Ultra-precise laser engraving in the center of Moscow

What is laser engraving? This is a modern application characterized by increased accuracy (up to 0.01 mm), speed of order fulfillment (from 15 minutes), excellent edge quality, high productivity (up to 100 mm/min), which makes it an indispensable method for wholesale orders; no deformation of the material. Using a solid-state laser, you can apply an image to almost any surface: metal alloys, precious metals, wood, leather, glass, porcelain, plastic, stone and even bone. And, of course, the engraving is durable. We work from 1 piece!

Our workshop has been engraving since 2001. We became the first Moscow company to use a “green” laser in our work. With its help, we engraved a huge number of products, such as gifts, souvenirs, industrial goods, devices, signs, badges, and all the engraving was of excellent quality. Our specialists know absolutely everything about laser engraving! We guarantee that we will not damage your product. Among our clients there are such reputable companies as Yandex, Azbuka Vkusa, MTS, Coca-Cola, Lukoil, Nestle, VTB, Sber, etc.

Most popular services

Awards

Old price: from 1000 rub. New discounted price: from 500 rub.

Glasses

Old price: from 1000 rub. New discounted price: from 600 rub.

Rings

Old price: from 1500 rub. New discounted price: from 800 rub.

Laptops

Old price: from 1000 rub. New discounted price: from 800 rub.

Signs

Old price: from 1000 rub. New discounted price: from 500 rub.

Badges

Old price: from 800 rub. New discounted price: from 450 rub.

Pens

Old price: from 1000 rub. New discounted price: from 600 rub.

Flash drives

Old price: from 800 rub. New discounted price: from 450 rub.

Watch

Old price: from 1500 rub. New discounted price: from 800 rub.

Awards

Old price: from 1000 rub. New discounted price: from 500 rub.

Glasses

Old price: from 1000 rub. New discounted price: from 600 rub.

Rings

Old price: from 1500 rub. New discounted price: from 800 rub.

Laptops

Old price: from 1000 rub. New discounted price: from 800 rub.

Signs

Old price: from 1000 rub. New discounted price: from 500 rub.

Badges

Old price: from 800 rub. New discounted price: from 450 rub.

Pens

Old price: from 1000 rub. New discounted price: from 600 rub.

Flash drives

Old price: from 800 rub. New discounted price: from 450 rub.

Watch

Old price: from 1500 rub. New discounted price: from 800 rub.

In addition to engraving, our company offers other types of application: sublimation and pad printing. Sublimation is used to convey the most accurate image possible. With its help, even photographs can be transferred without distortion. This is not done for every subject. Sublimation requires aluminum sheet with a certain coating. It is used to create colored plaques, office signs, and metal business cards. Sublimation printing is used to decorate mugs. Special mugs are sold for sublimation.

Pad printing can be applied to any material and shape. This is its peculiarity. You can apply color to a round object: pens, Christmas balls, cups. The recommended number of colors for pad printing is 4. Each shade of paint is applied with a separate soft pad. The result is a color image. This is how the logo and company name are printed. If you have any doubts about which type of application is suitable specifically for your case, leave a request on the website. We will select the appropriate method.

Laser Engraving is

- - quick application

- — order from 1 piece

- — image indelibility

- - transfer of small characters

Watch

Alternative - pad printing

- — color printing (up to 4 colors)

- - profitable for large circulations

- — printing on round surfaces

- - application to fragile materials

Watch

In addition to engraving, we use solid-state lasers to create shaped elements, such as signs, numbers, and even paper wedding invitations. This process is called laser cutting. Unlike scissors and cutting, a laser can cut out very small details, openwork patterns, complex logos, emblems, and coats of arms. The laser leaves smooth, smooth edges. It can cut materials that are resistant to high temperatures.

What is the procedure

Engraving is one of the ancient methods of finishing metal surfaces. Initially, it was used to add sophistication to household items, after which things were passed on from generation to generation. Despite the fact that this is an ancient art, today it is actively used for both personal and public purposes (decorating streets, city monuments, etc.).

Previously, painting was carried out exclusively by hand, without the help of special equipment. Now, for this purpose, various devices and devices are used that make it possible to create any pattern, inscription or picture. Depending on what is used to engrave on metal and how exactly to engrave (choice of technique), different results are obtained. Therefore, it is worth familiarizing yourself with the available methods, since each of them has its own characteristics.

Hand engraving on metal in Moscow

Hand engraving of metal has always been most valued. Even now in Moscow there are quite a few specialists who can do this work efficiently. A modern service - hand-engraved metal - is a very exciting process. This service is performed manually using special burrs, which is a rather delicate and painstaking job that requires care and a lot of experience. In our workshop, only the most experienced craftsmen with extensive work experience do this. They will quickly and efficiently apply any inscription or design to you, which will make your item much more individual and stylish. Any gift with hand engraving on it becomes more expensive and memorable, and it also looks great on watches, medals, Zippo and Pierre Cardin lighters, and various souvenirs. Undoubtedly, its advantage is that it is very durable. Any connoisseur of beauty will appreciate an object with an image or inscription applied to it with a pen, because what is obtained by this method is not stereotyped and is unique in its own way. Hand engraving of metal is exactly what will make any gift unique and memorable!

Manual engraving on metal allows you to do the following:

- Text inscriptions/congratulations;

- Monograms and monograms;

- Engrave complex, uneven surfaces;

- Can be applied to almost any item;

We apply it manually in front of the client and fully taking into account his wishes. The cost of the service is negotiable and is discussed individually with each client. You can contact us by phone +7 (499) 899-55-08 or by Email. Engraving on metal can be done at the address: Novaya Ploshchad, 8, bldg. We are located next to the metro stations Lubyanka, Revolution Square, Kuznetsky Most and Kitay Gorod.

- You may be interested in:

- Engraving on Zippo lighters

- Engraving on wristwatches in Moscow

Engraving method 1

What you will need:

- Glass container (according to the size of the workpiece being processed). Naturally, not a bottle with a narrow neck, but a jar, glass or bath.

- Constant voltage source (up to 15 V). It should provide a current of 0.5 A, at a minimum. The best option is a battery charger for a personal car. This is exactly what the author used. Although some craftsmen use battery chargers for household tools (screwdrivers, etc.) and even cell phones for these purposes.

- A couple of wires for connection and clamps (for example, alligator clips).

- Any metal workpiece (the same spoon) that will play the role of a second electrode.

- Saline solution. The concentration is determined by eye, so the general recommendation is as follows: per glass of water – 2 teaspoons.

- Varnish. You will need it to paint the segment of metal on which you plan to engrave. Most articles devoted to the electro/chemical method contain tips on using the nail composition. The author, in order not to “injure” his wife with such extravagance, used the so-called tsapon-varnish, which is well known to radio amateurs and electrical installers. It costs a penny, is not in short supply, and can be easily removed with a solvent.

How to make color engraving?

Color engraving has a more complex technological process, and it is only possible on metals prone to oxidation, such as

- titanium

- stainless steel

- zirconium

- aluminum

- nickel

- brass

- silver

The color appears as a result of tarnish, which occurs due to the interference of light in the oxide film. The hue and color saturation depend on several factors:

- duration of exposure to the laser beam;

- metal thickness;

- thermophysical parameters of the material;

- radiation power;

- thickness of the oxide film.

For example, on a titanium plate with a pulse duration of 80 nanoseconds, a beam speed of 24 mm/s, a pulse frequency of 95-100 kHz and a radiation power of 4.5 W, a purple engraving was obtained.

Description of technologies

The rapid development of this craft has led to the fact that there are several different ways of applying an image to a metal surface. If initially only the hands of a master and simple improvised means were used to realize fantasies, today engraving machines and even lasers are used for this.

Manual

This type is often called artistic, since it is extremely difficult to engrave metal by hand. This is a labor-intensive and time-consuming process that requires the master to have special skills, knowledge and patience. To create the required design or inscription, only a cutting steel tool is used - a graver. This is a special cutter for drawing lines and points of various indentations, which are later turned into a picture. Such work is considered exclusive, and therefore is of particular value to people who want to get a unique thing of its kind or a creation by a famous master.

Mechanical

Mechanical engraving on metal is popular because it is particularly durable - it is almost impossible to remove or erase the design. It is realized with a sharply sharpened rotating cutter by cutting material that has an exclusively flat surface. The cutter is located inside the engraving machine, which allows you to obtain three-dimensional and relief designs. The result depends on the depth of penetration of the drill, the use of various cliches (taking into account the characteristics of the cutter) and the skill of the person. The main advantages of this type are:

- Guarantee of high accuracy and obtaining the desired result while achieving the desired realism.

- Long service life. The created drawings do not lose their original appearance even after several decades and under unfavorable external conditions.

- Ability to create three-dimensional images.

A subtype of the mechanical method is the diamond method, which has some differences. In it, the cutter performs striking movements on the surface, as a result of which a certain ornament is formed. After pressing the diamond needle, microscopic dots are formed, due to which the resulting product receives a specific shine. A diamond cutter can cope with even complex tasks, but a perfectly flat surface is a prerequisite.

Sandblasting

This type has another name - abrasive processing. Engraved inscriptions or other images on metal are applied by etching the top layer of the product with sand or other abrasive powdery substances. They are sprayed with a powerful air flow, resulting in a matting effect. The use of special stencils allows you to obtain not only patterns, drawings or inscriptions, but even photographs.

This type of image application requires sandblasting systems, a mask and an air compressor. Most professionals prefer medium-sized closed units because they filter dust. Also, implementing this technology will require a lot of free space, since engraving on metal using the sandblasting method is only possible with an air compressor, which takes up a lot of space and makes a lot of noise.

Laser sublimation

This type involves the use of a color printer, special cartridges, sublimation paper and a heat press for coloring metal materials. To get the desired image, first of all, you need to print it. The resulting transfer is placed on top of the product, after which the latter is exposed to high temperatures, which promote coloring and the transition of substances from a solid to a gaseous state.

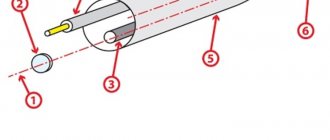

Deep laser engraving on metal is characterized by productivity and practicality, which is especially important for business, for example, for souvenirs when applying photographs. It simultaneously combines high speed, mass production, accuracy, low cost and excellent quality. This technique involves the use of a focused laser beam. It allows you to adjust the laser power, which gives the image a different tonality and relief. In addition, the resulting pattern is preserved for many years and does not deform under the influence of water or moisture.

Different laser powers for metal engraving allow you to create sophisticated and complex patterns that have the required depth. Laser engraving involves removing the outer layer of the metal surface, which is important to consider during the work process. Laser contour engraving stands out separately, implying the drawing of exclusively contours. In most cases, this technique is used for processing coins, awards and other souvenirs. The main advantages of the laser are:

- Ability to work on finished products.

- Unlimited number of processed copies.

- Low price of service and excellent quality.

- There is no need to install supports and foundations.

- The ability to apply sketches even to hard-to-reach parts of the product.

- High precision, thanks to which the products are distinguished by realism and excellent reproduction of even small patterns.

Is it possible to do engraving at home?

If we are talking about mechanical or manual engraving, then, of course, yes. It is enough to purchase only cutters and a drill.

But if you are planning to engage in laser engraving, then it is worth considering that the equipment for it is much more expensive, so it will only pay off if the craft becomes your business. Of course, for mass production it is better to allocate a special room, at least for safety reasons. After all, to work on laser equipment you will need voltage stabilization and grounding.

But we have several clients who use fiber markers at home for small production. Desktop markers with small dimensions are suitable for this.

Engraving logos and images on aluminum

Various items can be made from aluminum. These are dishes (forks, spoons), medals that imitate silver, various souvenirs, nameplates that are glued to main objects if for some reason it is difficult to engrave them. In most cases we are talking about gifts. An organization that gives a gift to its employees, business partners, or customers will benefit if a company logo is placed on it. The competition emblem is almost always present on award items.

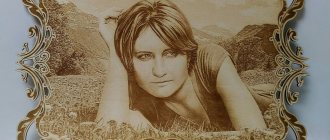

Engraving examples

Engraving on different objects has its own characteristics. Let's look at a few product examples.

Engraving on wedding rings

Usually they are engraved with words and inscriptions, but it is important that it is easy to read. But for this you need a suitable size of the product, because it will not be possible to apply such an inscription on a ring that is too narrow.

At the same time, engraving can be applied to any metal - gold, silver, platinum or titanium. But we recommend using soft metal, as the letters will be easier to read on it.

Engraving can be applied to the front, inner side of the ring and its side edges.

Engraving in production

It is usually used in the manufacture of nameplates, plates, serial numbers, license plates and many other products.

Let's look at the example of nameplates and plates. For their production, as a rule, brass or aluminum is used. In the first case they have a golden tint, and in the second - silver. Both materials can be laser engraved.

But most importantly, do not forget that when producing industrial nameplates you must comply with the requirements established by law. Using markings, information about the product and manufacturer is applied to the nameplate. It includes technical characteristics of the device, manufacturer data, Rostest data, device serial number and a description of safety when working with the item.

The inscriptions are very thin and clear, so the nameplate itself is small. In addition, when applying inscriptions to a nameplate, their durability is important, so production uses exclusively laser marking methods. And thanks to the high speed of work, their production has no restrictions on circulation.

Engraving on a thermal mug

Metal thermal mugs are especially popular now. And they are used not only on hikes, but also, for example, in bars and restaurants. Engraving a thermal mug using a fiber optic marker is not at all difficult. One caveat - you will need a rotating device.