Types of cold welding of aluminum

For aluminum parts, three joining methods are suitable, all of which can be called “cold welding”. The first is used in factories and other large industries and is based on the diffusion mechanism. The mutual penetration of metal particles into each other is characteristic not only of aluminum, but it is with this material that the process occurs faster. Diffusion of metals is achieved by applying pressure with special rods (punches), as a result of which new molecular bonds are formed and a strong seam appears.

Another method of joining components is shear welding. Here the pressure on the workpieces will not be point-like, but continuous with a displacement in the horizontal plane. In this case, a connection is created over a large surface. For work, machines with high force and clamping capacity are used.

At home, you can weld products using the methods listed above, but there is a simpler technology. This is cold welding or gluing aluminum with special chemical compounds. They are based on epoxy resin.

The products also contain metal powder, sulfur, other mineral components and additives. In appearance they resemble mastic, plasticine or are liquid. The resin is capable of melting the surface of parts, allowing molecules to penetrate each other. The result is a reliable, strong seam.

Application of cold welding

Repair and gluing of parts by cold welding is used in industry and everyday life. The method is indispensable in an emergency situation, when you urgently need to repair a broken pipe or broken fastener. Most often, such a measure will be temporary; if possible, the patch is removed and the defect is welded with argon or the part is replaced. Epoxy resin-based adhesives are also suitable for car repairs: they are used to seal bumpers, interior elements, and reconstruct other parts. The welding is well attached to the car body, after which it is sanded and painted.

There are high-temperature products on sale; they are applied in a similar way; during operation they can withstand temperatures up to +1000 degrees. Such materials become even more durable after contact with fire.

Cold welding in the form of glue

This is one of the simplest and most accessible methods. It does not require any specific mechanisms or tools, is very convenient, efficient and can help out in emergency situations even “in the field.”

Cold welding in the form of glue

The adhesive is a two-component adhesive based on epoxy resin with added steel powder. It can be produced in the form of mastic or liquid.

Thanks to the achievements of the modern chemical industry, special additives are added to the classic welding glue recipe to significantly improve adhesion, resistance to aggressive environments, operating temperature range, etc. The strength of such glue can even exceed the metal from which the parts being joined are made.

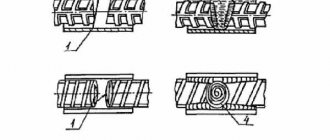

Strain welding methods

Is it possible to weld aluminum parts with your own hands? To create a permanent connection, you need to destroy the oxide film that is present on the surface of the metal, and also press the products tightly against each other. This will help create new crystal lattices between the molecules in the compounds. It is worth taking a closer look at the three possible strain welding methods to choose the best one.

Spot welding

Cold spot welding is the most popular and does not require clamps. The quality of the finished joint will depend on the severity of metal deformation at the weld point. The standards for the ratio of indentation depth to product thickness are as follows:

- pure aluminum – 60-70%;

- aluminum alloys – 75-90%.

This technique is only suitable for parts no more than 1.5 cm thick, but they can be quite large. The sheets are laid overlapping, compressed with punches pointwise, at a certain interval. The disadvantage of the technique is the leakage of the joint.

Seam welding

To perform this method of joining parts, you need special equipment - an annular punch or a rotating roller. By applying variable pressure, the joint becomes continuous. If one-sided welding is required, the roller can be stationary. For double-sided welding, two movable devices are used. The mechanism helps to compress the parts to the required depth and obtain a high-quality seam.

The technology gap is serious. Due to strong continuous compression, the strength of the structure itself decreases. Therefore, the technique was improved and combined elements of suture and point techniques. The joint is created by rotating a roller with protrusions, which exerts point pressure on the parts. The finished joint is an intermittent chain of welded sections, so the structure remains strong.

Butt welding

The method involves the use of clamping devices (jaws), and their dimensions determine the maximum length of the parts, thereby imposing certain restrictions on the process. The products are compressed by their end parts and the area in contact with the sponge. Next, axial pressure is directed to the support, promoting the formation of a strong seam. The downside of the technique is the difficulty of removing the device from the sponges.

Selecting adhesive for welding

When purchasing, you should carefully study the instructions, considering the following parameters:

- Operating temperature range;

- degree of adhesion;

- resistance to aggressive conditions.

For aluminum, it is more convenient to use plasticine-like products, especially if the repair is carried out in an emergency. All formulations are two-component, therefore, before use, they require mixing the components with strict adherence to proportions. Most welding works at temperatures up to +130 degrees, some – up to +260 degrees. If necessary, you can buy a high-temperature product, which costs much more.

Step by step cold welding process

You cannot use metal tools to knead the mass, otherwise it will react with them ahead of time. Before work, you need to put on personal protective equipment: gloves, a respirator, since before the epoxy resin hardens, the evaporation of the epoxy resin is harmful to health.

The procedure for working with welding glue is as follows:

- Degrease the surface. Otherwise, the quality of the clutch will suffer greatly. For this stage it is better to use alcohol and acetone. Dry the surface completely immediately before gluing.

- Prepare the material. Remove the two-layer block from the packaging and cut a piece of the required size strictly perpendicularly. Knead the mixture with your fingers, after wetting the gloves with cold water. You need to use the product for 15-20 minutes, depending on the brand.

- Apply glue to the future joint. After carefully placing the parts, they are securely fixed for 40-50 minutes until the welding hardens. It is better not to touch the products for 2-3 hours, and to use them only after a day, although many manufacturers indicate a shorter period.

- Remove excess adhesive mass. Until the material has completely hardened, you need to remove the glue that has come out from the sides using sandpaper or a sharp knife.

If it is necessary to fill a deep defect, layers up to 0.5 cm thick are successively applied to it and wait until it dries completely. Then repeat the process the required number of times.

Cold welding with glue

The composition is sold in hardware stores in the form of mastic or two liquid components packaged in tubes. The base consists of epoxy resin with added fillers and additives to improve adhesion, strength, resistance to aggressive substances and extreme temperatures. Having glue for liquid welding and damaged aluminum products, repairs can be carried out even in the field.

Cold welding adhesive for aluminum

Glue selection

The stores have a wide range of formulations of domestic and foreign production. When choosing an adhesive for cold welding, you must:

- compare the characteristics of available brands with those required to complete the job;

- pay attention to universal types designed for gluing aluminum parts with other materials;

- carefully study the instructions;

- consult with sellers;

- read customer reviews;

- Keep in mind that liquid compositions take longer to dry than mastic.

Step by step process

Tools for preparing the mixture should not be metal so that it does not react prematurely. For safe work you will need protective gloves and a respirator. The technology for welding aluminum with glue has the following sequence:

- The product is removed from the packaging.

- The quantity required for the job is cast or cut.

- The ingredients are mixed until a homogeneous mass is formed. The period before hardening begins is 30 minutes.

- The areas to be joined are degreased with acetone.

- Glue is applied, then the parts are compressed for 40 minutes.

- Then the protruding mixture is removed with sandpaper.

- The product is allowed to stand for a couple of hours until the product completely hardens.

- Defects and holes are sealed by sequentially applying 5 mm thick layers with each layer completely dry.

Precautionary measures

When working with cold welding, the use of special clothing is mandatory, especially when work is carried out in the following conditions:

- in aggressive environments, places with high temperatures or environmentally hazardous areas;

- when conditions change regularly;

- with vessels under pressure.

Gloves are used even when working with small pieces of welding glue. It is very irritating to the skin, so in case of accidental contact it should be washed thoroughly with soap. If the product penetrates into the eyes, despite the use of protective glasses, rinse them and then consult a doctor. The room must be equipped with an exhaust hood or otherwise provide fresh air, otherwise you can get poisoned by vapors of epoxy resin and solvents.

Step by step process

To perform cold welding on aluminum or its alloys, you must follow the recommendations indicated on the packaging of the product. They often boil down to the following:

- Print cold seal packaging.

- The polymer has a two-color structure, the components of which are either in different containers or wrapped in one another. It is necessary to cast or cut the required portion of the substance, visually sufficient to cover the crack or hole.

- The product is mixed together until smooth. It is best to do this with gloves to prevent skin irritation. The mixed composition is suitable for use for 30 minutes, with constant kneading, which maintains its temperature and plasticity.

- The sides to be welded must be degreased with acetone.

- Cold welding is applied to the future joint and the surfaces are tightly pressed together. A wait of 40 minutes is required until the material hardens.

- After this, excess particles of the substance are removed from the sides. This can be done with sandpaper.

- The product is left alone for another two hours until the materials are completely bonded.

Advantages and disadvantages of the adhesive technique

Cold welding adhesive is a convenient device; it can be used to quickly repair aluminum and other products at home. If you create a continuous seam, it will be sealed, moisture-resistant, and practically not subject to destruction even during vibration (due to elasticity). High temperature compounds allow bonded parts to perform under the most severe conditions.

Other advantages of the glue welding method:

- simplicity, no work experience required;

- low cost of repairs;

- short time before the start of product operation;

- no waste and energy costs;

- the ability to create seams, fill holes, chips, scratches;

- the ability to weld aluminum with any other materials.

The downside is that welding cannot be used on dishes and other utensils that come into contact with food. Also, parts that are exposed to shock loads on a daily basis should be immediately welded with argon - the strength of the adhesive joint will quickly decrease. Cheap compounds usually do not tolerate strong pressure well, although there are means that prevent even the breaking force.

Disadvantages of the cold method

Cold polymer welding allows you to quickly join aluminum parts without the use of a welding machine or clamping equipment. But this method also has a number of limitations:

- the composition, except for high-temperature welding, cannot be used in places of work with elevated temperatures;

- the product does not withstand high pressure (over 10 atmospheres);

- cold welding is not designed for aggressive environments and can only resist corrosion;

- a product welded by a cold method is intended for static loads (constant fluid pressure or holding an object), and can be destroyed by shock and strong vibration.

The use of cold welding allows you to quickly and economically join aluminum and its alloys. In industrial conditions, pressure units are used for this purpose, capable of applying spot or continuous seams. And in a domestic situation, it is possible to weld aluminum without a machine using a special polymer substance.

Manufacturers and popular brands

You should not buy welding compounds from unknown manufacturers; it is better to glue aluminum parts with reliable materials. The choice of brands is large, the following have proven themselves well:

- Diamond;

- Mastix;

- Zollex;

- Abro;

- Poxipol;

- Loctite;

- Weicon.

For car parts made of aluminum and duralumin, you can use Polyrem-Aluminum welding (it is also suitable for domestic needs). The product is designed specifically for aluminum and its alloys, allowing for high-quality repairs without a welding machine. Cold welding is suitable for car radiators, car bodies, panels, cylinder heads, and pipelines. In any case, the quality of the seam will depend on preliminary preparation, compliance with instructions and reliability of fixation, which should be given close attention.

Safety precautions

When working with cold welding on aluminum, due to the toxicity of the welding composition, you must follow the safety rules:

- When working, use rubber gloves and a respirator..

- If crumbs or product solution gets on your skin, wash with warm water and soap or wipe with ethyl alcohol.

- If cold welding dust gets into your eyes, rinse them with warm water and seek medical attention from a doctor.

- Carry out work in a ventilated room.