Using a snail device for cold forging, you can make shaped and beautiful metal parts with your own hands. A homemade snail machine is quite easy to assemble, so any home craftsman can make it, even with little skill in this work.

In the article we will look at the advantages of cold forging, and also tell you how to make a tool for work yourself - a template, drawings, photographs and videos can help you in your work, and as a result you will be able to assemble a simple and useful device for working with metal.

Types and purpose of forging machines

A machine for any purpose is used to facilitate manual labor.

For cold forging, various equipment can be used, minimizing the physical effort of the craftsman and allowing the following basic operations to be performed: Machine for creating a shaped profile using the cold forging method

- bending the profile at the desired angle or radius;

- making spirals or curls;

- longitudinal twisting of workpieces.

The variety of parts obtained allows you to arrange them in combinations and intricate designs, create a neat artistic canvas for fences and gazebos, symmetrical decor for park benches, as well as other items for various purposes.

Industrial bending machine, which allows you to obtain a workpiece with a given radius

Cold forging machines can be specialized (perform only one operation) or universal. There are the following types of special machines:

- bending machines (bending machines) – allow you to bend a workpiece at an angle or a given radius (wave);

- snails - twist the blanks into spirals and curls;

- torsion bars - help to longitudinally twist a workpiece or several such parts at the same time;

- stamping machines - they are used to make decorative clamps, shaped ends, and waves with fine pitches.

Universal machines include components of special equipment in various combinations.

Devices for cold forging are driven mechanically (manual machines) or by electric drive. Electrically driven equipment is characterized by speed and ease of processing workpieces. A cold forging machine, the price of which can be quite high, is characterized by high productivity. When there is no need for productivity and speed, then a manual machine will be quite sufficient to complete the work, especially if blacksmithing is a hobby.

Bent machine designed for processing pipes using cold forging

Is it possible to make a cold forging machine with your own hands?

You can buy a manual machine for cold forging in a specialized store that sells tools or order it online. The question is the price and solvency of the buyer. An alternative option is to assemble it yourself. The principle of operation will be no different from a product purchased in a retail chain, and the functions performed are absolutely identical to the factory ones. Additional advantages are a reduction in price, confidence that the design will not fail after the first use.

To begin with, it is worth familiarizing yourself with the design features of each type of machine in order to assess the possibility of its self-assembly.

A snail cold forging machine that allows you to create spiral elements

The torsion bar must twist metal rods, so its design assumes the presence of two elements that hold the workpiece. One of them serves as a clamp, and the other contains a rotating spindle, which, in fact, will twist the rod to the desired frequency of the helical wave. The device is quite easy to build yourself, and some craftsmen even make do with a vice and a simple hand crank.

The design of the bending machine is also simple, but it contains several mandatory elements, the assembly of which is impossible without specialized tools. The base is a massive metal plate with a groove in the middle into which a movable stop is inserted, moved by a worm mechanism. The other two cylindrical stops are stationary and are attached to the base on both sides symmetrically relative to the groove. It is the installation of stops that can cause difficulty, since holes for fasteners are drilled only on a specialized machine; such a workpiece made of high-strength steel will not yield to the influence of a drill.

Creating elements using the cold forging method on a homemade gnutik machine

A snail metal forging machine can have two types: with a collar or a lever type. The first option allows you to vary the shape of the bend during operation, however, it has a number of weak points in the design and is very demanding on the strength of the manufacturing materials. The second type is more stable, but less productive. Craftsmen consider the snail to be the simplest machine, the self-assembly of which will not cause difficulties.

Cold forging method

The method involves using an important property of metal - plasticity. With the help of various mandrels and mechanical devices, the rod is bent in different directions, twisted, and forms various three-dimensional shapes. As additional processing, welding and metalworking operations are used to connect parts of workpieces. Entry-level machines are quite simple and are driven by the muscular strength of the master working on them. The technology is quite accessible for mastering in a home workshop.

The minimum set of forging equipment for cold forging of metal includes:

- Bending machines, or Gnutiki, are used to bend workpieces at a given angle and radius.

- Twisters, or torsion bars, are used to twist a workpiece (or group of workpieces) around the longitudinal axis

- Wave - used to create periodic bends in different directions.

- Snail forging machine - used to create spiral-shaped curls at the end of a rod.

Cold forging Twister for cold forging Waves for performing wave-like bending of a workpiece Gnut for cold forging

Is it possible to master cold forging yourself? Yes, it is enough to have basic skills in metalwork, design and machining.

Many home craftsmen have made a snail - a cold forging machine on their own, without using expensive components.

Tricks of the Masters

The use of spacers allows for an instant change in the shape of the final structure or making bends in the opposite direction, which the plowshare does not allow for structural reasons.

Does not require increased precision in the manufacture of parts.

Fastening the workpiece is as easy as shelling pears – place it in a special recess.

Allows the use of a technique that is used in industry - a slight bend in the opposite direction in the core of the curl.

It is possible to use different techniques and bends in forging

Such cold forged products look better and are more expensive.

Additionally, it has a good and convenient advantage - the ability to produce flat bends with a thin core from a workpiece lying flat.

The lever machine allows the installation of a clamping roller at a height of strip thickness and a flange wider than a railway wheel. This method requires painstakingness: the lever must be moved little by little, otherwise the inner edge will be damaged. Unfortunately, this is the only method for making such curls in DIY production.

A machine with a lever is often created without the use of rare or expensive materials and without having accurate diagrams.

Video: homemade electric cold forging machine

Spiral like a spiral

Device for winding spirals manually

In some cases, ordinary smooth, straight, ascending spirals are used as an element of artistic forging. Making a spring twister machine for this on your own is absolutely unrealistic. But remember: the spirals in a forged pattern do not need to be springy and can be wound from ordinary ductile steel using a simple device (see figure on the right). The pitch (ascent) of the spiral is determined by the horn of the gate (filled in red); By bending the horn up and down, you can get thinner and thicker spirals. A square bar is taken onto the workpiece or a round one, it doesn’t matter. You can also twist spirals from a rod twisted on a torsion bar.

DIY cold forging photo

Making a simple snail with your own hands

If you settled on a simplified monolithic design, then you know that this device uses simple winding of a rod by hand or using a lever onto a form rigidly welded to the working surface. This machine can be used to create curls on rods of small cross-section (less than 12 mm).

Monolithic non-demountable snail

It is made like this:

- First, a diagram of the future template with the required dimensions is drawn on a sheet of paper (sometimes the template diagram is applied directly to the base of the conductor). This must be approached responsibly, because after welding the finished form, it will not be possible to correct errors. The thickness of the outline of the form in the drawing should be the same as the thickness of the metal strip used for its manufacture. It should be at least 3mm. The coils must be placed at a distance of 12–13 mm from each other, so that a 10 mm deformable rod fits into the groove between them.

- The base of the snail (preferably round) is cut out of a steel sheet with a thickness of at least 4 mm, the diameter of which is determined in proportion to the size of the template spiral and be larger than the size of the snail. Typically the diameter of the base is within 70 cm.

- In accordance with the drawing, the desired curl shape is made from a 3mm thick metal strip. To do this, it is better to calcinate the workpiece so that it is easier to machine. After making the mold, the excess end of the strip is cut off, and the edges of the snail are cut into a cone and cleaned.

- The finished form is welded to the base, which is mounted on the frame. Sometimes a template welded to the base is fixed to the frame using yews installed on it. To do this, a piece of timber is welded to the back side of the base of the form for gripping with a yew.

With the option of fixing the conductor in a yew clamp, you can easily change the templates and obtain different shapes of curls if you make several types, monolithically welded to the base of the devices.

Removable design

On the working base, first draw the contour of the snail with a mark along the contour of the holes for attaching the template.

Based on the sketch, a template is made from a thick steel strip and holes are drilled in it. It is attached to the base with bolts.

Forging a twisted shape should begin from the central curl. The end of the workpiece is inserted into the groove of the first curl of the form and pressed tightly against it. You can use a small clamping tool to secure the fixation. With force, the free part of the rod is screwed onto the template using a device - a lever. Advanced designs use a lever driven by a moving bearing mounted on it. The lever is made of a rod with a diameter of 20 mm.

You can watch the making of such a device in the video:

Collapsible snails with rotation

The snail template can consist of several parts, and the deformation of the rod occurs by rotating the conductor. This machine consists of the following elements:

- thick metal base in the form of a disk or square;

- a collapsible template fixed to the base area;

- rotation shaft;

- lever to drive the shaft.

The working base is made of metal, with a thickness of 4 to 10 mm.

The prefabricated template may consist of several parts that are connected to each other by hinge pins inserted into the holes of the lugs welded to the ends of the elements. Together they make up the outline of the cochlea.

To attach such a snail to the working base, you need to drill holes in it to fix it to the surface in a certain position. By changing the position of the prefabricated parts on the base, you can obtain different curvature of the curls and their shape. The size of the arc of the shape is regulated by special screws attached to the connecting hinges.

It is quite difficult to make a composite volute with hinged joints yourself. Typically, craftsmen purchase a stamp made in an industrial environment and attach it to the bed.

You can make a simpler collapsible template device yourself without using hinges. To do this, you need to make a sketch of the prefabricated parts of the snail with the locations of the holes. If you prepare several sketches and, in accordance with their contours, drill holes in the base in different places, then you can attach templates with different radii to one base. To do this, you will need to bolt the contour segments where the holes of the template and the base align.

For example, you can do this:

A device with removable parts of the volute and a rotating cylindrical shaft driven by a lever is shown in the video:

How to make a snail for cold forging with your own hands

First, you should select a tool model, then draw a sketch of the structure and create a template for the future spiral. It is necessary to proceed from the number of parts that are planned to be made and their standard sizes. To make a fence around your own home, you can use a non-separable tool.

Monolithic non-demountable snail

A non-removable conductor can be made in two hours in a garage if you have a welding machine:

- A life-size sketch of the future snail is made on a sheet of paper.

- A strip 40 mm wide is cut from a sheet of metal 4–5 mm thick.

- The strip is bent on a pipe bender, constantly adjusting to the template. You can use a homemade machine with a finger and a limiter for the movement of the sheet for unwinding.

- Cut a strip into a cone from the first section to the end. The minimum size remains 20 mm.

- Weld the resulting spiral with its flat end to a metal plate measuring approximately 10×200×200.

After cooling, the homemade stamp is ready for use.

Removable design

The removable jig is made of a sheet with a minimum thickness of 10 mm. Ideally, the spiral will be cut on a CNC machine, but you can make it yourself. The contours of the future part are applied to the sheet and cut out with a grinder. If there is a router, a template is made, and processing is carried out using a copy sleeve.

For fastening to the base, holes for bolts are marked and drilled in the manufactured spiral. The tool is quickly changed and various spirals can be made with minimal time spent on changing materials.

Collapsible snails with rotation

A conductor of complex shape is considered the most difficult to manufacture independently. Allows you to make spirals with a different number of turns on one stamp.

The collapsible rotary volute is a removable model made of several segments.

First, you can make a large, multi-turn spiral from a sheet. Then cut it into several segments. The cut should be very thin and at an angle. In each segment, 2 holes are made and pins are inserted into them. For precise assembly of the conductor, they must be made using the method of sweeping on the platinum. During the bar bending process, segments are added to the desired curl size. Collapsible snails made according to the golden ratio formula are universal.

Step-by-step manufacturing of a small-sized manual machine for making curls

A small machine is designed for the production of curls from rolled strip with a width of 20...30 mm. It's easy to make it yourself.

Center

First the center is made. To do this, a small fragment of round timber is sawed off. The workpiece is fixed in a vice and the cutting line is marked. Using a cutting disc and an angle grinder, the workpiece is sawed off.

It has a diameter of 38 mm. The side surface is not further processed.

The center length is 28 mm. A little more is possible, but this is enough to bend a strip 30 mm wide.

A hole Ø 8 mm is drilled on a drilling machine. It is placed eccentrically. This situation is due to the fact that it is necessary to make a clamp for the end of the workpiece.

A profile is drawn, which should be removed using cutting and cleaning discs installed on the grinder. The workpiece is secured in a vice and excess metal is removed.

The flap discs protect the surface so that there is a smooth transition between different surfaces of the clamp.

To make it easier to fix the end of the workpiece in the future, you need to drill a hole. It is placed on the radial surface of the center. A hole is drilled for an M10 thread.

Using a set of taps, the internal thread is cut. A headless screw will be used here. After fixing the workpiece, it will hide inside the metal of the center.

The center is welded to the 4 mm thick base plate. This completes the work of its production.

Making a fixture

To make it easier to work with the device, a shaft is welded to the back side of the plate. By rotating it in a special mandrel, the snail will rotate.

The outer surface must be ground so that the welds do not interfere with the free fit of future workpieces.

The future spiral is drawn on the plate. A contour is created where it will be welded later.

A spiral is bent from a strip 4 mm thick. It must correspond to the project.

After checking the spiral against the template, the excess is cut off, and the spiral itself is welded to the plate and to the center.

A 40×40 mm profile pipe with a 3 mm wall is used as a stand. Holes are drilled on it for attaching machine elements. Using support platforms, the prepared parts are fixed.

The handle is visible on the reverse side. It was secured to the shaft using a bearing. The prepared “Snail” can rotate.

A performance check is being carried out. The handle turns the spiral around the center axis.

Varieties

Among snail pens, there are several main varieties:

- Manual monolithic non-removable. It uses a fixed metal template.

- Manual removable design. When using it, the metal is bent around segments that are inserted into holes on the plate. Useful for creating a variety of parts with unusual shapes. The cross-section of the metal rod is limited.

- Collapsible models with rotation. Used using mechanical force, they allow you to obtain identical products with complex shapes. They work using levers.

- Horizontal and vertical models. They allow you to bend metal in a comfortable position and simplify your work.

Snail type machine PROMA/ Photo VseInstrumenty.ru

If the work takes place on a monolithic jig, then the final parts have the same shape. And when using removable structures, the curls are more diverse. But the reliability of fastening the template under such conditions is lower than that of a permanent one. The threaded connections will have to be constantly tightened, otherwise they will quickly weaken.

Types, structure and principle of operation of the cochlea

Several varieties of the popular machine are used. All of them, regardless of the details of the cochlea device, use a general operating principle. A strip or rod of metal is forcefully pressed against a stationary template or against a movable ploughshare of the snail, forcing it to take the shape specified in the drawing.

Monolithic volute for cold forging

Removable snail design

Collapsible snail with rotation

There are:

- monolithic non-separable volute using a fixed metal template. Used to produce series of identical products

- removable design - bending is carried out around pins inserted into holes on a solid plate. Suitable for the production of unique parts with complex configurations, the cross-section of the rod is limited.

- Collapsible volutes with rotation are more complex in design, but make it possible to obtain identical products of complex shape with great accuracy

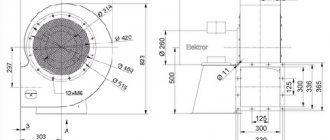

Drawings of a manual machine

Figure 3. Drawing of the base of the cochlea.

The machine, according to this drawing (Fig. 1), is mounted on a base, which is a rectangular slab with dimensions 220x190 cm.

This 5mm thick plate has two holes. One of them is round, with a diameter of 14 mm, for the shaft axis, and the second is oval, with a width from 6 mm closer to the shaft axis to 7 mm further from the axis (Fig. 2). This base is welded to two legs, which have a hole for their fastening (Fig. 3).

The shaft axis has a tapered end. It is firmly attached to the base with two M14 nuts.

The drive axle is freely put on the axle, which has a head with two mutually perpendicular through threaded channels (Fig. 4).

Handles are screwed into these channels.

Parallel guide runners (2 pieces) are welded to the lower surface of the base along an oblong hole.

Figure 4. Drawing of the cochlea axis.

The spiral-shaped element (the snail itself) is prefabricated. It consists of 4 elements, hingedly connected to each other by pins threaded through the eyes (Fig. 5).

Each cochlea segment connecting pin has a knurled head.

The arcuate lugs have holes for the connecting pin. They are welded to the ends of the segments. The amount of bending of the cochlea is regulated by special adjusting screws, which are screwed into the connecting end of each of the three segments so that they rest against the end of the previous segment.

Each adjustment screw has a slot on one end surface for a flat-head screwdriver.

The central segment of the volute is an eccentric with a hole for the drive axis, the first part of the spiral element and a fixing cutout. The fixing cutout is an eccentric semicircular recess in the first part of the segment with a radius of 7 mm, the center of which is located at a distance of 8 mm from the center of the part. The thickness of the central segment, like the other segments, is 25 mm.

Figure 5. Drawing of a cochlear segment.

An eccentric with a grooved lower part, into the transverse channel of the head of which a wing is inserted, is placed inside the guide. The latter is aligned coaxially with the semicircular cutout of the drive axle, and then welded.

A slider is inserted into the longitudinal hole of the base, which is pressed from below to the base. The slider fits freely between the guide rails using the flange cutouts.

A roller axis, which has a hex head, is screwed into the upper part of the slider.

The roller itself is loosely attached to the roller axis.

In this way, the roller can take a position along the oblong hole of the base and is fixed in any such position by screwing the roller axis onto the slider.

Working with this device is quite simple. To begin, insert the end of the rod or strip into the recess of the drive axle. By turning the eccentric using the thumb, the workpiece is clamped between its lower end and the walls of the recess. To do this, the roller is brought to the workpiece, the roller axis is screwed with a 12mm wrench onto the slider, clamping it. The workpiece is placed between the eccentric of the central segment of the volute and the roller.

Next, turn the drive axis clockwise, winding the workpiece over the central segment. When the workpiece is wound to the end of the central segment, a second segment is attached to it using a connecting pin. The roller moves to a new position.

And so on, it is bent until the workpiece is given the desired shape. To remove the resulting product from the machine, the eccentric is turned with a thumb and the end of the workpiece is released. Having lifted the drive axis with the eccentric and the entire volute, the latter are removed from the manufactured spiral.

Turn care - what is it?

“Care for the coil” is a loose interpretation of determining the condition of the cochlea. In this case, the mollusk moves the mantle away from the mouth of the shell and hides quite deeply into it. This state of the cochlea can be compared to a coma. She is greatly weakened, and is between life and death.

If the snail has gone deep into the shell, and at the same time has exposed the columella and growth, we can say that it has “gone behind the coil.”

The snail cannot constantly remain behind the coil without food and water. Her stay in stressful sleep conditions will soon end in death. But how do you understand that the snail has gone into a curl? After all, this could be ordinary hibernation.

If the mollusk goes deeper into the shell (its body may disappear during the next turn and will not be visible at all), there is cause for concern. In this condition, often the snail's leg may be located outside, and the mantle behind it.

Step-by-step technological process for making a reverse curl on the “Snail” machine

The rolling rollers perform sequential crimping of the pipe. Protruding ribs are formed, and the weld remains inside the layer, offset to the center.

The pipe ends are compressed on parallel eccentric rollers. It becomes like a stripe. In this form it is easier to fix it on the machine.

The shank is formed in a special device. Now the workpieces will be fixed on the machine in one movement.

The workpiece is fixed in the center. There is a groove that secures the shank. It can be seen that the spiral has a uniform descent in height.

After fixing the shank, the electric motor is turned on. Forming of the part begins.

The loop is formed when the workpiece touches a special support element. It is more often called the support shaft. To reduce the force, it is equipped with a bearing. The part rotates freely around the support.

Part of the spiral is formed. But if it is necessary to process for a longer length, a removable element will be installed.

A blank is also formed from the other end. Here the master determines in which direction to bend the part.

To continue work, a removable element of the “Snail” assembly is installed.

Now you can form the bend of large parts.

Even long workpieces are easily bent to specified dimensions. Marks are made on the work items. They are used to guide how much to bend.

On the reverse side, additional bending of the part is performed.

The product is being finalized on both sides.

The finished part has a finished appearance. If necessary, the shanks will be sawed off. Then no one will guess how the workpieces were fixed.

If you need to make a small part, then use another “Snail”. Experienced craftsmen have several of them.

Cold forging process

Cold forging is usually where beginners begin to learn metal processing, since this process is quite safe and simple, since in this case you will not have to deal with high temperatures, as with other types of forging.

For this process, as a rule, a ready-made template is used, namely, product blanks. Naturally, cold forging also has its own nuances, usually they consist in the fact that the part is easy to deform or damage during operation: forged products often break, and there is no way to correct this situation, so forging must be done very carefully.

But, with the help of a high-quality machine and a drawing of the future product, you can easily learn how to make products with wavy, twisted and other original shapes. The procedure for processing parts using cold forging takes place in several stages. First, create a drawing or template for the future product.

It is necessary to calculate the dimensions of the part in order to purchase the required amount of raw materials, as well as to correctly adjust the machine. Different machines may provide different possibilities for making patterns - this will depend on the complexity of making the fixtures. For example, the simplest machines, assembled with your own hands, can only bend parts, while using more complex designs you can create patterns and other products.

Then, when the drawing or template is prepared, you need to stock up on the required amount of raw materials in accordance with your calculations. For cold forging you will need metal rods; they can be purchased at the store. The rods must not be very thick, otherwise they will be difficult to bend. The next stage is the production of parts.

The most important thing here is to set the settings correctly so that during operation of the machine the parts do not become deformed or damaged, since this cannot be corrected.

At the very end, the manufactured parts are attached to the frame. This is done by welding. You need to be especially careful when welding with thin-walled tubes, since they are quite easy to burn through, in which case the design will be faulty and you will need to do everything again.

But before you start cold forging, you will naturally need to make the machine that is required for this. The “Snail” machine is the most popular device for making metal patterns using cold forging.

Do-it-yourself snail machine for cold forging

Using a jig, you can independently produce bent elements of the desired size, which are perfect for decorating ready-made street metal structures.

To create spiral curls, you can use different materials, but the most commonly used are square or round metal rods.

The main feature of the homemade “snail” machine is that the decorative elements are made “cold” - without preliminary temperature treatment. This reduces the labor intensity of the work.

Before moving on to the main question - step-by-step instructions on how to make a snail for cold forging, it is important to understand exactly what kind of machine you need. They come in different configurations.

1

Tools and equipment

A manual cold forging machine includes a number of elements. Necessary equipment that will be needed for work:

- twister;

- snail;

- gnutik;

- wave;

- globe;

- flashlight.

The main tool for the work will be a bender, which is used to change the shape of the metal. Its function is to bend a part at the required angle or bend arcs with different radii.

The snail is used, as a rule, for twisting steel rods into spirals. This is equipment for bending rods, strips, tubes, squares and profiles into a spiral shape, products with various shapes and radii. When using this tool, you can not limit the radius of the created spiral and make the size that is required.

The flashlight tool is necessary for bending metal parts. It is used to process metal rods with a cross-section of less than 30 mm, or square profiles with a cross-section of less than 16 mm.

Using a device such as a wave, wavy curved elements are made. It is also used for processing pipes that have a hexagonal or round cross-section.

Twister is somewhat similar to a flashlight. Using these two tools you can twist the rods around the axis.

Using a globe, you can make a large arc from a profile rod up to 12 mm thick. Moreover, the ends of the workpiece also bend smoothly.

This tool for cold forging is absolutely not complicated, so you can often see homemade ones. It is almost in no way inferior to the factory one.

https://youtube.com/watch?v=lXzm3RtqxS8

Design specifications

The dimensions of the volute for cold deformation are determined by the diameter of the rolled product being bent and the required curl size. A sketch of the design of the forged product is first made. It is broken down into individual elements. For each spiral, a conductor is made - a snail or any other.

The simplest machines for cold forging have a massive, durable stand, at the upper end of which there is a groove for fixing a plate with a jig. Deformation is carried out due to the efforts of the master’s hands. He clamps the end of the rod and walks around the fixture.

If there is a rotary table and a lever, it is possible to produce volutes for rolling of a larger cross-section.

Making a guide for the conductor

For these purposes, you will need an ordinary lathe of type 1K62 or 16K20, which is capable of cutting an Archimedean spiral, and, of course, an experienced turner.

The “Archimedean spiral” function in lathes is intended for cutting special threads, but it is also quite suitable for obtaining a groove in the base plate, where the jig guide itself will then be located.

When preparing the machine, the following transitions are performed:

- The small handle of the machine feed box is moved to the “Archimedes Spiral” position.

- The required spiral pitch, which will determine the dimensions of the conductor, is set using a large handle.

- The feed step is fixed by a lever, and the feed amount is determined by the depth of the groove in the plate (how to set this parameter will be discussed later).

- After turning on the machine, the feed lever remains in the same position, and cutting is performed during the reciprocating movements of the spindle.

- After each pass, the support is moved away from the end of the workpiece.

An example of obtaining an Archimedean spiral is presented in this video:

The fact that the frames show not metal, but plastic, does not fundamentally change anything: the spiral is obtained as a result of several successive passes of the cutter, which moves along a given path.

The dimensions of the spiral groove are determined based on the desired dimensions of the conductor and the height of its supporting surface. If in the first case everything depends on the size of the initial workpiece for the plate and the capabilities of the machine, then the depth of the groove should be calculated based on the height and thickness of the guide matrix.

Since in a cold state any metal has increased mechanical strength, then to make a guide matrix with your own hands you should use tool steel: for example, grade U7 steel according to GOST 1435-84. It is not recommended to use high- or medium-carbon structural steel such as steel 45 or steel 60G, since for tall volutes they may crack under the influence of a bending moment.

The dimensions of the guide matrix in plan are selected based on the available range of strip tool steel in accordance with GOST 4405-75. Since the jig must be compact, it is advisable to choose profiles 3×20, 3×25 or 3×30 with a maximum thickness deviation of 0.4 mm. When fitting the guide into the plate according to H11, the width of the spiral groove should be 0.5-0.7 mm greater than the width of the strip. The groove depth must be at least 1.5 times the strip height, i.e. 4.5 mm or slightly more. This parameter, by the way, will determine the thickness of the slab itself: it should be at least 6 mm.

The total length of the guide is determined from the cut groove in the slab (you can use a flexible tape measure or even regular thread to measure). Then they cut the required length of the strip “to size”, insert it into the groove and scald it along the contour (if the jig will produce only flat snails, then along the outer generatrix, and if three-dimensional, then along the inner one).

A support hook is bolted to the center of the conductor. It must have a lead-in section with which the workpiece is fixed at the initial moment of spiral formation (see Fig. 3).

Bends, flashlights, waves and other machines

As you can see, we have collected all other types of cold forging machines in one small section. Why is there such disrespect for them, in contrast to the snail and torsion bar, which we talked about in separate sections? The answer will be honest in the form of advice:

If you decide to make a forging machine with your own hands, opt for two machines: a snail and a torsion bar. Firstly, they are absolutely necessary from a functional point of view, and secondly, they are quite simple to implement independently.

Types of cold forging.

The remaining machines, such as a flashlight or a wave, can be built much later, when you realize that cold forging is for you, and when you have specific creative plans in your head.

There is no need to make a bending machine yourself; it is better to buy it ready-made for two important reasons:

- Wedges and rollers, which are used to change the dimensions of manufactured elements, must be machined to the ideal dimensions. It is almost impossible to do this at home.

- Bending machines are very inexpensive, so the budget saving requirement will be met.

Having at your disposal the three most necessary machines - a self-made volute and torsion bar and a purchased bending machine - you can begin cold forging of almost any complexity. There is one more small issue left to resolve.

Pros and features of the process

Cold forging is a popular type of work due to the fact that it can be used to create unusual parts of various shapes and sizes.

Using a cold forging machine, you can make a fence for a flower bed, a decorative lantern, an unusual fence, railings or handles for a bench and other elements. You can see what the parts created through this process look like in the photo.

Another advantage of cold forging is that it is quite easy to make a machine with which you can create such parts with your own hands. This will help you save on the purchase of expensive equipment.

The cold forging process consists of three main elements: bending, pressing and welding of parts. The equipment needed for this process is quite simple and compact, you can do it yourself and it will not take up much space in your workshop or garage.

You can start learning metal processing with cold forging, because... this process is easier and safer because you don't have to deal with high temperatures like other types of welding.

For this process, a ready-made template is usually used - that is, blank parts.

Of course, cold forging has its own subtleties, they mainly consist in the fact that the part is easily damaged or deformed during the process: forged elements often break, and the defect cannot be corrected, so forging must be done very carefully.

However, using a high-quality machine and a drawing of the future part, you can easily learn how to create products with twisted, wavy and other unusual shapes. You can see the options in the photo above.

The process of processing blanks through cold forging occurs in several stages. The first step is to create a template or drawing of the future design.

It is necessary to calculate the dimensions of the product in order, firstly, to purchase the required amount of material, and, secondly, to properly configure the machine.

IMPORTANT TO KNOW: Device for bending profile pipes

Different machines provide different possibilities for creating patterns - this depends on the complexity of making the tool.

For example, the simplest do-it-yourself machines can only bend products, while with the help of more complex models you can create patterns, etc.

After the template or drawing is ready, you need to buy the required amount of material in accordance with your calculations. For cold forging you will need iron rods, you can buy them in the store.

Rods for cold forging should not be too thick, otherwise they will be difficult to bend. The next stage is making the parts yourself.

Video:

The most important thing here is to set the settings correctly so that during operation of the machine the parts are not damaged or deformed, because it will be impossible to fix the problem.

Lastly, the completed parts are secured to the frame. This happens by welding.

You need to be especially careful when welding with your own hands with thin-walled tubes, because... It’s easy to burn through them, and then the design will become faulty and you’ll have to do it all over again.

You can watch the entire forging process in the video before you start working on your parts.

But before you start cold forging, you, of course, need to make the machine that is necessary for this. The “Snail” machine is the most common apparatus for processing metal products using the cold forging method with your own hands.

You can see all the stages of creating the machine in the video - there is nothing complicated about it, and almost everyone will be able to cope with this task themselves.