Necessary equipment for connection

Each connection method requires a specific tool:

- Soldering iron;

- Shaped parts with electric spirals.

When choosing a soldering iron for welding, you should remember that they are divided depending on the shape of the working body into:

Devices of the first type are usually used for butt welding pipes in hard-to-reach places. Regardless of which soldering iron is chosen, its power must also be taken into account. This parameter is selected as follows. The diameter of the pipe in mm is multiplied by 10. If you intend to connect elements with a diameter of 50 mm, then you should purchase a soldering iron with a power of 500 W.

Modern equipment for welding HDPE pipes is difficult to imagine without electronic filling. It is also available in soldering irons. Most models are equipped with electronic control that allows you to accurately set the heating temperature.

To weld HDPE pipes, you will also need soldering iron attachments. They are available with two types of coating:

Moreover, the latter has the highest strength characteristics. When choosing a tool for welding HDPE pipes with your own hands, you need to remember that a high-quality seam can only be obtained by using high-quality equipment.

Detachable connection and fittings for it

Pipe installation using couplings is not always highly reliable, but is still used quite often.

This method has its advantages:

- Firstly, it does not require special tools; you may only need a wrench, and only when working with large-diameter tubes.

- Secondly, a detachable connection can be made in places where welding is not possible, for example, under water.

- Thirdly, this method is designed for quick pipeline assembly.

For such a connection, brass or HDPE welded compression fittings can be used, complete with plugs and flexible seals. The preparation process is similar to that performed during welding.

The next step is preparing the fitting. To do this, unscrew the union nut several turns and forcefully insert the pipe into the seal. Next, put on a collet with an elastic ring and tighten the nut.

There are two ways to make a detachable connection:

- Bell-shaped, using rubber seals;

- Flange with mounting elements.

Experts recommend using the second method, as it is more reliable and almost as good as welding.

Installation of pipes with couplings

This method is very reliable, and in addition, it is simple to perform and does not require large financial costs. HDPE welded couplings are made of polyethylene, therefore they are low cost, but at the same time resistant to mechanical stress and temperature changes.

Various connection schemes and types of fittings

Another advantage of using such connecting elements is their versatility. They can be used to assemble various pipelines. In addition, special adapter couplings are produced for the installation of HDPE and metal pipes.

What mistakes should you avoid?

To install HDPE pipes yourself, you need to have basic knowledge of plumbing. This will help avoid assembly errors. One of the most important points is the linear expansion of the pipeline. Without this, high voltage occurs in the pipes, leading to a decrease in the service life of the system.

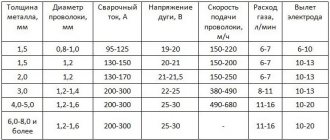

Technological pause table

If hidden installation is intended, then before starting cementing, it is necessary to wrap the pipes in insulating material. The same is done when laying a plumbing system, which avoids the formation of condensation on the surface. When welding HDPE pipes, you must follow certain rules. One of them is to moderately tighten the adapters to avoid compromising the integrity of the system.

Taking into account all the nuances listed above, you can install HDPE pipes yourself, without resorting to the services of specialists.

A high-quality connection guarantees the tightness and durability of the pipeline

Hello. Today I will talk about how HDPE pipes are welded when constructing domestic and industrial pipelines. The topic is of considerable interest, since pipes made of low-density polyethylene are becoming increasingly in demand due to their affordable cost, high strength and long service life.

Electrofusion welding

Electrofusion welding is considered a fairly popular method of soldering HDPE pipes. Its peculiarity is that such a connection can be used for products of a wide variety of diameters and thicknesses, including the smallest sizes.

True, this method is more expensive compared to butt technology, and, accordingly, the cost of welding increases. For work you will also need various fittings (for example, electric welding fittings).

Electrofusion welding is sold in any specialized store

The soldering procedure in this case looks like this:

- First, clean the inner surface of the electric coupling and the pipes themselves from contamination (you can use alcohol-soaked wipes);

- Next, the ends of the welded products must be cut evenly and carefully, and then the oxidized layer must be removed from the surface;

- Then the elements should be secured in the positioner, ensuring their compatibility;

- To protect the connection from dust, you can use adhesive tape for winding, and close the open ends with plugs to preserve heat;

- Voltage must be applied to the electrical coupling connectors, after which the fitting will begin to heat up, thereby welding the pipes.

It should be remembered that when soldering polyethylene pipes, as well as during their cooling, the place with the shaped elements should be very firmly fixed. It must remain stationary during the entire welding process.

This method is also convenient because it can be used in places with limited space where it is difficult to solder using another method.

You can weld HDPE pipes at home using various methods. The choice of any of them depends primarily on the temperature regime and the purpose of the products themselves. At the same time, you need to remember about safety precautions and operating rules for welding equipment.

Detachable connection of HDPE pipes

This method is often used to install HDPE pipes in apartments and residential buildings with your own hands. For these purposes, pipes with a diameter of less than 110 mm and fixing elements are usually used: compression plastic or brass fittings. A socket plug with a flexible seal will not be a superfluous detail.

The order of operations is as follows:

1. Preparation of pipe ends is the same as for welding. The only peculiarity: here it is necessary to carefully ensure that the cut is strictly perpendicular to the axis of the pipe.

2. Unscrew the fitting nut and firmly insert the end of the pipe into the fitting.

3. Next, assemble the fitting: put it on the pipe and insert the rubber seal into the fitting into a special socket (it should fit tightly, with force), then the collet and the notched O-ring. Everything should fit snugly and fit well.

4. Tighten the nut.

These manipulations can be performed without tools, by hand. But if large diameter pipes are being installed (from 160 mm or more), then you can use a wrench. If everything is done correctly, you don’t have to worry about the tightness of the connection. But you should check.

Return to content

Recommendations from experts

Soldering of pipes must be done in a room with a positive temperature: the colder the air, the longer it takes to warm up the parts. For a strong and tight connection, you need to pay attention to the following recommendations:

- Equipment for domestic use is used to work with pipes with a cross-section of up to 35 mm; in other cases, you need to use a professional soldering machine.

- The power of the tool for home use must be 1500 W.

- There is no need to press the parts together tightly. Because the molten material will be forced inward and reduce the fitting bore, this will in turn reduce the performance of the system.

When deciding to do the work yourself for the first time, it is best to purchase material with a certain reserve. Knowing only theoretically how pipes can be soldered correctly, you need to practice before starting installation. If the experience was not entirely successful, then it is better to entrust the installation of the pipeline in the house to specialists .

Source

Finishing features

Since the bathroom has a specific microclimate with high humidity, finishing materials must be chosen especially carefully. The best option is good old ceramic tiles, you just have to choose a beautiful design.

You can also make decorative inserts from mosaics or artificial stone. More economical methods would be painting with water-repellent compounds and PVC panels.

Try to adjust the space of your small bathroom using geometric lines. Horizontal stripes on the walls can visually expand them, and vertical stripes can raise the ceiling. Tiles laid diagonally on the floor will also visually increase the space and give the interior some dynamism.

Decorate one of the walls of the room with a darker color, for example, in the area of the shower, bathtub or sink. This technique will also visually add volume to a small room.

Detachable connection methods

If we consider detachable connection options, they are implemented using flanges and compression fittings.

With strict adherence to installation, they turn out to be as reliable as those created by using a welding machine

Any type of permanent connection includes an elastic part. When compressed with a tightening tool, it fills all the voids in the joint area, thereby eliminating leaks.

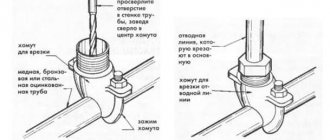

Using HDPE fittings

To implement this method, compression fittings are used, which are fittings supplemented with external threads on both sides.

They are able to join pipes, providing a tight connection with high sealing performance. In this case, the detachable connection will not be difficult to remove at any time in order to change the configuration of the main line or carry out urgent repairs.

This method of detachable connection is often chosen in private households, when it is necessary to connect a branch from the water supply source to the water supply coming from the house.

Sequence of actions to obtain a fitting connection:

- A spacer ring made of polyurethane or rubber is put on the prepared ends of both pipes. The outer diameter of the ring must be equal to the inner size of the pipes being joined.

- The ends are equipped with a tension nut and two washers. The first washer is designed to press out the spacer ring, the second is designed to seal the nut relative to the end of the pipe.

- The connection is joined according to the “pipe - fitting - pipe” principle. To increase reliability, it is pressed all the way on both sides with a tension nut.

A special key is used to assemble the mounted parts. They unscrew the clamping nuts on the connecting fittings.

Parts assembled using compression fittings can be repeatedly disassembled and reused without compromising the reliability of the connection

The main advantage of this connection method is that it is convenient to carry out even with a significant decrease in ambient temperature. While the limit for welded joints is at least +5°C. A wide range of connecting elements with different diameters makes it possible to assemble any wiring, making the necessary branches in the pipeline.

By installing a flange

The flange type of connection is chosen when it is necessary to connect the HDPE pipeline to steel pipes. Using flanges, it is convenient to connect valves, regulators and gate valves to pipelines.

On sale there are slip-on steel flanges and those equipped with bushings that are welded to the ends of polymer pipes

For installation on polyethylene pipes, flanges are used that comply with GOST 12882.80. They have an expanded inner diameter.

Work on installing the flange is carried out in the following sequence:

- At one end of the communication a thread is made.

- The element is screwed into the thread.

- The outlet of the connected pipe is placed on the element.

- The joint is heated with a coupling or a hair dryer.

Before putting on the flange, it is necessary to inspect it for the presence of sharp protrusions and burrs that could damage the end of the polyethylene pipe.

Socket welding (socket)

Connecting pipes using couplings and fittings is shown for HDPE pipes with a diameter of up to 63 mm. For these purposes, use a hand-held household soldering iron (welding machine). PE tubes of larger diameter are welded using an industrial mechanical apparatus.

Important: before performing socket welding, you must stock up on the required number of fittings plus a small reserve in case of defects in the work.

To carry out socket welding, in addition to a soldering iron, you need to prepare a pipe cutter and a tape measure.

READ ALSO: Which pipes to choose: polypropylene or metal-plastic?

The work of welding HDPE tubes is carried out in this way:

- The welding machine is installed on the platform and securely secured. Nozzles of the required diameter are attached to the heating surface using a special wrench. The welding machine is set to the desired temperature. For pipes made of PE (polyethylene) it should be 220-230 degrees.

- The parts prepared for welding are put on nozzles and held until the plastic is thoroughly heated. As a rule, this is 5-7 seconds.

- After the parts have warmed up, it is necessary to slowly but fully connect the two elements and hold them in this state for at least 10 seconds so that the fitting and pipe do not change their welded position.

- After such manipulations, the internal lumen of the pipe remains smooth and sealed, and the polymer processed by the welding machine forms a single whole.

Important: Excessive overheating of the pipes should be avoided. Otherwise, when connecting two elements, the plastic will simply fold into an accordion, which will disrupt both the internal lumen of the pipes and the quality of the connection.

Tip: after each welding procedure, be sure to clean off the melted polymer from the Teflon surface of the nozzles. Otherwise it will interfere with the next welding process. Moreover, you need to remove the plastic exclusively with a wooden spatula. This way you can keep the Teflon intact and unharmed. It is prohibited to remove cold plastic or metal objects.

Instructions: how to weld plastic pipes

You need to learn how to socket weld plastic pipelines in practice. Pipe blanks and components for systems are always purchased with a reserve. To acquire skills in operating equipment, plastic elements are cut into small pieces. The technological process consists of several stages, each of them is considered separately.

Preparing pipes for welding

Cut the plastic into fragments in accordance with the wiring diagram. The edges are made at right angles. First they make markings, then cut into the plastic. Only after this the workpiece is finally cut with a sharp force. The elements are laid out on a clean, flat surface in an order convenient for welding. The necessary connecting elements are placed nearby: fittings, bends, tees, couplings.

Before welding, each joint is cleaned so that no burrs remain and degreased. Pipes with a foil layer must be folded - the metal layer is completely cut off at the joint.

Setting up the welding machine

Nozzles of the required diameter are attached to the soldering iron. The welding tool is firmly placed on a flat surface so that it does not wobble. The heating regulator is moved to the desired position. To weld plastic pipes, the soldering iron is heated from +255 to 280°C, regardless of the thickness of the pipelines. The only thing that changes is the heating time of the parts during welding and the holding interval of the joint before hardening.

The welding machine comes with attachments for pipes of various diameters.

Heating of parts

When welding, both elements are heated simultaneously: pipe blanks from the outside (they are inserted into the heating element), fittings from the inside (they are placed on the heater). The parts are advanced with moderate force until it stops – the iron plate. The heating time is counted from the moment of contact, the interval depends on the diameter of the pipe workpiece:

| Workpiece diameter, mm | Heating time, sec | Nozzle depth, mm |

| 20 | 8 | 14 |

| 25 | 9 | 16 |

| 32 | 10 | 20 |

| 40 | 12 | 21 |

| 50 | 18 | 22,5 |

| 63 | 24 | 24 |

The holding time of the joint is from 4 to 8 seconds. The data given in the special propylene welding tables are approximate. Before installing the pipeline, heating and holding times are established experimentally. The plastic should not be heated to the entire depth of the wall, so that there are no internal sagging. The experimental workpieces are made small so that the inner surface of the socket joint can be seen.

Connecting parts

The polymer pipe and fitting heated on the nozzles must be connected quickly, with force, avoiding distortions. They do this in one movement, without turning. Workpieces for welding with a diameter greater than 50 mm (for the drainage system) are connected using a centering machine; high-quality connections cannot be obtained manually. The blanks are held in your hands until the plastic hardens. After this, the formed unit is left until completely cooled for 3-10 minutes, depending on the thickness of the workpieces.

Parts heated on the nozzles must be connected quickly, with force, avoiding distortions

Stripping

Use a file to carefully remove the outer deposits of polymer. They should not be large if properly heated and compressed. There should be no internal sagging on the seams, this is a defect. After installing the water supply, you need to make sure that the seams are secure. Water is supplied to the system no earlier than an hour of exposure. If a leak is detected, the joint is cut out and a new flange connection is made in its place.

Butt welding of HDPE products

Butt welding of HDPE pipes requires the use of welding equipment. Due to the fact that no additional parts are used during welding, the installation process is greatly simplified. Only HDPE workpieces can be welded in this way.

Attention: high-quality butt welding of HDPE products will only be possible if it is performed using one seam. Thanks to this, the strength of the joining of the connected parts will be maximum.

Butt welding of polyethylene pipes is the most effective and versatile technology, since it maintains the flexibility of the material throughout the entire pipeline. This method can be used regardless of the type of pipeline installation used (trench, trenchless or open).

Butt soldering of polyethylene pipes is performed in the following sequence:

- To begin with, the ends of the workpieces to be joined must be installed in the centralizer of the welding equipment.

- After the parts are aligned and fixed, using a cotton cloth and alcohol, it is necessary to clean the ends from dust, dirt and grease.

- Then the welded ends are processed using a facing device. Trimming is stopped when uniform chips with a thickness of no more than 0.5 mm begin to form. Now the workpiece can be removed and the parallelism of the ends checked by hand.

- If an unacceptable gap is detected between the surfaces being welded, the trimming operation must be repeated.

- After this, the pipes are soldered. To do this, using a heating element with a non-stick coating, the ends of the workpieces are heated to the required temperature.

- When the ends are sufficiently melted, we separate the products to be welded, and also remove the heating element from the welding zone.

- After this, the ends to be welded can be closed and the clamping pressure increased until it reaches the required value.

- The weld must be kept under pressure for the specified period of time.

- After this, the welding quality is checked. To do this, evaluate the appearance of the burr, width and height.

Pipe connection methods

There are two types of HDPE pipe connections:

- one-piece (butt joint with a welding machine and electrofusion welding);

- detachable (using connecting parts).

Permanent connections

They are usually used in areas where pipes have to operate at high pressures. Welding connections are suitable for all HDPE pipes with a diameter of more than 50 millimeters. The seam resulting from welding is several times stronger than the pipe itself and ensures absolute sealing of the joint.

Butt welding of pipes

Butt welding of HDPE pipes is carried out using a special machine. The essence of such a connection is to heat the ends of the pipes with a special heating element to a viscous state. The softened ends of the pipes are connected under pressure and the joint is left to cool naturally. First, the ends of the pipes are degreased and cleaned of contaminants.

The resulting weld seam should be smooth, the height of its protrusion should be the same. Only in this case will it be as strong and reliable as possible.

Butt welding is the main method of connecting HDPE pipes. With strict adherence to welding technology, strong and durable connections are obtained

Butt welding is considered one of the most popular methods of connecting pipelines, but one cannot discount the second, no less effective method - connection using electric couplings.

Electrofusion welding

For this type of welding, a polyethylene shaped coupling is used. Electric spirals are inserted into it and when an electric current passes through them, the coupling heats up to the required temperature and is welded to the pipes, firmly holding them together when they harden. As with butt welding, the ends of the pipes are thoroughly cleaned before starting work.

Electrofusion welding technology is actively used in cramped conditions - when creating inserts into previously connected pipes, in wells, during repair and installation of bends, etc.

Welded joints must meet the following requirements:

- the displacement of the welded sections relative to each other should not be more than 10% of the wall thickness of the polymer pipe;

- the butt seam should not be located below the outer level of the pipe surface;

- a high-quality weld has a bead height of no more than 2.5 millimeters on pipes with a wall thickness of up to 5 millimeters, and on thick-walled pipes with a wall thickness of 6-20 mm, its height should not be more than 5 millimeters.

Detachable connections

This type of connection is carried out in areas where reconstruction or repair may be required in the future and there will be a need for disassembly. This occurs in private households when you need to connect a pipe from a water supply source to a section of the water supply leading to the house.

There are also situations when it is impossible to use the welding method (there is no necessary equipment or the connection must be made in water). In such cases, a coupling connection is used. Couplings specially produced for HDPE pipes reliably fasten the joined sections.

The detachable connection of pipes is carried out in two ways:

- socket connection (using elastic sealing gaskets);

- flange and fitting connections, for which special fasteners are used.

To assemble the mounted parts, there is no need for tools and devices, except for a special wrench, which is used to unscrew and tighten the clamping nuts on the connecting fittings. This method is suitable for connecting small diameter pipes (20-35 mm).

The use of compression fittings makes it possible to connect HDPE pipes without using a welding machine - their installation is carried out by assembling fitting elements using a threaded method

The advantage of compression fittings is the ability to disassemble mounted parts if necessary, and this can be done repeatedly and even a person without special training can perform such work. In addition, this type of installation can be performed even at very low temperatures, and the availability of a large assortment of connecting elements of various diameters on sale allows you to assemble any necessary wiring and branches in the pipeline.

Do-it-yourself welding and installation of HDPE pipes: work technology

After installation, the system must be thoroughly checked by filling it with water. If a leak is detected, the connecting parts must be tightened. However, the press fitting in such a situation must be completely replaced.

It is necessary to check underfloor heating systems before installing the screed. In such a situation, it is prohibited to use compression assembly technology.

Secondary compression of the press fittings must not be allowed, so maximum physical force must be applied during installation.

Small diameter HDPE pipes can be bent without the use of tools.

When laying a pipeline under the surface of the earth, where the aesthetic component does not matter, it is recommended to warm up the required area with a hairdryer, and then carefully bend the pipe.

If you need to create neat bends of small diameter, after heating the product, you need to place it in a mandrel made from scrap materials. After heating, the pipes should cool for 10-15 minutes. If possible, it is advisable to use a special pipe bender.

Installation options

Technologically, it is possible to connect HDPE pipes without welding or using a special welding machine. Both methods have their advantages and disadvantages; let’s look at the advantages of each fastening method.

Cold welding or pressing is the simplest option; it is a very cheap and accessible method, which is performed through the use of special couplings. This technology is used mainly for large diameter pipelines - from 20 to 300 mm. Compression fittings for cold welding have the following advantages:

- Ease of use;

- Large selection of sizes;

- Ensuring a tight connection with high sealing performance.

But pressing is mainly used only for fastening non-pressure water connections. Plastic pipes have relatively low rigidity, due to which, under strong internal pressure, the seam can simply separate, unlike welding fasteners, which are considered “dead.”

Classic welding, or as they say, soldering of HDPE pipes can be performed using the electrofusion method, or a specific welding apparatus is used to carry it out. Electrofusion couplings are a very practical method of connecting metal gas pipes, as well as plastic water supply communications. A coupling of a certain diameter is installed on the free section of the outlet, after which the second section of pipe is pushed into it. This kind of soldering is also called butt soldering, due to the fact that in order to achieve the most durable and tight fastening, it is necessary to install parts of the pipeline very tightly with a minimum gap.

Photo - fittings

It is convenient to work with couplings on large diameters, but this is not the best solution for washbasin outlets or heating communications. But flanged HDPE connections, if necessary, can be removed and urgent repairs can be made.

Photo – butt

Manual soldering of pipes is carried out using a soldering iron; it requires special equipment for organizing HDPE connections. For such work, the temperature of the heating elements and the holding time are very important.

Please note that these parameters are selected based on the technical characteristics of the soldering device, the thickness of the HDPE and the diameter of the taps

Advantages of the technique:

- This is the most durable and reliable option. Due to the implementation of permanent fastening, it can be used both for pressure HDB and for non-pressure connections of shut-off valves;

- Flange connections can be used both when attaching an external system and when installing internal main pipes;

- No prior training required. It is enough to watch the video and read the SNiP standards, which detail how to trim, install and fasten.

But the disadvantages are that the connection cannot be removed if necessary. Despite all the advantages of this, sometimes it is necessary to open and clean the pipe.

Leak test

Checking the quality of soldering is carried out only after all connections have been installed and cooled down. Why water is supplied to the installed system and the pipeline is inspected to determine leaks. Before adding water, it is necessary to let the installed system stand for at least an hour at normal room temperature, and if the air is at a low temperature, then a test run is carried out after at least 5 hours.

If loose connections are identified, then you need to drain the water and redo this part of the pipeline, using new fittings and selecting a piece of pipe of the required size. An attempt to somehow seal the connection is doomed to failure from the very beginning. Pipeline installation requires precise technology implementation.

After completing the repair, check the quality of the connection again by pouring water. If a heating system is being considered, then the pipeline can only be tested after the coolant has heated up when supplied under high pressure.

Reasons for the uniqueness of PE

We can talk about the noticeable rigidity of high-density polyethylene pipes. This is due to the strong bond of this product at the molecular level. For this reason, the production is considered extremely durable.

The main advantage of low pressure PE is that it is made from petroleum. This material is resistant to low temperatures, does not emit harmful substances into the environment and is not considered dangerous to people.

According to their purpose, the following types of high-density PE pipelines are distinguished:

- Technical (used in sewerage, gas supply and cable production);

- Food grade (suitable for designing drinking elements).

Depending on the connection method, there are detachable (easily disassembled after soldering) and permanent (they cannot be disconnected; they are used at high pressure).

Soldering of reinforced pipes

In this case, an indispensable condition is the removal of the protective material. The presence of a reinforced layer in the pipe requires additional heating. But this is not the most important thing. As a rule, these products have a non-standard cross-section and do not fit conventional welding device attachments. They need to be cleaned before soldering. The only exceptions are pipes that are reinforced with fiberglass; these products are connected as standard.

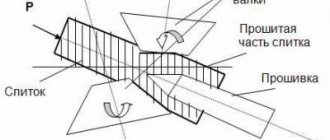

Taking into account the variety of pipe reinforcement methods, different processing options are used before joining. Most often, a seamstress is used for stripping. This is the name of a special device in the form of a steel sleeve with knives. The end of the pipe to be soldered is placed on the seamstress, and the reinforcement layer is removed with rotational movements until plastic appears.

If the reinforcement layer is located in the middle of the pipe walls, then in this case it is best to use other equipment called a trimmer for processing.

The tool is practically no different from a seamstress, except for the location and design of the knives. After using the trimmer, the end part of the element being processed is aligned with the end, and part of the reinforcement layer is also cut to a depth of 2 mm around the circumference. This treatment makes it possible to perform soldering without defects.