Wheel nuts are part of the mounting system for mounting the rims to the hub. The special shape ensures reliable fastening while the car is driving and firmly presses the discs to the drum. Used for a car whose wheels are held in place by studs and mounting bolts. Maximum number of wheel nuts:

- For passenger cars – 4.

- For freight transport – 12.

- For special equipment – dozens.

It is difficult to overestimate the importance of fastening systems, since the safety of passengers in any vehicle depends on it. If lost or damaged, metal parts must be replaced.

The quality of the nuts directly affects the strength of the wheels.

In order to choose the right fasteners, you should understand the types, designs and use cases.

Types of fasteners

Here are the types of fasteners needed for alloy wheels:

- Bolts are metal rods with a screw thread at the end. Used to connect detachable elements.

- Nuts are round-shaped parts designed to fasten elements by screwing a metal die onto threaded rods.

Steel, aluminum or titanium alloys are used to produce products.

Titanium bolts are distinguished by high quality indicators. Black bolts for alloy wheels are made from steel with the addition of molybdenum or steel with a chrome or nickel coating.

Appearance and service life

The issue of appearance is also important, since ferrous metal fasteners can easily spoil the appearance of the most spectacular alloy wheels. Products with a wide variety of decorative coatings are widely represented on the automotive spare parts market, so, as a rule, there are no problems with choice. The industry produces chrome-plated bolts, as well as parts coated with molybdenum and nickel. Chrome products look the most attractive - they go well with polished wheels and shiny parts of the car body. In addition, there is an opinion that chromium provides the best protection for nuts and bolts from corrosion, extending their service life. What does practice say? In fact, unfortunately, there is no direct evidence that coated fasteners for disks last longer, and experts say that the service life of regular, chrome-plated and nickel-plated nuts is approximately the same.

As for the appearance, any experienced motorist will say that the excellent appearance of even the highest quality coated nuts is maintained under our road conditions for no longer than one year.

Characteristics of bolts and nuts

Bolts and nuts differ in design features, so the choice is determined by the type of disk. The stamped disc is made from a durable type of steel. Moreover, it has a small thickness at the point of attachment to the central part of the rotating part. For an optimal connection, the bolt and nut must have a flat surface. The composition of cast wheels includes relatively light alloys. They have reduced reliability characteristics. The fastening system of the products is made in the form of a cone.

Thread

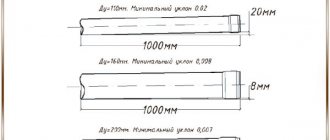

When purchasing bolts, you should pay attention to the threaded part. Not all elements have the same thread pitch. More often there are hardware with a thread pitch of 1.25 and 1.5 mm with a diameter of 12 or 14 mm. It is recommended to purchase new wheel bolts complete with rims or take into account the requirements of the car manufacturer's instructions.

Types and characteristics

On a note!

Wheel nuts are part of a wide group of fastening systems. The elements come in a variety of designs, types of thrust surfaces, installation methods, and applications.

Depending on the form, two groups can be distinguished:

- Non-standard models in the form of caps with a closed threaded part. Inside the element there is a blind channel with a section of thread. Thanks to these design nuances, an aesthetic appearance is achieved and additional protection is provided. The top of the cap follows the shape of the key for which the product is selected: external and internal hexagon for open-end wrenches, for a key with a central point, for a “secret key”. Locking nuts have an additional function - protection against wheel theft. This is achieved thanks to a complex design designed for a secret key, without which dismantling is impossible. It is enough to use 1 piece for each wheel and tighten firmly with a special wrench, which is sold in the kit.

There is a pressing surface at the bottom of the nut

- Classic nuts with through threads and an external hexagon for L-shaped keys. The product is asymmetrical. The lower part is occupied by the clamping surface to ensure reliable fixation of the disk, support and centering. The upper part is distinguished by an oblique edge of the material at the end.

Both types of fasteners are cast from alloy steel, which is characterized by increased strength and corrosion resistance. Manufacturing method: cold stamping with finishing machining. For additional protection, the metal is coated with hot zinc. Liquid nickel and chromium play the role of decorative coating.

Depending on the profile of the pressing surface, the following types of products are distinguished:

- Spherical models with an increased diameter compared to a nut. Products may vary in height.

- Flat models with increased diameter.

- Products with a truncated cone.

You might be interested in this About wheels for Land Rover Freelander 2

What is a bolt pattern

Bolt pattern - indicators indicating the correspondence of the sizes of bolts and disks. The information is useful for searching for disk products. Based on the data, identical holes are found on new disks. The number of recesses is between three and six pieces, but the diameter and distance indicators differ for each manufacturer.

Full and abbreviated bolt pattern formula

Manufacturers provide detailed wording that reflects all important meanings. Motorists use abbreviations that do not fully describe the product.

Abbreviated

PCD (Pitch Circle Diameter) is a short formulation that includes two parameters. It is indicated: 4×98 - wheel bolt pattern on a VAZ-2110. The number of four indicates the number of bolt recesses. The number 98 was obtained as a result of the transverse method of measuring their circumference.

Full

Let's look at an example: the full bolt pattern formula is indicated on the rim: 7.5 J×15 H2 5×100 ET 40 D 54.1.

Decoding of alphanumeric groups means:

- 5 JX 15 – rim width 7.5 inches and diameter 15 inches;

- X – indicates that the disc is made by casting or forging;

- J – it is recommended to use the product on single-wheel drive vehicles;

- JJ – marking of all-wheel drive models;

- H2 – the number of protrusions that secure the tires. Models with one protrusion - H1. Absence of protrusions - marking AN;

- Hump - indicates high-quality rubber retention; this feature eliminates depressurization.

Wheel nuts

Wheel nuts, like bolts, are distinguished by 4 main parameters: diameter and thread pitch, profile of the clamping part, nut height, wrench size.

Wheel nut diameter and thread pitch

The diameter and thread pitch of the nut must match the stud, i.e. car make and model. Possible wheel nut thread options for passenger cars and light commercial vehicles: 12 x 1.5, 12 x 1.25, 14 x1.5, 16 x 1.5, as well as inch threads. Determine the diameter and thread pitch of the wheel nut using the selection by car function in our online store.

Profile of the wheel nut clamping part

The profile of the clamping part of the wheel nuts can be conical, spherical, or flat. As with bolts, wheel nuts are selected solely according to the profile of the well in the wheel rim. The consequences of incorrect selection are described in detail in the previous article.

When making your own selection, you need to take into account the following facts:

- spherical nuts

- only for original Honda, Rover and several older VW models; - flat nuts

- only for original alloy wheels of Toyota, Mitsubishi, Hyundai, some global models of Peugeot and Citroen; - cone nuts

- for original wheels of those car brands that are not mentioned in the previous paragraphs; - Third party discs are designed to use flare nuts only.

Nut height, spanner size, form factor

The height of the wheel nut is not of fundamental importance. The main thing is that the nut is not lower than the original sample, otherwise there is a risk that the wheel stud will rest against the “bottom” of the nut. As a rule, for disks with deep wells, nuts are installed higher.

Wheel nuts come in open and closed types. In most cases, steel disks are fastened open because it is assumed that such a disk will be covered with a cap, and a high closed nut can prevent this. Secondly, saving money, because... open wheel nuts are significantly cheaper.

Choose wheel nuts that match the size of your original wheel wrench. This must be done for several reasons. Firstly, in the future this will eliminate confusion when selecting a nut based on the car model. Secondly, you don't have to buy a new wheel wrench.

Consequences from another bolt pattern

Using inappropriate bolts is a safety hazard. When a bolt pattern occurs, an axial displacement of the entire wheel relative to the hub occurs. At high speeds, the wheel spins unevenly, the car will shake, which is accompanied by a beating in the steering wheel.

When installing wheels, car enthusiasts often encounter such a problem as a discrepancy in the diameter of the fasteners. In this case, eccentric bolts with a movable conical part are suitable, which will eliminate discrepancies in size.

How to choose the length of the wheel bolt?

A properly selected rim bolt is one that protrudes beyond the rim by approximately 12mm. Using bolts that are too short will prevent the nut from being torqued enough, which will loosen the rim fit. In turn, a screw that is too long will be exposed to the elements and will quickly corrode. In some cases, this may even make it impossible to remove the rim.

It is also worth remembering that for each screw there is a certain number of turns required to fully screw in. For example, 5, 6, 7 or 8 full turns. Remember that bolt length is measured from the beginning of the seat to the end of the bolt. It is a mistake to measure the threaded part or the entire bolt.

Tightening fasteners on alloy wheels

Before installing the bolts into the mounting recesses, it is recommended to treat the hardware with graphite lubricant. As a result, when it comes into contact with the disk, the head of the bolt or nut will rotate and make full contact. This will prevent blocking during starting power due to friction between the disc and the mounting system. Bolts are produced that compensate for minimal deviations in fastener dimensions. A loose connection will lead to cyclical failures in the fastening system; the bolts and nuts will begin to unscrew themselves.

How to choose the right wheel bolt

The selection is based primarily on the type of disks that are installed on the car:

- Cast. To secure them securely, longer and thicker bolts are required. That is, they must have an impressive width, length and thread size. But you can’t tell this by eye, can you? The solution is very simple - when unscrewing old bolts, count the number of turns they make. The recommended quantity is at least six to nine. Absolutely any sample in terms of parameters, while the price for each wheel bolt will be lower than in any auto parts store and will really please you, can be found in “Matrix-Auto”.

- Stamped. Here the situation is the other way around - the characteristics are much smaller and when purchasing you need to determine them as accurately as possible in order to avoid the bolt sticking into the hub and disrupting the normal functioning of the brake elements.

Wheel bolts and another important nuance

A significant point when choosing them is the thread pitch. It is also not a constant parameter. The meaning of each is specified by the automaker. Most often, the diameter is twelve or fourteen millimeters, but the pitch itself is about one and a half.

But this is just an average statistical indicator in terms of frequency of occurrence; it is important to know exactly your specific indicator.

Locking bolts for alloy wheels

Secret bolts for alloy wheels are another subtype. If you install locks, car tires will be protected from theft. You won't be able to remove the wheel with a regular wrench. To unwind the secrets, you will need a key that comes with them in one set.

When selecting fasteners for wheels, you should remember that cast products are relatively thick. Accordingly, longer bolts are selected for them than for stamped discs.

Did you manage to solve your problem using the recommendations from the article?

Yes!

45.45%

No. More answers required. I'll ask in the comments now.

38.29%

Partially. There are still questions. I'll write in the comments now.

16.25%

Voted: 363

Selection rules

Even the bolts and nuts for alloy wheels are different. Therefore, it is highly advisable to purchase them with the discs themselves. The choice of bolts will need to be made depending on the material:

- budget models are made of ordinary metal;

- expensive models are made of steel.

The optimal bolt length is measured by fitting. This is unlikely in a shop environment, since (with rare exceptions) there is no practice of screwing an unpaid bolt into a wheel rim.

It will be easier to take out the old fastening element, count the number of revolutions there, and then divide by the length of the product. This will allow you to determine the length of one turn.

As for the nuts, due to their use on domestic, American or Japanese cars, they are made of different materials. It is believed that it is better to choose titanium products due to their quality. But they cost an order of magnitude more than others. A more affordable option is aluminum (sometimes with silicon and magnesium). It is quite light, but not very durable. Steel is the optimal combination of quality and price for a nut. Pay attention to the presence or absence of collars, as well as the type of model (open or closed). The latter will better protect the connection from dirt and moisture.

Non-standard key fasteners are designed to protect the car from wheel theft. How to choose the right one? And will it be of any use? Our expertise includes eight different types of security locks (bolts and nuts) to suit any wallet. Does more expensive mean better? Let's check!

We naively thought that the times when parked cars were “undressed” were forever in the past. But no, history repeats itself. Only the stakes have increased: it’s not the wipers that are being removed, but the headlights and wheels. And if everything is not simple with the headlights, then wheel locks can save your shoes. At least the thieves will definitely have more trouble. And there is a chance that they will go looking for easier prey.

Let’s figure out which of the “secret” fastener kits sold on the market will cope with their task better than others.

WHERE TO HIDE THE KEY?

When buying a set of security locks, it is better to take the one that contains a pair of keys. You can keep one at home or in the garage, and take the other with you. It is highly advisable not to store it in plain sight. There are cases when wheel thieves first broke the windows in the hope that the key was in the glove box. Do not store the key next to the tank: this is the second place where thieves look. Sometimes they simply puncture one of the wheels and watch from the side where the angry owner will reach to get the key and put on the spare tire.

Simpler or more cunning?

When choosing wheel locks, many people ask the question: what to do if the key is lost? Maybe buy something very simple that can be used with a regular screwdriver? But it’s the same as locking the door and hanging the key on a nail next to it! Secret fasteners must resist hacking attempts as much as possible - this is its main task. And the owner does not need to scatter the keys anywhere.

The approximate price of the set is 1200 rubles.

Weight of one bolt 90 g

For ease of use, the keys are equipped with plastic guide bushings. But overall the set did not excite me. The code element in the shape of a small-toothed star easily yielded to a powerful slotted screwdriver.

The approximate price of the set is 1200 rubles.

Weight of one bolt 40 g

Titanium cannot be confused with anything else: it is lightweight. Secrets made of this metal are not afraid of corrosion. It was not possible to mechanically compress the bushing with a gas wrench in order to unscrew it. But, unfortunately, the nice bolts gave in when the twelve-sided head was driven in “16”.

Read also: How to install wiring for spotlights

The approximate price of the set is 1000 rubles.

Weight of one bolt 81 g

I didn't like the set. The bushing is very flimsy and immediately cracked. Then we stuff the head on top - alas, it’s opened. And on a steel disk, a pipe wrench helped to deal with the lock.

The approximate price of the set is 530 rubles.

Weight of one bolt 68 g

The cheapest products in our sample will be surrendered to a thief with almost no resistance. The simplest pentagon without a protective sleeve was opened by stuffing it on top of a standard head.

We decided to buy everything that the Moscow market offers. Restrictions were introduced only for the standard size of the secrets. We settled on the popular group of cars on the B0 platform - this includes Logan, Sandero, Duster, Almera, Largus, XRAY. The choice turned out to be limited: there were only eight suitable sets. Moreover, if six of them are bolts, then the other two are nuts. Why were nuts needed? Consider this our optional offer, with details in the Hairpin section.

The approximate price of the set is 1040 rubles.

Weight of one nut and stud is 65 and 38 g

To unscrew this type of nut, just drive a screwdriver into the code slot of the nut. The second option is to use a gas wrench. Resistance to burglary is mediocre.

The approximate price of the set is 1010 rubles.

Weight of one bolt 77 g

They were able to cope with the closest relatives of the secret nuts of the same name using the same algorithm - they surrendered to both a screwdriver and a gas wrench.

The approximate price of the set is 3150 rubles.

Weight of one bolt 75 g

The most expensive kit justified the price: it is the best in all respects. The ring does not allow turning the lock with a gas wrench, the chisel also failed. Such fasteners are usually overcome by welding or using an extractor inserted into the drilled hole. The low protrusions of the ring will not allow you to securely hammer in the special puller - when you try to unscrew the lock, the tool turns outward.

The approximate price of the set is 1040 rubles.

Weight of one nut 80 g

The asterisk, as one would expect, succumbed to the “persuasions” of a powerful slotted screwdriver.

Check and choose

Sellers of secrets talk about the dominance of inexpensive Chinese products and the almost complete absence of exclusive, difficult-to-open secrets made by domestic craftsmen. Of the eight sets purchased, only six had packaging - two were simply sold in plastic bags.

We tested each product on both a steel disc and a cast one. In addition to the main parameters, cryptographic strength was checked. No, no, we didn’t help the crooks - they already know everything. A situation may simply arise in which the owner himself turns out to be the burglar.

As usual, we expressed our opinion about each product in the photo gallery. The clear winner was the McGard Ultra High Security set: it resists hacking much better than others. And some secrets can be unscrewed almost with a screwdriver.

By the way, the results of a survey we conducted during the preparation of the material showed that the majority of readers do not use secrets, because “they will steal it anyway”! And only a third of respondents said that they always use fasteners. Apparently, until the thunder strikes, the man will not cross himself.

TIPS FOR BEGINNERS

- When you go to the store, take your original wheel bolt with you. If you use different wheels in winter and summer, then the bolts may be different - take both with you. This will help you navigate not only the size of the fastener, but also the type of connection to a specific wheel (cone or sphere).

- The presence of deep coded elements on a “secret” fastener usually indicates low quality metal. That is, the manufacturer fears that small elements will not withstand proper tightening. But the deep ones can easily be opened.

- Steel wheels are generally more difficult to protect than alloy wheels. Access to the fasteners is not difficult, so attackers silently twist the secrets with a gas wrench. But, on the other hand, there are much fewer hunters for “steel”.

- If you install two locks on each disk, this will not allow a thief to use the method of tightening adjacent bolts to loosen the tightening force of the lock.

- It is often advised to tighten the “secret” fasteners to incomplete torque. If the goal is to make life easier for crooks, then this advice, of course, makes sense. But good-quality locks, as our tests have shown, calmly pull at the standard torque, allowing for several dozen cycles of unscrewing and wrapping.

- The locking nuts for the studs are taller than the bolts and will stick out strongly on the steel disc. Therefore, it is better (from a protection point of view) to install alloy wheels on hubs with studs.

- The most advanced thieves make a cast of the “secret” wheel fastener. The simplest attachments from the threaded part of the neck of a plastic bottle and a cork will help you track whether this happened on your car. Found that the traffic jam has disappeared? It is possible that they are interested in your wheels. Among other things, such caps will help keep secrets clean.

- The locks do not have a real effect on the balancing of the wheel, since they are located near the center of rotation. For reference: the mass of the standard wheel bolt in our case was 69 g, and the mass of each of the locks is indicated in the description.

- Operating a vehicle without at least one wheel bolt (nut) is prohibited. Don’t be too lazy to take a quick look at the fasteners before your trip.

Read also: What are sexually transmitted diseases

HAIRPIN

If the wheels are secured with nuts rather than bolts, it is more convenient to mount them: protruding studs help to quickly install the wheel in its rightful place, since it is much easier to orient it. Therefore, when replacing standard bolts with locking bolts, many people prefer to screw a stud into the hub, placing it on a threaded anaerobic adhesive-sealant.

Most new cars reach their owners with the most common stamped metal rims. This option does not suit many motorists, so one of the first purchases of a car owner is alloy wheels, which look great and are not subject to corrosion. Such simple auto-tuning allows you to change the appearance of the vehicle and somewhat improve its performance characteristics. Standard wheel mounts are usually not suitable for casting, and along with the question of purchasing rims, another one arises - how to choose bolts and nuts for rims?

Very often, the entire set of fasteners for alloy wheels comes with them. But it also happens that you like the wheels that come without bolts or nuts, and it’s up to the owner of the car to choose these parts.