Dye composition

Silver enamel is not a paint with silver ions that is supposed to protect the floors and walls inside the house from the growth of microbes. There are no ions in this dye. Silver paint owes its name not to the content of silver ions in its composition, but to the silver-metallic tint that appears after the mixture dries.

Its main composition is aluminum powder, which varies in grinding size:

- PAP-1;

- PAP-2.

PAP-1 has slightly larger particles, but the quality of painted surfaces with diluted aluminum powder does not depend on the degree of grinding.

Silver aluminum powder is diluted for painting with various enamels or varnishes, most often alkyd and acrylic. If desired, you can use paints and varnishes with added ions for dilution - this is good for decorating interior walls.

Properties of paints with aluminum

The characteristics of solutions largely depend on the enamel or varnish used to prepare the composition with aluminum powder. But there are qualities that are inherent in this entire group of coloring compositions:

- Creating a barrier effect (after drying, a thin, durable film is formed on the surface, which serves as protection against moisture and other external aggressive influences).

- The property of reflecting light. The ability of the material to reflect sunlight and most of the ultraviolet spectrum makes it possible to protect industrial and residential buildings from overheating. If you paint the roof and walls of a building with silver, then, due to the property of reflecting sunlight, you can protect buildings from overheating in hot weather.

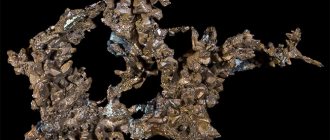

- High protective qualities. The composition with aluminum powder is not subject to rust and reliably adheres to the surface being treated. Metal products painted with this mixture acquire anti-corrosion properties.

Additional properties to the above qualities will be the technical characteristics of the varnishes or enamels used for the manufacture of the painting composition (alkyd, acrylic).

Application of silverfish

Serebryanka has become widespread both in the domestic and industrial spheres. It is used in everyday life to a greater extent, for decorative finishing of products. It is used to apply it to the fences of houses to make them look more attractive. Interior items made of wood or metal are coated with such a paint and varnish substance to make them look more organic. Even swimming pools are covered with this paint.

On an industrial scale, the use of this paint is due to the need to protect equipment and other objects from corrosion.

As you know, this paint and varnish substance covers metal products with a dense film, which performs a protective function.

Silver paint is often used to cover moats and various fences. It significantly increases the resistance of objects to environmental conditions, which are not always favorable.

Painting with silver is a fairly simple process. After all, it has a fairly dense structure and practically leaves no streaks or streaks. It lays down in an even and neat layer.

First, the paint must be thoroughly mixed. After this, you can begin preparing the surface for painting. If it is metal, you should first thoroughly clean it of roughness and rust, if any. If necessary, a primer must be applied to create a smooth material. Only after it has dried should you start painting.

If the surface is wooden, you must first level it with sandpaper to sand off all the unevenness. After this, apply paint.

The paint must be applied using a roller, brush or special sprayer. In any case, you can do this in one layer or in several. In each individual case, the number of layers is determined individually and depends on the condition of the surface.

In what form is it produced?

Silverstone can be found on sale in the following forms:

- A powder that must be mixed with a suitable paint and varnish composition before use.

- Ready-made mixtures that need to be stirred before use and, if necessary, diluted with a suitable solvent to the required painting consistency.

Ready-made dyes can be sold:

- In cans or paint buckets.

- In cans. The aerosol form of release is very convenient to use and store, because aerosol paints last longer and no additional painting equipment is required when working with them. Acrylic or other water-based dyes are available in aerosol form.

As sales practice shows, people most often purchase powder formulations for making the necessary mixtures themselves and aerosol cans, often having different colors for decorating walls or painting small surfaces.

Pros and cons of using silverware

What makes silver enamel popular for many decades? This is facilitated by the following characteristics of the coloring composition:

- Ease of application. The dye spreads well on the prepared surface in an even layer, without streaking. Drips do not occur even when painting walls, steep roof slopes or other vertical bases.

- Strength. A thin, uniform layer of coloring substance after drying forms a thin film, adheres firmly to the base, and does not peel off.

- Versatility. Silver painting is most often used to protect metal from rust, but a composition with aluminum can be used on any other substrate (wood, stone). For example, painting the wooden walls of a gazebo with silver powder, diluted varnish or acrylic-based enamel will prolong the life of the structure for a long time, reliably protecting it from rot and drying out.

- Environmentally friendly. Silver powder is non-toxic. The composition can acquire toxic properties only after dilution with toxic enamel. If non-toxic paints and varnishes were used to prepare the mixture, for example, acrylic water-dispersed ones, then this dye can be used to decorate walls inside residential premises.

- Aesthetics. The dye after drying has a pleasant metallic tint. If you wish, you can not limit yourself to just one tone, but before painting, tint the mixture in any color you like. This is not difficult to do, especially since there are various colors on sale, you just have to choose the one that matches the paint base. Different colors of metallic shades will look unusual when decorating walls outside and inside buildings. Or you don’t have to paint it yourself - stores offer a wide range of aerosol paints (usually acrylic), thanks to which you can create beautiful graffiti on the walls.

- Durability. As practice has shown, the roof and walls of the facade painted with silver do not need repairs for up to 6-7 years. If the surface is constantly in contact with water, then the period of protective properties is reduced to 3 years, and on the walls inside residential premises, beautiful decor can last up to 15 years.

The disadvantages include the fact that the powder for mixing is flammable and even explosive, and therefore requires proper storage conditions. But these qualities of aluminum powder do not in any way affect its protective and decorative properties - they are lost after diluting the powder with enamel or varnish and no longer require special storage conditions other than protection from drying out.

Serebrol (barrier) - waterproof aluminum anti-corrosion primer-enamel for metal protection

Serebrol (barrier) is a one-component waterproof anti-corrosion primer-enamel “serebryanka” for ferrous and galvanized metals with a high content of aluminum powder and special modified waterproof components.

During polymerization, the coating creates a powerful barrier protection of the metal from moisture and other corrosive environments throughout the entire period of operation of the product.

It is used as an independent coating, as well as in systems with anti-corrosion primer for ferrous metals Grunkor , or with zinc-rich protective primer Zinconol . The paint coating system, consisting of one layer of primer and 2 layers of enamel, retains its protective properties for up to 15 years , depending on the type of primer and operating conditions of the product.

Aluminum primer-enamel Serebrol (barrier) can significantly increase the service life of tanks and metal structures, giving the painted surfaces resistance not only to sea and fresh water, but also to short-term gasoline spills.

Primer enamel has a number of advantages over coatings of this type:

- barrier protection of the surface from the damaging effects of moisture;

- weather resistance protects the metal from exposure to aggressive environments;

- wear resistance of the coating to rupture and damage, guarantees a high level of protection against mechanical influences;

- accelerated drying time allows you to apply the second layer within an hour after applying the first, significantly reducing the time for painting work;

Purpose

Aluminum primer-enamel for metal Serebrol (barrier) is designed to obtain long-term anti-corrosion protection:

Serebrol (barrier) , by reflecting the rays of sunlight, scatters infrared radiation, which protects the surfaces of metal structures, hangars and roofs from overheating.

- for painting steel tanks and water tanks;

- metal platforms and pools,

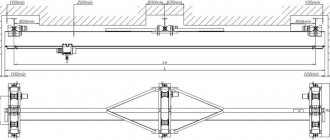

- bridges and hydraulic structures,

- metal pipes and steel structures;

- trestles and floating docks,

- power line supports;

- galvanized roofs and domes;

- pipelines and oil and gas pipelines;

- any metal structures operating in a humid atmosphere, in sea and fresh water conditions.

Tara

Container 20kg.

Attention!

- Supplied in lithographed containers!

- The label is equipped with protective elements against counterfeiting!

Areas of use

Despite its versatility, silver is most often used to create protection against corrosion. It is often used for painting:

- various metal structures for industrial purposes (power lines, pipelines);

- automotive industry products: both for tuning a car and for giving its individual parts additional strength;

- galvanized or metal roofs;

- hangars and other utility rooms made of metal (not only the roof, but also the walls are painted to protect against overheating during the hot season);

- structures in constant contact with fresh or sea water.

In addition, much less often, silver dye is used to protect and decorate buildings made of concrete, stone or wood; it is possible to use silver dye based on acrylic enamel for painting plastic products.

Details

Characteristics

Serebryanka has a rich silvery color. Apply on the surface in an even and dense layer. Can be used on both metal and wooden surfaces.

The name silver comes from the fact that it forms a thin film on the surface being painted, which has a silvery tint. The structure of the paint is not capable of forming smudges and cracks on the surface. Thanks to its dense structure, it does not delaminate over time and also hides defects.

With the help of silver, any product will acquire an aesthetic appearance. It is used not only as a decorative finish, but also protects the surface from external influences.

All types of silver create a barrier on the surface being painted with a thin, durable film. This barrier protects the surface from moisture and other negative external factors.

Aluminum dye has reflective properties, which protects the surface of a building or structure from overheating by ultraviolet rays in the hot season.

Also, coloring compositions based on aluminum powder have good protective properties, thanks to which silver has good adhesion to the surface being painted and is not subject to corrosive formations. It also acts as a barrier to the passage of air into the structure of the material.

Areas of use

Despite the fact that silver is considered a universal paint, it is still more often used on metal to protect the material from corrosive formations.

It is most common for painting industrial-scale metal structures, such as poles, power lines and pipelines, in the automotive industry - car tuning, as well as for strengthening individual parts and structures that are in constant contact with water.

In addition, silver can be used for painting buildings made of stone, metal and concrete. Paint with an acrylic enamel base can be used for painting plastic products. It is widely used in everyday life. For example, for painting a galvanized garage or fence.

One-component formulations are available in buckets, cans, and aerosol packages. Spray cans are considered the most convenient packaging, both in use and storage.

Storage

Silver paint should be stored in tightly closed containers, away from heating devices. But since the substance in cans is highly flammable and explosive, it should not be exposed to ultraviolet rays or moisture.

Naturally, children should not have access to it. Products should also not be stored together with paint.

How to prepare yourself

When planning to make silver paint yourself, you should pay attention to the following:

- Grinding character (PAP-1 or PAP-2). The ratios for dilution with paints and varnishes are always indicated on the packaging of aluminum powder, and it is not recommended to violate these proportions.

- Method of application to walls: aerosol, using a spray gun or roller. For the aerosol method, the composition should be made more fluid, using acrylic or other water-based varnishes. Acrylic paint and varnish mixtures are not only convenient for aerosol application - after drying, all acrylic paints provide high protection from adverse influences.

- Do not use nitro enamels or oil paints for dilution - they do not combine well with the aluminum base.

To obtain a homogeneous mass, mixing must be carried out according to the following scheme:

- Measure out the required amount of powder and pour into the prepared container.

- Add a little paint base and stir until a thick paste forms.

- Add the remaining varnish to the resulting slurry, gradually stirring.

Next, you should evaluate the thickness and, if necessary, dilute with a solvent suitable for the base: for the aerosol method it will be larger, but for application with a painting tool you will need a thicker mixture.

How to properly breed silverfish?

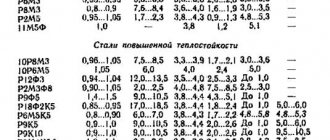

Important! There are two different silver powders, which differ from each other in their preparation technology. The powder can be diluted with varnish or synthetic drying oil. The main difference in the preparation of PAP-1 and PAP-2 are the proportions.

So, PAP-1 is diluted in a special ratio with BT-577 varnish - 2 to 5. This paint can withstand temperatures up to 400 degrees and not fade. First, add the powder, and then pour in the varnish in portions and mix the resulting mixture using a mixer.

PAP-2 is diluted in a ratio of 1 to 3 or 1 to 4 with any varnish. Mix everything thoroughly again. But it is worth noting that as a result of mixing, a rather thick mass is obtained that cannot be used. Therefore, it should be brought to the so-called painting consistency.

Important! The degree of fluidity of the paint must be selected based on the method in which you will apply it - roller, spray, brush, etc.

To make the paint more liquid, use a mixture of solvents or one thing - white spirit, turpentine, solvent. If you are going to spray silver paint, then the paint and solvent should be mixed in equal proportions, and for a roller and brush a 2 to 1 ratio is suitable.

When diluting paint with synthetic drying oil, the process will not be much different; the proportions are the same as for varnishes. The shelf life of silver powder has no limits, but the diluted composition has no more than six months.

How to paint

Painting with silver paint, no matter using an aerosol method or using a painting tool, is carried out in exactly the same way as for most dyes:

- Surfaces are cleaned of remnants of old decor and degreased.

- A primer is applied to the cleaned base (one layer is enough for silver).

- After the primer has dried, paint is applied in several layers.

Easy to use and durable silver will protect structures from the aggressive influence of external factors, and its durability will allow you to significantly save on repairs, because subsequent repair and restoration work will not be required soon.