What is considered a refractory metal?

The sign by which a metal is classified into a group is indicated by its name.

Refractory metals are chemical elements with a melting point higher than most others:

- In the classical sense, this is more than 2200°C. Five metals have this property.

- However, the term “refractory” is also used in relation to metals with a melting point higher than iron, i.e. from 1850°C. According to this parameter, nine more elements are refractory metals.

Thus, the list of refractory elements includes 14 positions.

Niobium

The melting point of niobium is 2741 °C. In its chemical, physical and mechanical properties it is very similar to tantalum. It is quite flexible. It has good weldability and high thermal conductivity even without additional heating. Like all other metals, it is obtained from powder. Final niobium workpieces - wire, tape, pipe.

Read also: Led controller dc12 24v how to connect

The metal itself and its alloys demonstrate the effect of superconductivity. It is widely used for the manufacture of anodes, screen and anti-dynatron grids in electric vacuum devices. Due to its good porosity, it is successfully used as a gas absorbent. In microelectronics, it is used to make resistors in microcircuits.

Niobium has proven itself well as an alloying additive. It is used to create various heat-resistant structures and units operating in aggressive and radioactive environments. Some elements of jet engines are made from an alloy of steel and niobium. Due to its property of not interacting with radioactive substances at high temperatures, for example, uranium, it is used in the manufacture of shells for uranium elements that remove heat in reactors.

Physico-chemical characteristics

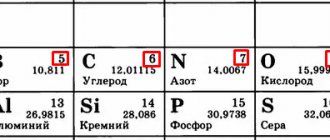

The main characteristic of the group - refractoriness - is provided by the structure of the atoms. The electrons are located so close that breaking the interatomic bonds requires temperatures of up to two thousand degrees.

The second common feature is the slowness of creep deformation. For them to begin to “spread,” heating of 1500+°C is required. Unlike low-melting metals, which spread at a couple of hundred degrees.

However, most of the properties of refractory metals (density, hardness, compression resistance) vary due to belonging to different groups and differences in the structure of the crystal lattice.

More similarities in chemical properties:

- The ease of formation of compounds with other elements, which makes it impossible to detect refractory materials in their pure form.

- When exposed to air, they are covered with a protective film. Speed is determined by temperature.

- When heated or interacting with gases (nitrogen, hydrogen, carbon), the original properties are lost, corrosion develops, and fragility appears.

- Resistance to acids.

Given these characteristics, the elements are worked in a vacuum. The most common example is the tungsten filament inside a household light bulb.

Receiving technology

The source of most refractory materials is ore.

The process is traditional:

- Impurities are removed from it.

- Refined (restores the desired element). The recovery method depends on the required degree of metal purity. Therefore, arc-shaped, electron beam or plasma melting is used.

- Plasma produces the best product. It comes in the form of small granules, powder or blanks (wire, foil, ingots, fittings, rolled products).

The melting technology is specific, so special enterprises deal with such raw materials. There were only two of them in the USSR.

Processing of refractory metals is possible only by powder metallurgy methods.

Areas of application

The use of refractory metals is not limited to household light bulbs.

Their properties ensure use by all sectors of the industrial complex, military-industrial complex, and in everyday life:

- Metallurgy. Ligature component for alloys.

- Shipbuilding, aviation, space construction . Engine parts.

- Nuclear sector . Material of reactor parts.

- Khimprom. Catalyst, light source.

- Electronics. Capacitors.

The material is popular as a base for heat-resistant, highly resistant structures (refractories) for these industries. Especially if parts of a complex configuration are required.

The cultivation of rubies is special. To do this, microdoses of chromium are added to the colorless crystal.

Alloys are almost always used. For example, a molybdenum-tantalum-tungsten composition is in demand among nuclear scientists and spacecraft builders. It does not deform at temperatures of about 4000°C, is elastic, plastic, and resistant to rust.

Tungsten

This metal was discovered back in 1781. Its melting point is 3380 °C. Therefore, it is by far the most refractory metal. Tungsten is obtained from a special powder by subjecting it to chemical treatment. This process is based on pressing followed by sintering at high temperatures. Next, it is subjected to forging and drawing on machines. This is due to its greatest refractoriness. This is how a fibrous structure (wire) is obtained. It is quite durable and practically does not break. At the final stage, it is rolled out into thin threads or flexible tape. To carry out mechanical treatment, it is necessary to create a protective environment of inert gas. In this environment the temperature must exceed 400 °C. At ambient temperatures it acquires paramagnetic properties. It has the following disadvantages:

- difficulty in creating conditions for mechanical processing;

- rapid formation of oxide films on the surface. If there are sulfur-containing substances in contact, sulfide films are formed;

- creating good electrical contact between several parts is only possible when creating high pressure.

Classification

Depending on the melting point, refractory metals are assigned to the main or additional group.

Main group

This segment includes five positions: tungsten, niobium, tantalum, molybdenum, rhenium.

Melts at 2200°C+. Properties of the fourth group of elements

| Name | Niobium | Molybdenum | Tantalum | Tungsten | Rhenium |

| Melting temperature | 2750 K (2477 °C) | 2896 K (2623 °C) | 3290 K (3017 °C) | 3695 K (3422 °C) | 3459 K (3186 °C) |

| Boiling temperature | 5017 K (4744 °C) | 4912 K (4639 °C) | 5731 K (5458 °C) | 5828 K (5555 °C) | 5869 K (5596 °C) |

| Density | 8.57 g cm³ | 10.28 g cm³ | 16.69 g cm³ | 19.25 g cm³ | 21.02 g cm³ |

| Young's modulus | 105 GPa | 329 GPa | 186 GPa | 411 GPa | 463 GPa |

| Vickers hardness | 1320 MPa | 1530 MPa | 873 MPa | 3430 MPa | 2450 MPa |

Molybdenum

The most popular of the refractory elements.

The number one area of use is metallurgy:

- Molybdenum is used to “strengthen” steel to produce a hard alloy.

- Together with stainless steel, it is used as a material for the infrastructure of pipelines, car parts, and other mechanical engineering products.

- Due to its melting point, wear resistance, and low abrasion, it is used as an alloying additive.

Molybdenum requires a couple of percent of alloys in the composition for the properties of the alloy to change.

For example, half a percent titanium plus 0.08% zirconium creates a molybdenum alloy that does not lose strength up to 1060°C.

Extraordinary friction parameters have led to the use of molybdenum as a long-lasting lubricant with high efficiency.

The material is indispensable for mercury relays, since an amalgam with this metal is not formed by mercury.

Tungsten

Opened at the end of the 18th century. The hardest and most refractory (3422°C) metal.

Refractory durable metal, light gray in color - tungsten

Together with copper and iron, it is used as the basis (up to 80%) of alloys with rhenium, thorium, and nickel. Such additives increase density, rust resistance threshold, and reliability.

It is in demand as a material for power supply systems, instruments, ammunition, and nuclear missile warheads. Nickel alloys are valued by golf fans as club materials.

Tungsten ingots

Tungsten and its alloys are in demand where increased density is needed at extreme temperatures.

Tantalum

The most resistant to acids and corrosion from the segment of refractory metals.

Heavy, hard metal of gray color – tantalum

Therefore, it is used in capacitors of smartphones, tablets, and other gadgets.

Compatible with biological organisms (does not change under the influence of natural acids). Because of this, it is used in medicine.

In nature, niobium and tantalum are neighbors. It is no coincidence that they are named after father and daughter – Tantalus and Niobe, characters from ancient Greek myths.

Niobium

Metal with unusual characteristics:

- The lightest (low density) in the segment.

- It is unique due to its ability to change the coefficient of hardness and elasticity depending on the degree of annealing.

- Most common in superconducting alloys.

It is used as a material for capacitors, gas turbines, rockets, and aircraft. As well as an element of nuclear reactors and lamps of electronic devices.

Together with hafnium and titanium, it is a material for spacecraft engines (for example, the American Apollo).

Rhenium

It was discovered later than all of the previously listed metals. It fully lives up to its name "rare earth metal" because it is found in small quantities in the ore of other metals such as platinum or copper. It is mainly used as an alloying additive. The resulting alloys acquire good strength and ductility characteristics. This is one of the most expensive metals, so its use leads to a sharp increase in the price of all equipment. However, it is used as a catalyst.

Chrome is a unique metal. It is widely used in industry due to its remarkable properties: strength, resistance to external influences (heat and corrosion), ductility. A fairly hard but brittle metal. It has a steel-gray color. All the chromium needed is extracted from the ore of two types of iron chromite or chromium oxide.

Its main properties are:

- Even at normal temperature it has almost perfect antiferromagnetic ordering. This gives it excellent magnetic properties.

- Reacts differently to exposure to hydrogen and nitrogen. In the first case, it retains its strength. In the second, it becomes brittle and completely loses all its plastic properties.

- It is highly resistant to corrosion. This happens due to the fact that when interacting with oxygen, a thin protective film is formed on the surface. It serves to protect against further corrosion.

It is used in the metallurgical, chemical, and construction industries. Chromium, as an alloying additive, is necessarily used for the production of various grades of stainless steel. It occupies a special place in the manufacture of such material as nichrome. This material can withstand very high temperatures. Therefore, it is used in various heating elements. Chrome is actively used to cover the surfaces of various parts (metal, wood, leather). This process is carried out using electroplating.

The toxicity of some chromium salts is used to preserve wood from damage and the harmful effects of fungi and mold. They are also good at repelling ants, termites, and insects that destroy wooden structures. Chromium salts are used to treat the skin. Chromium is used in the manufacture of various dyes.

Due to its high heat resistance, it is used as a refractory material for blast furnaces. The catalytic properties of chromium compounds are successfully used in the processing of hydrocarbons. It is added when producing the highest quality magnetic tapes. It provides low noise figure and wide bandwidth.

If you find an error, please select a piece of text and press Ctrl+Enter.