Flange connection unit for polyethylene pipes and steel pipes

Everyone knows a simple connection unit between polyethylene pipes and steel pipes using flanges.

In this article, I would like to draw attention to the diameter of the connecting elements.

I had a project on external water supply networks with a large pipeline diameter. And without hesitation, I laid all the flanges according to the nominal diameter. After a while, I received a note from the construction site from the installers about the impossibility of connecting the pipelines according to my node. I decided to draw the assembly in detail, and indeed discovered that for large-diameter pipelines the flange must be selected more carefully and carefully looked at the dimensions.

Let's first consider a standard connection unit, which is relevant for small pipeline diameters (up to 160 mm).

For example, I suggest looking at a unit for a polyethylene pipe with a diameter of 160 mm. This diameter is most often found in projects.

Flange connection unit for a polyethylene pipe with a diameter of 160 mm and a steel pipe with a diameter of 159x5 mm.

According to the drawing, the connection consists of:

- from a steel welded flange with a diameter of DN150mm (from the steel pipe side);

- bushings for a flange with a diameter of 160 mm (from the side of the polyethylene pipe);

- free steel clamping flange (to connect both flanges)

Flange connection unit for a polyethylene pipe with a diameter of 450 mm and a steel pipe with a diameter of 500 mm.

When connecting a polyethylene pipe with a diameter of DN=450mm (DN=400mm) with a steel pipe using a standard connection: flange-sleeve-flange, we get a steel pipe with a diameter of DN=500mm.

According to the drawing, the connection consists of:

- from a steel welded flange with a diameter of DN500mm (from the steel pipe side);

- bushings for a flange with a diameter of 450 mm (from the polyethylene pipe side);

- free steel clamping flange (to connect both flanges)

Flange connection unit for a polyethylene pipe with a diameter of 450 mm and a steel pipe with a diameter of 400 mm.

When connecting a polyethylene pipe with a diameter of DN=450mm (DN=400mm) with a steel pipe DN=400mm using the connection: flange-sleeve-flange-adapter.

Flange connection unit for a polyethylene pipe with a diameter of 450 mm and a steel pipe with a diameter of 350 mm (300 mm).

When using a polyethylene transition. You can connect polyethylene pipes with a diameter of 450mm to a steel pipe with a diameter of 350mm or 300mm (and other smaller diameters).

For other pipeline diameters, see the specification of connecting elements in the table:

| Diameter DN, mm | Diameter Dу, mm | Diameter of flat steel flange Dу, mm | Sleeve diameter under DN, mm | Diameter of free steel clamping flange for PE pipes PN16, DN, mm |

| 63 | DN=50 (D=57x4mm) | 50 | 63 | 50 |

| 75 | DN=65 (D=76x5mm) | 65 | 75 | 65 |

| 90 | DN=80 (D=89x5mm) | 80 | 90 | 80 |

| 110 | DN=100 (D=108x5mm) | 100 | 110 | 100 |

| 125 | DN=100 (D=108x5mm) | 100 | 125 | 100 |

| 160 | DN=150 (D=159x6mm) | 150 | 160 | 150 |

| 200 | DN=200 (D=219x6mm) | 200 | 200 | 200 |

| 225 | DN=200 (D=219x6mm) | 200 | 225 | 200 |

| 250 | DN=250 (D=273x7mm) | 250 | 250 | 250 |

| 315 | DN=300 (D=325x8mm) | 300 | 315 | 300 |

| 355 | DN=350 (D=377x8mm) | 350 | 355 | 350 |

| 400 | DN=400 (D=426x8mm) | 400 | 400 | 400 |

| 450 | DN=500 (D=530x8mm) | 500 | 450 | 500 |

| 500 | DN=500 (D=530x8mm) | 500 | 500 | 500 |

| 630 | DN=600 (D=630x8mm) | 600 | 630 | 600 |

Bibliography:

- GOST 12820-80

- GOST 18599-2001

- GOST 10704-91

Happy designing! And have a nice working day!

Which polyethylene pipes are better?

For the production of water pipes, two grades of polyethylene are used - PE 80 and PE 100. The hundredth polyethylene is more dense and durable than the eightieth. For water supply systems in a private home, the strength of PE 80 is more than enough - they can withstand pressure up to 8 atm. If you like a large margin of safety, you can take them from PE100. They work normally at 10 atm.

What you should pay attention to is the country in which the product was produced. The leaders in quality are European manufacturers. High precision execution guarantees high system reliability. Average quality and prices are from Turkish companies, in the cheaper price segment are Chinese manufacturers. Their quality, as usual, is also much lower. It’s difficult to give advice here; everyone chooses at their own discretion (or what is available in the region).

Types of connections between PE pipes and steel pipes.

Permanent connection of polyethylene-steel (NSPS)

A permanent polyethylene-steel connection (NSPS) or a PE-steel adapter is used in the construction of gas pipelines, water pipelines, and pressure sewers to make the transition from a steel pipe to polyethylene HDPE or vice versa. Used when installing pipeline fittings or inserting into an existing steel pipeline. The steel-PE transition does not require maintenance; it can be placed directly in the ground without wells on straight sections of the pipeline. The polyethylene-steel transition is a connection obtained by welding a steel pipe to a polyethylene one. The length of the pipes is regulated by the technical conditions for gas pipelines TU 4859-026-03321549-98, for pressure pipelines according to TU 2248-001-86324344-2009. The maximum operating pressure for gas pipelines made of PE80 is 0.64 MPa, PE100 is 1.0 MPa. The maximum operating pressure for pressure water pipes is PE80 1.25 MPa, from PE100 1.6 MPa. In the manufacture of permanent polyethylene-steel joints, polyethylene pipe HDPE GOST R 50838-95 for gas pipelines and GOST 18599-2001 for water pipelines are used. And a steel water and gas pipe according to GOST 10705-80, GOST 10704-91, GOST 8731-74, GOST 8732-78. NSPS is a connection that is made by welding a steel pipe to a polyethylene pipe. The length of the product is regulated by specifications for pressure pipelines and gas pipelines. Pressure for gas pipelines PE 80 - 0.64 MPa, PE 100 - 1 MPa; for pressure pipelines PE 80 - 1.25 MPa, PE 100 - 1.6 MPa.

Most often, NSPS is used for connecting metal shut-off devices to a polyethylene pipeline, gradually replacing sections of a steel pipeline with polyethylene, and inserting a branch made of polyethylene. The principle of the NSPS part is a strong and tight connection of a pipe or part made of steel with a polyethylene pipe of the same diameter.

The permanent connection to the end of the pipe occurs through thermistor welding, which requires special equipment. The end of the polyethylene pipe is heated to a viscous-ductile state and is connected under pressure to the steel end. To strengthen the connection, polyethylene couplings are used, but you can do without them. It allows the use of such a connection in high-pressure pipelines.

NSPS allow:

- Use them as plugs;

- Use metal shut-off valves on HDPE polyethylene pipelines

- Produce gas inlets of various diameters based on them

- Drain polyethylene into an existing steel pipe

- Use welding on steel pipelines with steel pipes in accordance with regulatory documents.

- Installation of metal shut-off valves in HDPE polyethylene pipelines

- Alternately replacing sections of steel pipelines with polyethylene ones with permanent connections until the complete replacement of the existing steel pipeline with polyethylene

- Inserting branches from HDPE polyethylene pipes with permanent connections into an existing steel pipeline

- Welding with steel pipes in accordance with the current regulatory documentation for steel pipelines with permanent connections.

Threaded compression couplings

Compression polyethylene HDPE fittings. This type of connection hardware is called compression tube fittings. They are attached to the system using gasket material and crimp rings. This type of use does not require any additional equipment. In addition, when producing gasket material, you can replace the old gasket with a new one. That is, HDPE fittings of this type can be used repeatedly, especially in hydraulic systems.

Compression products are mainly used for hydraulic water supply systems. They can be built into such a system even if they are not fully assembled. This allows their application in water supply systems to vary widely. Compression fittings come in the following types:

- adapter couplings of different diameters;

- couplings, including those with internal and external threads;

- tee without thread and adapter with thread;

- square;

- tap;

- stub.

They come with both internal and external threads. Like other fittings, these come in a variety of shapes. They are: coupling, triple, cross, plugs, flanges, bends.

They are made in different diameters: from 16 to 110 mm. Working pressure, depending on the diameter, can range from 10 to 16 atmospheres.

All design components are modular and can be disassembled. This has a good advantage, since in the future such pipes will be easy to replace and the connection can be reused.

Application of polyethylene HDPE fittings

Most often, these fittings are used to connect pipes in places where a change in the direction of the pipeline is expected, as well as the presence of branches or transitions to pipes of a different material. They are used for both technical and drinking water supply, in irrigation systems or as cable ducts. Thanks to the material, these fittings allow for complete tightness of pipe joints.

Application of compression fittings for connecting pipes

Also, their ease of installation allows you to install small-diameter parts without outside help or special equipment. These parts are stored in dark rooms, away from direct sunlight.

Structure of compression fittings

This part consists of 5 collapsible parts. To secure the crimp, there is a nut cover, which has external grooves for ease of tightening and an internal thread. It is made from polyethylene copolymer.

The crimp ring is a part that allows you to prevent any movement of the pipe, including spontaneous unscrewing.

Structure of compression fittings

The sleeve fixes the sealing gasket in a stable position, limits its compression and pipe deformation. Made from polypropylene copolymer.

The sealing gasket is made of rubber. Provides good tightness, even if the pipe is kinked.

The body itself is made of polypropylene copolymer, has a special pipe stop and trapezoidal thread.

HDPE bushing for flange

flange sleeve

Among HDPE bushings there are 2 groups:

Segmental HDPE bushings - Such bushings are butt-welded HDPE elements, partially or entirely consisting of HDPE pipe.

Cast HDPE fittings differ from segment ones in that they are made by injection molding and do not have welds. Fittings of large diameters are sometimes produced by casting followed by machining.

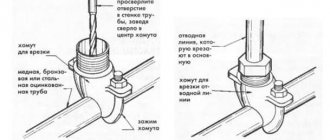

The principle of using this fitting is to provide support for the flange placed on the sleeve and eliminating the possibility of disconnecting the unit during its operation. Use a bushing for the flange at the transition points of the polyethylene pipeline on the valve or a steel pipe if there is a counter flange on it.

The HDPE flange sleeve is used in conjunction with a pressure flange, which must have a wider internal diameter than a regular standard flange. The need for boring the inner part of the flange lies in the presence of a reinforcing expansion of the polyethylene part of the sleeve at the base of the collar, which prevents the flange from fitting tightly to the clamping part.

After installing the sleeve on the pipe, using a steel flange and bolts with nuts, the pipe is attached to the valve, and the collar on the sleeve prevents the flange from coming off when the pipeline is operated at operating and maximum pressures.

Using HDPE bushings

Installation of bushings is quite simple, because all modern elements of connecting fittings strive to simplify their use. This saves time and money when creating the pipeline, and also allows for long-term operation of the system without problems. The benefits of installing different types of system elements using bushings are as follows:

- complete tightness of the connection points and no risk of sudden breakdown;

- the system does not require maintenance, any problems can be quickly corrected;

- installation of HDPE pipeline elements is quick and very simple;

- You can find a wide range of bushing diameters in stock from the supplier.

When organizing a pipeline for a liquid or vapor working medium, you can rely on the quality and reliability of molded plastic flange bushings at the connection points. These elements will help organize a reliable and durable pipeline system.

You can buy HDPE pipe (PE pipe, polyethylene pipe), find out prices and ask any questions you are interested in from our managers by making a request by email or calling the office by phone

Flange adapter (connection) “Astore” Italy

The “ASTORE” flange adapter is used to convert a polyethylene pipe to steel reinforcement. Using a coupling (collet), the HDPE pipe is connected, and using a flange, the entire assembly is connected to the flange of a shut-off valve, gate valve or flanged ball valve. You can also switch to a steel pipe by welding a flange to it.

| vendor code | dхDN, inch/mm | Number of holes at the flange, pcs | Weight, g | Price including VAT [RUB/piece]* | Basket |

| 1011040006 | 40x1.1/2″(40) | 4 | 488 | 780,00 | |

| 1011050006 | 50x1.1/2″(40) | 4 | 588 | 830,00 | |

| 1011050007 | 50x2″(50) | 4 | 588 | 830,00 | |

| 1011063007 | 63x2″(50) | 4 | 720 | 890,00 | |

| 1011063008 | 63х2.1/2″(65) | 4 | 720 | 890,00 | |

| 1011076008 | 75x2.1/2″(65) | 4 | 920 | 1 200,00 | |

| 1011076009 | 75x3″(80) | 8 | 1050 | 1 380,00 | |

| 1011091009 | 90x3″(80) | 8 | 1200 | 1 550,00 | |

| 1011091010 | 90x4″(100) | 8 | 1440 | 1 870,00 | |

| 1011111010 | 110x4″(100) | 8 | 1780 | 2 200,00 |

| vendor code | DxDN, mm | Number of holes at the flange, pcs | Weight, gr. | Price including VAT [RUB/piece]* | Basket |

| GR.520.75H.00 | 75×2 1/2″(65) | 4 | 886 | 1 250,00 | |

| GG.520.75I.00 | 75×3″(80) | 8 | 1005 | 1 420,00 | |

| GR.520.90I.00 | 90×3″(80) | 4 | 1198 | 1 600,00 | |

| GG.520.90L.00 | 90×4″(100) | 8 | 1395 | 1 830,00 | |

| GR.250.11L.00 | 110×4″(100) | 8 | 1684 | 2 300,00 |

*There is a flexible system of discounts; it is possible to buy a flange adapter at retail.

Structurally, this part consists of a flange collar and a compression coupling connected together. On the pipeline side there is the same collet clamp, as with all compression fittings. And on the collar side there is a flange with a universal arrangement of holes for bolts suitable for all types of steel flanges.

The method of installing the pipe and fitting remains unchanged: the pipe is inserted until it stops, a special washer is installed on it, which, in turn, is clamped with a nut. The entire mechanism is very easy to install, the connection of the pipe and the flange end is done manually, and the connected parts ensure reliable and uninterrupted operation of the unit for many years with a maximum operating pressure of up to 10 atmospheres.

The compression flange of the Italian manufacturer “Unidelta” is equipped with a metal flange during the production process, which allows you to avoid, during installation, overtightening of plastic parts, to prevent their splitting and further leakage of the unit, which distinguishes the “Unidelta” compression flange connection from flange connections of other manufacturers.

HDPE compression flange is available in sizes 40, 50, 63, 75, 90, 110 mm and flange sizes from 1.1/2″ (40 mm) to 4″ (100 mm). Suitable for use under direct exposure to UV rays. Has excellent chemical resistance.

The dimensions of the flanges and holes for its fastening correspond to standard welded flanges. The metal flange is made of zinc steel, which increases anti-corrosion protection. And the part itself is made of high quality polypropylene. Thanks to this material, the adapter is not susceptible to corrosion and is not afraid of low temperatures. The quality of the material and the fitting made from it allows the entire assembly to be buried in the ground without fear of leakage or damage.

The service life of flange connections is at least 20 years. They can be used with all types of water supply and technical polyethylene pipes transporting drinking and industrial water, in watering and irrigation systems, in drainage and sewer systems, for pumping chemical solutions.

Part Features

The fixing fitting for PE and PVC pipes is a flat disk with equally spaced holes for bolts. This product is installed together with a collar or bushing.

The flange sleeve, which is mounted directly in front of the collar, has an extension for reinforcement. Because of this, the part itself does not fit tightly to the flange.

To eliminate this problem, special bored products are used, in which the internal diameter is increased to the required size, which contributes to the complete tightness of the joint. The remaining parameters of the part are completely similar to standard steel analogues.

Field of application of flanges

Steel products are used quite widely:

- in pressure and non-pressure pipelines;

- in precipitation drainage systems;

- in industrial networks;

- in storm sewer lines.

With the help of flange products, it is possible to achieve the most durable and tight connection of various network elements.

Welding a plastic pipe with a flange sleeve using an electric coupling

If necessary, such a unit can be easily dismantled for repair work or cleaning the system.

How to connect a plastic pipe to a metal pipe: methods and necessary details

When carrying out major repairs, it is often necessary to partially or completely replace water pipes and sewer systems. Due to the high cost of materials, homeowners decide to connect old metal pipeline elements with new plastic pipes. Despite the fundamental difference between these materials in physical and chemical characteristics, today there are several options for bringing such an idea to life.

To connect the plastic and metal segments of the pipeline you will need special fittings

Types of products

The main parameters by which flange products for PE and PVC pipes are characterized are the internal diameter, external dimensions, weight and operating pressure.

Depending on what tasks these parts perform, there are the following types of adapters:

- adapter with special welded bushings;

- slip-on metal flange;

- free-type flange adapter supported by a straight or tapered collar.

The best way to connect light and medium PE pipes with a diameter of no more than 150 mm and light pipes with a diameter of up to 300 mm is a loose flange supported by a straight collar. A loose flange with a tapered collar is used for fittings with a diameter of more than 200 mm.

Characteristics of the fixing flange for polyethylene pipes (video)

Advantages and disadvantages of a flange for PE and PVC pipes

The clamping steel loose flange adapter has several advantages over other parts, which makes it more popular to use. The main advantages of the fitting are as follows:

- The adapter allows you to install PE and PVC reinforcement elements into a metal pipeline, which also makes the repair of such systems more affordable.

- To install the flange, there is no need to use any special tools or spend a lot of time: a wrench and a little skill allow you to install the part without any problems.

- Also, the clamping flange adapter has the ability to compensate for the process of compression and expansion of the axis, and this allows for easier installation and operation, and reduces installation time.

As for the disadvantages, the most significant is the fact that the gasket that ensures a tight fit is destroyed. This occurs due to the fact that they are clamped as tightly as possible, and this leads to exceeding the tensile strength of the material.

Flange connection is the most reliable type of pipeline installation

Structurally, the flat clamping adapter is most unsuccessful in this regard, since it cannot protect the gasket from deformation.

Those product models in which gaskets are provided in some recesses are considered more protected from gasket rupture, however, they do not provide full protection, especially with a long service life of the part.

When installing a flange, take into account the fact that metal can expand when exposed to heat. This causes the fastener elements to elongate more than the adapter itself, which can compromise the seal of the flange connection.

Procedure for installing a flange for polyethylene pipes

Connection using a flange adapter is widespread due to its simplicity and efficiency. To install a product with welded bushings, it is necessary to make a perfectly even cut of the pipe at the intended joint. After this, a flange adapter is welded to the end of the pipe.

Before soldering, place a flange on the plastic sleeve

The flange itself is installed on it using a thread. When installing, pay attention to the presence of burrs on the flange, which can damage the pipe or fittings.

On another section of the pipe or fittings, a counter element is installed in the same way. The connection of these parts is done using bolts.

If it is necessary to install a slip-on fixing flange, then perform the following operations:

- Carefully cut off the edge of the pipe (the cut should be even).

- A metal flange is placed on the pipe.

- Insert a rubber gasket with an overlap of no more than 10 mm onto the pipe cut.

- The flange is pushed onto the gasket and the pipe with the mating part is secured using bolts.

In both cases, the flanges are secured with bolts, so it is important to tighten them with uniform force in a cross pattern. When performing this final operation, you must strictly adhere to the recommendations of the technical documentation for the product.

When installing a fixing clamping flange with a glued gasket, you must first remove the chamfer from the end of the pipe and wet it.

Preparing pipes and flanges for installation

After this, the pipe is pushed all the way into the loosely assembled flange, put it on the pipe and pushed in until it stops. Next, fully tighten the clamping ring bolts and fix the flanges themselves.

A steel flange for polyethylene or PVC pipes is considered a strong and reliable component of the system highway, with the help of which a sealed detachable flange connection is mounted.

Features of the “cold” method

It is assumed that compression fittings are used in this case. As far as tools go, a regular crimp wrench will suffice.

The installation process looks like this.

- As usual, work begins with cuts at the ends. After this, you need to check whether the edge is in a perpendicular position. Cleaning the ends from burrs is carried out with a wire wool or fine-grained sandpaper.

- The fitting is threaded onto the surface of the end prepared in advance. The part is inserted into the inner surface until it stops.

- After this, the coupling nut is fully tightened. The system is checked for leaks.

The coupling nut is placed on one end of the pipe. The thread should go to the fitting. Then they move on to using compression rings. They also go to the fitting side, but with long bevels.

Video

What points should you pay attention to when welding?

Professional soldering irons are quite expensive. It is better to purchase inexpensive “amateur” options if the work is not constant. These usually have several running attachments at once. You can rent tools. This will not affect the quality of the final connections.

A stable stand has become a must-have element for almost all soldering irons. Even professionals make connections only if the tool remains stable. It takes no more than 10-15 minutes to heat up the working surfaces.

The connecting nozzles have only 2 parts - the drone, on which the coupling is heated, and also the sleeve, inside of which there is a pipe with the drone.

The nozzle parts are installed on the soldering iron when it is still cold. And only after this the device is connected to the network. Work should begin only when the indicators go out.

Video

This occurs during the second heating cycle. But the heating time is determined by several factors:

- Type of pipe.

- Wall thickness.

- Diameter of the structure.

All these values are usually indicated in the table that comes with soldering irons.