Nichrome from used products or purchased, but not in demand, goes through non-ferrous metal collection points for recycling

.

Nichrome in any form is purchased by both small outlets and reputable companies; the price also varies.

Where to go is decided by the deliverer after studying the conditions.

Let's consider what nichrome and its scrap are, how much they pay for 1 kg of this alloy and why.

An alloy of nickel and chromium in a ratio of 80 to 20, obtained in 1905

, due to its technical properties, has found application in many devices and products. Despite the high cost of the resulting material, obvious benefits were observed due to the durability and trouble-free operation of the devices.

The percentage ratio of nickel-chromium was selected experimentally and solved the set goal: to achieve properties of the metal that were not provided by any of those used in technology at that time.

Advantages

nichrome:

- plasticity (an important property in the production of nichrome products);

- heat resistance;

- low expansion coefficient when exposed to high temperatures;

- does not create a significant electromagnetic field when operating products in electrical appliances:

- high current resistance (the main parameter for use in electric heating devices);

- small specific gravity.

Currently, the alloy composition may vary. Supplements may be added

from:

- manganese;

- gland;

- silicon;

The main brands of nichrome are X20H80

and

Х15Н60

.

Products

produced from a nickel-containing alloy:

- ribbon;

- rod;

- wire;

- certain types of fasteners;

- parts for operating devices under conditions of sudden and repeated temperature changes and (or) in an aggressive environment.

They are used

V:

- electrical engineering;

- instrument making;

- metallurgical;

- machine tool and some other industries.

Sources of nichrome scrap

Modern heating equipment (household and industrial) contains products made of nichrome. High resistance resistors

, including

ballast ones

, are often made of this alloy.

A thrifty owner, before throwing away a device that cannot be repaired, will disassemble it and sort it by type of recyclable material. Then he will receive monetary compensation for his efforts.

A burnt-out radiator can be returned without disassembling it. In this case, it will be accepted at the price of regular scrap metal. But it also contains non-ferrous metals, albeit in small quantities.

In case of separate delivery

components,

the amount due will look much nicer

.

In addition to privately owned equipment that allows you to extract nichrome parts and wire, there are other sources.

The most attractive - warehouses with surplus goods

. It is not always possible to sell unclaimed items as products. The solution is to hand over it as non-ferrous metal.

When product certificates have been preserved and the batch is large (in weight terms), nichrome will be accepted on the most favorable terms.

Money from the delivery of recovered nichrome products will not be superfluous.

During reconstruction

or

re-profiling of production

you can hand over

:

- ovens;

- CNC machines (plastic molding);

- other electrical devices.

If you are involved in the collection and delivery of ferrous metal, then it will be useful for you to know. Don't know where to find non-ferrous metals? Read this. Not sure which metal detector model to choose? Check out our overview of popular models

Features of wire reception

metals, taking wire

, usually pay for it at a reduced rate. With nichrome wire the situation is the opposite.

This type of waste is often more expensive

, how:

- tape trimmings;

- canvases;

- monolithic parts.

Maximum

wire

in coils

. Even scraps of burnt out coils can be returned at a very reasonable cost.

Selling scrap as an additional source of income

In the house and garage, you won’t earn much from your own nichrome reserves. But everyone has neighbors who are ready to give away spoiled household appliances for a modest reward or even for nothing, subject to self-delivery or self-pickup.

All you have to do is:

- Equip a site for dismantling.

- Get the necessary tools

.

A few extra thousand rubles a month will not be superfluous.

Where is nichrome wire used?

Plasticity, resistance to aggressive substances and high yield strength are used by nichrome in industrial production and a number of industrial areas where electric heating furnaces are widely used. The alloy has also found application in electric furnaces, the heating temperature of which is extremely high.

Wire is also used in other areas:

- in homemade welding machines;

- in ovens for drying and firing;

- for machines cutting foam plastic;

- in the heating system of car windows and mirrors;

- in devices where an increased degree of reliability is required, etc.

This property of the alloy, such as strength, has provided nichrome wire with a place in all environments where chemicals, heat and high temperatures are indispensable.

Admission conditions and restrictions

When choosing a point for delivery of nichrome raw materials, you should pay attention to some information about the conditions for receiving a particular point.

The seller must pay attention

for the following points:

- The maximum declared value refers to an alloy in which the nickel content approaches 80%

, and scrap in its pure form (without dirt or chemical residues). - Is there a limit on the weight of the batch

(some have a minimum weight, for example, 500 kg). They will, of course, accept less, but the price will be reduced. - What method is used to check the nickel content in raw materials ().

What is nichrome

It is worth noting that such an alloy contains a large concentration of chemical elements, which ensures strength and resistance to electrical influences.

Why is nichrome in demand in various fields? Here are some features of this material:

- sustainability. The product does not rust and has excellent corrosion resistance, which cannot be said about other types of metals;

- cannot be deformed. Nichrome wires retain their properties under any influence;

- elasticity. The material can be given various shapes.

Nichrome wires are used in various fields. The product is used for the manufacture of machines and devices for wood processing.

Wire has found wide application in the creation of ordinary household heaters.

There is a certain classification of nichrome products, which is necessary if they are used in various systems. For example, marking C indicates that the product is used for the manufacture of various elements characterized by resistance.

The letter H on the wire indicates that the material is used to create heating systems.

The article number of the heating element means that nichrome wire is used in the manufacture of electrical options. Most often these are heating systems.

Factors affecting the cost of scrap

Why does the price of nichrome vary significantly between different receivers? What does it depend on? Is it possible to get maximum benefit by studying the market and preparing your existing nichrome waste accordingly?

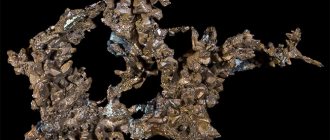

Included in the alloy is an expensive raw material. In its pure form it is present only in meteorites

.

Recycling nichrome is economically beneficial. The higher the nickel content in the sample, the higher the acceptance cost. For each percentage, on average, from 3 to 5 rubles

.

An increase or decrease in the price of nickel on the stock exchange responds, albeit not instantly, to the assessment of secondary nichrome.

Demand for raw materials in a specific region.

The more enterprises that consume nichrome scrap, the higher the purchase cost. In large industrial cities, the price per kilogram of alloy is higher (up to three times) than in the outback.

The type of nichrome being handed over also affects the cost.

Let us highlight the following types

nichrome scrap:

- wire;

- ribbon;

- rod;

- scrap of unknown origin at first glance.

At points where the assessment is carried out for each type separately, the maximum assessment is for new wire with a thickness of 3 mm or more

.

Let's move on to the numbers:

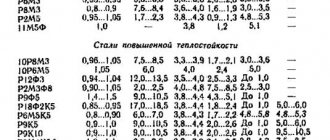

The table shows approximate scrap prices per 1 kilogram for the most expensive brand of nichrome. For brand Х15Н60

prices are 20% lower.

The price of nichrome scrap per 1 kg in small points is lower than the cost indicated in the table, by approximately 20-25%

.

How to get the maximum benefit

When planning to hand over the nichrome that you have collected, it would be useful to carry out reconnaissance in order to find out the conditions for receiving non-ferrous metals at the nearest point. If the price list contains nichrome in one line, without dividing it by type and brand, you can lose up to 30% of the amount that can be earned for sorted metal.

It is impossible to determine the percentage of nickel in a metal or alloy at home, but the fact of its presence is quite real.

Such an alloy is not magnetic or only slightly magnetic

, and when exposed to it with a grinder, it produces small reddish sparks.

The cost of the alloy sold directly depends on the amount of nickel in it and the price of nickel itself.

You can find out where to get nichrome from this video:

Nichrome wire is an alloy of nickel and chromium in different proportions with a predominance of nickel. It was created at the beginning of the 20th century in the USA. It has different cross-sectional shapes, for example, circle, square or oval. The final physical properties of the material are affected by the percentage of nickel content in the alloy.

Nichrome wire: description and main characteristics

Nichrome wire is a metal cord that is produced in different lengths, thicknesses (from a fraction of a millimeter to several centimeters) and cross-sections: round, oval, square or trapezoidal.

The most common type of cross-section is round, since such wire has the maximum ratio of cross-sectional area to its perimeter. The weight of the product directly depends on the composition of its alloy and the diameter of the wire itself.

Nichrome has a rare combination of properties that make it simply an exceptional alloy, the only analogue of which, fechral, is much inferior to it in all respects.

The heat resistance of this material can reach up to 1400 degrees Celsius (two-component alloy). The maximum permissible exposure temperature depends on the composition of the alloy. Also, this wire does not change its shape under the influence of heat and does not sag.

Nichrome wire has a high resistance to electric current, which means that much less of this metal will be required than a similar one without loss in the amount of heat generated. Consequently, devices that use nichrome wire will have smaller dimensions and weight.

The two-component alloy has no magnetic properties. They occur only with the addition of iron, but have very weak indicators.

Nichrome is not subject to corrosion, is resistant to aggressive environments, due to which it has an almost unlimited service life. Nichrome wire has good ductility and is perfectly formed, while having high strength and hardness, and is not afraid of mechanical stress.

The composition of the metal alloy varies the indicators of these characteristics. The photo shows the main options for winding nichrome wire.

Characteristics of nichrome and its application

The alloy consists of 50−80% nickel and 15−24% chromium with a small amount of additives in the form of aluminum, manganese and chromium. Alloying with rare earth components is possible to increase service life.

Cr20Ni80 is the most common type of material, and wire made from this alloy is the most popular. In second place are stripe and ribbon, and the least popular is the leaf shape.

Depending on the grade of the alloy, it has the following physical characteristics:

- Melting point 1100 - 1400 °C, operating temperature 800−1100 °C.

- Specific resistance depending on the alloy = 1.05−1.4 Ohmxmm²/meter.

- Thermal conductivity coefficient = 11.3W/(mxK)

Nichrome has a number of advantages over wires made of other alloys:

Nichrome is used in most devices, such as:

As you can see, nichrome has good physical properties and is not subject to corrosion, which extends its service life compared to other types of similar materials used for the same purposes. The scope of its use in everyday life is also vast, so the question is often asked - where can you get nichrome thread. Most common options for obtaining nichrome will be listed below.

Application

The quality always justifies the cost. The same applies to nichrome alloy. Wire and tapes made from this material are widely used in areas where any other metals could not replace them. High resistance to oxidation, high-quality mechanical characteristics, including for aggressive environments, high-temperature operating conditions - all this allows it to be used in various fields.

In industry:

- Thermocouples of metallurgical electric heating furnaces.

- Structural elements for induction metal smelting equipment.

- Industrial ventilation dryers.

- Parts of boilers and heat exchangers.

- Electrical production: resistors and rheostats.

- Some electrodes for welding.

- Single-core and multi-core electrical wires.

It is the main structural element for all modern household appliances:

- Heating elements in electric kettles, boilers, boilers, heaters.

- Heating elements in hair dryers, curling irons, irons.

- Automotive spark plugs and heating systems.

- E-Sigs.

Perhaps the price is the only drawback of the nichrome material. Two-component nickel-chrome wire will be more expensive. The iron content and the reduction in the amount of nickel, in turn, dictate a lower cost, but do not provide the same opportunities as X20N80. The choice depends on technical needs.

When choosing nichrome products, it is important to use information about the chemical composition of the brand of interest, its electrical conductivity and resistance, physical characteristics of diameter, cross-section, and length. It is important to be interested in documentation of compliance, as well as to be able to visually distinguish the alloy from its “competitors”. Correctly selected material is the key to the reliability of equipment and technology for its use.

Among precision alloys subject to large temperature changes, nichrome occupies a special place. Due to its high heat resistance, its use is more justified in the manufacture of heating devices and key components of furnace equipment. The working material in this case is nichrome wire of a certain grade. Each of them differs in the percentage of various alloying additives, which allows, based on design performance indicators, to make a choice in favor of one or another sample, depending on its main quality characteristics, the main of which is the resistance of the nichrome wire.

Examples of where you can get nichrome alloy

There are several ways to get nichrome. Each of them differs in the ease of obtaining and the quality of the material, but it is worth considering all possible options.

Ordering material

Nichrome, kanthal, nickel, and wire of some other alloys are sold in wholesale stores. The assortment provided by wholesalers is very large; you can order wire of any desired alloy of any cross-section and thickness. Relevant information about available stores can be found by calling the city's information service, or using an Internet search.

Even if the customer lives in a remote locality where the supplier’s organization is not located, you can request delivery, choosing the most convenient of the proposed options.

The caveat is that you will have to pay a considerable amount for delivery, and intermediaries send orders in large quantities and are unlikely to agree to supply a couple of meters of material.

But if you need a large batch of goods, then this is an ideal option. This is due to the fact that the wholesale price of a meter of wire is almost zero.

Shopping in stores

Probably the most adequate option of all possible for those who require high-quality wire of a certain cross-section, especially when only a few meters of material are required.

Purchasing also has its options:

Soldering Features

The features of nichrome soldering are as follows:

- Use of tin-lead materials POS 50 and POS 1 for solder.

- Careful preparation of flux.

- Proper processing of the working surface.

Before soldering, the working surface is cleaned with sandpaper and treated with cotton wool soaked in an alcohol solution of copper chloride. Next, apply flux and begin the process.

IMPORTANT . Flux is prepared by mixing several elements: 100 g of technical petroleum jelly, 5 g of glycerin and 7 g of zinc chloride powder.

When tinning nichrome with copper leads, it is better to use 2-3 g of citric acid. This is enough to service one wire. To remove acid, the wire must be placed on rosin, dipped, and a soldering iron is used for further work.

ATTENTION TO THOSE WHO WANT TO REGISTER ON THE FORUM. Problem activating your account? Write to (ignel(gav)mail.ru, ICQ 50389649), indicating your nickname and the address from which you registered. Don't forget to look at the forum rules. Ignorance of the rules does not exempt you from responsibility! Don't forget to look at the TB Section. Knowing the rules can save lives. Have questions about using the forum? Look for answers in the FAQ (FAQ). There's a lot of useful stuff there. Looking for interesting materials? Guide to master classes from our forum members

- Artisan »

- Our works »

- We make it ourselves (Moderator: AndyAB) »

- Topic: How to distinguish nichrome wire by eye?

Author Topic: How to distinguish nichrome wire by eye? (Read 31354 times)

0 Users and 1 Guest are viewing this topic.

Among precision alloys subject to large temperature changes, nichrome occupies a special place. Due to its high heat resistance, its use is more justified in the manufacture of heating devices and key components of furnace equipment. The working material in this case is nichrome wire of a certain grade. Each of them differs in the percentage of various alloying additives, which allows, based on design performance indicators, to make a choice in favor of one or another sample, depending on its main quality characteristics, the main of which is the resistance of the nichrome wire.

Self extraction

In household heating devices, a nichrome thread is responsible for heating. Where can I get wire at home, other than from them? This method is not ideal, because the cross-section and length of nichrome involved in each individual device are not known in advance.

But in case of serious need, you can resort to it. Below are examples of things from which nichrome can be obtained.

Nichrome from a soldering iron

In this case, the nichrome thread heats the soldering iron tip. In order to get the wire, you need to disassemble the tool body. As a rule, it uses very thin nichrome. It is important to know that you need a soldering iron with a copper tip, since a ceramic one has a completely different heating element.

Hair dryer

You can get nichrome from a hair dryer, no matter a hair dryer or one used for drying hair. The heating power in it is higher than in a soldering iron; therefore, there will be more wire, and, as a rule, it has a thicker cross-section. To obtain nichrome, simply disassemble the device and remove the spiral-wound wire.

In addition to hair dryers, there are electric room heaters of the same operating principle, they contain nichrome with an even larger cross-section.

Electric stoves, kettles and boilers

Probably the most difficult process of obtaining wire of all those listed. The wire in these devices is located inside the heating element - a tubular electric heating element.

In order to remove it, it is necessary to disconnect the heating element from the device body. It can be powered directly from the mains, so in some cases the wires are cut.

As a rule, the heating element is a spiral, therefore, for more convenient removal, and also so as not to tear the nichrome wire, the spiral should be bent to the state of a straight tube.

The cavity of the heating element pipe, in which the desired spiral is located, is filled with bulk insulating material, which may look like white sand or gypsum. Under high pressure, this substance is pressed into a monolithic state, so to remove the nichrome thread, you must first remove all the insulating material.

The easiest way to do this is to crumble part of it on one side of the tube, and then lightly tap the insulating material with a hammer. This is a very long and tedious process, after which the required nichrome thread is easily removed from the tube.

How to determine nichrome at home?

- 1 How to determine nichrome: How to determine nichrome at home - Heating - How to determine nichrome wire at home?

- 2 We sell nichrome: price per 1 kg, what type of scrap is valued more, who accepts nichrome

- 3 Where can I get nichrome thread at home? — Machine tools, welding, metalworking

- 4 What is nichrome wire: properties, scope, marking and characteristics

- 5 How to determine nichrome at home

- 6 Is nichrome wire magnetic? — Metals, equipment, instructions

- 7 Methods for connecting a nichrome spiral. How to weld nichrome. How to solder nichrome. How to check the resistance of nichrome in an electric spiral

Nichrome wire is a popular material that has already taken its place as a “traditional” one among many similar products. It is obtained thanks to an alloy of nickel and chromium.

If you are also looking for such an option, then simply enter nichrome wire to buy into your search query and then look through all the proposed products.

How to distinguish

During purchase, it is quite difficult for some buyers to distinguish nichrome wire from other products. Most often the material is confused with tungsten.

To avoid such questions, you can use the following tips:

- corrosion resistance. Nichrome has less resistance, so when exposed to an acidic environment, the wire may change color;

- heating. When exposed to high temperatures, tungsten can be deformed;

- appearance. Nichrome wire differs significantly in color.

Also, “cold” processing methods are not used to create the product, which cannot be said about other metals. Most often, during manufacturing, it is rolled into coils, which is quite convenient to use.

An option for “mining” nichrome wire is in this video:

Elektrovek-stal LLC+7(495)639-93-00 Moscow+38(056)790-91-90 Dnepropetrovsk

www.evek.org

How to determine nichrome at home - VashSlesar.ru

You are a young and ambitious vaper. You now have an electronic cigarette that allows you to install your own coils and vape on them. You've learned how to wind very cool coils, but here's the problem. When you want to make a nichrome spiral, if your thermal control on nichrome works perfectly, you may be misled by the price question for this material.

And if you don’t want to spend a lot of money on this wire, then the question arises - where to get nichrome wire so as not to buy it in the store? Let's try to help all novice vapers in this difficult matter.

We sell nichrome: price per 1 kg, what type of scrap is valued more, who receives nichrome

Nichrome from used products or purchased, but not in demand, ends up through non-ferrous metal collection points for recycling .

Nichrome in any form is purchased by both small outlets and reputable companies; the price also varies.

Where to go is decided by the deliverer after studying the conditions.

Let's consider what nichrome and its scrap are, how much they pay for 1 kg of this alloy and why.