Character traits

When C345 is exposed to a temperature of 20 °C, the steel is endowed with a short-term strength of 490 MPa, a fluidity of 345 MPa and an elongation at break of 15%. And the thicker the alloy, the lower these indicators will be. However, the elongation will increase to 21%. Rolled metal itself can be produced in 4 classifications, each of which has certain test indications: 1st and 3rd have impact strength at T = -40 °C, but at T = -70 °C such properties disappear. The 2nd and 4th categories are endowed with opposite indicators. As for viscosity after mechanical aging, they can only be observed in grades 4 and 3 of steel.

Properties of steel C345

Such characteristics make it possible to produce complex building structures that can withstand extreme loads. The lowest alloy ingot can be used to make fences and enclosures of any size, water pipes for various liquids, tanks for storing emulsions and other products for typical applications. Also, due to its resistance to aggressive factors, steel is often used in mechanical engineering to create elements of cranes, rails, and power line supports.

Chemical elements and manufacturing technology

Each spare part contains many chemical components, the proportions of which will determine the quality of the future workpiece. If we talk about C345, then it includes 10 components, each of which plays an important role:

- Carbon (C) – no more than 0.15. It is added to any low-alloy ingot to increase strength. This effect occurs due to the release of carbides; however, an increase in hardness negatively affects the ductility and weldability of the object.

- Silicon (Si) – up to 0.8%. It is the main deoxidizing agent, the content of which will determine the quality of the finished product. Si also provides better hardenability of objects.

- Manganese (Mn) – 1.3-1.7%. It is added to the joint of almost any ingot to remove oxygen. Its properties have a beneficial effect on the future weldability of parts.

- Nickel (Ni), Chromium (Cr), Copper (Cu) – about 0.3%. These three elements protect the plane from rust and increase the elasticity of the metal as the thermal state increases.

- sulfur (S) – 0.04%. It has a negative effect on weldability, but this component is necessary for further mechanized finishing.

- Phosphorus (P) – 0.035%. Reduces ductility, but increases resistance to brittleness at low temperatures.

- Nitrogen (N) – 0.012%. Increases resistance to scale, and is mixed into heat-resistant workpieces.

- Iron (Fe) – 96%. The main component.

Read also: Why the knife does not sharpen

Equal-flange steel angle C345

All components are added during further melting. At the first stage, the recycled iron is collected in a large container, where it is heated to extreme temperatures and kept for several hours. Then the substance goes into a molten state, and additional components float to the surface. The result is steel without impurities. And at the last stage, the hot iron is poured into another tank, where it is cooled and given new compounds.

Application

The main and only purpose is the production of rolled profiles for the construction of metal structures. C345 is supplied to the rolled metal market in the form of:

The use of steel in construction is due to high technological properties on the one hand: ductility and weldability, and on the other hand, low cost relative to other steel alloys, which became possible due to the content of inexpensive components in its composition. Plus, C345 steel has sufficient strength for metal structures. All this makes c345 one of the most popular steels in construction.

Source

Symbol meaning and classification

The name of any product contains important characteristics. And if we consider this variety, then its decoding has the following meaning: The symbol “C” says that the object belongs to the construction category. The following figures indicate the turnover of rental products. That is, the maximum stress at which plastic deformation of this material begins to appear reaches 345 MPa.

Floor beam C345

Steel grade C345 is mainly produced in accordance with GOST 27772-2015, and can be in the form of sheets, bent profiles, wide-band and shaped types. Rolled metal products belonging to this standard can have a wide range of applications. In some cases, compaction by heat treatment and the addition of impurities from other models are allowed. But all manufacturing methods must be discussed in advance with the customer, and the corresponding mark must be placed in the documents. In this case, the buyer will be provided with a quality guarantee.

Properties

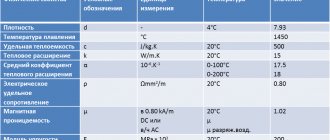

The density of c345 is 7850 kg/m3. The melting point is about 1550 ºC. A complete transition from solid to liquid is observed at 1620 ºC. Has good thermal conductivity. When the temperature increases by 20 ºC, it expands by 30-40 microns. Poorly conducts electric current. Magnetic

Brand C345 is not characterized by increased resistance to aggressive environmental influences. Reacts with oxygen under normal atmospheric conditions, forming rust. For this reason, it is used in construction after applying moisture-proof coatings to its surface. C345 dissolves in all types of acids and alkalis.

Steel has a low hardness of about 20.24 on the Rockwell scale. Temporary tensile strength - the load at which steel breaks - is 440-470 MPa. The metal begins to deform already at 345 MPa. Quite plastic. The relative elongation at break is 21%.

Steel C345 belongs to the first group of weldability. Welding does not require any preparatory operations: heating the surface, using fluxes, etc. The welds are dense and their strength under compressive load is not inferior to that of solid metal.

The steel is welded using manual arc welding. To prevent overheating, a low current of about 40 A is used. For better adhesion of the edges, the surface of the steel is pre-cleaned before welding.

Not hardened by heat treatment. The reason for this lies in the low carbon content and the lack of sufficient amounts of alloying elements such as chromium.

What can be replaced?

Category C345 can be replaced by many alternative alloys, for example, 09G2S. Items from both brands have identical composition, but the latter has up to 0.08% (As) arsenic. This analogue is often used in industry for servicing metal structures operating under high pressure or at T = from -70 to +425 °C. The name contains the sign “G”, which means manganese, and the number 2 indicates its percentage (2%). Indicator 09 indicates total carbon (0.9%).

As for the hardness of 09G2S, its value can reach up to 490 Brinell pascals, which also increases the demand for this product. The materials are also capable of withstanding work in severe climatic conditions. The sheets themselves, the impact strength of which reaches 49KCU, can undergo hardening and heat treatment.

Also on the modern metallurgical market you can find German, Japanese, Bulgarian, Romanian versions of the C345, which will differ slightly in options and composition. However, objects can function freely with each other and under the same factors.

If you find an error, please select a piece of text and press Ctrl+Enter.

Steel 09g2s is a very popular steel, used both in construction and in many industries. There are domestic and foreign analogues of this type. It is most often used for the manufacture of pipes, rolled metal and welded metal structures, the temperature range of which is from -70 to 425 0 C9 with permissible loads on them).

How to decipher steel markings?

To make deciphering the designations of different types of steels easy, you should know well what they are. Certain categories of steel have special markings. They are usually designated by certain letters, which allows you to immediately understand both the purpose of the metal in question and its approximate composition. Let's look at some of these brands and understand their designation.

Properties and purpose of structural alloy steels

Structural steels specially intended for the manufacture of bearings can be recognized by the letter “Ш”; this letter is placed at the very beginning of their marking. After it in the brand name there is a letter designation of the corresponding alloying additives, as well as numbers by which the quantitative content of these additives is determined. Thus, steel grades ShKh4 and ShKh15, in addition to iron and carbon, contain chromium in amounts of 0.4 and 1.5%, respectively.

The letter “K”, which appears after the first digits in the brand name, indicating the quantitative carbon content, denotes structural non-alloy steels used for the production of vessels and steam boilers operating under high pressure (20K, 22K, etc.).

High-quality alloy steels, which have improved casting properties, can be recognized by the letter “L” at the very end of the marking (35ХМЛ, 40ХЛ, etc.).

Deciphering the grades of construction steel can cause some difficulty if you do not know the specifics of the markings. Alloys of this category are designated by the letter “C”, which is placed at the very beginning. The numbers following it indicate the minimum yield strength. These brands also use additional letter designations:

- letter T – heat-strengthened rolled products;

- letter K – steel, characterized by increased corrosion resistance;

- letter D is an alloy characterized by a high copper content (S345T, S390K, etc.).

Unalloyed steels belonging to the tool category are designated by the letter “U”; it is affixed at the beginning of their marking. The number following this letter expresses the quantitative carbon content in the alloy in question. Steels of this category can be high-quality and high-quality (they can be identified by the letter “A”, it is placed at the end of the brand name). Their marking may contain the letter “G”, which means a high content of manganese (U7, U8, U8A, U8GA, etc.).

Tool steels containing alloying elements in their composition are marked similarly to alloyed structural steels (KhVG, 9KhVG, etc.).

Composition of alloy tool steels (%)

The marking of those steels that are included in the high-speed cutting category begins with the letter “P”, followed by numbers indicating the quantitative content of tungsten. Otherwise, brands of such alloys are named according to the standard principle: letters denoting the element, and, accordingly, numbers reflecting its quantitative content. The designation of such steels does not indicate chromium, since its standard content in them is about 4%, as well as carbon, the amount of which is proportional to the vanadium content. If the amount of vanadium exceeds 2.5%, then its letter designation and quantitative content are affixed at the very end of the marking (З9, Р18, Р6М5Ф3, etc.).

The influence of some additives on the properties of steel

Unalloyed steels belonging to the electrical category are marked in a special way (they are also often called pure technical iron). The low electrical resistance of such metals is ensured due to the fact that their composition is characterized by a minimum carbon content - less than 0.04%. There are no letters in the designation of grades of such steels, only numbers: 10880, 20880, etc. The first digit indicates the classification by type of processing: hot-rolled or forged - 1, calibrated - 2. The second digit is associated with the category of the aging coefficient: 0 - non-standardized, 1 - normalized The third digit indicates the group to which this steel belongs according to the standardized characteristic taken as the main one. The value of the standardized characteristic itself is determined from the fourth and fifth digits.

The principles by which the designation of steel alloys is carried out were developed back in the Soviet period, but to this day they are successfully used not only in Russia, but also in the CIS countries. Having information about a particular grade of steel, you can not only determine its chemical composition, but also effectively select metals with the required characteristics.

Understanding this issue is important both for specialists who develop and design various metal structures, and for those who often work with various steels and manufacture parts from them for various purposes.

Carbon steel of ordinary quality (GOST 380-81), depending on the guaranteed characteristics, is divided into three groups:

- Group A steel is supplied according to its mechanical properties and is manufactured in the following grades: St0, St1, St2, St3, St4, St5, St6;

- Group B steel is supplied according to its chemical composition and is manufactured in the following grades: BSt0, BSt1, BSt2, BSt3, BSt4, BSt5, BSt6;

- Group B steel is supplied according to its mechanical properties and chemical composition and is manufactured in the following grades: VSt1, VSt2, VSt3, VSt4, Vst5;

Depending on the standardized indicators, the steel of each group is divided into categories:

- steel group A – 1;2;3;

- steel group B – 1;2;

- steel group B – 1;2;3;4;5;6.

Steel of all groups with grade numbers 1; 2; 3 and 4 according to the degree of deoxidation is produced boiling (least deoxidized and cheap), calm (most deoxidized and expensive) and semi-calm, with grade numbers 5 and 6 - calm and semi-calm. Steel grades St0 and Bst0 are not distinguished by the degree of deoxidation.

Steel grades VSt1, VSt2, VSt3 of all categories and degrees of deoxidation, including those with a high manganese content, are supplied with a guarantee of weldability; The supply of group B steel with a guarantee of weldability is specified in the order.

Read also: How to assemble a simple electric generator with your own hands

In brand designation:

- letters St – steel, numbers from 0 to 6 – conventional brand number depending on the chemical composition and mechanical properties, for example St0, St1.

- the letters B and V before the letters St – steel group; group A is not indicated, for example St3, B St3, Vst3;

- letters added after the brand number indicate the degree of deoxidation: kp - boiling, ps - semi-calm, sp - calm, for example St3kp, St3ps, Vst3sp;

- numbers added at the end of the brand designation indicate the category of steel, for example St3ps2, Bst3kp2; The 1st category is not indicated in the brand designation;

- the letter G after the steel grade number indicates a high manganese content, for example St3Gps. The mechanical properties of steel must comply with the standards specified in Table 1.1.

| steel grade | Temporary resistance sв, kg/cm2 | Yield strength st, kg/cm2 for thicknesses, mm | |||

| No less | |||||

| up to 20 | 20-40 | 40-100 | >100 | ||

| St0 | >3100 | – | – | – | – |

| St1kp | 3100-4000 | – | – | – | – |

| St1ps,St1sp | 3200-4200 | – | – | – | – |

| St2kp | 3300-4200 | 2200 | 2100 | 2000 | 1900 |

| St2ps,St2sp | 3400-4400 | 2300 | 2200 | 2100 | 2000 |

| St3kp | 3700-4700 | 2400 | 2300 | 2200 | 2000 |

| St3ps,St3sp | 3800-4900 | 2500 | 2400 | 2300 | 2100 |

| St3Gps | 3800-5000 | 2500 | 2400 | 2300 | 2100 |

| St3Gsp | 4000-5800 | – | 2500 | – | – |

| St4kp | 4100-5200 | 2600 | 2500 | 2400 | 2300 |

| St4ps,St4sp | 4200-5400 | 2700 | 2600 | 2500 | 2400 |

| St5ps,St5sp | 5000-6400 | 2900 | 2800 | 2700 | 2600 |

| St5Gps | 4600-6000 | 2900 | 2800 | 2700 | 2600 |

| St6ps, St6sp | >6000 | 3200 | 3100 | 3000 | 3000 |

The chemical composition of ordinary quality steels is given in table. 1.2.

| steel grade | Mass fraction of elements, % | ||

| carbon | Manganese | silicon | |

| St0 | – | – | |

| St1kp | 0,06 – 0,12 | 0,25 – 0,50 | |

| St1ps | 0,06 – 0,12 | 0,25 – 0,50 | 0,05 – 0,15 |

| St1sp | 0,06 – 0,12 | 0,25 – 0,50 | 0,15 – 0,30 |

| St2kp | 0,09 – 0,15 | 0,25 – 0,50 | |

| St2ps | 0,09 – 0,15 | 0,25 – 0,50 | 0,05 – 0,15 |

| St2sp | 0,09 – 0,15 | 0,25 – 0,50 | 0,15 – 0,30 |

| St3kp | 0,14 – 0,22 | 0,30 – 0,60 | |

| St3ps | 0,14 – 0,22 | 0,40 – 0,65 | 0,05 – 0,15 |

| St3sp | 0,14 – 0,22 | 0,40 – 0,65 | 0,15 – 0,30 |

| St3Gps | 0,14 – 0,22 | 0,80 – 1,10 | |

| St3Gsp | 0,14 – 0,20 | 0,80 – 1,10 | 0,15 – 0,30 |

| St4kp | 0,18 – 0,27 | 0,40 – 0,70 | |

| St4ps | 0,18 – 0,27 | 0,40 – 0,70 | 0,05 – 0,15 |

| St4sp | 0,18 – 0,27 | 0,40 – 0,70 | 0,15 – 0,30 |

| St5ps | 0,28 – 0,37 | 0,50 – 0,80 | 0,05 – 0,15 |

| St5sp | 0,28 – 0,37 | 0,50 – 0,80 | 0,15 – 0,30 |

| St5Gsp | 0,22 – 0,30 | 0,80 – 1,20 | |

| St6ps | 0,38 – 0,49 | 0,50 – 0,80 | 0,05 – 0,15 |

| St6sp | 0,38 – 0,49 | 0,50 – 0,80 | 0,15 – 0,30 |

The mass fraction of nitrogen in steel is no more than 0.008%, sulfur is no more than 0.050%, phosphorus is no more than 0.040%, arsenic is no more than 0.08%.

Rolled products for building structures are manufactured in accordance with GOST 27772-88 from steels S235, S245, S255, S275, S285, S345, S345K, S375, S390, S390K, S440, S590, S590K, where the letter “C” stands for “construction steel” , the numbers conventionally indicate the yield strength, “K” is a variant of the chemical composition. The correspondence of steel names to steel grades according to current standards is given in table. 1.3.

| Name of steel | Brands according to current standards | |

| steel grade | ¦ standard | |

| S235 | VSt3kp2 | GOST 380 |

| S245 | VSt3ps6 | – |

| S255 | VSt3sp5 | – |

| – | VSt3Gps5 | – |

| – | VSt3Gsp5 | – |

| S275 | VSt3ps6 | – |

| S285 | VSt3sp5 | – |

| – | VSt3Gps5 | – |

| – | VSt3Gsp5 | – |

| S345 | 12G2S | GOST 19282 |

| – | 09G2S | – |

| S345D | 12G2SD | – |

| – | 09G2SD | – |

| S345K | 10KhNDP | – |

| S375 | 12G2S | – |

| S375D | 12G2SD | – |

| S390 | 14G2AF | – |

| S390D | 14G2AFD | – |

| S390K | 15G2AFDps | – |

| S440 | 16G2AF | – |

| S440D | 16G2AFD | – |

| S590 | 12G2SMF | – |

| S590K | 12GN2SMFAYU | – |

High-quality structural carbon steel (GOST 1050-74) is supplied according to its chemical composition and mechanical properties. Steel grades: 05kp; 08kp; 08ps; 08; 10kp; 10ps; 10; 11kp; 15kp; 15ps; 15; 18kp; 20kp; 20ps;20; 25; thirty; 35; 40; 45; 50; 55; 58; 60.

In brand designation:

- two-digit numbers – average carbon content in hundredths of a percent;

- letter G – high manganese content (about 1%);

- letters kp – boiling; ps – semi-quiet steel. The absence of the letters kp and ps indicates calm steel.

In steels of all grades, the sulfur content is not allowed more than 0.04%, phosphorus - no more than 0.035% (unlike ordinary quality steel, where the sulfur content is allowed no more than 0.05%, and phosphorus - no more than 0.04%).

Alloy structural steel (GOST 4543-71), depending on the chemical composition and properties, is divided into categories; quality; high quality - A; especially high quality – Ш

In the designation of brands, the first two digits mean the average carbon content in hundredths of a percent, the letters behind the numbers mean: P – boron; Yu – aluminum; C – silicon; T – titanium; F – vanadium; X – chromium; G – manganese; N – nickel; M – molybdenum; B – tungsten.

The numbers after the letters indicate the approximate content of the alloying element in whole units. The absence of numbers means that the brand contains up to 1.5% of this alloying element. The letter A at the end of the brand means high-quality steel. The letter Ш separated by a dash at the end of the steel grade denotes especially high-quality steel. For example, steel grade 09G2S contains carbon - 0.09%, manganese - 2%, silicon - up to 1.5%, or steel 12Х18Н10ТА-Ш contains carbon - 0.12%, chromium - 18%, nickel - 10%, titanium - up to 1.5%, especially high-quality steel .

Steel 09g2s 12: decoding

Understanding how labeling is formed allows you to clearly understand what product the manufacturer represents, as well as its main features. For those who are interested in details about 09g2s, the breakdown of steel is as follows:

- 09 – quantitative fraction of carbon content in the alloy (0.09%);

- G2 is manganese and its part in the entire volume fluctuates around 2% (the exact figure ranges from 1.3 to 2%);

- C - denotes silicon, the absence of numbers after the symbol indicates that it is less than 1%.

Thus, the decoding of 09g2s clearly looks like this:

| Element | Content, % |

| C (carbon) | up to 0.12 |

| Si (silicon) | 0,5 – 0,8 |

| Mn (magnesium) | 1,3- 1,7 |

| Ni (nickel) | up to 0.3 |

| S (sulfur) | up to 0.04 |

| P (phosphorus) | up to 0.035 |

| Cr (chromium) | up to 0.3 |

| N (nitrogen) | up to 0.008 |

| Cu (copper) | up to 0.3 |

| As (arsenic) | up to 0.08 |

| Fe (iron) | 96-97 |

As can be seen from the table, the interpretation of steel 09g2s is not limited to only three alloying components. In addition to carbon, silicon and manganese, it is supplemented by the following elements: nickel, sulfur, phosphorus, chromium, nitrogen, copper, etc. The percentage component of alloying metals is no more than 1-2 total%.

Marking 09g2s on a steel sheet

Also, for steel 09g2s, not only the alloying level is taken into account, but also other factors. Here are just a few of them that are significant for a particular case:

- constructiveness (purpose);

- eutectoid (structure: hexagonal, cubic, etc.; changes after hardening, etc.);

- production method (open hearth, conventional or electric steel);

- chem. steel composition 09g2s (in this case low-alloy).

As a result, analogues appear in relation to which questions like the following are often asked: is 345 steel 09g2s ? The designation C345 was introduced for builders , where the numbers do not indicate the chemical composition of the material, but its important property - the yield strength; for steel 09g2s it corresponds to the construction standards C345, which is reflected in a number of GOSTs (27772-88).

Below, several classic options are considered, including when one grade of steel corresponds to several strength classes.

General characteristics of the material

Any product has mechanical and physical properties that are determined during various tests. Knowledge of these indicators is a necessary condition, without which it is impossible to use the product correctly.

Properties of steel 17G1S

The characteristics of 17G1S steel are presented as follows:

- short-term strength limit – 490-510 MPa;

- maximum fluidity – 343-355 MPa;

- elongation at break – 20-23%;

- impact strength – 390-440 kJ/m2.

These indicators were obtained at T=20 °C and refer to sheet and pipe metal products.

It is important for metallurgical enterprises to produce high-quality products that meet the above criteria. To properly regulate this process, created objects are checked for compliance with state standards

The 17G1S steel itself belongs to GOST 19282-73, 19903-74, 5520-79 and 82-70.

These subparagraphs indicate all product indices, as well as the chemical composition of the steel, which, in this case, looks like this:

- “C” (carbon) – 0.15-0.2%. The substance is added to increase the density of the workpiece.

- “Si” (silicon) – 0.4-0.6%. Designed for hardening.

- “Mn” (manganese) – 1.15-1.6%. Removes excess oxygen.

- “Ni” (nickel), “Cu” (copper), “Cr” (chrome) – no more than 0.3%. The elements protect the plane from corrosion and protect it from the formation of cracks during loads.

- “S” (sulfur) – 0.04%. Improves the properties of future processing.

- “P” (phosphorus) – 0.035%. Increases the durability of an item.

- “N” (nitrogen) – 0.008%. Eliminates the alloy's tendency to age and increases its hardness.

- “As” (arsenic) – no more than 0.08%. Gives minor resistance to rust, and this amount does not make the steel harmful.

- “Fe” (iron) – 96%. The main component, without which it is impossible to create any iron part.

Rolled steel 17G1S

The above components must strictly correspond to the declared ones. Any, even minor, deviation can have a detrimental effect on the workpiece, which completely precludes its further sale.

Technical characteristics: subtleties of using reference manuals

The properties of 09g2s steel are largely determined by the chemical composition of the alloy, its specific parameters, which today are quite accurately calculated by metallurgists.

Steel grade 09g2s has the following critical points :

- Ac1 =”” 732, when austenite transforms into pearlite during cooling processes;

- Ac3(Acm) =”” 870 (s – from French chauffage/heating) the end point of cementite dissolution;

- Ar3(Arcm) =”” 854 (refro >Classical symbols, numbers 1 and 3 indicate the numbers of points on the graph. Symbols cm usually mark hypereutectoid steels.

If we talk about other features of St 09g2s, the following characteristics are noted: easy weldability of the material . For this purpose, RDS, ADS under flux and gas protection are used. Only products that have undergone chemical-thermal treatment cannot be welded.

The mechanical properties of steel 09g2s are tabular values that were developed by a number of GOST standards and describe the material at room temperature, as well as for its other states.

Among the important mechanical properties of 09g2s steel are the following:

- Yield strength for permanent deformation, measured in MPa;

- Relative values of elongation at break and contraction;

- Impact strength (use under load is one of the main applications);

- Brinell hardness (HB).

Strength class of steel 09g2s: the table for the list of grades includes the one indicated, which, as already noted, corresponds to C345 . This also includes a number of other brands. Thus, steels that are different in chemical composition and even in the method of producing steel can have the same strength class. This data can be found for 09g2s according to GOST 19281-2014; the characteristics of the alloys are presented in convenient tables that are easy to navigate. You can view (download) GOST 19281-2014 here .

But the opposite situation is also possible. For example, for 09g2s GOST 19281-89 and grade 16GS there is data on strength classes 265 and 296.

The same GOST describes the types of rolled metal:

- Varietal, round, shaped with various sections (including circle 09g2s).

- Wideband profiles with a certain thickness of products.

Read also: How to charge a battery with an automatic charger

Large diameter circles steel 09g2s

Similar information is provided for other brands.

The density of steel 09g2s fluctuates, somewhere around the mark of 7800 kg/m 3. But alloying elements can either increase the specific gravity or reduce it. Tungsten tends to be the first. The second is achieved by adding: cobalt, nickel, copper.

The hardness of steel 09g2s can be determined by Brinell, Rockwell, Vickers, etc. the choice of system is determined by the type of products for which parameter determination is required. It is also important when choosing a welding method; the hardness of the steel at the weld should remain fairly high.

Most of the listed parameters can be found in TU 14 3 1128 2000 for steel 09g2s, as well as for other grades. The technical specifications describe the requirements for the materials from which pipes are made for servicing gas fields and other areas of the industry.

The permissible stress for steel 09g2s is calculated depending on the following values:

- strength class and grade;

- temperatures at which it will be operated;

- thickness, sometimes configurations (circle, sheet, etc.).

Existing 09g2s analogues are foreign (European, Asian, others), most similar in mechanical and technical properties to the specified brand. However, the chemical composition can vary greatly. The Bulgarian version of this brand has the closest configuration.

steel grade, analogues, explanation, characteristics

In the production of metal structures, C245 steel is a low-carbon grade used for building structures.

Chemical composition

Steel consists of approximately:

- 98% iron,

- 0.2% carbon,

- 0.65% manganese,

- from 0.05 to 0.015% silicon,

- up to 0.3% chromium, nickel and copper combined.

The presence of up to 0.05% sulfur, 0.04% phosphorus and 0.08% arsenic is allowed.

Decoding steel C245

In the designation of steel, the letter C means “construction”, the numbers 245 are the yield strength (T) in megapascals (MPa). In more conventional units σT = 24.5 kg/sq. mm.

Among other parameters characterizing the mechanical properties of steel, we note the tensile strength = 370 MPa (37 kg/sq. mm).

Weldability

To assess weldability, use the criterion of carbon equivalent, calculated by the formula

Se=C+G/6+X/5+(N+D)/15, where C, G, X, N, D – the amount of carbon, manganese, chromium, nickel and copper as a percentage in the composition of the steel or alloy.

For C245, the equivalent carbon is below 0.25%, which means good weldability. The weld seam is not prone to the formation of hot and cold cracks. Parts can be welded by any method without additional measures - preheating, forging the heat-affected zone, etc.

Plastic

Plastic qualities, i.e. the ability to deform in a cold state without signs of destruction, are characterized by the relative elongation of the sample at break and the size of the yield area.

Steel C245 has a relative elongation at break, i.e., the elongation of the sample relative to the initial size after fracture, of 25%.

The length of the yield plateau, i.e. the change in relative elongation at which the stress does not change, is at least 2.5%.

This indicates the possibility of bending and stamping thin sheets of steel. For thick ones, local heating should be used to avoid cracks.

To understand the difference in the deformation capacity of thin and thick sheets, you should refer to the course on strength of materials. When bending a sheet, the difference in changes in the dimensions of the outer and inner sides will be greater, the greater the thickness. This means that for a thick sheet, the relative deformation will be greater and the probability of destruction - the appearance of cracks - will be higher.

With increasing temperature, the yield strength of the metal decreases, and the yield area increases. Therefore, to deform a thick steel sheet, it must be heated or the bend radius increased.

Corrosion resistance

Alloying components—silicon, copper, etc.—slightly increase the corrosion resistance of steels.

C245 has moderate oxidation resistance. It is sufficient for inter-operational storage of workpieces, as well as for operation inside dry rooms without additional protection. In other cases, paint and varnish coatings corresponding to the operating conditions of the structure should be applied.

Analogs

According to GOST 27772-88, steel grade C245 corresponds to:

- St3ps5 and St3sp5 according to GOST 380 and GOST 535 (Appendix 1 GOST 27772-88)

- VSt3ps6 according to GOST 380-71 (Table 51b appendix 1 SNiP II-23-81)

- VSt3ps6-1 according to TU 14-1-3023–80 (Table 51b, Appendix 1, SNiP II-23-81)

- 18ps according to GOST 23570–79 (Table 51b appendix 1 SNiP II-23-81)

- E235-B, E235-C, Fe 360-B and Fe 360-C according to ISO 630:1995 (Appendix A GOST 380-2005)

Application

Grade C245 is used for the production of sheet and shaped rolled products - equal and unequal angles, channels, T-beams, I-beams. Rolled steel is used in the production of metal structures for various purposes. Due to their good weldability, welded joints are widely used in their production.

Particularly critical structures operating under conditions of constant increased vibration loads are required to be connected with rivets or other methods that prevent the spread of possible cracks.

As analogues of steel grade C245 we can name steel St.3ps, steel St.3sp, which are similar in mechanical properties and chemical composition. It should be noted that a mandatory requirement is the complete or partial completion of deoxidation of steels before the process of casting into molds. This is indicated by the letters ps and sp in the designation of brands.

Low-alloy structural steel C245 has properties that meet the requirements for metal structures for general use.

It can be welded well by all types of welding without additional measures to reduce red and blue brittleness.

The steel has average corrosion resistance. This requires the use of protective paint and varnish coatings for metal structures made from the described steels used outdoors.

Rating: 0/5 – 0 votes

Steel 09g2s: characteristics and application

The main areas of use of this brand: sheet and shaped products. For hot-rolled strip, GOST 103-2006 standards are used, but steel circles are in accordance with GOST 2590-2006.

As already noted, steel 09g2s and analogues are easy to weld. The characteristics already listed allow the use of this material for products that require high wear resistance: beams, channels, corners.

Brand 09g2s, its technical characteristics, are necessary in the creation of vehicles, construction, oil and chemical industries. A wide temperature range allows the material to be used where severe deformations occur over a long service life. At the same time, the limiting temperature of -70 degrees facilitates the use of products made from St. 09g2s in harsh climatic conditions.

Steel 09g2s is used in the construction of RVS for storing petroleum products in the North

Steel 09g2s-15 also fits this description well. It is used for all of the above points. It only remains to add that in addition to welding, installation can be carried out using bolted connecting elements. The metal's resistance to chemical influences makes it interesting in the relevant industry. At the same time, high mechanical qualities are used for the construction of bridges, roads, port stations, etc.

The 09g2s-12 brand is also popular among builders. It also has stable plastic properties. It is distinguished by a special chemical composition, which includes arsenic. Used for the manufacture of pipeline fittings. Cannot be used in the food industry.

In the north of Russia, many kilometers of pipelines were built using just this brand. There, more than anywhere else, frost resistance and easy weldability of products are useful. This allows you to create complex, at the same time socially significant objects (metal structures) from 09g2s and analogues.

At the same time, for cities with a temperate or continental climate, steel 09g2s according to GOST standards of various numbers is suitable for beautifying streets. Square pipe is extremely popular as fencing, posts for billboards, installation of mobile trading platforms, and much more. For the same purposes, the rectangular configuration of products is used.

Steel 09g2s, the characteristics of which have already been discussed in some detail in this presentation, is of interest to welders, regardless of the method of performing work. Flanges made of this material are especially popular. Features of the work are described in GOST 19281-73. The craftsmen are quite welcoming to the news about the need to work with this brand.

The boiler tank itself is made of steel 09g2s

Steel 09g2s with different strength classes can be used for the production of steam boilers, as well as equipment used in the agricultural complex. Details about the requirements for steel 09g2s in GOST-5520 79.

An additional reason for using alloys of this brand is high efficiency, achieved not only due to low cost of production. The ease and speed of construction of buildings, structures, installation of equipment also allows you to optimize the costs of enterprises in various industries.

Features of electric welding

There are special requirements for working with this material, which are determined by the need to comply with the technological process. The need to maintain the strength of steel at seams has already been noted. However, under normal conditions it is hardly possible to achieve an absolutely positive result.

For example, the condition for preventing overheating is achieved by using low currents of 40-50 A / 1 mm electrode. Welding work is accompanied by subsequent hardening of materials at a temperature of 650 0 C. However, based on the critical points of the alloy, you can make your own calculations for carrying out these works. Moreover, the specified hardening T is applied sequentially to every 25 mm of the seam, for about an hour. Cooling is carried out in ordinary water or in air. Thanks to technology, they achieve quality that is not inferior in properties to even more expensive alloys.

Comparison with another steel grade

For example, for 09g2s and st3 the difference is determined primarily by the carbon content. For St3sp it is 10-20 times higher than what is found in the low-alloy alloy.

St3sp – refers to carbon alloys. This grade of steel is characterized by high brittleness and rapid destruction at low temperatures. If the brand being described has a lower limit of -70 degrees, then the object of comparison is only -20.

The quality of St3sp is ordinary, which indicates a likely high presence of sulfur and phosphorus. Then, like 09g2s is high quality. All other advantages are already in the previous description. It only remains to note that the cost of this brand is significantly higher than the price of St3sp.

Video about low alloy steels: