History of discovery

Today it is difficult to imagine a world without numerous inventions.

Many of them were made by accident. This is how stainless steel appeared. The first historical mention of this metal can be found in the records of Harry Brierley. This metallurgist researcher in 1912 took an order from one of the weapons companies to find an effective way to extend the service life of gun barrels. The practitioner began to work in his usual style - he began mixing different components. The man tested the finished alloys for heat resistance and durability. If the indicators were low, the blanks were sent to a landfill. One of the details stood out among all with its brilliance. After a detailed study of the analysis, scientists found that the alloy consists of several elements:

- iron - 85.3%;

- chromium - 12.8%;

- manganese - 0.44%;

- carbon - 0.24%;

- silicon - 0.2%.

Not all researchers give the lead in the discovery of the stainless flock to Harry Brierley. Some believe that stainless steel was discovered by Pierre Berthier, a French mining engineer. He discovered that certain compounds of iron and chromium, which can be found in nature, stand out for their high acid resistance. He was the first to suggest making dishes and cutlery from them.

Receiving technology

When processing parts, it is important to obtain the desired mechanical properties. Their combination is obtained thanks to two components:

- chemical composition;

- thermal and/or mechanical treatment - steel 08Х18Н10Т is no exception.

Stainless steel has features that combine plasticity, which makes it possible to roll out metal with a thickness of less than 1 mm, and strength, which is sufficient for the manufacture of critical utilities and parts operating under high pressure in highly aggressive environments.

Decoding stamps

The marking of alloy steels consists of letters and numbers. At the beginning there is a two-digit number that characterizes the amount of carbon in hundredths of a percent. The following are letters of the Russian alphabet, denoting a specific element:

- X – chromium;

- N – nickel,

- T – titanium;

- B – tungsten;

- G – manganese;

- M – molybdenum;

- D – copper.

After the letter designation of the alloying element in the decoding there is a number indicating its content in stainless steel, rounded to the nearest whole percent. If there is no such figure, then the additive in the alloy is in the range of 1-1.5%.

Stainless steel strength class A2, A4

For example, the designation on the head: A2-70, A4-70

Group Steel grade Diameters, in mm Strength class Tensile strength, N/mm2 Limit. yield N/mm2 Elongation at break, mm

| Austenitic | A2, A4 | up to M39 incl. | 50 | 500 | 210 | 0.6d |

| Austenitic | A2, A4 | up to M24 incl. | 70 | 700 | 450 | 0.4d |

| Austenitic | A2, A4 | up to 24 incl. | 80 | 800 | 600 | 0.3d |

Types of stainless steel and its classification

The entire variety of anti-corrosion steel types is divided into 5 large groups. The basis for this division is the microstructure of the material. Of these, representatives of the following 3 groups are most often found:

- Martensitic steel is distinguished by the letter “C” in the marking. It acquires its properties not only due to its composition, but also as a result of hardening and tempering. Applicable in the production of cutlery and cutting tools. Slightly magnetized, has increased hardness.

- Ferritic alloy is softer than martensitic alloy. Also endowed with magnetic properties. Its designation contains the letter “F”.

- Austenitic steel, containing 15-20% Cr and 5-15% Ni, is not magnetized and has the highest resistance to corrosion. Denoted by the letter "A". Steel grades from this group are most common in industrial production, as well as in the manufacture of hardware and fastening devices.

In turn, austenitic alloys are divided into 5 classes, additionally indicated by a digital value:

- A1 is the least resistant to corrosion due to the sulfur contained in the chemical composition. Used for the manufacture of parts for mechanical and moving units.

- A2 is steel that is resistant to moisture, but is not suitable for work in environments containing acids, alkalis, chlorine and salts. Ecologically harmless, not magnetized, not subject to hardening. Excellent for the manufacture of all types of fasteners intended for use in non-aggressive conditions.

- A3 - similar in properties to class A2 steel. However, this metal better resists corrosion in high-temperature environments, due to the stabilization of the alloy with niobium, titanium or tantalum.

- A4 - differs from A2 steel in the presence of molybdenum in an amount of 2-3%. This small additive gives the metal high resistance to acids, alkalis, and salts. Can operate in low temperatures, down to -60°C. A4 fasteners are intended for the construction of bridges and coastal structures. It is used in shipbuilding, chemical and oil and gas enterprises.

- A5 is steel stabilized with titanium, which makes it highly resistant to corrosion at high temperatures. Other technical characteristics are similar to class A4.

This is interesting: Hole diameter for metric threads: with and without a table.

In different countries, fasteners are produced according to different standards. In Russia these are GOST standards, in Germany – DIN, in the USA – AISI, in Europe – EN and international ISO. Many fasteners manufactured according to the standards of different countries are considered analogues. However, this is not entirely correct, since small differences still exist, if only due to the inconsistency of measurement systems. Therefore, it is better to entrust the replacement of fasteners when assembling structures that differ from those indicated in the drawings to specialists.

Types of stainless steel corrosion

Despite the name, high-alloy steel is still susceptible to corrosion if it is not used properly and is poorly maintained. The following types of environmental damage are possible for stainless steel:

- Crevice type corrosion occurs where a stainless steel element works in tandem with another material. An aggressive substance may leak between them, and oxygen access will stop. The oxide film is destroyed without restoration, and the metal begins to rust.

- Pitting corrosion, which affects stainless steel products with a matte surface. Damage begins with microscopic scratches or cracks. This kind of corrosion can be “cured” by high-quality grinding and polishing.

- Contact corrosion occurs when high-alloy parts are combined with low-carbon steel elements.

In welds, corrosion can be caused as a result of overheating or poor-quality processing of the joint.

Mechanical properties of the alloy

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Cold-deformed pipes, GOST 9941-81 | 549 | 37 | ||||||

| Pipes, GOST 10498-82 | 529 | 40 | ||||||

| Pipes, GOST 11068-81 | 530 | 216 | 37 | |||||

| Hot-deformed pipes, GOST 9940-81 | 510 | 40 | ||||||

| Rod, GOST 5949-75 | Ø 60 | 490 | 196 | 40 | 55 | Quenching 1020 - 1100oC, Air cooling, | ||

| The rod is cold-worked, GOST 18907-73 | 880-930 | |||||||

| The wire is annealed. | Ø 8 | 1400-1600 | 20 | |||||

| Forgings, GOST 25054-81 | 490 | 196 | 35-38 | 40-52 | ||||

| Thick sheet, GOST 7350-77 | 510 | 205 | 43 | Quenching 1030 - 1080oC, Air cooling, | ||||

| Thin sheet, GOST 5582-75 | 530 | 205 | 40 | Quenching 1050 - 1080oC, Cooling water, |

Stainless steel 08Х18Н10Т

Substitutes for steel 08Х18Н10Т

Substitute - in terms of corrosion resistance and heat resistance, the steel is close to steel grade 12Х18Н10Т

Foreign analogues

| Germany DIN | Brand | X6CrNiTi18-10 |

| Number | 1.4541 | |

| USA (AISI, SAE, ASTM) | 321 | |

| France (AFNOR) | Z6CN18-10 | |

| UK (BS) | 320S51 | |

| Sweden (SS) | 2337 | |

| Italy UNI | X6CrNiTi18-11 | |

IMPORTANT!!! The possibility of replacement is determined in each specific case after assessing and comparing the properties of steels

Interpretation of steel 8Х18Н10Т

The number 08 indicates the average carbon content in hundredths of a percent, i.e. for steel 08Х18Н10Т this value is 0.08%.

The letter “X” indicates the chromium content of the steel. The number 18 after the letter “X” indicates the approximate amount of chromium in steel as a percentage, rounded to the nearest whole number, i.e. chromium content about 18%.

The letter “N” indicates the nickel content of the steel. The number 10 after the letter “N” indicates the approximate amount of nickel in steel as a percentage, rounded to the nearest whole number, i.e. Nickel content is about 10%.

Type of delivery

Long products, including shaped steel: GOST 5949-75, GOST 2590-88, GOST 2591-88, GOST 2879-88. Calibrated rod GOST 7417-75, GOST 8559-75, GOST 8560-78. Polished rod and silver steel GOST 14955-77, GOST 18907-73. Thick sheet GOST 7350-77, GOST 19903-74, GOST 19904-90. Thin sheet GOST 5582-75. Tape GOST 4986-79. Strip GOST 4405-75, GOST 103-76. Forgings and forged blanks GOST 1133-71, GOST 25054-81. Pipes GOST 9940-81, GOST 9941-81, GOST 11068-81, GOST 10498-82, GOST 14162-79.

Weldability

Welding methods for steel 08Х18Н10Т: RDS, ADS under submerged arc and gas shield, ArDS, KTS and EShS.

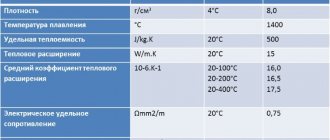

Physical properties

Density ρ at test temperature, 20 °C - 7900 kg/cm3 Modulus of normal elasticity E, GPa, at test temperature 20 °C - 196 GPa

Thermal conductivity coefficient λ W/(m*K) at test temperature, °C

| Steel | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 08Х18Н10Т | — | 16 | 18 | 19 | — | — | — | — | — | — |

Linear expansion coefficient α*106, K-1, at test temperature, °C

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 |

| 16,1 | — | 17,4 | — | 18,2 | — | 19,1 | — | — | — |

Chemical composition, % (GOST 5632-2014)

| WITH | Si | Mn | Cr | Ni | Ti | S | R |

| no more | no more | ||||||

| 0,08 | 0,8 | 2,0 | 17,0-19,0 | 9,0-11,0 | 5,0-0,7 | 0,020 | 0,04 |

Application 08Х18Н10Т

Steel 08Х18Н10Т is used for the manufacture of: welded equipment operating in highly aggressive environments (solutions of nitric, acetic acids, solutions of alkalis and salts), heat exchangers, muffles, pipes, parts of furnace fittings, electrodes of spark plugs. The steel is corrosion-resistant and heat-resistant austenitic class.

Application of steel 08Х18Н10Т for bodies, covers, flanges, membranes and valve assembly made from rolled products, forgings (stampings) (GOST 33260-2015)

| steel grade | ND for supply | Temperature of the working medium (wall), °C | Additional instructions for use |

| 08Х18Н10Т GOST 5632 | Long products GOST 5949, Sheets GOST 7350 M3b, M2b. Pipes GOST 9940, GOST 9941. Forgings GOST 25054 | -270 to 610 | For welded fittings operating in aggressive environments: HNO3, alkalis, ammonium nitrate, food media, special equipment media, ship fittings, cryogenic media, hydrogen sulfide-containing media; for membranes |

Application of steel 08Х18Н10Т for fittings fasteners (GOST 33260-2015)

| Steel grade, according to GOST 1759.0 | Material standard or specification | Application options | |||||

| Bolts, studs, screws | Nuts | Flat washers | |||||

| Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | ||

| 08Х18Н10Т | GOST 5632 | -196 to 600 | Not regulated | -196 to 600 | Not regulated | -196 to 600 | Not regulated |

Application of steel 08Х18Н10Т for the manufacture of spindles and rods (GOST 33260-2015)

| steel grade | ND for supply | Working environment temperature, °C | Additional instructions for use |

| 08Х18Н10Т GOST 5632 | Long products GOST 5949 | -270 to 610 | It is used for work in aggressive environments: nitric acid, alkalis, ammonium nitrate, food environments, environments of special equipment, shipbuilding, cryogenic equipment and hydrogen sulfide-containing environments. Used for welded joints |

Application of steel 08Х18Н10Т for bellows (GOST 33260-2015)

| steel grade | ND for supply | RD for the production of bellows | Working environment temperature, °C | Operating pressure Pp, MPa (kgf/cm2), no more | Additional instructions for use |

| 08Х18Н10Т GOST 5632 | Sheet GOST 5582. Tape GOST 4986, (for steel 1.4541) | GOST 21744, GOST 22388 | -260 to 550 | From 0.6 to 25.0 (from 6 to 250) | For water, steam, inert gases and cryogenic temperatures. For mildly aggressive environments - up to a temperature of 350°C. For corrosive environments - up to 150°C |

| Pipe GOST 10498. Pipe blank | -260 to 465 | From 0.15 to 3.10 (from 1.5 to 31.0) |

NOTE The table shows the limit values for temperatures and operating pressures. Specific combinations of application parameters (working pressure, axial stroke, temperature and full assigned life) are given in the regulatory documentation for bellows.

Application of steel 08Х18Н10Т for valve valve assembly

| steel grade | Working environment temperature, °C | Hardness | Additional instructions for use |

| 08Х18Н10Т GOST 5632 | -100 to 300 | 155…170 HB | The functionality of the valve assembly is ensured by the presence of surfacing or other wear-resistant coating in the mating part |

Application of steel 08Х18Н10Т for gaskets

| steel grade | Type of semi-finished product | Application temperature, °C | Additional instructions for use | |

| Name | ND for supply | |||

| 08Х18Н10Т GOST 5632 | Thick heat-treated sheets | GOST 7350 | -253 to 600 | Suitable for use in corrosive environments |

Resistance of steel 08Х18Н10Т to sulfide corrosion cracking

| Method of forming blanks | Name of parts |

| Forgings, stampings, rolled products | Body, bonnet, stem, spindle, valve seal parts, bellows end parts |

Maximum permissible temperature for using steel 08Х18Н10Т in environments containing ammonia

| steel grade | Temperature of application of steels, °C at partial pressure of ammonia, MPa (kgf/cm) | ||

| St. 1(10) to 2(20) | St. 2(20) to 5(50) | St. 5(50) to 8(80) | |

| 08Х18Н10Т | 540 | 540 | 540 |

Maximum permissible temperature for the use of steel 08Х18Н10Т in hydrogen-containing environments

| steel grade | Temperature, °C, at partial pressure of hydrogen, PH2, MPa (kgf/cm2) | ||||||

| 1,5(15) | 2,5(25) | 5(50) | 10(100) | 20(200) | 30(300) | 40(400) | |

| 08Х18Н10Т | 510 | 510 | 510 | 510 | 510 | 510 | 510 |

NOTE

- The parameters for using steels indicated in the table also apply to welded joints.

- The partial pressure of hydrogen is calculated by the formula: PH2 = (C*Pp)/100, where C is the percentage in the system; PH2—hydrogen partial pressure; Pp is the operating pressure in the system.

Resistance of steel 08Х18Н10Т against crevice erosion

| Durability group | Point | Erosion resistance against steel 12X18H10T |

| Persistent | 2 | 0,75-1,5 |

Application of steel 08Х18Н10Т for the manufacture of main parts of nuclear power plant fittings

| steel grade | Type of semi-finished product or product | Maximum permissible temperature of use, °C |

| 08Х18Н10Т GOST 5632, GOST 24030 | Sheets, pipes, forgings, long products. Fasteners | 600 |

Mechanical properties

| GOST | Delivery status | Széchenyi | σ0.2, MPa | σв, MPa | δ5, % | ψ% |

| no less | ||||||

| GOST 5949-75 | Bar. Quenching from 1020-1100 °C in air, oil or water | 60 | 196 | 490 | 40 | 55 |

| GOST 18907-73 | Ground rod, processed to a specified strength | 1-30 | — | 590-830 | 20 | — |

| GOST 7350-77 (transverse samples) | Hot-rolled and cold-rolled sheets: hardening from 1000-1080 °C in water | St. 4 | 206 | 509 | 43 | — |

| GOST 5582-75 (transverse samples) | hardening from 1050-1080 °C in water or air | Up to 3.9 | — | 520 | 40 | — |

| GOST 25054-81 | Forging. Hardening from 1050-1000 °C | 196 | 490 | 35 | 40 | |

| GOST 9940-81 | Seamless hot-deformed pipe without heat treatment | 3,5-32 | — | 510 | 40 | — |

Impact strength of rods with a cross section of 12 mm

| Heat treatment | KS, J/cm, at temperature, °C | |

| +20 | -25 | |

| Quenching at 1050 °C in water | 216/187 | 181/147 |

Note.

The numerator is KCV; the denominator is KST.

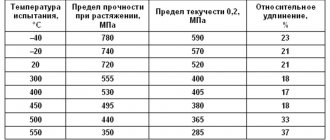

Mechanical properties at elevated temperatures

| tsp, °С | σ0.2, MPa | σв, MPa | δ5, % | ψ% | KCU, J/cm2 |

| 20 | 275 | 610 | 41 | 63 | 245 |

| 300 | 200 | 450 | 31 | 65 | — |

| 400 | 175 | 440 | 31 | 65 | 313 |

| 500 | 175 | 440 | 29 | 65 | 363 |

| 600 | 175 | 390 | 25 | 61 | 353 |

| 700 | 160 | 270 | 26 | 59 | 333 |

Mechanical properties during long-term strength testing

| tsp, °С | Creep limit, MPa | Creep rate, %/h |

| 600 | 74 | 1/100000 |

| 650 | 29-39 |

| tsp, °С | C Long-term strength limit, MPa | τ, h |

| 600 | 147 | 10000 |

| 108 | 100000 | |

| 650 | 78-98 | 10000 |

Technological properties

Forging temperature, °C: beginning 1220, end 900. Sections up to 300 mm are cooled in air.

Find out more

Stainless steel 12Х18Н10Т

Steel 14Х17Н2 (EI268)

Steel 40Х13 is corrosion-resistant…

Steel 20Х13 is corrosion-resistant, heat-resistant, open-hearth...

Chemical composition

Steel is an alloy of carbon and iron, in which the iron atoms are located in a crystal lattice, and the remaining elements, depending on their size and behavior, change it. In terms of carbon concentration, steel 08Х18Н10Т is a highly alloyed carbon alloy. Where the main alloying elements are chromium, nickel and titanium.

The basic rule of metallurgy on which changes in strength are based is: “Distortion of the structural lattice increases strength.” Thus, a carbon atom, which has a size much smaller than an iron atom, penetrates into the crystal lattice and distorts it, giving it strength. Other elements that can replace iron atoms and exhibit properties characteristic of each of them also merge in the same way.

Chrome is the hardest metal in existence. At a concentration of more than 13% it imparts corrosion resistance. How does this happen. By reacting with an oxygen atom, chromium creates an oxide film only a few atoms in size. The oxides are not much larger in size than the chromium atom itself (unlike iron oxides, which have a 3-volume), so it creates a dense shell on the surface itself, preventing the penetration of oxygen and other gases. This protection works even when heated. If such a film is scratched, new oxides immediately form in its place. This process is called patenting.

In difficult temperature operating conditions, where steel experiences constant temperature loads, chromium carbides are formed along the grain boundaries, which leads to the destruction of the metal, i.e. intergranular corrosion. To eliminate this process, nickel is added to the alloy, which is an austenite stabilizer, preserving this structure at room temperature (for comparison: in conventional carbon steels, the temperature of transformation of austenite into more stable structures is 650-750 ºC).

Titanium is added to the alloy in an amount of 0.6% and contributes to the stability of 08Х18Н10Т in aggressive environments.

08Х18Н10Т: steel characteristics, interpretation, analogues

Food grade stainless steel or steel 08Х18Н10Т belongs to chromium-nickel alloys of the austenitic class. The main features for which the brand is valued are heat resistance and heat resistance, as well as corrosion resistance in highly aggressive environments at high temperatures. The characteristics of steel allow it to be used in a wide range of jobs where:

- corrosion resistance at temperatures up to 800 ºC;

- corrosion resistance in highly aggressive environments in the temperature range -196 to 600 ºC;

- high ductility and ability to deform by cold and hot rolling;

- high impact strength;

- High weldability and machinability.

First of all, these are parts that are produced by stamping and/or turning. The lion's share of products made from steel 08Х18Н10Т are pipes and containers for the oil refining and chemical industries.

Receiving technology

When processing parts, it is important to obtain the desired mechanical properties. Their combination is obtained thanks to two components:

- chemical composition;

- thermal and/or mechanical treatment - steel 08Х18Н10Т is no exception.

Stainless steel has features that combine plasticity, which makes it possible to roll out metal with a thickness of less than 1 mm, and strength, which is sufficient for the manufacture of critical utilities and parts operating under high pressure in highly aggressive environments.

Decoding

Russian steel marking determines the chemical composition. It indicates the main alloying elements that largely influence the character of the alloy. In this case, the marking 08Х18Н10Т determines the content:

- carbon – 0.8%;

- chromium – 18%;

- nickel – 10;

- titanium – 0.4-0.6%;

- silicon and manganese (by default, they are not indicated in the labeling) - up to 0.8 (practically, the manganese content is always higher)

Analogs

In the standards of other countries, this brand may have the following markings:

- America – AISI 304; 321;

- Japan - SUS321;

- Germany - 1.4541;

- China - 2337.

The Russian analogues are two types of alloys:

- with the addition of molybdenum - 10Х17Н13М2Т, 10Х17Н13М2 (without titanium); 10Х17Н13М3Т (with an increase in molybdenum to 3%);

- without Ti - 08Х18Н9 or with nickel content up to 10;

- a cheaper analogue that is corrosion resistant at normal temperatures and slightly aggressive environments is 12X17.

Chemical composition

Steel is an alloy of carbon and iron, in which the iron atoms are located in a crystal lattice, and the remaining elements, depending on their size and behavior, change it. In terms of carbon concentration, steel 08Х18Н10Т is a highly alloyed carbon alloy. Where the main alloying elements are chromium, nickel and titanium.

The basic rule of metallurgy on which changes in strength are based is: “Distortion of the structural lattice increases strength.”

Thus, a carbon atom, which has a size much smaller than an iron atom, penetrates into the crystal lattice and distorts it, giving it strength.

Other elements that can replace iron atoms and exhibit properties characteristic of each of them also merge in the same way.

Chrome is the hardest metal in existence. At a concentration of more than 13% it imparts corrosion resistance. How does this happen. By reacting with an oxygen atom, chromium creates an oxide film only a few atoms in size.

The oxides are not much larger in size than the chromium atom itself (unlike iron oxides, which have a 3-volume), so it creates a dense shell on the surface itself, preventing the penetration of oxygen and other gases. This protection works even when heated.

If such a film is scratched, new oxides immediately form in its place. This process is called patenting.

In difficult temperature operating conditions, where steel experiences constant temperature loads, chromium carbides are formed along the grain boundaries, which leads to the destruction of the metal, i.e. intergranular corrosion.

To eliminate this process, nickel is added to the alloy, which is an austenite stabilizer, preserving this structure at room temperature (for comparison: in conventional carbon steels, the temperature of transformation of austenite into more stable structures is 650-750 ºC).

Titanium is added to the alloy in an amount of 0.6% and contributes to the stability of 08Х18Н10Т in aggressive environments.

Heat treatment

But it is not enough to obtain an alloy with a given chemical. composition, it is much more important to obtain the desired mechanical properties of the 08Х18Н10Т alloy. To obtain a stable structure and stabilize austenite in the finished product, the steel is subjected to hardening at a temperature of 1020-1100ºC followed by low-temperature tempering.

Additional advantages 08Х18Н10Т

- High ductility, which is used for the manufacture of thin-walled parts;

- Excellent weldability, which does not require heating and subsequent tempering of the weld;

- High machinability with milling tools;

- Absolute inertness to food products;

- And of course, the price, or more precisely the ratio of price and capabilities - all this makes 08Х18Н10Т steel accessible and widespread in everyday life.

Physical properties of steel 08x18n10t

Stainless steel 08x18n10t has good weldability. Recommended welding methods are manual arc welding, argon-arc welding in a protective gas environment with a tungsten electrode, spot welding, ESW.

In an unhardened state, this grade of steel is prone to intergranular corrosion. The recommended maximum temperature at which it is possible to operate steel 08x18n10t without changing the mechanical properties is 800°C.

Steel 08x18n10t is well polished, including to a mirror finish.

Physical properties of steel 08x18n10

Stainless steel 08x18n10 is an austenitic type steel that belongs to the class of corrosion-resistant, heat-resistant steels. The operating temperature range of stainless steel 08x18n10 without changing the basic properties is from -196 to +600 °C.

Hardening of stainless steel 08x18n10 is carried out at 1020 – 1100°C

Weldability of steel: without restrictions.

Table of physical properties 08x18n10

Heat treatment

But it is not enough to obtain an alloy with a given chemical. composition, it is much more important to obtain the desired mechanical properties of the 08Х18Н10Т alloy. To obtain a stable structure and stabilize austenite in the finished product, the steel is subjected to hardening at a temperature of 1020-1100ºC followed by low-temperature tempering.

Additional advantages 08Х18Н10Т

- High ductility, which is used for the manufacture of thin-walled parts;

- Excellent weldability, which does not require heating and subsequent tempering of the weld;

- High machinability with milling tools;

- Absolute inertness to food products;

- And of course, the price, or rather the ratio of price and capabilities - all this makes 08Х18Н10Т steel accessible and widespread in everyday life.

This is interesting: At what angle to sharpen drills for metal. Sharpening options that can be done by hand

Corrosion-resistant, heat-resistant steel 08Х18Н10 - supplier's guide

/ Directory of rolled metal / Steel brand /

Corrosion-resistant, heat-resistant steel

Characteristics of material 08Х18Н10

| Brand: | 08Х18Н10 |

| Classification: | Corrosion-resistant, heat-resistant steel |

| Application: | pipes, furnace fittings parts, heat exchangers, muffles, retorts, pipes, exhaust system manifolds, spark plug electrodes, welding apparatus and chemical engineering vessels operating at temperatures from -196 to 600 °C in medium activity environments. |

Chemical composition in % of material 08Х18Н10.

| C | Si | Mn | Ni | S | P | Cr | Ti | Cu |

| up to 0.8 | up to 0.8 | up to 0.2 | 9-11 | up to 0.02 | up to 0.035 | 17-19 | up to 0.5 | up to 0.3 |

Mechanical properties at T=20

oC of material 08Х18Н10.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Bar | F 60 | 470 | 196 | 40 | 55 | Hardening 1020-1100oC, |

Physical properties of material 08Х18Н10.

| T | E 10-5 | a106 | l | r | C | R 109 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 1.96 | 17 | 7850 | 800 | ||

| 100 | 16.0 | 504 | ||||

| 200 | 17.0 | |||||

| 300 | 17.0 | |||||

| 400 | 18.0 | |||||

| 500 | 18.0 |

Technological properties of material 08Х18Н10.

| Weldability: | no limits. |

Designations:

| Mechanical properties: | ||

| sв | — Short-term strength limit, [MPa] | |

| sT | — Proportional limit (yield strength for permanent deformation), [MPa] | |

| d5 | — Elongation at break, [%] | |

| y | — Relative narrowing, [%] | |

| KCU | — Impact strength, [kJ/m2] | |

| HB | — Brinell hardness | |

| Physical properties: | ||

| T | — Temperature at which these properties were obtained, [degrees] | |

| E | — Modulus of elasticity of the first kind, [MPa] | |

| a | — Coefficient of thermal (linear) expansion (range 20o - T), [1/degree] | |

| l | — Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] | |

| r | — Material density, [kg/m3] | |

| C | — Specific heat capacity of the material (range 20o — T), [J/(kg deg)] | |

| R | — Electrical resistivity, [Ohm m] | |

| Weldability: | |

| no limits | — welding is performed without heating and without subsequent heat treatment |

| limited weldability | — welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | — to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

www.scmetal.ru

Purpose of stainless steels

Corrosion-resistant steel is an alloy that is resistant to corrosion. The chromium content in the chemical composition is 10.5-11%. Combining with oxygen, the component forms an oxide film. Having received minor mechanical damage, the protective barrier is able to recover.

Most of the alloy consists of iron. The addition of carbon up to 1.2% ensures tensile strength. To obtain other beneficial properties, alloying additives are added: titanium, phosphorus, molybdenum, sulfur, nickel, niobium, cobalt. One of the frequently used grades of stainless steel is 12x18n10t.

The disadvantages of stainless steel include high cost and poor machinability. The advantages are the following:

- resistance to corrosion;

- high strength, load resistance;

- good weldability;

- service life – 20-50 years;

- preservation of properties;

- resistance to aggressive environments;

- attractive appearance - does not require painting.

The listed characteristics ensure the use of stainless steels in a wide variety of areas. The material is used to produce pipeline fittings, cutlery, cars, airplanes, spaceships, medical instruments, etc. Among the areas of application:

- mechanical engineering;

- chemical, pulp and paper, food industry;

- architecture;

- electric power industry;

- aircraft manufacturing;

- medicine and healthcare.

Stainless steel piping parts

Weldability of steel 08Х18Н10

Metal can be welded using almost any modern method. Before welding, the alloy does not need to be heated, and after welding, the seams do not need to be heat treated. Some experts recommend additional annealing (as a preventive measure for intergranular corrosion); in this case, the alloy needs immediate cooling. The cooled seam should be treated with etching paste and cleaned of scale. The resulting seam is durable and corrosion resistant (due to the presence of nickel).

The main advantages of the alloy

Stainless steel grade 08Х18Н10Т is manufactured in accordance with the requirements of GOST 5632-72. It has high ductility, allowing it to easily produce thin-walled parts. When welding, it does not require preheating and subsequent cooling of the weld. The metal can be perfectly processed using any milling equipment.

Pots, pans and other utensils can be made from it. And due to the affordable price, the cost of such dishes turns out to be very affordable.

Stainless steel sheets 08Х18Н10

| Name | Short description | Full description | Price |

| Food grade stainless steel sheet St08Х18Н10 | 0.5x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Food grade stainless steel sheet St08Х18Н10 | 0.5x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Food grade stainless steel sheet St08Х18Н10 | 0.6x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Food grade stainless steel sheet St08Х18Н10 | 0.6x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Food grade stainless steel sheet St08Х18Н10 | 0.7x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Food grade stainless steel sheet St08Х18Н10 | 0.7x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Food grade stainless steel sheet St08Х18Н10 | 0.8x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Food grade stainless steel sheet St08Х18Н10 | 0.8x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Food grade stainless steel sheet St08Х18Н10 | 1x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 1x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 1.2x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 1.2x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 1.4x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 1.4x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 1.5x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 1.5x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| To check availability and price, call: (351) 248-46-94 or send a request to | |||

| Stainless steel sheet St08Х18Н10 | 2x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 2x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 2.5x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 2.5x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 3x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 3x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 4x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 4x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 4x1000x4000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 5x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 5x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 5x1000x4000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 5x1500x6000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 6x1000x2000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 6x1250x2500 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 6x1000x4000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 6x1500x6000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Stainless steel sheet St08Х18Н10 | 7x1500x6000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| Food grade stainless steel sheet St08Х18Н10 | 8x1500x6000 | Sheets are manufactured according to GOST 5582-75, GOST 19904-90 and GOST 7350-77, GOST 19903-74. | on request |

| To check availability and price, call: (351) 248-46-94 or send a request to | |||

spec-stali.ru

Analogs

In the standards of other countries, this brand may have the following markings:

- America – AISI 304; 321;

- Japan - SUS321;

- Germany - 1.4541;

- China - 2337.

The Russian analogues are two types of alloys:

- with the addition of molybdenum - 10Х17Н13М2Т, 10Х17Н13М2 (without titanium); 10Х17Н13М3Т (with an increase in molybdenum to 3%);

- without Ti - 08Х18Н9 or with nickel content up to 10;

- a cheaper analogue that is corrosion resistant at normal temperatures and slightly aggressive environments is 12X17.

Application of carbon steels

The mechanical properties of carbon steels are affected by the percentage of carbon. Based on this indicator, the following types of carbon steel are distinguished:

- low-carbon – carbon content up to 0.25%;

- medium carbon – 0.3-0.6%;

- high-carbon – 0.6-2%.

The amount of other elements (manganese, magnesium, silicon, etc.) in alloys is limited. There are no alloying components.

The main disadvantage of the material is its susceptibility to rust upon contact with air and moisture. At the same time, pipeline parts and shut-off valves are produced from carbon steel. In addition, smaller items: nails, wire, screws, gears, flywheels, crankshafts, drills, forging tools, etc.

The areas of application of alloys are regulated by regulatory documents. Ordinary quality steel - GOST 380-85; structural – GOST 380-88; instrumental - GOST 1435-54 and 5952-51.

The Art. brand is in demand in production. 20, high quality construction. It is used in construction and mechanical engineering, in the construction of pipeline systems.

Advantages:

- low price;

- good weldability;

- pliability to cold and hot processing;

- resistance to high temperatures.

Rolled steel

Forging 08Х18Н10Т – MEKOM

| Name (Changable size | Remaining (kg) |

| Circle 08Х18Н10Т Ф160 (1150mm) | 175 |

| Circle 08Х18Н10Т Ф160 (1120mm) | 178 |

| Circle 08Х18Н10Т Ф170 (4320mm) | 776 |

| Forging 08Х18Н10Т Ф180 (1000mm, UZK) | 410 |

| Circle 08Х18Н10Т Ф200 (360mm, t/o, mechanical) | 105 |

| Wheel 08Х18Н10Т Ф200 (1140mm, t/o, mechanical) | 293 |

| Forging 08Х18Н10Т Ф205 (430mm, mechanical) | 116 |

| Forging 08Х18Н10Т Ф235 (800mm, t/o, machining) | 274 |

| Forging 08Х18Н10Т Ф235 (1120mm, t/o, machining) | 391 |

| Forging 08Х18Н10Т Ф235 (1070mm, t/o, machining) | 373 |

| Circle 08Х18Н10Т Ф260 (50mm, mechanical) | 26 |

| Forging 08Х18Н10Т Ф263 ((260), 240mm, t/o, machining, MSK) | 104 |

| Forging 08Х18Н10Т Ф270 (450mm, UZK) | 216 |

| Forging 12Х18Н10Т Ф275 (45mm, mechanical) | 24 |

| Forging 08Х18Н10Т Ф345 (525mm, mechanical) | 146 |

| Forging 08Х18Н10Т Ф398 (775mm, mechanical) | 770 |

| Forging 08Х18Н10Т Ф410 (1840mm, machining, UZK 2p gr.) | 1 990 |

| Forging 08Х18Н10Т Ф440 (25mm, machining, UZK 2p gr.) | 32 |

| Forging 08Х18Н10Т Ф449 (100mm, mechanical) | 125 |

| Forging 08Х18Н10Т Ф450 (100mm, mechanical) | 120 |

| Forging-ring St 08Х18Н10Т Ф470ф195*140 (UZK) | 170 |

| Forging 08Х18Н10Т Ф475 (780mm, mechanical) | 390 |

| Forging 08Х18Н10Т Ф503 ((500), 100mm, machining, ultrasonic testing) | 161 |

| Forging 08Х18Н10Т Ф545 (1140mm, mechanical) | 2 122 |

| Wheel 08Х18Н10Т Ф550 (30mm, mechanical) | 60 |

| Forging - ring St 08Х18Н10Т Ф600ф100*150 | 390 |

| Forging 08Х18Н10Т Ф610 (3350mm, peeling, MKK, SFF, Co up to 0.2, non-metallic incl., ultrasonic testing) | 7 730 |

| Forging 08Х18Н10Т Ф610 (2400mm, roughing, MKK, SFF, Co up to 0.2, non-metallic incl.) | 5 508 |

| Forging - ring St 08Х18Н10Т Ф630ф440*210 | 294 |

| Forging 08Х18Н10Т Ф650 (3030mm, peeling, MKK, SFF, Co up to 0.2, non-metallic incl., ultrasonic testing) | 7 785 |

| Forging 08Х18Н10Т Ф650 (2540mm, peeling, MKK, SFF, Co up to 0.2, non-metallic incl., ultrasonic testing) | 6 498 |

| Forging - ring St 08Х18Н10Т Ф660ф560*150 | 130 |

| Forging 08Х18Н10Т Ф700 (130mm, machining, UZK 4p gr.) | 410 |

| Forging St 08Х18Н10Т-У Ф740 (210mm) | 745 |

| Forging - ring St 08Х18Н10Т Ф790ф660*140 | 180 |

| Forging 08Х18Н10Т Ф795 (100mm, mechanical) | 394 |

| Forging 08Х18Н10Т Ф810 (160mm, УЗК-2п) | 770 |

| Forging - ring St 08Х18Н10Т Ф900ф280*110 | 620 |

| Forging 08Х18Н10Т Ф1040 (350mm, UZK) | 2 785 |

| Forging 08Х18Н10Т Ф1300 (225mm, УЗК-4п) | 2 400 |

| Forging St 08Х18Н10Т 60х ((70), 140(150)х450) | 40 |

| Sheet 08Х18Н10Т 60х (130х150) | 12 |

| Forging St 08Х18Н10Т 65х (130х310) | 25 |

| Sheet 08Х18Н10Т 70х (100х150) | 9 |

| Forging St 08Х18Н10Т 80х (130х180) | 18 |

| Forging St 08Х18Н10Т 80х (115х130) | 10 |

| Sheet 08Х18Н10Т 80х (80х310) | 20 |

| Forging St 08Х18Н10Т 110х (130х230) | 27 |

| Forging St 08Х18Н10Т 140х (280х2940) | 1 010 |

| Forging St 08Х18Н10Т 150х (280х2410) | 860 |

| Forging St 08Х18Н10Т 160х (290х3000) | 1 070 |

| Forging St 08Х18Н10Т 160х (210х1940) | 520 |

| Forging St 08Х18Н10Т 170х (300(280)х3100) | 1 220 |

| Forging St 08Х18Н10Т 175х (410х510, UZK) | 337 |

| Forging St 08Х18Н10Т 180х (420х540, UZK) | 362 |

| Forging St 08Х18Н10Т-Э 200х (235х1150) | 439 |

xn--35-6kch3bbzbg.xn--p1ai

Which is better: carbon steel or stainless steel?

Stainless steel is used:

- in the energy and chemical industries when working with aggressive environments;

- in medicine, aircraft manufacturing, where durability and increased strength of instruments are required;

- in construction and other areas where the type of parts plays an important role.

Carbon steel is needed there:

- where a lot of durable material is required - for example, in the construction of pipelines;

- where there is no need for improved metal properties - in particular, in the production of small parts of mechanisms and tools.

The considered types of steel cannot be placed in the same row. Materials are selected based on the project budget and area of application.

What is unique about stainless steels?

Stainless steel was patented in England in 1913. The author of this invention, which, without exaggeration, became the most important stage in the development of not only steel, but also other industries, is metallurgist Harry Brearley.

The addition of an element such as chromium to their chemical composition made it possible to endow ordinary steel alloys with unique characteristics and obtain corrosion-resistant steels from them.

It is chromium, which must be at least 10.5% in stainless steel alloys, that provides these materials with such characteristics as:

- exceptionally high corrosion resistance;

- very high strength;

- good weldability;

- ease of processing using cold deformation methods;

- long service life without loss of original characteristics;

- aesthetically attractive appearance of products made from alloys of this category.

Influence of alloying elements on the properties of steels

Stainless steels necessarily contain chromium and iron in their chemical composition. These elements complement each other, which is what gives these materials such unique characteristics. In particular, chromium, combining with oxygen, creates an oxide film on the surface of the stainless alloy, which becomes a reliable obstacle to corrosion processes.

In order to provide stainless steel with additional characteristics and significantly improve existing properties, alloying additives are introduced into its chemical composition - nickel, titanium, molybdenum, niobium, cobalt, etc. This alloying makes it possible to create various types of stainless steel alloys that differ from each other their characteristics and, accordingly, purpose.

This is interesting: How to distinguish between brass and bronze - proven methods

We are already so accustomed to corrosion-resistant steel that we don’t even notice how much more comfortable our lives have become due to the presence of stainless steel in it.

Stainless steel contains carbon in its chemical composition, which gives it high hardness and strength. It should be noted that this chemical element is an essential component of any steel alloy and has a serious impact on its properties.

The unique characteristics of stainless steel make it possible to successfully use this metal in a variety of areas related to the operation of products and equipment in conditions of high humidity and constant exposure to aggressive environments. Stainless steels are actively used for the production of products for both industrial and household purposes. In particular, it is from this metal that cutlery and knives are most often made, elements of communications and enclosing structures, equipment parts, etc.

Stainless steel tape 08Х18Н10Т

Steel 08Х18Н10Т for strip production

Tape 08Х18Н10Т is made of steel with the addition of titanium, which significantly affects its strength characteristics. Stainless steel 08Х18Н10Т, or AISI 304 - in accordance with the international classification, belongs to the main grades of these metal alloys.

The main distinguishing qualities of this steel are its formability, toughness, impeccable mechanical characteristics and high resistance to rust formation. Chromium is the main element that makes up this steel. It determines the degree of its resistance to oxidation. The excellent low temperature properties of this metal alloy make it widely used in industry.

Application of tape 08Х18Н10Т

Stainless steel tape 08Х18Н10Т is used for the production of various industrial equipment. Chemical industry enterprises use these products to create equipment, the main purpose of which is the storage and transportation of reactive substances.

In the food industry, 08Х18Н10Т tape serves as a material for creating containers used for the production, transportation and storage of dairy products, wine, kvass, etc. Kitchen and tableware can also be made from this tape.

Thanks to its excellent performance characteristics, stainless steel strip 08Х18Н10Т has become one of the most popular types of stainless steel products by enterprises. A huge number of household items and parts and spare parts used in industry are made from this stainless steel tape 08Х18Н10Т.

Sale of stainless tape 08Х18Н10Т

It is very convenient to use these products in production due to their supply in rolls. This also makes it easier to calculate the required amount of material. You can always buy stainless steel tape 08Х18Н10Т in our company! Contact our managers for additional information, and they will help you place an order for the products you are interested in, not only stainless steel, but also non-ferrous and ferrous metal products. Call!

www.alfa-sous.ru

The most popular brands and areas of their application

To choose the right stainless steel for the manufacture of products for a specific purpose, you can use special reference books that list both all grades of such material and their main characteristics. Meanwhile, in each of these groups there are the most popular brands, which are most often chosen by the consumer. Let's list them.

- 10Х17Н13М2Т and 10Х17Н13М3Т are steels that are characterized by good weldability and excellent corrosion resistance. Thanks to these properties, stainless steel alloys of these grades are successfully used for the production of products that, during their operation, are constantly exposed to high temperatures and aggressive environments. The properties of steels of these grades are formed due to the presence in their chemical composition of the following elements: chromium (16–18%), molybdenum (2–3%), nickel (12–14%), carbon (0.1%), silicon (0 .8%), copper (0.3%), sulfur (0.02%), phosphorus (0.035%), manganese (2%), titanium (0.7%). If there is a need to select stainless steels of these grades, then you should keep in mind that their foreign analogues can also be purchased on the domestic market, namely: SUS316Ti (Japan), 316Ti (USA), OCr18Ni12Mo2Ti (China), Z6CNDN17-12 (France) ).

- 08Х18Н9 and 08Х18Н10 are stainless steel alloys from which pipes of both round and any other cross-section are made. These materials are used for the production of various structures used in the mechanical engineering and chemical industries, as well as for the production of pipeline elements and furnace devices. The chemical composition of these grades of steel contains the following elements: chromium (17–19%), carbon (0.8%), titanium (0.5%), nickel (8–10%).

- 10Х23Н18 - steel of this grade is characterized by a high content of nickel (17–20%) and chromium (22–25%), as well as manganese (2%) and silicon (1%) in its composition. This combination of elements gives the alloy the required characteristics and creates an increased tendency to temper brittleness. It should be noted that the alloy of this grade belongs to stainless steels of the heat-resistant category.

- 08Х18Н10Т - a stainless alloy of this brand is characterized by high resistance to oxidation processes, as well as good weldability, and to obtain a high-quality connection using this technology, the products do not need to be preheated, and they also do not require heat treatment after welding. To improve the strength characteristics of products made from such steel, they must be hardened, as specified in the relevant regulatory document.

- 06ХН28МДТ - an alloy of this grade is optimally suited for creating welded structures that will subsequently be used in aggressive environments. The chemical composition of this steel contains the following elements: chromium (22–25%), nickel (26–29%), copper (2.5–3.5%).

- 12Х18Н10Т – products made from steel of this grade are mainly used to equip enterprises in the chemical, pulp and paper, construction, food and fuel industries. This metal is characterized by thermal resistance, good impact strength and practicality of use.

- 12Х13, 20Х13, 30Х13 and 40Х13 – stainless steel alloys of these grades are practically impossible to weld, but they also have positive properties. The latter lies in the fact that these steels do not have a tendency to temper brittleness, and their internal structure is not affected by defects, which in professional language are called flakes. Cutting and measuring tools, as well as springs and springs for various purposes are made from these grades of stainless steel.

- 08Х13, 08Х17, 08Х18Т1 are stainless steel alloys of the ferritic group, from which products are produced that do not experience shock loads during operation, as well as exposure to low temperatures.

Types of stainless steel surfaces

Features of care

There is no need to follow any special rules for caring for stainless steel. Dirt can be wiped off with a damp cloth and detergent. It is important not to use hard brushes to maintain the integrity of the surfaces.

Stainless steel is used in various fields of activity. To obtain alloys with modified properties, they are saturated with alloying additives. Metal can be used in non-standard areas.

Sources

- https://metalloy.ru/metally/nerzhaveyka

- https://prompriem.ru/stati/stal-08x18n10t.html

- https://www.navigator-beton.ru/articles/marki-nerzhaveyushhej-stali.html

- https://svm24.ru/articles/oboznacheniya_marok_nerzhaveyushchikh_staley/

- https://traiv-komplekt.ru/articles/vidy-nerzhaveyushchey-stali-i-ee-primenenie-v-proizvodstve-krepezha/

- https://ScrapTraffic.com/splav/08x18n10t/

- https://intehstroy-spb.ru/spravochnik/nerzhaveyuschaya-stal-marki-08h18n10t.html

- https://www.chelarm.ru/articles/chem-otlichaetsya-uglerodistaya-stal-ot-nerzhaveyushchey/

- https://svarkaipayka.ru/material/stal/tehnicheskie-harakteristiki-stali-08h18n10t.html

- https://met-all.org/metalloprokat/nerzhaveyushhij/nerzhaveyushhaya-stal-sostav-vidy-svojstva-korrozionnostojkaya.html

Application of stainless steel 08x18n10

Stainless steel 08x18n10 (food grade stainless steel) is used in all sectors of industry and the national economy.

Pipe 08x18n10 is used in the design of pipeline systems for various purposes, including for food production. Thick-walled round pipe 08x18n10 is used in the construction of load-bearing structures. Polished and mirror pipes 08x18n10 act as a material for the production of railings, stair railings, balconies, and handrails. In addition, mirror pipes made of this stainless steel are used to decorate entrance areas.

Stainless steel sheet 08x18n10 is used in the manufacture of containers and reservoirs, including for the food industry, refrigeration, washing and disinfection chambers, equipment elements in contact with moderately aggressive materials, industrial metal furniture (tables, cabinets, shelving). Decorative and mirror sheets 08x18n10 can be used for finishing elevator cabins, escalators, and so on.

In addition, due to its heat resistance, stainless steel 08x18n10 is used in the construction of low-temperature furnaces, elements of furnace fittings, is used for the production of shut-off pipeline valves (fittings, bends, flanges), for the manufacture of vessels and apparatus for the chemical industry, which operate at temperatures from -196 to 600°C.

Rating: 9.50/10 — 71 votes