Advantages of stainless steel corrugated pipes

For the production of stainless steel pipes, high-quality alloy steel with a high content of nickel and chromium is used. The popularity of corrugated pipes is due to its high technical characteristics:

- not afraid of sudden increases or decreases in temperature;

- suitable for autonomous and centralized heating/water supply;

- not subject to linear deformation - this disadvantage, leading to curvature of the line, is characteristic of polypropylene pipes;

- the corrugated pipe is cut with a regular grinder or metal scissors;

- the corrugated structure of the material ensures its resistance to significant pressure drops and defrosting;

- the pipe is easily connected to the units, for which brass fittings and polymer O-rings are used;

- The stainless steel line is not subject to corrosion;

- the elasticity and flexibility of the pipe allows you to bend it manually and install a route with sharp turns - without the risk of squeezing the internal clearance or deforming the material;

- pipes in coils have a large footage, which allows you to draw a line with minimal joints.

Corrugated stainless steel pipe: product classification

Corrugated stainless steel pipes have their own classification. Pipes are divided into types depending on the diameter, scope of application and degree of flexibility of the corrugation. In the installation of household communications and for industrial needs, as mentioned earlier, pipes with a diameter of 15, 20, 25 and 32 mm are mainly used. These are the most popular models, but they are no exception.

They produce products of different diameters, including pipes with a meter cross-section. Such products are used for transporting various liquids in production. They can also produce models of other sizes to order, but the price of a corrugated stainless steel pipe made in this way will be significantly higher.

Helpful advice! Due to their special flexibility, corrugated pipes can be used to create systems and communications of varying levels of complexity.

Depending on the purpose of the pipe, its properties are determined and products are classified into the following types:

Depending on their purpose, corrugated pipes in domestic construction are used for installation of heating, water and gas supply

- corrugated annealed stainless steel pipe – characterized by increased flexibility; to achieve this effect, it is subjected to special heat treatment during production;

- unannealed pipe – cannot be heat treated, therefore it has less elasticity and weighs a little more;

- stainless corrugated pipe with a protective coating of polyethylene - intended for gas supply, for systems that are subject to concreting, and it is also used for laying communications underground.

Depending on their purpose, corrugated pipes in domestic construction are used for installation of heating, water and gas supply. We will talk in more detail about the scope of corrugated pipes below.

Scope of application of corrugated stainless steel pipe

Corrugated pipes are distinguished by their versatility, which is why they are widely used in the installation of both centralized and autonomous water supply and heating. This is possible due to the properties of stainless steel to withstand high pressure, although the walls have a maximum thickness of 0.3 mm.

Due to their special flexibility, corrugated pipes can be used to create systems and communications of varying levels of complexity

Corrugation perfectly withstands high temperatures, when exposed to which it does not deform. In this regard, corrugated pipes outperform analogues made of polypropylene and metal-plastic. Therefore, a corrugated pipe for heating and hot water supply is ideal. In frosty conditions, such a stainless steel product does not suffer from compression and expansion of the material, so freezing and thawing do not affect its flexibility. The flexibility of the material is so high that the hoses, depending on the diameter, can bend with a radius of up to 30 mm.

Due to these unique advantages, stainless steel pipelines are used in a variety of applications. They are used by builders, repair workers, electricians and utility mechanics as:

- flexible pipes for heating;

- wall and floor insulation systems;

- corrugated pipes for water supply and hot water supply;

- pipes for piping boilers;

- channels for connecting meters;

- heat exchangers;

- gas distribution pipes;

- corrugated pipes for ventilation, chimney and air conditioning.

These are the most common cases of using corrugated pipelines, but in modern construction they have also begun to be actively used to create metal hoses in electrical wiring and as elements in solar collector systems.

Due to its unique advantages, stainless steel pipelines are used in a variety of applications.

Corrugated stainless steel pipe for heating

Corrugated stainless steel pipes for heating began to be used relatively recently, but they have already proven themselves excellent in this area. Due to the fact that the product has the property of adapting to changes in temperature and pressure, it is installed both at heat supply inputs and directly in heating systems.

Helpful advice! Due to flexibility, excellent thermal conductivity and increased strength, corrugated stainless steel heating pipes are most often used in “warm floor” systems. The price of such products is slightly higher, since they have a special coating that allows for smooth filling of floors.

A special advantage of corrugated pipes for heating is that installation is carried out without the presence of special equipment and tools. In this case, the products are bent at different angles without narrowing the ducts.

When purchasing a corrugated pipe for heating, you should listen to some advice from experts; in particular, it is recommended to study the markings that are contained on the label of the coil and indicate the scope of application, since it is impossible to apply it to the pipes themselves. If the integrity of the packaging is compromised, you must beware of substitution. The real price of a fake corrugated pipe can be an order of magnitude less than the cost of the original.

When purchasing a corrugated pipe for heating, it is recommended to study the markings that are contained on the label of the coil and indicate the scope of application

Thus, high-quality corrugated products are distinguished by the following properties:

- the price of heating pipes is slightly higher than the cost of water pipes and an order of magnitude higher than the price of chimney products;

- pipes have a very high degree of flexibility;

- the seams must be smooth, without visible irregularities;

- It is difficult to detect defects during visual inspection.

Gas Corrugated Stainless Steel Pipe

To connect heating boilers, gas stoves, gas-type water heaters to the gas supply system, flexible connections have recently been most often used. There are several types of products that differ in size, material and price of corrugated stainless pipe. Flexible gas connectors can be manufactured:

- made of elastic material and braided with stainless steel;

- made of stainless steel, and have the form of a bellows.

Experts advise using flexible hoses of minimal length to connect gas appliances, which guarantees reliability and safety. It is better to move the plate as close to the pipe as possible than to use a long corrugation.

Experts advise using flexible hoses of minimal length to connect gas appliances.

The braid of a corrugated stainless steel pipe for gas is marked with a yellow stripe. This is done due to the fact that outwardly flexible hoses for water and gas are very similar to each other, therefore water pipes are designated in red and blue, and gas in yellow. Inch stainless steel hoses are usually equipped with special fittings, which are secured with nuts at the joints, and copper or aluminum washers are used for additional tightness.

The price of stainless steel pipes for gas is slightly lower than the cost of rubber-fabric analogues, but no less reliable. This feature has influenced the increase in demand for corrugated steel products.

The price of a stainless steel bellows-type water pipe is higher than the cost of products for gas equipment, which is justified by their reliability. The bellows itself looks like a corrugated pipe with fastening fittings at the ends. Connect the bellows line using washers and nuts. The connection can withstand a pressure of 6 atm.

Metal corrugation for ventilation and chimneys

Stainless steel pipes are used as connectors between hoods and ventilation ducts, as well as chimneys. At the same time, the steel product in many ways outperforms aluminum pipes, although the price of stainless steel and aluminum is almost the same.

Stainless steel pipes are used as connectors between hoods and ventilation ducts, as well as chimneys

Helpful advice! It is steel corrugation that is best used for chimneys, as the material is durable and has anti-corrosion properties, which ensures safety and a long service life.

A typical corrugated stainless steel pipe for a chimney in diameter ranges from 10 to 15 cm with a compressed length of 60-70 cm. Inside, it is reinforced with thicker steel wire, which gives it the desired configuration. When stretched, the pipe can reach three meters. In this case, you can select the required length of the chimney.

Corrugated stainless steel pipes can withstand temperatures up to 900 °C, so they can be used in heating systems with a variety of fuels, including coal and wood. Combustion products from such pipes are quite easy to remove. In addition, harmful condensate containing sulfuric acid, which forms inside the chimney, does not have a destructive effect on steel, since it is resistant to chemicals.

Fitting

To connect corrugated stainless steel pipes, brass fittings with silicone or rubber O-rings are used. To connect steel pipes, it is convenient to use special fittings for steel pipes.

You can make a flexible hose with permanent union nuts from a piece of corrugated stainless pipe yourself, using a hand roller.

Technology for manufacturing flexible hoses from corrugated stainless pipes using a manual roller:

- a piece of pipe of the required length is cut;

- the cut edges are carefully cleaned;

- the pipe is inserted into the roller;

- using a hammer, the corrugated pipe is flared;

- put on the union nut;

- a rubber gasket is installed;

- the procedure is repeated with the second end of the pipe.

Fittings for connecting corrugated pipes

Product classification

Stainless steel corrugation can be of several types. Each product option has its own purpose.

The pipe products under consideration may be:

- Covered with polyethylene coating. Such products are intended for creating gas pipelines or structures mounted under concrete.

- Unannealed. It has a good indicator of flexibility, but quite a significant mass.

- Annealed. The most optimal option for arranging heating systems.

For installation purposes, it is necessary to use fittings made of brass. Connecting components can be of different diameters and design configurations. It all depends on their purpose. In most cases, the fitting consists of a main component, a union nut, a retaining ring and a silicone gasket used to create a sufficient seal.

When installing corrugated stainless steel heating lines, it is necessary to use only high-quality connecting elements. The use of unreliable fittings can lead to accidents that can paralyze the operation of the entire heating circuit.

Review of manufacturers

There are quite a lot of factories producing corrugated steel pipes. We have selected the most popular ones.

Products suitable for arranging heating lines include products manufactured by the following brands:

- Meibes. These products have a decent level of quality. However, many consumers may be confused by the rather high cost of this manufacturer's products.

- Lavita. One of the advantages of products from this brand is their affordable price. It is worth considering that there are some complaints about its strength. Consumers have noticed that when tightening the sealing ring of the connecting component, the walls of this company's pipe products are sometimes damaged. This in turn leads to leaks. However, this defect is leveled out by competent and careful installation.

- Hydrosta. The price of corrugation from this company is comparable to the products of the previous brand. At the same time, there are more complaints about the quality of these pipe products. Consumers note that these pipes are often characterized by manufacturing defects. According to existing statistics, leaks occur in seven cases out of a hundred. Moreover, this defect has nothing to do with the quality of the installation.

- Kofulso. The stainless corrugation of this plant is recognized as the standard. It is considered the most reliable and high quality. This is the most expensive product from the list. But if you want to equip the most reliable heating system, choose this one. The connecting components supplied with the products have sealing rings of a special design, which significantly increase the tightness of the joint.

Watch the video:

Installation technology for corrugated stainless steel pipes

It should be noted that the installation of corrugated pipes is a simple process. Thanks to the variety of types of fittings, it is quite possible to assemble any system yourself, without the involvement of specialists. The main thing is to follow the sequence of technological steps during the installation process and the correctness of the work performed, which will ultimately allow you to obtain a strong, reliable and durable pipe connection.

The installation technology itself requires a clear sequence of certain actions:

- Connecting fittings to pipes and faucets. At this point you need to make sure that the union nut on the side of the pipe connection is not tight.

- Trimming the required amount of material. This must be done using a special tool - a roller pipe cutter. The cut should be neat, without burrs.

- The pipe is inserted into the fitting and the union nut is tightened.

- The pipeline is fixed in the desired position using special fasteners in the form of clips and clamps for this purpose.

- Checking the health of the system. If a leak is detected, you need to tighten the union nuts a little more.

Thanks to the variety of types of fittings, it is quite possible to assemble any system yourself, without the involvement of specialists

Interesting to know! Installation of a corrugated pipeline takes significantly less time than installation of rolled pipes, since such a labor-intensive process as welding is not involved. For example, installing a conventional annealed stainless steel pipe is three times faster than installing its counterparts made of other materials.

Disadvantages of flexible stainless steel pipeline

The disadvantages that a corrugated annealed stainless steel pipe has must be taken into account when performing installation work. The main negative qualities include:

- Susceptibility to mechanical damage;

- Exposure to aggressive environments;

- Danger of using cleaning products;

- Flexible pipe will break if bent repeatedly in the same place, so repeated bending or twisting should be avoided whenever possible.

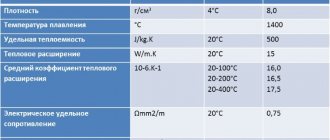

Specifications

According to the standards, metal corrugated culverts do not lose their functional characteristics at temperatures of -50... +110°C.

The pipes are also resistant to pressure changes. The average value reaches 50 atm; higher quality products can withstand short-term exposure to up to 210 atm.

The corrugated structure provides plasticity to the products, which does not lead to deformation and a decrease in water flow. In accordance with the diameter indicators, the bending radius varies from 25 to 150 mm. When bent, the pipes do not deform, do not break, and retain their structure.

The standard thermal conductivity characteristics of corrugated pipes are about 17 W/m*K. The average roughness coefficient of the coating reaches 0.008 n, this indicator indicates a low level of siltation of pipelines.

Common pipeline diameters range from 1.5 to 3.2 mm. Models with a diameter of up to 1 mm are optimal for transporting various substances in enterprises. Pipes are produced to order in the sizes required for the construction project.

The technical characteristics of the products ensure simple installation of pipes with connecting fittings selected by diameter.

What is it and where is it used?

The technology for manufacturing pipes with a corrugated surface was mastered in Japan. At the end of the 20th century. the technique was adapted for pipelines. Corrugated pipes are made of stainless steel (annealed or unannealed) and are distinguished by high-quality performance characteristics (strength, ductility).

In Russia, steel corrugated products are used in the areas of the national economy, residential and industrial construction, in the creation of household equipment, hot and cold water supply. Corrugated pipes are used in repair work to replace failed water supply systems.

Strength and wear resistance allow the pipes to be used for laying in grooves in concrete, for wiring behind protective and finishing panels. The flexibility of the products allows the use of pipes when installing routes of complex configurations.

Corrugated pipes are suitable for underfloor heating and creating insulated wall panels. The corrugated surface allows you to compensate for linear compression of the pipeline and smooth out the expansion of raw materials when changing temperature conditions. Resistance to increased pressure and vibration allows the use of corrugated products instead of metal-plastic and polymer ones.

The products are produced with a standard cross-section, the diameter of which can be from 8 to 15 mm. Products are also produced with non-standard cross-section configurations:

- square;

- arched;

- pear-shaped, etc.

The square section is used when laying tunnels and complex drainage structures.

Large-diameter arch pipes are used to create throughput tunnels under railway tracks and highway forks.

Pear-shaped cross-section configurations are optimal for culvert pipelines.

A section in the shape of a vertical ellipse is used to form tunnels for sewer systems and culverts.

The cross section of the arched configuration is used to create bridge structures and tunnels.

A cross-section in the form of a horizontal ellipse is optimal for water-pressure systems.

Low profile pipes are used in the construction of railway tracks, tunnels, etc.

Large-diameter corrugated pipes with a round cross-section are used to create culvert systems. Compact analogues are optimal for the construction of private residential buildings.