The sewer hatch, despite its apparent simplicity, should be chosen extremely carefully. The thing is that it performs a rather important function, simultaneously providing access to the inspection or inspection well, and protecting the underground part of the sewer network from damage.

Below we will tell you what features of this part you should pay attention to first, and which product is better to choose when equipping a drainage line in different conditions.

Care must be taken to protect the manhole!

Classification

Sewer hatches have a corrugated surface that prevents slipping and provides good traction with shoe soles and car tires. The weight of structures mounted on the roadway must be at least 60 kilograms to prevent spontaneous opening when vehicles collide with them.

By purpose

According to their purpose, sewer manholes are divided into the following groups:

- Inspection rooms are designed to monitor the condition of engineering systems and pipelines. They are installed at turns, branches, and in places where pipeline diameters or slopes change.

- Storage tanks are used for access to storage tanks when pumping out sewage.

- Stormwater. Installed on rainwater wells.

- Inspection hatches are suitable for servicing internal water supply and sewerage systems. They are mainly produced in rectangular shape. They can be installed in bathrooms or bathrooms in a wall or box, made of plasterboard or siding.

All hatches are designed to protect wells for various purposes. Ensure the safe presence of people, animals and vehicles in areas where utility lines pass.

By shape

The most popular shape of hatches is round. This design looks compact and is easy to use. Has no sharp corners. If necessary, the heavy round lid can be rolled for ease of transportation.

Square or rectangular hatches are less common. They are usually installed on storm sewer wells. Available in one side sizes from 300 to 800 mm.

The production of square hatches is not economically profitable, since more raw materials are spent on them than on round hatches of similar sizes.

The rectangular cover is not convenient for transportation, installation or maintenance. It may fall into a well if you accidentally move it diagonally.

2. According to their design, hatches are:

- standard parameters;

- with locking mechanisms that prevent entry into the well and theft of products;

- with recesses in the lid for the possibility of weighting using concrete or polymer fillers;

- with devices built into the lid for lifting them using lifting equipment.

By application

Utility hatches according to intended use are divided into two main groups:

- Hatches installed on expressways, airfields, transport terminals and production sites, parking areas for tracked vehicles and heavy vehicles. Heavy T-type cast iron products weighing 80-150 kilograms are suitable for these purposes.

- Well covers installed on sidewalks, in squares and parks, city yards and private households are marked with the letter “L”. Lightweight hatches are made of polymer, rubber and composite materials and weigh from 15 to 60 kilograms.

Heavy cast iron hatches are much more expensive than their light counterparts.

Design Features

Device

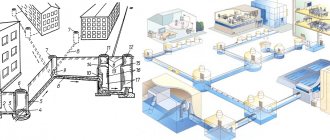

The sewer manhole is a structure that is installed in the upper part of the inspection or inspection shaft.

As mentioned above, this part performs two functions:

- On the one hand, it prevents unauthorized access to the pipes.

- On the other hand, using a hatch, we ourselves can go underground to perform diagnostics or repairs.

Hinged neck and lid

The hatch design is not complicated:

- An annular neck is fixed in the well itself - a stationary part.

- A lid is installed on top, which can be removable or hinged (hinged design).

- In some cases, two covers are mounted in the neck: a protective one, which is placed on top, and a locking one, equipped with a lock.

Note! Many people wonder why sewer manholes are round and not square. There are quite a few possible answers to this question, but the most plausible would be the following: a round lid, unlike a square one, will not be able to fall into the neck, no matter how you turn it.

So you don’t have to pull out a heavy cast iron “pancake” from a depth of several meters.

This is how the square lid falls into the neck. A similar “trick” won’t work with a round one – it will still get stuck!

- The outer surface of the lid is made smooth or convex. The use of concave parts is irrational: rainwater will collect in them.

Hatch locks

Typically, the connection between the neck and the lid is equipped with various locks.

Their main function is to prevent spontaneous opening, and - less often - to block the opening of the lid without a special key.

- The heavy cast iron sewer manhole we are familiar with, as well as some models made of polymer-sand composite, are equipped with side projections that fit into grooves on the neck.

- A plastic sewer manhole can be produced with a threaded connection between the lid and the well itself.

Locking system element

- Steel models are equipped with mechanical locks of the flag, bolt or spacer type. However, such structures are rarely used in drainage systems: more often, locking covers are used to equip shafts of communication lines, power transmission lines, etc.

Functional classification

Part marking allows us to determine how much a sewer hatch weighs and what networks it is intended for

The weight of a sewer hatch depends on two parameters: its dimensions and the type to which it belongs. Today, the most commonly used varieties are made of cast iron, and therefore in the table below we present exactly their characteristics:

| Marking | Product type | Weight, kg | Usage | |

| lid | frame | |||

| R | Repair | – | 35 | Used for temporary blocking of the neck during road work. |

| L | Easy | 30 | 35 | Installed within green spaces, on pedestrian paths, in private households. |

| T | Heavy | 50 | 50 | It is used when equipping inspection wells on highways. |

| TM | Heavy trunk | 45 | 50 | It is mounted in the neck of wells located on highways with high traffic intensity. |

Note! In addition to the type, the marking of sewer manholes, which is applied to the products upon their release, must include the designation of the utility network for which the part is intended, the year and month of production, etc.

The diameter of the sewer hatch and the dimensions of the main structural elements

The dimensions of cast iron sewer manholes according to GOST are also strictly fixed. Most often, models with a diameter (over the cover) of 645 or 800 mm are used for equipment of underground networks. However, polymer and steel models may have other dimensions.

Materials

A variety of compositions are used for the production of sewer manholes.

Cast iron

Until recently, the most common material for the manufacture of hatches was SCh 20 cast iron, which is an alloy of iron with carbon and graphite.

Fig.2. Cast iron hatch.

Cast iron structures are durable, practical and have a long service life. They are not afraid of extremely low or high temperatures. Not susceptible to the effects of aggressive deicing agents, fuels and lubricants, salts and acids.

Cast iron hatches can be installed on the roadways of city roads and highways, in unloading terminals and airports, in heavy vehicle parking lots and in places where weight control passes.

It is the weight of the cast iron hatch that prevents children and adults from entering the wells.

Depending on the area of application, cast iron sewer manholes are: light, medium, heavy and super-heavy.

The disadvantages of cast iron hatches include their high price, which is offset by practicality, durability and wear resistance.

Plastic hatch DN600 with holes and polymer concrete base, load B125 N=140 mm

RUB 22,111

RUB 25,981

Order

Plastic hatch DN600 without holes with a polymer concrete base, load B125 N=140 mm

RUB 22,111

RUB 25,981

Order

Cast iron hatch DN600 load D400 without holes, anti-slip coating

RUB 69,559

Order

Cast iron hatch DN600 load D400 with holes, anti-slip coating

RUB 68,177

Order

Plastic

Manufactured from thermoplastic polymers using injection molding. To increase the strength characteristics of the products, they are reinforced with fiberglass reinforcement or other compatible materials.

Fig.3. Lightweight plastic hatches.

Plastic models can be installed on lawns and sidewalks where there is no traffic. They are environmentally friendly and durable. Available in different color options. Products with various patterns are produced for use in parks and urban areas. They can imitate natural stone or various decorative items.

Plastic hatches are an ideal option for installation in a private house or on a summer cottage.

Polymer-composite

They are made on the basis of polyester resin, various fillers and dyes. To increase strength they are reinforced with fiberglass. Inexpensive, durable structures are suitable for installation in city yards, parks and pedestrian areas. Withstand loads up to 40 tons. Composite products are more expensive than plastic ones, but much cheaper than cast iron ones. They are easy to use. The lids do not freeze to the neck in winter.

In addition, like all polymer products, they are not in demand among vandals.

Fig.4. Polymer-composite sewer manhole.

Polymer-sand

Durable and practical hatches are made from a mixture of polymers with the addition of sand and iron oxide.

Often plastic bottles and other synthetic waste are used as polymer raw materials, which significantly reduces the cost of products.

Currently, polymer-sand hatches are in greatest demand due to their high technical and operational properties:

- the service life of polymer-sand hatches ranges from 30 to 50 years;

- products do not lose their quality at temperatures from -60 to +60 °C;

- the material is not subject to corrosion, is not susceptible to the action of fuels and lubricants, acids and salt mixtures;

- easy to use, inexpensive;

- Available in a wide range of colors and do not fade in the sun.

- withstand loads from 1.5 to 12.5 tons, depending on the class of the product and their purpose.

If damaged, polymer hatches can be recycled.

Concrete

Least common. They are heavy, inconvenient to use, and not airtight. They are a reinforced product with hinges for ease of installation. They are used in cases where the well has non-standard dimensions and does not require regular maintenance.

Sometimes concrete covers are installed on top of cast iron ones to prevent theft of cast iron.

Fig.5. Concrete sewer cover.

Rubber hatches

They are made from a mixture of rubber with various fillers, stabilizers and plasticizers. Products do not crack under high loads and extreme temperatures. Suitable for installation directly into hot asphalt. Designed for wells for various purposes located in green and pedestrian areas, sports fields, bicycle paths, courtyard areas with low traffic.

Polymer and rubber hatches are not stolen, unlike cast iron or steel hatches, which can be sold for scrap.

Table 1. Comparative characteristics of hatches.

| Hatch material | Technical and operational characteristics | ||||

| Design loads (tons) | Withstands temperatures °C | Cover weight (kg) | Service life (years) | Installation locations | |

| Cast iron | 40-61 | -50 — +90 | 60-155 | 50-100 | Highways, airfields, transport. terminals. |

| Polymer | 1,5-12,5 | -40 — +50 | 12-15 | 15-20 | City roads, squares, green and pedestrian areas |

| Sand polymer | 1,5-12,5 | -60 to +60 | 40-50 | 30-50 | Roads, courtyards, sidewalks, car parking lots. |

| Composite | 1,5-40 | -60 to +60 | 40-45 | 40-50 | Courtyards, green areas, sidewalks. |

| Rubber | 12,5 | -40 — +50 | 25-40 | 15-20 | City roads, driveways and sidewalks. |

| Plastic | 1,5-15 | -40 — +40 | 10-30 | 20 | Green areas, pedestrian paths, suburban areas. |

Sometimes, hatches made of lightweight steel sheets are used as temporary structures. They are made to individual orders. Steel hatches are inconvenient to use, do not provide airtight protection and quickly rust.

Can be used as an internal cover with locks in telephone sewer wells to prevent cable theft.

What shape do the hatches have?

Since sewer wells can have a variety of shapes and sizes, the covers for them are made taking these parameters into account. Most tanks are shaped like a pipe with or without a bottom. The round cross-section gives the product strength and resistance to lateral soil pressure. In addition, the absence of corners prevents debris from accumulating and mold forming.

Cylindrical pipes are much easier to manufacture, install and maintain, which is why, when it comes to hatches, manufacturers and customers tend to choose a circle shape. Such products are more resistant to vertical pressure, which can be applied briefly or continuously.

However, an unconventional approach to territory development involves a departure from established stereotypes. Today, developers at various levels are increasingly using floor slabs with hatches of the most intricate configuration to equip areas.

Lids of the following shape are made to order:

- square;

- rectangular;

- oval;

- triangular;

- polygonal.

As a rule, due to the complexity and high cost of making an order from cast iron, the choice is made in favor of lids made of polymer plastic or painted concrete. If the technology of their production is followed, the finished products are not inferior in strength and practicality to metal hatches. Today, decorative covers made from modern composite materials are becoming increasingly popular.

GOST and marking

Technical characteristics and requirements for sewer manholes are regulated by GOST 3634-99. This standard applies to covers of wells and chambers of underground networks of storm and city sewerage, water supply, heat supply, communications and gas pipelines.

The properties of telephone sewer manholes are regulated by GOST 8591-76.

Hatches made from modern polymer materials that do not meet GOST requirements are manufactured according to the customer’s technical specifications or according to the technical conditions developed by the manufacturer.

According to interstate standards, hatches are marked with alphanumeric abbreviations and are divided into the following types:

- ST (E600) - Extra heavy, designed for loads up to 61 tons. The hatch weighs more than 155 kg. Designed for installation in unloading terminals, airfields, and on expressways.

- TM (D 400) - Heavy highway. Designed for installation on high-speed roads. Easily tolerate local loads of up to 40 tons. They weigh up to 140 kg.

- T (250) - Heavy hatches are installed on urban roads with heavy vehicle traffic. The dead weight of heavy hatches can reach 120 kilograms. Designed for loads up to 25 tons.

- C (B125) Medium sewer structures, for installation in city yards, on sidewalks and lawns. Designed for loads of up to 12.5 tons. The weight of the structure is up to 95 kg.

- L (A15) Lightweight hatches that can withstand loads of up to 1.5 tons are installed in pedestrian areas where there is no traffic. They weigh 45-60 kg.

To simplify the procedure for selecting sewer manholes, manufacturers use special markings in accordance with the purpose of utilities:

- K - domestic and industrial sewerage;

- D - rain and storm drainage;

- GW - city water supply networks;

- B - water conduit;

- TS - heating networks;

- PG—fire hydrants;

- MG—trunk gas supply networks;

- GTS - city telephone networks.

According to State standards, sewer manholes must be equipped with special inscriptions and trademarks or logos of the manufacturer.

Fig.6. Storm drain hatch.

Conclusion

A polymer or cast iron sewer hatch must be selected in accordance with the loads that it must experience. Then the drainage system will be reliably protected, and you won’t have to spend money on replacing the part very soon (see also the article “Domestic sewer pump: installation, features, advantages”).

The video in this article will help you understand the nuances of the issue raised, so we recommend that you study it carefully.

Did you like the article? Subscribe to our Yandex.Zen channel

Main sizes

Sewer hatches usually have standard sizes corresponding to the dimensions of the wells.

The diameters of the hatches should allow service personnel to easily enter the well to carry out repair and maintenance work on the networks.

For sewer manholes, heavy, medium or light manholes are usually used.

Common dimensions of hatch bodies with covers:

- body 720 × 60 with cover 600 × 25;

- body 750 × 90 with lid 690 × 55;

- body 750 × 100 with lid 690 × 50;

- body 800 × 110 with cover 700 × 70.

Square hatches usually come in dimensions of 640 x 640 mm, with the cover size being 600 x 600 mm.

Fig.7. Heating main hatch.

Safety of sewer manholes

Hatch with hook hole

Why are sewer manholes made round? To protect the population from falling in them - this is one of those disasters that people begin to be warned about from childhood.

However, despite such warnings, such cases occur quite often. Previously, this was caused by absent-mindedness, but now it is added to the distraction of talking on a cell phone or writing text messages.

The large number of thefts of manhole covers covering the sewerage system only aggravates the current situation. Falling into a hatch can not only result in broken legs, but can also lead to death if the depth of the hatch is sufficiently deep.

The danger of open hatches is no less evident on highways. Colliding with a car on an open hatch can cause serious damage to the suspension and wheels, and also very dangerous accidents for cyclists and motorcyclists - even fatal.

Criterias of choice

When choosing hatches, you need to take into account the climatic conditions of the area, the purpose of the engineering systems running in the well, the location of the hatches, and possible maximum loads.

- For unguarded open areas, it is better to choose hatches equipped with locking devices. This will help avoid theft of products and protect the well from unauthorized entry.

- In parks, recreation areas and in the immediate vicinity of residential buildings, it is better to install composite and rubber structures that have good noise insulation properties.

- Covers intended for installation on the roadway must weigh at least 50 kilograms so that they do not move during heavy traffic.

On the territory of private households and summer cottages, you should not use expensive and bulky cast iron hatches. Polymer or composite hatches will withstand one-time loads from trucks or cars.

Manhole covers for sewer wells should not slam or make sharp sounds when impacted. The front surfaces must have a relief rough texture and have good grip on car tires and shoe soles.

Square cast iron hatch with holes DN600 with cover fastening, load D400

RUB 67,163

Order

Square cast iron hatch without holes DN600 with cover fastening, load D400

RUB 60,991

Order

Brick sewer well

Brick construction includes:

- Base or bottom. Located on the same level with the passing highway.

- Walls.

- The tray is of an open type, made in the direction of flow in a smooth rotation.

- Floor slab.

- Luke.

- Wall brackets are designed to make pumps easier to clean and remove possible blockages.

Advice: In order for a person to freely descend and work there, the diameter of the device must be at least one meter.

The use of modern plastic products makes their construction and maintenance easier. They are produced as almost finished products with holes for the inlet and outlet of pipes, with a tray for drains. The instructions allow you to install prefabricated plastic structures very quickly, the material is environmentally friendly, durable, and the price of the finished structure will be quite reasonable.

How does a filtration well work?

After the septic tank, a well is installed in the sewer system, which serves to filter wastewater. Its main purpose is to receive wastewater after preliminary treatment, and then pass it through a layer of soil, in this case it acts as a filter. This water treatment element is most often installed when it is impossible to discharge wastewater into the central sewer system or underlying soils.

Filtration well

On the diagram:

- 1 – hatch cover.

- 2 – exhaust pipe.

- 3 – neck body.

- 4 – cover for insulation.

- 5 – pipe for supply.

- 6 – gravel on the outside.

- 7 – body.

- 8 – shield.

- 9 – filter layer inside.

Advice: When planning the place where the filtration well will be installed, you need to take into account the distances to the buildings of the site and other wells from which drinking water is obtained (according to SNiP it should be no less than 10 and 30 meters, respectively).

The shape of the filtration structure can be very different, but when planning the construction of a sewer well from reinforced concrete rings, a foundation must be made along the perimeter of the base. The rings must have holes, through which the filtered moisture will flow out.

Construction of a sewer well made of concrete rings

The internal part is filled with gravel, expanded clay, broken bricks and other material with a fraction size of 10 to 70 mm. The outer part along the entire perimeter is sprinkled with the same composition as the inner part, but not more than one meter. There should be a supply pipe approximately 15 cm above the filter layer.

Tip: To prevent the bottom filter from being washed out, you need to place a wooden shield under the stream of water, which is pre-treated with an antiseptic composition.

Advantages and types of polymer sewer covers

The basis for the manufacture of polymer hatches is a polymer-sand mixture. The introduction of various additives makes it possible to obtain a protective device with the desired performance properties. Due to a number of advantages, this type of sewer hatches has become the most popular:

Dimensions of polymer manholes

- high permissible mechanical load (up to 25 tons);

- high-precision pressing method ensures excellent tightness;

- Several colors allow the equipment to fit organically into any landscape;

- long service life (20–50 years);

- ease of transportation and installation - one person can handle the installation;

- interchangeability of parts in case of damage - lid sizes are standardized;

- operating temperature from -50 to +50 degrees;

- resistance to chemicals;

- do not rust or fade;

- do not emit a metallic ringing sound and do not spark when a car collides;

- low cost compared to cast iron analogues.

The whole variety of hatch models is classified according to several criteria.

Other varieties

Naturally, the list of used parts is not exhausted by these two varieties.

The most popular, in addition to cast iron and polymer-sand ones, also include plastic and reinforced concrete hatches:

- Plastic structures are made from PVC-based technopolymers. The most common method is injection molding.

- The advantages of plastic manhole structures include low weight and relatively low price.

- Along with this, significant elasticity and high fragility at low temperatures limit the use of these products. Much more often they are used in garden plots, and they are installed where virtually no one walks.

- Reinforced concrete structures with steel reinforcement are also often used. They have a good margin of safety, so they can be installed on construction sites and other similar objects.

- To remove the part from the neck, a steel bracket is used, which is welded to the reinforcement frame at the production stage.

- The key disadvantages of cement products are their unaesthetic appearance and difficulty in installing flush with the neck. As a rule, a cement “plug” is used as a temporary measure, for example, to block a hole in a well when a standard cast-iron hatch is stolen.

Features of installing sewer covers

Installation of a cast iron and polymer sewer hatch is carried out according to the same scheme. The difference is that the installation of a lighter polymer product will be performed by one person.

Work order:

Diagram of the main elements of the construction of a sewer well

- Gain access to the well neck. If necessary, remove the top soil in such a way that after installation the hatch does not protrude above the surface of the area. Recommended depth levels: 24–45 mm for light, 60 mm for medium, 85 and below for heavy models.

- Install a concrete support ring K60 or KTs01, which will reduce the load-bearing load on the slab. You can build brickwork, but it will not be durable enough. Over time, under the influence of precipitation, the bricks will begin to collapse, which will lead to deformation and failure of the entire structure.

- Install the shell without allowing a slope - this can lead to sagging of the hatch during operation. If necessary, install a sealant. Check with a level, secure firmly - the presence of grooves for fastening greatly simplifies this stage.

- Build formwork around the shell and fill it with concrete mortar. Allow to dry completely for 2-7 days.

- Lubricate the working surface of the ring with grease or lithol - this will prevent freezing at sub-zero temperatures.

- Place the cover on the hatch, check the opening, and lock it.

If the product does not fit well into the landscape, it can be disguised with decorative elements in the form of a boulder stone, stump, sign, statue or flower bed. This is not only an original exterior solution, but also additional protection. At the same time, the area should not be overloaded - access to the inspection well should be easy at any time of the year.

How to hide a sewer hatch