with a calibrator.

For soldering, the connector and workpieces are coated with flux, connected (the workpiece is inserted into the connector), heated with a gas burner to 250-500 °C, and a solder rod is passed along the joint of the tube and the connector. The solder melts and is drawn between the parts by capillary action. The connection is then cooled.

The unscrewed crimp nut is put on the workpiece, the workpiece is put on the collet and rests against the support ring, the nut is tightened and the workpiece is clamped, and the o-ring seals it. The nut is tightened by hand, then using a wrench one turn/turn and a quarter.

The sleeve is placed on the end of the workpiece, the pipe is placed on the body, after which the sleeve is pressed with a special hand press (press pliers). Characteristic ridges form on the sleeve above the sealing ring.

Advantages of copper pipes and their disadvantages

At present, it is impossible to say for sure why copper pipes for water supply are used extremely rarely in the CIS. One of the likely reasons is the high cost of such products, although if we take into account the costs of repairs in one particular apartment, the difference is not so great.

Another factor is the huge variety of alternative options on the building materials market, which can be a worthy replacement for steel pipes, which are prone to oxidation and difficult to install. However, most likely the reason is still in long-rooted habits passed on from generation to generation.

Let's look at the main advantages of copper pipes:

- they are practically not subject to oxidation and corrosion;

- the threshold of permissible temperatures for pipe operation ranges from -110 ℃ to 250 ℃;

- the properties of the material make it possible to avoid the formation of any deposits on the internal walls of the pipes;

- The service life of copper pipes for water supply is quite long, and the costs of their installation and maintenance are extremely low.

However, it is impossible not to note some of the shortcomings of copper pipes for water supply:

- With some metals, in particular aluminum and steel, copper forms a galvanic couple. Therefore, if even a very weak current flows at the point of contact between the thread and the copper pipe, serious complications can occur.

- Copper is an excellent conductor, which in some situations can cause electric shock. This can happen even through no fault of yours - for example, if, as a result of a breakdown of your neighbors’ washing machine, a breakdown occurs between the phase and the ground to the water supply.

- Installing copper plumbing pipes and fittings is quite labor intensive. Although the principle of installing compression fittings will not differ from, say, working with metal-plastic pipes, however, much more effort will have to be applied (read: “How to install copper pipes correctly - expert advice”). If the joining of pipes is carried out using the soldering method, then consumables (solder, flux), a special tool (blowtorch), and also skills will be required.

Advantages of copper alloys

Copper fittings have the following advantages:

- Good strength. The strength of copper is much lower than that of steel. However, it is enough for the manufacture of high-quality reliable pipes and fittings. Copper perfectly withstands the loads created by the transported substance. Copper tolerates both water and other substances - gas, oil, steam, and some types of toxic liquids. Technological studies show that if installed correctly, the service life of a copper fitting will be 20-30 years. This is a good indicator.

- Easy to install. Copper is a fairly ductile material compared to other metals (steel, iron, aluminum + alloys). Therefore, it is easy to install such spare parts, and a person will not need skills or abilities for installation work. Copper solder fittings are often used, but other fastening methods are also widely used - locking, threading.

- High corrosion resistance. A thin oxide film is created on the surface of the copper, which protects the fitting from corrosion. This is an important parameter because copper pipes usually transport ordinary or chlorinated water, which often reacts with metals to form rust. In the case of using copper fittings, such a development scenario is completely excluded, since copper does not react with chlorine and water molecules.

- Temperature stability. Copper retains its strength at temperatures up to 600 degrees Celsius. Therefore, fittings made of this material can easily withstand thermal loads created by various heated substances. It can be hot water, steam. Most modern copper alloys have a thin protective film on their surface that prevents the material from contacting the external environment. Therefore, these spare parts can also withstand the load of certain toxic substances heated to high temperatures.

Elements for copper pipe connections

Copper fittings, which are used to connect copper pipes, are presented on the modern market in a wide variety of sizes and designs. The most well-known types of such connecting elements are:

- threaded fittings for copper pipes;

- self-locking connecting elements;

- compression or crimp fittings;

- so-called press fittings;

- capillary type connecting fittings.

Of all the listed types of connecting elements, in our time, press fittings for copper pipes are the least used, which is explained by the following reasons: their installation requires the use of complex and expensive equipment: special presses. The design of press fittings was originally developed in order to connect plastic and metal-plastic pipes with their help, so their use for the installation of copper products is not always advisable.

Press fitting pliers

In order for a pipeline in the construction of which copper parts are used to serve as long as possible and be highly reliable, it is advisable to use elements made of homogeneous materials during its installation. Connecting copper pipes with fittings that are made from other raw materials should only be done in rare exceptions.

If it is not possible to avoid the use of fittings made of dissimilar materials when installing pipelines, then this process must be carried out by adhering to the following simple rules:

- copper pipes in communications, for the creation of which elements from different materials are used, are always installed after products made of ferrous metals: in the direction of fluid movement;

- copper parts of pipelines cannot be connected to fittings made of galvanized steel; failure to comply with this requirement will lead to electrochemical reactions occurring in such systems, which will significantly accelerate the corrosion process of steel parts;

- copper elements of pipe structures can be connected to parts made of acid-resistant steel, but if there is such a possibility, it is better to replace such parts with fittings made of polyvinyl chloride.

Classification and types

Fittings are primarily divided into parts for soldering and for installation without welding - threaded, compression, press and push fittings. For soldering, pure copper products are used; for other fittings, bronze or brass is used. Brass and bronze are harder and stronger than copper, so parts made from them retain their shape better, including the geometric dimensions of the thread.

Solder fittings

Capillary soldering provides the most reliable and tight pipe connection. Therefore, it is chosen in hard-to-reach places or where special reliability is required (for example, in a heated floor pipeline). They are also chosen because they are the most compact and inexpensive of all types of fittings.

Structurally, the elements for soldering are tubes and tees of simple shape, with diameters slightly larger than the diameters of the workpiece being joined.

Threaded

Threaded connecting elements are mounted into the system using external or internal threads.

There are quite a lot of varieties of threaded products:

- Plugs.

- Bends 90 and 135°.

- Couplings for connecting pipes (with internal thread, sometimes with 2 union nuts).

- Crosses and tees; Available with external threads or union nuts.

- Squeegees are tubes with external threads, couplings and locknuts.

- American union nut.

- Nipple is a connection element with two threads and a hexagon wrench in the middle.

- A fitting is an element with a “ruff”.

- Inset.

- A fitting is a connecting element for moving from diameter to diameter; it has internal and external threads.

- Eccentric - for mounting faucets.

On copper pipes, threaded connection elements are used very rarely due to the difficulty of making threads on copper - copper structures are plastic and have a thin wall, the thread weakens the pipe and reduces the strength of the connection point and the entire system.

It is much safer to use compression and press connectors for installation. In addition, threaded parts are serviceable connections and require regular inspection.

Compression

A very quick connection is achieved when installed using compression connectors. Such fittings have a thread or a union nut on one side; with their help, the pipeline is connected to pipes made of another material or other elements of the system (metering unit, mixers, taps, radiators). There are double-sided compression fittings.

This type of connection cannot be used for heated floors.

The compression connection is a collapsible connection and requires systematic inspection and tightening.

Installation using compression elements requires minimal costs and does not require special equipment, except:

- Pipe cutter.

- Calibrator.

- Wrenches.

Structurally, a compression fitting consists of a threaded body (also called a collet), a metal thrust ring, an O-ring, and an external compression nut.

Collet

Push-in fittings are simply another name for crimp-on compression connectors.

Press fittings

Press fittings form a very tight, permanent connection; they can even be installed in underfloor heating systems and gas pipelines.

Structurally, press connectors consist of a body, a press sleeve, a metal thrust ring and an O-ring.

If the connection is leaking

Unfortunately, errors are periodically found in articles; they are corrected, articles are supplemented, developed, and new ones are prepared.

How to distribute responsibilities while hiking... Tips for organizing a tourist trip, selecting participants, optimal…

Making soup - puree from gravilate. Ingredients, composition. Dietary... How to prepare soup - puree from gravilata. Personal experience. Advice. Detailed instructions...

Cladding of walls and ceiling with clapboard…. How to cover with clapboard to make it look beautiful and professional. Practical experience...

Auchan is a chain of shops and hypermarkets. Customer review, prei... Let's talk about Auchan. What do I like to buy in it, what do I prefer to buy...

Copper pipes are connected in three ways: using compression fittings, by capillary soldering and using press fittings. Each of these methods has its pros and cons. It all depends on the exact conditions in which you plan to operate the plumbing system.

Copper pipe rolling process

When installing heating and plumbing systems, the parts of which are made of copper, such technological operations as flaring or beading of copper pipes are often performed. With this operation, which can be performed using various tools, the geometric parameters of the ends of the connected pipes are changed without changing the performance characteristics of the product.

Flared copper pipes

The simplest tool with which this operation can be performed is a rod with a conical tip, which is inserted into the end of a copper pipe and rotated in it until it acquires the desired geometric shape. Although this device is quite simple to use, it does not allow for high-quality flaring, ensuring uniform pressure on the walls.

A more effective device for performing flaring is a device that consists of a clamp that exerts pressure on the working cone, as well as a stand with several holes or one universal one into which copper pipes of various diameters are inserted. For the installation of heating or plumbing systems consisting of copper elements, home craftsmen most often use just such devices.

Specialists who professionally install communication systems consisting of copper elements use devices for flaring, the design of which includes an eccentric and a safety ratchet. The ends of the pipes, on which the nuts are previously put on, are evenly rolled out on such a device along their inner surface, for which an eccentric is used.

Copper pipe flaring kit

A ratchet, which limits the force exerted on the end of the pipe, is necessary in such a device so that the walls are not pressed through when there is excessive pressure on them. The big advantage of using such a professional device is that when used, small grooves and dents do not form on the inner surface. It is these grooves and dents that occur when using more primitive devices that are the most likely sources of leaks, which ultimately significantly reduce the life of the pipeline.