The carburetor of the internal combustion engine of the Carver chainsaw is responsible for supplying the correctly dosed fuel-air mixture. By increasing the mixture supply when pressing the throttle, engine speed increases. Stable idle speed also depends on proper carburetor operation. This is an important chainsaw system and you need to have an understanding of how it works, know the basics of diagnostics, and also be able to adjust and repair it.

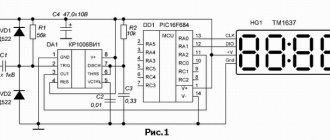

Carburetor design on a Carver chainsaw

Most modern chainsaws (Carver is no exception) have either completely identical carburetors from one manufacturer (for example, Walbro), or very similar in design. But even with differences in the appearance of the body, the operating principle of all carburetors is absolutely the same.

But the carburetors on Carver saws differ from other chainsaws in the availability of adjustment. The adjustment screws on most other saw models are hidden under the body and often have unique shaped notches. Therefore, they can only be adjusted with special “branded” screwdrivers, which are sold in service centers. The Carver carburetor is adjusted with a regular flathead screwdriver. There are three holes in the housing for adjusting screws. Therefore, the carburetor on a Carver chainsaw can be adjusted without even removing the casing.

Main components of the Carver carburetor

The chainsaw carburetor consists of the following main components:

- cast light alloy body;

- diaphragm pump for manual pumping of fuel before starting (suction);

- diffuser;

- jets (strictly calibrated holes in bronze bushings for dosed fuel supply);

- float chamber;

- spray.

Chainsaw carburetors also have fuel passages, an adjustable throttle (gas) valve, an air damper, filters and adjustment screws.

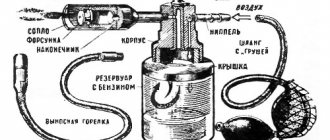

Operating principle of a Carver carburetor

After starting the internal combustion engine of the chainsaw, the air damper opens, through which purified air enters the diffuser through a fine filter. Gasoline also enters there through calibrated holes in the nozzles. The amount of air-fuel mixture that enters the combustion chamber from the carburetor is regulated by the position of the throttle valve, connected by a rod to the throttle handle.

The needle valve stops the flow of gasoline into the carburetor when it is filled. Gasoline passes through a filter before entering the nozzles, which reduces the risk of clogging the calibrated holes in them.

What the three carburetor screws L, H, and T regulate.

On older models of chainsaws there are only two adjustment screws. One of them adjusts the idle speed by simply lifting the throttle. When it is twisted, the passage under the damper increases, the supply of fuel to the combustion chamber increases, and the engine increases speed. Essentially, twisting "adds throttle" without pressing the throttle.

In modern Carver chainsaw carburetors, the idle speed screw T adjusts not the throttle position, but the amount of fuel flowing through the idle jet.

The screw L inside has a sharp needle-shaped tip and regulates the main flow of fuel through the calibrated hole of the nozzle.

Modern models have two such screws. One - L, regulates the main fuel flow at low and medium speeds (not to be confused with idle). The second - H, determines the fuel supply at maximum speed.

Ill-considered adjustment of screw H can lead to unpleasant consequences. For example, the internal combustion engine of a Carver chainsaw, designed for a maximum speed of 12 thousand rpm at full throttle, will reach speeds of up to 15 thousand rpm and fail. Moreover, any adjustment of H only leads to an imbalance in the fuel supply, and the engine may “sag” at certain speeds.

Chainsaw won't idle

The problem is quite common. The most common causes of stalling at start-up and cranking of the chain:

- The air and fuel filters are clogged;

- Low-quality fuel is used or the fuel mixture is incorrectly prepared;

- Problems with the ignition module;

- The carburetor unit settings do not correspond to the load level;

- Deformation or rusting of motor components.

Algorithm of actions:

- The fuel hose is thoroughly washed or replaced;

- The air filter is cleaned of all contaminants. The reusability of filters allows them to be removed and cleaned with detergents;

- Fuel and oil are checked for quality. It is better to use the mixtures specified by the manufacturer in the instructions;

- The carburetor block and spark plugs are tested.

When customization is required

Modern “three-screw” carburetors of Carver chainsaws are practically not designed for manual adjustment at home. The screws are provided for factory settings, are securely secured against rotation during vibration by tenacious springs and do not change their position arbitrarily.

But the screws on the carburetors of Carver chainsaws can be adjusted through special holes without removing the casing using a regular screwdriver. This suggests that such models structurally require carburetor adjustment from time to time.

The reason for this cannot be precisely stated from a technical point of view. Only versions are possible:

- The carburetor of the Carver chainsaw is located in an area of high vibration, which causes the screws to unwind spontaneously.

- A rough spring is installed, which cannot fix the screw as on other models.

- Periodic adjustment is required due to the technical features of the carburetor and the internal combustion engine of the Carver chainsaw as a whole.

Malfunctions of the chainsaw fuel supply system

What else could be the reason that the chainsaw does not work?

A chainsaw malfunction can be caused by one of the breakdowns in the fuel supply system:

- the fuel supply system filter is clogged;

- the hole in the tank lid is clogged;

- Not enough fuel is supplied to the chainsaw engine.

What you can do yourself to fix the problem:

- sometimes, to make the chainsaw work, it is enough to clean the hole in the tank lid with a needle;

- the fuel filter must be cleaned and changed from time to time;

- It is also necessary to clean and change the air filter of the chainsaw on time.

How to adjust the carburetor on a Carver chainsaw

Adjusting the idle speed with the T screw is always separate. If the Carver chainsaw engine stalls at idle, this may be due to:

- poor spark plug performance;

- loss of compression due to critical wear of the piston system;

- bad fuel;

- poor carburetor performance not related to adjustment;

- filters clogged with paraffin in the tank and carburetor.

For the same reasons, the engine of a Carver chainsaw may work poorly not only at idle, but in general - it does not pull, does not develop speed, stalls when the throttle is pressed, etc. Therefore, we must first try to deal with these reasons. And lastly, if the problems are not solved, you can try to increase the idle speed by turning screw T clockwise.

- If the engine does not start at all at idle precisely because of a violation of the adjustment, screw T is tightened 1/2 or 3/4 of a turn and the engine is started.

- Then they adjust by ear with the engine running, observing all safety measures. (With a strong increase in speed, the chainsaw chain may begin to rotate, and this is dangerous).

- If the chain spins at idle, screw T is unscrewed back to a position in which the engine idles confidently and does not stall, and the chain does not spin.

Then check the operation of the chainsaw engine in all modes. If it idles steadily, but stalls when you press the gas, this is a sure sign of a lack of fuel supply to the combustion chamber. If all systems are working properly, filters and jets are clean, the cause is most likely a violation of the adjustment of screw L.

- It is also better to adjust it with the Carver chainsaw engine running and warm, screwing it in 1/4 turn and trying to rev it up.

- If the fuel supply is too plentiful, the engine will operate as if idling when the throttle is in the “full throttle” position. This means that screw L is tightened too tightly and you need to unscrew it back in 1/4 turn increments, trying to give gas.

If, after adjusting screw L, the Carver engine does not produce the power required for operation, you can carefully try to increase the maximum speed by adjusting screw H.

It is also adjusted with the engine running, but in the “full throttle” position. Extremely carefully, screw in the screw 1/5, 1/6 of a turn and listen to the operation of the engine.

Increasing the speed ceiling can slightly extend the life of an old chainsaw with a worn piston. Weak compression is compensated by a higher mixture supply at maximum speed.

There is no point in experimenting with such adjustments in new chainsaws.

Professional adjustment of screw H is carried out using a tachometer to determine the speed ceiling and an oscilloscope to monitor the frequency of flashes on the spark plug. Compression is pre-checked.

After adjusting screw H, operation in other modes may change. Therefore, it will be necessary to test the operation in all modes and, if necessary, slightly adjust the adjustment with screws L and T.

Many people recommend adjusting the screws by tightening them all the way, and then turning them out 1.45 or 1.5 turns.

This is not always worth doing for the following reasons:

- If twisted too hard, the sharp end of the screw can destroy the loose powder bronze jet on cheap chainsaws, and this will cause a breakdown.

- 1.45-1.5 turns from “to the end” may not correspond to the old position of the screws, in which the chainsaw still worked to the last, and to the actual factory settings.

Therefore, it is necessary to adjust based on the “as it was” position by no more than 1/4 turn at a time. It is important to remember how much and in what direction the position of the screw was changed.

If you still need to tighten the screw “to the end”, count the number of turns from the “as it was” position, this will make it possible to return the settings to their previous position. You need to tighten it “all the way” without effort.

The general principles of self-adjustment of a chainsaw carburetor are presented in the following video:

Burnt out piston: reasons and what to do

A study of various piston damage shows that all causes of defects and breakdowns are divided into 4 groups:

- cooling interruptions

- imperfection of lubrication

- excessively large thermal influence from gases in the combustion chamber

- mechanical problems.

However, many of the causes of piston defects are interrelated, as are the functions performed by its various elements. In particular, defects in the sealing belt cause overheating of the piston, damage to the fire and guide belts, and scuffing on the guide belt leads to disruption of the sealing and heat transfer properties of the piston rings.

Ultimately, this will most likely cause the fire belt to burn out.

Why did the piston burn out?

Lean mixture

1 liter of gasoline contains more than 16 kg of oxygen. It does not burn very quickly, the motor overheats, the energy drops, and as a result the entire engine overheats. The piston is key in this list, because it is aluminum (if you do not take into account tuned pistons) and is located directly in the fuel combustion zone. As is well known, aluminum melts at about 660 °C, and when you consider that the maximum permissible engine temperature is only 150 degrees, and then no oil can lubricate 200 °C, it doesn’t take long to calculate that a lean mixture can still heat up the parts in the middle of the engine more than rather than 4 times more.

Bad gasoline

Fresh gasoline burns the piston for the same reason - as a result of overheating. Because the gasoline that we pour into our gas tank often cannot be called gasoline. Proper gasoline burns at a fairly low temperature, while expanding very intensely, because the essence of any gas driven to the top dead center (TDC) is that it expands to the maximum relative to its original volume, thereby pushing the piston downwards with the utmost convincing force, and combustion and the generated temperature are all side effects, without which the engine would do just fine. Bad gasoline, like normal gasoline, contains components such as benzene, gasoline and other bad substances. The fact is that they are contained in low-quality “gasolines” in completely different proportions, and in fact in larger proportions than the standards allow.

Burnt out piston signs and symptoms

These two marvelous components burn, releasing more heat and at the same time have a low expansion coefficient during combustion, and at the same time, being part of gasoline, they slow down the combustion rate, reducing power. Consequently, when driving on such fuel, in order to achieve proper traction, it is necessary to twist the throttle more than when driving on normal gasoline, but here’s the misfortune: we get the necessary traction complete with a much higher combustion temperature and excessive fuel consumption, and the result of this is a hole in piston

The operation of the piston is affected by many factors and it is impossible to give an unambiguous answer as to whether a specific piston will burn out or some other defect will occur. You can estimate the probability of a particular event occurring. And in order to prevent the occurrence of such an unpleasant event as piston burnout, it is necessary to follow the rules written in the manual. After all, piston burnout is a purely operational defect.

skuterov.ru

No spark when starting the chainsaw

The first and most obvious reason that “kills” a spark is poor contact between its tip and the wire. It is necessary to adjust the gap to 0.6-0.7 mm. If there is carbon deposits on the spark plug, it should be removed or the spark plug replaced.

It happens that fuel floods the spark plug when starting the chainsaw. In this case, the candle must be dried (but not calcined). The remaining fuel is drained through the hole in the spark plug, after which it is left in a dry place for half an hour. Then the spark plug is put back in place and the start is repeated. It is better to always have a couple of spare spark plugs, this will help you immediately determine the malfunction and not interrupt work if it is urgent.

Inspecting the spark plug will help determine the problem.

Inspecting the spark plug always provides important information. If it is dry, it means that gasoline is not entering the cylinders and you need to inspect the entire fuel supply chain from the carburetor. The appearance of carbon deposits indicates an excess fuel supply or excess oil.

If, upon inspection, this area appears to be in good working order, but a spark still does not appear, then the problem is in the ignition unit . It is easier to replace it with a new assembly.

Everything you need to know about chainsaw spark plugs

Chainsaws use electric spark plugs for two-stroke engines. Similar or completely similar spark plugs work on lawn mowers, gas generators, small motor pumps and other devices with a small two-stroke internal combustion engine.

Exceeding the permissible engine speed

Another common cause of damaged piston rings, piston pin circlips, and bearing failure is excessive engine speed.

Piston ring destruction usually occurs when the permissible engine speed is exceeded. The increased temperature causes the ring to get stuck in the piston groove as it moves, which prevents the piston ring from completely moving into the groove. As a result, the sharp edge of the ring protrudes, which can begin to cling to irregularities and become pinched in the cylinder, leading to its breakage.

Additionally, running the engine at too high a speed can cause the ends of the piston ring to tap against the pin as the ring moves along its groove. If this knock becomes intense, it can knock the pin out of the piston, causing significant damage to both the cylinder and piston.

Chainsaw chain problems

In addition to problems with the engine, the chainsaw may experience operational problems due to a malfunction of the cutting (sawing) unit, consisting of an oil pump, bar and saw chain.

There is no oil getting to the tire

Usually, if oil does not flow to the chainsaw chain, you need to check the channels through which oil is supplied to the tire and clean them of dirt. If the previous steps did not reveal the cause of the problem, then you will have to check the oil pump. To do this you need:

- remove part of the chainsaw casing;

- remove the coupling;

- unscrew the 3 screws and remove the cover hiding the pump;

- get to the worm gear gear that rotates the pump shaft.

If the thread on it is worn out, the shaft does not rotate, the pump does not work, and the chain is not lubricated. A worn gear needs to be replaced. You can also remove the oil pump itself and manually try to pump oil through it. If it does not pump, the pump should be replaced.

Chainsaw oil filter

Also, a lack of lubricant may be due to its leakage

. You should check how tightly the pipes coming from the oil pump are connected. If the tightness is broken, the tubes are replaced with new ones.

The chain breaks

If the chain breaks while the chainsaw is running, this could happen when it hits a hard object, such as a nail. If the chain constantly breaks, then the reasons may be the following.

- Low quality metal

from which the saw chain is made. It is necessary to buy gas cutter saws from reputable brands. - Chain overheating due to poor lubrication

. As a result, the saw overheats, the properties of the metal change, and it breaks under load. It is necessary to check the entire chainsaw lubrication system (discussed above).

You can also learn about the reasons for frequent circuit breaks from this video.

The chain doesn't turn

This nuisance often plagues inexperienced chainsaw owners. to remove the brake after starting the engine.

. As a result, the chain does not spin, the brake system overheats, and the clutch mechanism fails. The problem is solved by removing the saw from the brake. If the clutch is not burnt out, you will notice the chain turning. Otherwise, the clutch mechanism will need to be replaced.

The chain gets dull quickly

Basically, the reason that the chain becomes dull quickly is the poor quality of the saw.

. Trying to save money on buying branded chains, chainsaw owners buy saws from unknown manufacturers, or, due to inexperience, purchase counterfeits of well-known brands. It is best to buy a cutting element for a gas cutter in company stores. Stihl saw chains are very popular among owners of this equipment.

The chain doesn't stop

If, when working with a chainsaw, you notice that the saw chain does not stop at the right moment, then this breakdown may have 2 options.

- The brake band is dirty

. When operating the saw, dirt, sawdust, dust, etc. may get under the band. As a result, the brake mechanism becomes blocked and the chain does not stop when the gas is released. The problem is eliminated by cleaning this unit. - The brake band is worn out

. This element of the brake system needs to be replaced.

The chain is jammed

This happens when the drive or driven sprocket wears out.

The chain usually starts to jam under load. But without load the saw can rotate. The photo below shows a worn chainsaw drive sprocket.

The next photo shows that the reason why the chain jams must be looked for at the location of the driven sprocket.

But what to do if the chainsaw is completely jammed?

and all attempts to pull the starter are unsuccessful? This malfunction sometimes occurs on Chinese-made chainsaws. It is caused by the bolts that screw the engine to the plastic casing of the unit becoming loose due to vibration. These bolts are located directly under the flywheel (magneto). In the photo below, arrows show the location of the problem bolts.

As they unscrew, they begin to rub against the flywheel and can completely jam the chainsaw. The following photo shows the flywheel with some scuff marks from the bolts.

To fix the problem, you will need to remove the flywheel from the engine shaft and tighten the bolts.

The chainsaw cuts crookedly

This problem can occur if the chain is dull or improperly sharpened. This applies to a greater extent to new chainsaws. But if the tire wears out

, then even after replacing the chain you will notice that the saw is pulled to the side. Tire wear can be easily determined by placing it on a level table and applying a square to it, as shown in the following photo.

In this case, you can see that there is a gap of about 2 mm between the tire and the corner. It is because of this one-sided tire wear that the chainsaw cuts crookedly. The problem can only be solved by replacing the tire with a new one.

Types of chainsaws

Chainsaws are divided by class and purpose.

- Household. These saws are used in everyday life. For example, for harvesting firewood, cutting boards. A household saw can be used to cut down branches and trees of small thickness. The tool has a minimum of functions, low power and weighs up to 4 kg. Household saws are the cheapest and are not designed to last long. Recommended use is up to 20 hours per month, that is, 40 minutes per day. Women and older people can easily use such saws.

- Semi-professional. Used for felling trees and construction work. They are often purchased for professional use, for example, by employees of landscaping companies. But such saws can also be used in everyday life due to their smaller size and weight than that of a professional tool. Technical characteristics and price are between household saws and professional ones. The disadvantage of these saws is that you cannot work for 10 hours continuously. Large intervals must be taken.

- Professional. Such saws have all the necessary functions, high power up to 6400 W, large size and weight. They are used by utility and rescue services, but they are mainly used by lumberjacks. After all, with such a powerful tool you can cut down trees with a diameter of more than 70 cm and work for 8–10 hours without breaks. Professional chainsaws last for years. They have the most reliable piston system, chrome-plated cylinders. The service life is 3 times greater than that of household models. Accordingly, the price of such a tool is the highest.

The purpose of the tool affects power, weight and size. Chainsaws have three purposes:

Video text

Find out how to fix the most common chainsaw problems using just two standard wrenches!

1. The chainsaw does not start 0:30 1.1. Checking the fuel mixture 1.2. Checking the spark plug of a chainsaw 1.3. Checking chainsaw compression 1.4. Checking the chainsaw carburetor

2. The chainsaw chain does not rotate 5:46 2.1. Removing the chainsaw chain from the brake 2.2. Development of a chainsaw tire sprocket

3. The chainsaw does not cut 6:45 3.1. Checking chainsaw chain teeth 3.2. Checking the sharpening of the chainsaw chain 3.3. Checking chainsaw chain lubrication

What to do if nothing helps 7:58

Stepan Latypov, director of the Belarbo enterprise, says:

Almost every village resident and many dacha owners have chainsaws on their households. They are easy to use and can be repaired yourself. Finding out the reason why the device does not start, troits, or has problems with idling is not so difficult. Despite the types of chainsaws, the principles of repair are the same.

Proper operation and care of a chainsaw

Before the first start, carefully study all the main elements of the chainsaw, their location and purpose. When assembling, follow the instructions in the instruction manual, especially the highlighted words “Warning”, “Danger”, “Caution”, etc. Incorrect assembly can lead not only to damage to saw parts, but also to injury.

Correct assembly will help avoid breakdowns during operation.

Before starting work, each time check the integrity of the components, connections, their strong and reliable fastening. Early detection and replacement of parts that show signs of damage can prevent further serious damage.

Pay special attention to operation in winter. Good models of chainsaws are equipped with temperature regulators. This will help avoid problems when starting the engine in subzero temperatures.