Nichrome is an alloy of 80% nickel and 20% chromium with a melting point close to 1400 C. It is gray in color and is resistant to corrosion. Due to its high resistance and difficult oxidation at high temperatures, it is widely used in manufacturing. Nichrome wire is a resistive material that is used to improve the high temperature performance of many materials at very high temperatures where other conductive metal elements cannot operate.

Specific resistance of nichrome, its melting point and applications

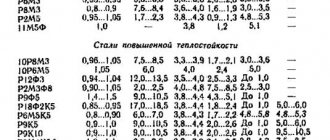

The table shows the electrical resistivity of nichrome depending on temperature in the range from 20 to 1200°C. The resistivity of nichrome is indicated in µOhm m. For example, at a temperature of 900°C, nichrome X20N80-N has a specific electrical resistance equal to 1.149 micro Ohm m (or 1.149 10 -6 Ohm m).

With increasing temperature, the resistivity of nichrome increases. During the heating process, the increase in nichrome resistance as a function of temperature can be 7...11% in the range of 20...1200°C. However, a direct linear dependence of resistivity on temperature is characteristic only of ferronichrome X15N60, which contains a large amount of iron.

Ni-Cr alloys with low iron content have a different nature of the dependence of resistance on temperature: nichrome X20N80 shows a decrease in resistivity in the range from 500 to 900°C; The resistivity of Nikrothal 80 nichrome does not depend on temperature in the range 400...900°C.

Nichrome resistivity (µOhm m) depending on temperature

| Temperature, °C | Х15Н60 | Х20Н80-Н | Nikrothal 80 |

| 20 | 1,12 | 1,13 | 1,09 |

| 100 | 1,135 | 1,137 | 1,101 |

| 200 | 1,152 | 1,147 | 1,112 |

| 300 | 1,172 | 1,155 | 1,123 |

| 400 | 1,189 | 1,163 | 1,134 |

| 500 | 1,203 | 1,166 | 1,134 |

| 600 | 1,213 | 1,156 | 1,134 |

| 700 | 1,213 | 1,148 | 1,134 |

| 800 | 1,22 | 1,147 | 1,134 |

| 900 | 1,229 | 1,149 | 1,134 |

| 1000 | 1,238 | 1,158 | 1,145 |

| 1100 | 1,248 | 1,167 | 1,155 |

| 1200 | — | 1,175 | 1,166 |

The melting point of nichrome is 1400°C. Ferronichrome X15N60 has a slightly lower melting point. The maximum operating temperature of the considered alloys is 1125...1200°C.

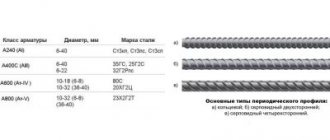

The main purpose of nichrome is to use it in the form of tape and wire for electric heaters. It should be noted that the maximum temperature for using nichrome wire depends significantly on its diameter . For example, according to GOST 12766.1-90, for wire X20N80-N with a diameter of 0.2 mm, the maximum operating temperature in air is only 950°C. By increasing the diameter of such wire to 1 mm, its operating temperature can reach 1100°C.

Composition of nichrome, its melting point and maximum operating temperature

| Nichrome brand | Compound | tmelt, °C | trab, °C |

| Х15Н60 | 55-61% Ni, 15-18% Cr, rest Fe | 1390 | 1125 |

| Х20Н80-Н | Basic Ni, 20-23% Cr, Fe no more than 1% | 1400 | 1200 |

| Nikrothal 80 | Basic Ni, 19-21% Cr, Fe no more than 2% | 1400 | 1200 |

What is nichrome

Nichrome alloy has good ability to resist electron flow. These unique properties make it suitable for applications in heating elements of hair dryers and heat guns. It has high oxidation resistance, which also makes it a suitable material for heating technology. Nichrome wire is wound into coils with a specific electrical resistance of nichrome through which a current is passed to produce heat.

Nickel-chromium 90/10 alloy is used in thermocouples in combination with Ni/Al 95/5 alloy. This combination is called chromel-alumel, represents heating elements with a maximum operating temperature of 1100 C and is subject to drift in the region of 1000 C due to oxidation. This effect is eliminated by adding silicon. Commercial grades include Nicrosil (containing 14% Cr and 1.5% Si) and Nisil (containing 4.5% Si and 0.1% Mg).

What does nichrome look like?

Nickel-chromium 80/20 metal is a high-temperature corrosion-resistant alloy used for wrought and cast parts because it has better resistance to oxidation and hot corrosion than cheap iron-nickel-chromium alloys.

Heat capacity, linear expansion, density and thermal conductivity of nichrome

The table presents the following physical properties of nichrome: specific heat at 25°C, average coefficient of thermal linear expansion in the temperature range from 20 to 1000°C and density of nichrome at 25°C.

It should be noted that the considered grades of nichrome have similar values of physical properties. The density of nichrome is in the range of 8200...8660 kg/m 3 and increases with increasing nickel content in the alloy. The coefficient of thermal linear expansion of nichrome at 20...1000°C has the value (17...18)·10 -6 deg -1. The specific heat capacity of nichrome, depending on the brand, is 440...460 J/(kg deg).

Specific heat capacity, linear expansion and density of nichrome

| Nichrome brand | C, J/(kg deg) | α·10 6 , deg -1 | ρ, kg/m 3 |

| Nichrome (10%Cr + 90%Ni) | 460 | 18 | 8660 |

| Х15Н60 | 460 | 17 | 8200 |

| Х20Н80-Н | 440 | 18 | 8400 |

| Nikrothal 80 | 460 | 17,2 | 8300 |

The thermal conductivity of nichrome is similar in value to the thermal conductivity of stainless steel. The table shows data on the thermal conductivity of the considered alloys at various temperatures in the range from 0 to 600°C.

The thermal conductivity of nichrome increases when heated. With increasing nickel content in the alloy, its thermal conductivity coefficient increases. For example, an alloy containing 10% Cr and 90% Ni has the highest thermal conductivity of the alloys considered, equal to 17.4 W/(m deg) at 20°C.

Source

Scope of application

Based on application, the global nichrome alloy market can be segmented into architectural, automotive, electronics, aerospace and others. Nichrome alloys are used to make monel from iron and steel, to produce stainless steel. Nichrome alloys are used for architectural purposes such as lead for water pipes, roofing and windows.

Nichrome is used in gears, driveshafts, and special vehicles for operating in areas with low temperatures or heavy wear. It is also used for special engineering purposes. Nichrome alloys are primarily used for electrical resistance heating. They have high electrical resistance, good strength and ductility at operating temperatures.

Nichrome is widely used in the fireworks and explosives industry and to prepare wires for electrical ignition systems such as lighters, electric matches and electronic cigarettes.

This substance is used in ceramic works. It serves to provide internal support structure and helps keep the shapes of clay sculptures soft. Because of its resistance to high temperatures, it is used when pieces of clay are fired in kilns. Nichrome wires are used to test the flame color in unlit parts of a cationic fire for sodium, copper, potassium and calcium cations.

Nichrome is also used in microbiology laboratories and to make thermocouples.

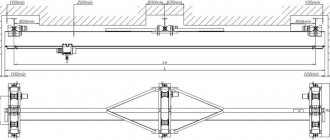

Calculation of nichrome spiral

Resistance calculation method

First, let's take a closer look at calculating the length of nichrome wire based on power and electrical resistance. First, you need to decide how much power the heating coil will need. Let's say we need to make a small heater for a device with a power of 10 W and a voltage of 12 Volts. Let's say we have nichrome wire with a cross-sectional diameter of 0.1 mm.

The most basic calculation, without taking into account heating, is made according to the formula familiar to us from a school physics course:

Р=U∙І → І = Р/ U = 10/12 = 0.83 A

R= U/ I = 12 / 0.83 = 14.5 Ohm.

Application of nichrome

Nichrome is used in electric heaters for furnaces for all industries, household appliances and thermal devices. Widely used in high-temperature electric furnaces, roasting and drying furnaces, and various electrical thermal apparatuses. Used as heating and resistor elements. It has increased heat resistance, creep resistance, ductility and shape stability. Nichrome is also used as a heat-resistant (heat-resistant) alloy and a chemically resistant alloy in certain aggressive environments.

Calculation methods

By resistance

Let's figure out how to calculate the length of nichrome wire based on power and resistance. The calculation begins with determining the required power. Let's imagine that we need a nichrome thread for a small soldering iron with a power of 10 W, which will operate from a 12V power supply. For this we have wire with a diameter of 0.12 mm.

The simplest calculation of the length of nichrome by power without taking into account heating is performed as follows:

Let's determine the current strength:

We calculate the resistance of nichrome wire according to Ohm's law:

The length of the wire is:

where S is the cross-sectional area, ρ is the resistivity.

Or using this formula:

But first you need to calculate the resistivity for nichrome wire with a diameter of 0.12 mm. It depends on the diameter - the larger it is, the less resistance.

The same can be taken from GOST 12766.1-90 table. 8, where the value of 95.6 Ohm/m is indicated, if you recalculate it, you get almost the same thing:

For a 10 watt heater powered by 12V, you need 15.1cm.

If you need to calculate the number of turns of a spiral to make it from nichrome wire of this length, then use the following formulas:

Length of one turn:

where L and d are the length and diameter of the wire, D is the diameter of the rod on which the spiral will be wound.

Let's say we wind nichrome wire on a rod with a diameter of 3 mm, then we carry out the calculations in millimeters:

But at the same time, it is necessary to take into account whether nichrome of such a cross-section is even capable of withstanding this current. Detailed tables for determining the maximum permissible current at a certain temperature for specific sections are given below. In simple words, you determine how many degrees the wire should heat up to and select its cross-section for the calculated current.

Also note that if the heater is located inside a liquid, then the current can be increased by 1.2-1.5 times, and if in a confined space, then vice versa, it can be reduced.

By temperature

The problem with the above calculation is that we calculate the resistance of the cold spiral by the diameter of the nichrome thread and its length. But it depends on the temperature, and you also need to take into account under what conditions it will be possible to achieve it. While such a calculation is still applicable for cutting foam plastic or for a heater, it will be too rough for a muffle furnace.

Let us give an example of calculations of nichrome for a furnace.

First, determine its volume, say 50 liters, then determine the power, for this there is a rule of thumb:

- up to 50 liters – 100 W/l;

- 100-500 liters – 50-70 W/l.

Then in our case:

Next we calculate the current and resistance:

For 380V when connecting the spirals with a star, the calculation will be as follows.

We divide the power into 3 phases:

Pf=5/3=1.66 kW per phase

When connected by a star, 220V is applied to each branch (phase voltage may differ depending on your electrical installation), then the current:

For a triangle connection, we calculate using a line voltage of 380V:

To determine the diameter, the specific surface power of the heater is taken into account. Let's calculate the length, take the resistivity from the table. 8. GOST 12766.1-90, but first we will determine the diameter.

To calculate the specific surface power of the furnace, use the formula.

Bef (depends on the heat-receiving surface) and a (radiation efficiency coefficient) – are selected according to the following tables.

So, to heat the furnace to 1000 degrees, let’s take the temperature of the coil at 1100 degrees, then according to the selection table Veff we select a value of 4.3 W/cm 2, and according to the selection table for coefficient a - 0.2.

The diameter is determined by the formula:

RT – specific resistance of the heater material at a given t, determined according to GOST 12766.1, table 9 (shown below).

For nichrome Х80Н20 – 1.025

Then to connect to a three-phase network according to the “Star” scheme:

The length is calculated using the formula:

The values differ due to the high temperature of the coil; the test does not take into account a number of factors. Therefore, let’s take the length of 1 spiral to be 42 m, then for three spirals you need 126 meters of 1.3 mm nichrome.

Grades of nichrome and percentages of metals in them

From the point of view of the domestic industry, there are two main types of nichrome.

- Brand Х20Н80. This brand contains 74% nickel and 23% chromium. In this case, the alloy is characterized by the percentage of iron, silicon and manganese.

- Brand X15N60. This brand contains 60% nickel and 15% chromium. The third most important component is iron, the content of which is in the alloy at 25%.

In the second type of brand, the use of iron is explained by the desire to reduce the final cost of the product while maintaining its performance characteristics. In addition, iron makes it possible to greatly simplify the subsequent processing of the alloy. The selection of chemical composition in different proportions can be used to achieve a variety of end goals.

Application and calculation of an electric spiral made of nichrome

A nichrome spiral is a heating element in the form of a wire, rolled with a screw for compact placement. The wire is made of nichrome , a precision alloy whose main components are nickel and chromium. The “classic” composition of this alloy is 80% nickel, 20% chromium. The composition of the names of these metals formed the name that denotes the group of chromium-nickel alloys - “nichrome”.

The most famous brands of nichrome are X20N80 and X15N60 . The first of them is close to the “classics”. It contains 72-73% nickel and 20-23% chromium. The second is designed to reduce the cost and increase the machinability of the wire. The nickel and chromium content in it has been reduced to 61% and 18%, respectively. But the amount of iron has been increased - 17-29% versus 1.5 for X20N80.

Based on these alloys, modifications with higher survivability and resistance to oxidation at high temperatures were obtained. These are brands X20N80-N (-N-VI) and X15N60 (-N-VI). They are used for heating elements in contact with air. Recommended maximum operating temperature – from 1100 to 1220 °C

Furnace repair, nichrome winding

Range of nichrome alloys with high ohmic resistance

Alloy X20N80 has the following physical properties:

- resistivity 1.0-1.1 106 Ohm m;-

- nichrome operating temperature 800-1100 °C, melting point from 1100 to 1300 °C;

- nichrome density – 8200-8500 kg/m3;

- specific heat capacity of nichrome - 0.45 kJ/(kg K);

- tensile strength - 0.65-0.70 GPa;

- high heat resistance of nichrome up to 1250 °C;

Nichrome wire

has minimal electrical resistance when heated, increased heat resistance, ductility, and holds its shape well.

The high ductility of the alloy makes it possible to subject it to turning, welding, stamping, drawing, stamping and other mechanical processing. The price of nichrome is quite high, but given its durability and reliability, you can live with this. The most popular grade of nichrome is X20N80

, which is recommended for heating electrothermal equipment. Nichrome X20N80 contains 20% chromium Cr, and 80% nickel Ni. The alloy has a resistivity of 650 Ohms/cmf, an operating temperature of 1100 °C and a melting point of up to 1300 °C.

Nichrome wire Х15Н60

contains – Ni60%, Cr15%, Fe24%. The alloy has a resistivity of 675 Ohms/cmf and a melting point of 1390 °C.

Nichrome wire Х20Н80

As a rule, this is a wire with a round, sometimes square cross-section. The most optimal cross-section is considered to be round, since it has the maximum ratio of cross-sectional area to the perimeter of the wire. Polymetallic and bimetallic wires are also available for sale. They are made by drawing metal through successively smaller holes. In this way it is possible to obtain a product of a wide variety of diameters. Nichrome is different, the weight directly depends on the diameter of the wire and the grade of the metal alloy.

The most important characteristic of nichrome is electrical resistance. It is determined by a variety of factors, for example, resistance depends on the diameter of the wire and the grade of the alloy. With a significant increase in temperature, the resistance of nichrome remains the same, which makes it possible to use nichrome wire in the manufacture of heating devices and in resistance units, for example, in resistors, rheostats, and in the production of electric heating equipment.

Nichrome wire has corrosion resistance when working in aggressive environments, high yield strength, and strength, allowing the use of wires of smaller diameters.

The wires are marked on:

- N – for heating elements

; - C – for resistance elements

; - Heating element – for tubular electric heaters

.

Application of nichrome wires

Wire grades Х20Н80 and Х15Н60

have a very wide range of applications, for example they are used as heating and cutting elements in packaging knives. They are used as heating elements in industrial electric furnaces, and in various electrical heating devices, for example, in household heating appliances. In industry they are used in water and air heaters. On average, nichrome wire has a density of 8.4 g/cm3. It is often used in the production of electrical wires, drills, thermocouples, hardware, electrodes, springs, electronic devices and other elements. Very often, nichrome is used as a heat-resistant alloy and in highly aggressive work environments.

Nichrome wire can be purchased from Atomtekhnologii LLC from stock in the warehouse in Dnepr.

Nichrome is a group of alloys consisting of percentages of nickel ranging from 55 to 78 percent, chromium ranging from 15 to 23 percent and various additives such as silicon, aluminum, manganese and iron. The main purpose of this element is to create heating elements and resistors.

The nichrome alloy was first developed in 1905 in the United States of America by A. Marsh.

Application of nichrome wire

The main quality of nichrome is its high resistance to electric current. It determines the applications of the alloy. Nichrome spiral is used in two qualities - as a heating element or as a material for electrical resistance of electrical circuits.

For heaters, an electric spiral made of X20N80-N and X15N60-N alloys is used. Application examples:

- household thermoreflectors and fan heaters;

- Heating elements for household heating devices and electric heating;

- heaters for industrial furnaces and thermal equipment.

Alloys Kh15N60-N-VI and Kh20N80-N-VI, produced in vacuum induction furnaces, are used in industrial equipment of increased reliability.

A spiral made of nichrome grades X15N60, X20N80 , X20N80-VI is distinguished by the fact that its electrical resistance changes little with temperature changes. It is used to make resistors, connectors for electronic circuits, and critical parts of vacuum devices.

Advantages of nichrome

Nichrome is an expensive group of alloys. In search of savings, it is often replaced with an analogue - fechral. However, the latter is not always fully capable of replacing nichrome, so their use often depends on the direction of work.

Nichrome has the following advantages:

- A large number of on-off cycles

- Enormous ductility at temperatures above 200 degrees Celsius

- Fully rust resistant

- Does not have magnetic properties

- High creep resistance

- Does not react with fireclay lining and iron oxides

- Low chance of sagging

Despite the fact that this material is expensive, its reliability and durability will ensure a high demand for this type of alloy for a long time.

How to wind a spiral from nichrome

A resistive or heating coil can be made at home. To do this, you need nichrome wire of a suitable grade and the correct calculation of the required length.

The calculation of a nichrome spiral is based on the resistivity of the wire and the required power or resistance, depending on the purpose of the spiral. When calculating power, you need to take into account the maximum permissible current at which the coil heats up to a certain temperature.

Temperature accounting

For example, a wire with a diameter of 0.3 mm at a current of 2.7 A will heat up to 700 ° C, and a current of 3.4 A will heat it to 900 0 C. There are reference tables for calculating temperature and current. But you still need to take into account the operating conditions of the heater. When immersed in water, heat transfer increases, then the maximum current can be increased by up to 50% of the calculated one. A closed tubular heater, on the contrary, impairs heat dissipation. In this case, the permissible current must be reduced by 10-50%.

The intensity of heat removal, and therefore the temperature of the heater, is affected by the pitch of the spiral winding . Densely spaced coils generate more heat, while a larger pitch increases cooling. It should be taken into account that all tabular calculations are given for a heater located horizontally. When the angle to the horizon changes, the heat removal conditions worsen.

Calculation of the resistance of a nichrome spiral and its length

Having decided on the power, we proceed to calculate the required resistance. If the determining parameter is power, then first we find the required current using the formula I=P/U. Having the current strength, we determine the required resistance. To do this, we use Ohm's law: R=U/I.

The notations here are generally accepted:

- P – allocated power;

- U is the voltage at the ends of the spiral;

- R – spiral resistance;

- I – current strength.

The calculation of the resistance of nichrome wire is ready. Now let's determine the length we need. It depends on the resistivity and wire diameter. You can make a calculation based on the resistivity of nichrome: L=(Rπd 2 )/4ρ. Here:

- L – required length;

- R – wire resistance;

- d – wire diameter;

- ρ – resistivity of nichrome;

- π – constant 3.14.

But it’s easier to take ready-made linear resistance from the tables of GOST 12766.1-90. You can also take temperature corrections there if you need to take into account changes in resistance when heated. In this case, the calculation will look like this: L=R/ρld, where ρld is the resistance of one meter of wire having a diameter d.

Application of nichrome

The use of nichrome is extensive, especially in areas where reliability and durability are most valued. Among the main directions it is worth highlighting:

X15N60 and X20N80 are the most commonly used chromium-nickel precision alloys. As already mentioned, they are distinguished by high electrical resistance. Nickel is the main metal in this alloy. There is a lot of it in nichrome - as much as 55-78 percent. It is almost as good as chromium, of which nichrome contains 15-23 percent. In addition to nickel and chromium, nichrome also includes iron, titanium, phosphorus, aluminum, manganese, sulfur, carbon, and silicon.

The properties of nichrome are determined by nickel and chromium. Nickel has the ability to dissolve a variety of metals in itself, and at the same time remain very ductile. In liquid and gaseous media it easily resists corrosion. As mentioned many times, it is resistant to high temperatures. Chrome is also heat-resistant, has hardness and high resistance to corrosion processes. So it turns out that chrome itself is endowed with all these positive qualities.

Resistance to elevated temperatures determines the impressive operating temperatures of nichrome. Nichrome belonging to the X20N80 brand can withstand up to 1200 degrees Celsius (here we also pay attention to the diameter of the wire), for nichrome belonging to the X15N60 brand the maximum temperature is up to 1125 Celsius. The figures are given in accordance with GOST 12766.1-90. How much influence the percentage of nickel in the alloy composition has, we draw a conclusion from this characteristic. The higher the percentage of nickel in nichrome, the greater the heat resistance of nichrome.

Another quality that makes nichrome a widely sought-after metal is its high ductility. Plasticity can be attributed to technological features, which indicate what kind of processing the material can be subjected to without damage - this is either turning, or welding, gilding, stamping, and so on). Due to the excellent ductility of nichrome, it can be used to make products of this kind, such as, for example, nichrome tape or nichrome wire, and some other types of very thin wire. How is nichrome wire made? Using drawing.

The most important physical features of nichrome include the presence of a low electrical resistance coefficient and high electrical resistivity. These features, coupled with heat resistance, allow nichrome to be the material from which wires are made, as well as tapes for the production of various heating elements.

Nichrome X20N80 and nichrome X15N60 (nichrome tape) are most often used in electrical engineering. This alloy is used to create wirewound resistors (and there are also tape resistors); rheostats in devices for heating; electric heaters, electric heating elements that operate for a long time in air at temperatures up to 1250 degrees Celsius. Nichrome is also successfully used in the manufacture of electrothermal equipment, which must be very reliable. Nichrome X15N60 is also used in the production of non-precision resistors.

Consisting of the following elements: (73-78%); (19-21%); (1 %); (0.7%); the rest. Sometimes the alloy is alloyed with rare earth metals to achieve longer service life.

Nichrome X20N80, especially wire, is the most liquid assortment of nichrome. Nichrome tape and strip remain less popular compared to wire, but are more in demand than rods and sheets. It is generally accepted that the X20N80 grade contains about 20% chromium and 80% nickel, which does not quite correspond to GOST, which allows microalloying of precision alloys to improve their consumer characteristics.

Spiral winding

Now let's make a geometric calculation of a nichrome spiral . We have selected the wire diameter d, the required length L has been determined, and we have a rod with diameter D for winding. How many turns do you need to make? The length of one turn is: π(D+d/2). Number of turns – N=L/(π(D+d/2)).

In practice, rarely does anyone wind their own wire for a resistor or heater. It’s easier to buy a nichrome spiral with the required parameters and, if necessary, separate the required number of turns from it.

Source

Areas of use of nichrome

At the time of the invention of nichrome, it was expected that this alloy would be used for the subsequent manufacture of heating elements for high-temperature equipment. Due to the fact that the melting point of nichrome is 1400 degrees Celsius, it has become possible to use it in the creation of drying devices and firing furnaces. In addition, it has become widespread when it is necessary to create structures that will function in extremely aggressive environments.

Nichrome spiral for iron

From the point of view of the production of household materials, nichrome is most widespread in the production of irons. Over time, it turned out that the use of nichrome is effective in the food industry when creating kitchen equipment with heating elements. The main advantages of nichrome are the absence of sparking, rust, and areas of melting, which makes it extremely beneficial from the point of view of use in everyday life.

This avoids burning and unpleasant odors when cooking.

The high plasticity of nichrome has led to its use in the creation of resistors, rheostats, and resistance units. Nichrome filament retains its properties despite its small size, which makes it possible to create even smaller device components. The modern electronic cigarette manufacturing industry also requires nichrome.