Soil mill for walk-behind tractor

A tiller for a walk-behind tractor is used during the pre-sowing period in the spring, after moldboard cultivation. It is not recommended to use cutters on light soils to avoid spattering.

Externally, rototillers look like bent knives or sabers, which are attached to a shaft in a certain order. The shaft rotation speed reaches 200 rpm. It is hung on the back of the walk-behind tractor. The operation of the rototiller depends on the power take-off shaft. The cutter gives better results when the speed of movement increases.

Is it necessary to sharpen cutters on a walk-behind tractor - let’s figure it out together

It is quite difficult to give a definite answer to this question due to several factors. Firstly, the recommendations of the cutter manufacturer are of great importance. Some companies that produce high-quality equipment for plowing the soil do not recommend sharpening the cutting elements, as this will lead to a deterioration in the efficiency of the cutters and void the warranty on their service. Other manufacturers, on the contrary, recommend sharpening the cutters before each season of operation of the walk-behind tractor.

The second important factor is the result that sharpening cutters can bring. The only, but very important, advantage that this procedure gives is the ease of cultivation, because it will be much easier for sharpened cutting knives to go deep into the soil and effectively plow it. The disadvantages of sharpening include the need to dismantle and install equipment on the walk-behind tractor each time. Another very important drawback is the ability of cutters to crush weed roots deeply hidden in the ground, which will lead to their intensive vegetative reproduction throughout the entire area of the garden.

The third factor is the type of soil being cultivated. If a rototiller on a walk-behind tractor is used primarily for processing hard clay soils and virgin soil, then sharpening the cutting knives will help plow such soil faster and better. If the soil in the garden is soft, then, as a rule, there is no need to sharpen the set of cutters used.

All the tips listed for the manufacture, installation and sharpening of devices are suitable for operating the equipment in tandem with Neva MB-1, MB-2 walk-behind tractors, as well as agricultural machines of the MTZ, Tselina brands and units of other imported and domestic manufacturers.

A tiller for a walk-behind tractor is one of the most common types of additional equipment for tillage. It is a set of special knives mounted on an axis. With their help, you can quickly and easily get rid of weeds and cultivate the soil on the site. In order to choose the optimal type of cutter for your walk-behind tractor, you should classify them a little.

Diagram and device of a cutter for a walk-behind tractor

Thanks to their saber-shaped shape, cutters for walk-behind tractors are safe to use. If the walk-behind tractor hits a root or stone, the cutters lift it like a car wheel, while continuing processing. If the cutters are straight, then they can catch on an obstacle and overturn the walk-behind tractor. The consequence may be the operator losing his balance and possibly falling onto the cutters.

The knives are attached to plates, which are welded to the shafts at various angles. Thanks to this, the cutters enter the soil smoothly, one at a time. This has a positive effect on the transmission of the walk-behind tractor. Carbon steel is used to make knives. If you have access to a forge, using a spring, you can make such knives. For the manufacture of other parts, the following steel grades are used: St-25, St-20, St-10, which are easy to weld.

Is it necessary to sharpen cutters for a walk-behind tractor?

Any tillers are self-sharpening tools. Sharpening is not necessary for them, as it can only ruin the design. Only in some cases, if you have been using a cutter for a very long time and see that it has begun to work the ground poorly, you can sharpen the knives.

The tiller is an important element of each unit. Homemade, correctly assembled cutters can be used on any modern walk-behind tractor, in particular on Neva MB 1 and MB 2, MTZ and others. Such structures will help in cultivating the land and make agricultural tasks easier.

Soil milling machines with crow's feet for walk-behind tractors

To give greater strength to the cutters, they are made of steel, all-welded and non-separable. These cutters are called crow's foot cutters for walk-behind tractors. They are successfully and effectively used when working with hard soil. They are installed on almost any motor-cultivator or walk-behind tractor.

The main thing is that the axle diameter is correct. Houndstooth cutters are ideally used when there is hard soil to plow it “under potatoes.” They are also used for prevention against garden pests (wireworms or Colorado potato beetles) or for quickly plowing the garden.

Crow's feet cutters are divided into 3 and 4 rows. If the axis diameter is 25 mm, 3-row cutters are used for motor cultivators Texas, Krot, Caiman, Neva, and 4-row cutters are used for walk-behind tractors Farmer, Salyut, Favorit. If the axis diameter is 30 mm, 4-row cutters are used for walk-behind tractors Cascade, Pubert, Master Yard, Neva.

Tips for choosing

In the process of selecting this element for a walk-behind tractor, you should pay attention to its dimensions. Here it is important to choose the correct diameter of the crow's feet axis. It must match the diameter of the landing shaft of your device. The nozzle can have sizes of 30 mm and 25 mm. The 25mm cutters have three separate rows of three blades. Such products are used in walk-behind tractors such as “Mole”, “Neva”, “Texas” and others. 30 mm models have four rows of blades.

Another factor to consider when choosing this part is the outside diameter. This indicator determines the plowing depth. Among other things, the nozzle must be made of high-quality material, otherwise the part can easily break.

Do-it-yourself active cutter for a walk-behind tractor

Typically, an active cutter for a walk-behind tractor is sold complete with the walk-behind tractor. But sometimes you need to get the job done using specialized cutters that are not sold anywhere. In this case, you need to make cutters for the walk-behind tractor yourself.

In this case, you can go two ways: make the cutter yourself or order production from a master. The first option is quite labor-intensive. But a little time and money will be spent on manufacturing the cutter, as well as the cost of materials.

The second option has a number of advantages: the master has all the necessary tools and materials, and as a result the cutter will be more practical.

First you need to think about the functionality and design of the cutter. To do this, you should familiarize yourself with the analogues. To achieve maximum functionality and safety, all design details must be taken into account. If this is not taken into account, then the cutter will not do the necessary work, and all the work on its manufacture will be a waste of time. You need to prepare the necessary materials after you have prepared the drawings. If the cutter design contains figured or pobedite elements, their production is ordered in the workshop. And other elements are bought in the store or those that are available are used.

After all the parts are made, it is necessary to assemble a normally working cutter, which not everyone can do. Assembly must proceed strictly according to the drawings, without any deviations in the design. Otherwise, the cutter will constantly move to the side, which will greatly complicate the work.

After the cutter is assembled, you need to test its operation. If the need arises, we alter the cutter so that it does the required job.

How to properly assemble cutters on a walk-behind tractor?

Assembling the cutter with your own hands should be done as correctly as possible. And here it is especially important to ensure that the active part crashes into the ground during operation. To do this, it is initially recommended to study the drawings and then begin manufacturing the equipment.

To create cutters, the following tools are required:

- The rotor axis is of the required length. It can be divided into two parts if you need to assemble a cutter from two blocks.

- Short axis.

- Gearbox with clamps.

- Left and right knives.

- Bolts, washers, nuts.

Assembling the structure does not take more than an hour, but here it is important to install the knives in such a way that they do not interfere with the rotation.

- The long rotor axis is equipped with knives at an angle of 30 degrees.

- It is necessary to combine four knives on one block, securing them to the gearboxes.

- Next, the correctness of the design is checked and all fasteners are tightened.

This design is very reliable and can withstand fairly high loads.

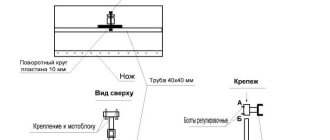

Drawing of cutters for walk-behind tractor

Assembling crow's feet with your own hands

If for some reason the existing rotary cutters are not satisfactory or have become unusable, home-made rotary cutters for a walk-behind tractor can be an alternative to purchased devices. This task is not particularly difficult and at the same time has advantages in the form of the desired degree of reliability of the structure and its features, increasing the efficiency of land cultivation and, of course, saving money on the purchase of a ready-made device.

The easiest way to make it is to study the design of industrial cutters and diagrams of how to assemble a cutter, and then create an analogue, making the desired adjustments if required. It makes sense to draw drawings for assembly that take into account the necessary parameters and requirements for the device.

When assembling crow's feet, the homemade design includes the following parts:

- bushing (can be made of a tube having a diameter of 50 mm);

- flange (made of a thick sheet of steel, can be round or square, which is easier to make);

- racks for knives (easy to make from a steel angle, profile, car spring);

- blades (the optimal material is tool alloys; springs from cars are suitable).

You can either make cutters for a walk-behind tractor yourself or purchase them in a store.

The knives are welded to the stands, which, in turn, are fixed to the flanges, and the flanges to the bushing. Sometimes bolts are used for connections, but practice shows that it is much more reliable to use a welded connection.

To prevent premature wear of the knives when processing particularly difficult and turfy soils, it is recommended that the design include lightening the load by additionally installing limit wheels on the sides of the device. This complicates the processing process somewhat, since only the top layer of soil is cultivated, after which the restrictions must be dismantled and re-processed.

How to properly plow with a walk-behind tractor with cutters

As mentioned above, one of the important factors in the efficiency of soil treatment with rotary cutters is the level of depth of the coulter. The second no less important point is the correct choice of unit speed. Experienced users recommend using second gear, as this increases the number of revolutions and improves the quality of crushing the soil and immersion to the desired depth. Milling cutters for walk-behind tractors are attachments designed for plowing, loosening soil, mixing it with mineral and organic fertilizers, controlling weeds and pests .Thanks to high agrotechnical characteristics and a high degree of crumbling, rotary cutters create optimal soil density, increase its biological and biochemical activity, while significantly increasing productivity. Tillage is carried out in the spring before planting crops and after autumn harvesting of rough-stemmed plants. The devices are installed on walk-behind tractors and cultivators as a working tool. They can be supplied as a basic kit when purchasing motorcycles, sold separately on domestic markets, and some craftsmen make them themselves.

When heated, the pre-sharpened strip bends 90˚. The length of the bent part usually does not exceed 80 mm. It is advisable to combine cooling of the workpiece with its tempering for comfortable drilling of mounting holes. Upon completion, the axial pipe is hardened and installed on the flange.

Which ones are better

Milling cutters for motor cultivators are selected for each type of work and depending on the soil structure. Saber-shaped cutters, loosening the soil to a depth of 35 cm, raise weeds to the surface. At the same time, they do not cut them into small pieces, but wind them around themselves and the shafts. What prevents them from reproducing? In addition, the soil is more coarsely ground. But on dense or virgin soils, saber knives do not penetrate the ground well. Large and climbing weeds quickly wrap around the working part and slow down processing.

Houndstooth cutters do an excellent job with difficult soils and all types of weeds. However, because they cut them into pieces with a sharp edge, the weeds multiply. There is an option for combined use. In the fall, you should go through the area with these cutters, and in the spring and throughout the season you should work with saber cutters.

Cutting element (knife)

It is made of durable, non-fragile steel type 65-70G, 3-5 mm thick. The triangular shape of the knife is considered optimal for the least resistance when entering the ground.

Homemade workers often use the triangular cutting element of a segment mower as a knife. Since the steel of the pillar and segment has a different composition, welding must be done after tempering, followed by hardening. Milling cutters with such knives are used on clean work areas. For heavy, virgin soils, it is recommended to make cutting elements from thicker steel, which will make it possible to make a high-quality welded joint.

As practice shows, the optimal width of knives is 50-80 mm. Larger sizes create increased soil resistance.

Main advantages and nuances of assembly

The widespread use of such cutters began in the second half of the last century, when the process of mechanization gained great momentum. Immediately after their appearance, crow's feet showed effectiveness in use. The main advantage is that the design is divided into several parts, which can be created separately. In addition, if a certain element fails, you can simply replace it, and then the device will again become suitable for use.

READ How to Disassemble the Gearbox of a Cascade Motoblock

Before assembling the crow's feet, you need to decide on the type of structure. This is extremely important, since each walk-behind tractor has its own suitable options. Only after selecting the optimal type can you begin to select the materials used.

When assembling such a cutter, it is extremely important to take a responsible approach to the installation of all elements, regardless of their purpose and other features. Under no circumstances should any deviations or errors be allowed. This can not only cause complete failure of the walk-behind tractor, but also have a negative impact on human safety.

During the installation process you will have to use a hexagon, which will significantly simplify the work and allow you to correctly install the elements. The dimensional characteristics of crow's feet may vary, however, most models on the market differ in dimensions of 300x400x23 mm.

Most users are interested in the question of whether it is worth sharpening knives when installing these cutters. There is no clear answer today. There are several factors to consider. First of all, the manufacturer’s recommendations are of great importance in this matter.

Some companies that specialize in the production and sale of crow's feet do not recommend additional sharpening, as this may negatively affect the efficiency of the cutters. Others advise sharpening before the start of each season so that the knives can cope with their task without problems.

The main advantage of sharpening is that the cultivation process will become simpler, since it will be much easier to process the soil with such knives. However, each time you sharpen you will have to dismantle and install new equipment, which takes a lot of effort and time.

Thus, “crow’s feet” are one of the most popular options for cutters for walk-behind tractors. High quality, durability and efficiency of use set these cutters apart from others.

You will find out more information about “crow’s feet” for walk-behind tractors below.

Instructions for creating a cutter

Assembly diagram of a cutter for a walk-behind tractor.

Self-assembly allows you to adjust the working width of the plot to the characteristics of the land plot. To make a simple cutter for a walk-behind tractor you will need:

- a small metal tube with a diameter of no more than 42 mm;

- parts that can be used to dig up the ground;

- welding machine;

- Bulgarian.

As plowing parts, you can use unnecessary springs from a car or remnants from any other equipment that meets the requirements. The blades of the future cutter need to be adjusted to size and bent in one direction. Then, using a welding machine, attach them to the pipe from different sides. If desired, the blades can be sharpened in the direction of their intended movement. The finished structure should be attached to the walk-behind tractor to the hitch. The design is ready for use. If a malfunction is detected in the operation of the device, it can be removed and adjusted.

Self-assembly of a cutter on a walk-behind tractor requires some effort and time, but the result of the work will not be long in coming. Only you can make a cutter yourself that will best meet your requirements and correspond to the characteristics of the land and soil.

A tiller for a walk-behind tractor is one of the most common types of additional equipment for tillage. It is a set of special knives mounted on an axis. With their help, you can quickly and easily get rid of weeds and cultivate the soil on the site. In order to choose the optimal type of cutter for your walk-behind tractor, you should classify them a little.

Installation of cutter

The process of installing a cutter on a walk-behind tractor is quite simple, but before starting work you should carefully study the manufacturer’s instructions and understand the installation features. The standard cutter design includes a rotor axis, a pin equipped with a special lock, several knives and fastening materials. This equipment must be installed in such a way that the cutter rotates counterclockwise. Rotary cutters are self-sharpening tools, which greatly simplifies the process of using them. In other words, you will not need to constantly disassemble the structure in order to sharpen the knives. It should be noted that problems may arise during the installation of the cutter

, so experts do not recommend carrying out the installation yourself - it is best to get an assistant in advance. The installation of a saber cutter deserves special attention. The fact is that it is not a monolithic structure, so first you will have to assemble the product correctly. The main thing is to set the correct direction of rotation, since without this the device will not perform its tasks.

Assembling such an element with your own hands for a walk-behind tractor is quite easy, because this is a task that can be quickly mastered, but first it is better to study the functions that the unit will have to perform. Before starting a homemade assembly of a saber-shaped cutter, you need to carefully understand the drawing, and after installation, you must check the unit for functionality. Usually, it is not possible to fine-tune the equipment the first time, so you have to make some adjustments to its operation. Cultivation or milling of the soil is one of the most important stages in cultivating a plot of land. During the milling process, the soil is loosened and mixed. The choice of depth for such cultivation is very important; up to 25 cm will be optimal. Thus, the properties of the soil, its fertility are improved, and the land area is leveled. This process is also often combined with the application of fertilizers. For owners of dachas and vegetable gardens, mechanization of this process has become more accessible with the advent of walk-behind tractors. The choice between a shovel and a walk-behind tractor with a milling cutter became obvious. The power of the walk-behind tractor is quite enough to process not only sandy soils, but also virgin soil. The main thing here is to competently approach the choice of additional equipment.

What depends on the correct choice of cutter for a walk-behind tractor:

- Quality of cultivation. In most cases, you can even do without a plow;

- Your strength and time that you will spend on completing a certain amount of work;

- Ease of control of the walk-behind tractor and load on the operator during milling;

- Load on the walk-behind tractor, in particular on the gearbox.

Today, you can already choose the cutters that will be used to mount your walk-behind tractor, depending on its power and the type of soil being processed.

Factory cutter

Most walk-behind tractors and cultivators are equipped with such cutters when sold. Depending on the situation, they can be assembled or disassembled. You can choose any walk-behind tractor you want, but unfortunately, you cannot choose which cutter to equip it with initially. The design is an axle with welded plates, to which saber-shaped knives are directly attached. The finished cutter can consist of several such sections connected to each other using bolts. By adding or removing a section, you can adjust the width of the cultivation. Pros and cons of a factory cutter:

The most important plus is that it comes immediately complete with the walk-behind tractor. The cutter copes well with its main task, provided that the work is carried out on a previously processed area. Now about the realities. When it comes to Chinese walk-behind tractors, the cutter blades are their weak point. Bad metal will make itself felt, perhaps even in the first season; bolts and welding joints also leave much to be desired. If you cultivate virgin land or where there is a lot of grass, the process will not be pleasant. It will be difficult to hold the walk-behind tractor, and the load on the gearbox will be high. But do not rush to get upset, it is no longer a problem to find high-quality knives of Polish or Ukrainian production, there is plenty to choose from, the issue with bolts is even easier to solve. And making a better welded joint is not a problem for our brother either. Such a cutter is an all-welded structure, an axis and knives welded to it, with triangular tips or, as they are called, crow’s feet.

Pros and cons of the crow's feet cutter

The main disadvantage is the non-collapsible design. But this is not significant if you choose a high-quality cutter. But there are many advantages:

- You yourself choose the number of sections to install on the walk-behind tractor. Depending on the technical characteristics of your walk-behind tractor and your requirements, the milling width is adjusted in this way.

- Can handle harder soils.

- It breaks up plant residues better.

- The bushing can be hexagonal or round. An important point when choosing attachments, due to which it can be used on different models of walk-behind tractors.

- Reduces the load on the gearbox.

- Significantly facilitates handling.

Based on our experience, the crow's feet cutter is the optimal choice for an air-cooled walk-behind tractor. Largely due to its versatility, reliability and practicality.

“Virgin” - spiral cutter for walk-behind tractor

If you need to cultivate virgin land, the best choice would be a spiral cutter. Like the Crow's Feet, the Tselina has an all-welded design, this was done specifically to strengthen it and allow it to withstand higher loads. Spiral-welded knives are equipped with “virgin” type tips.

Pros and cons of the Celina cutter

The disadvantages, perhaps, include slower operation, but this is not surprising, you will not accelerate in virgin lands. As a disadvantage, it can be noted that during the cultivation process, the soil is pushed from the center to the edges. A small ditch will form and the land will require subsequent leveling. The advantages are difficult to overestimate:

- It copes with virgin soil better than other existing cutters.

- Great depth of cultivation.

- Excellent soil loosening.

- Very reliable and durable design.

So, we can safely conclude that for better processing of your land, you should not opt for a factory cutter. If you want to increase productivity, reduce the load on the walk-behind tractor and save time and effort, we recommend choosing a crow’s foot cutter. If you are faced with difficult development of a virgin plot, the “Virgin” soil cutter is your choice. Mills for a walk-behind tractor. Choice, comparison. was last modified: April 24th, 2021 by administratorThe tiller for the walk-behind tractor is used to destroy weeds, intensively crumble the soil, mix soil layers, level the field surface and wrap up fertilizers. Milling cutters are used especially effectively when heavy, waterlogged soils are processed, silty layers are developed, hummocks are cut off, and meadows and pastures are improved.

In an active saber cutter, only bolted connections of the component parts are used. This means that complex and expensive equipment (for example, a welding machine) will not have to be used. Just as it is not necessary to have special work skills - virtually anyone can do it, even without special training. Bolts, nuts, and washers, as a rule, are already included with the cutters. But it happens that the factory completely forgot to put the required bag or made a mistake with the quantity (the package contains fewer fasteners than required). Then the necessary parts can be purchased at the market, in a construction supermarket or in a specialized store - this is not a problem at all. Many people also have a wrench of a suitable size in the garage or at home, and if suddenly they don’t have it, then buying the right tool won’t break the budget.

Which cutters are better

Saber-type attachments are suitable for any soil. For areas with stones and large roots, it is recommended to use high-performance attachments. In active cutters, the knives do not break due to the high-quality material used. The cutting elements are characterized by maximum reliability, strength and durability. The cutters are installed on cultivators. Crow's feet are distinguished by the high passability of the cutter on virgin soil, untouched by agricultural machinery, as a result of which the soil is easily and quickly processed, the earth ball is thoroughly crushed, and mixed at a depth of 30-40 cm. They are convenient for cultivating rocky and hard soil types , weed control and are installed on both motor-cultivators and walk-behind tractors.

The disadvantage of the weapon is its lower strength. During operation, knives must be constantly inspected for damage and repaired. The material of the crow's feet does not have such high strength characteristics as alloy or high-carbon steel, but nevertheless lends itself well to welding processes. If the cutting elements break or crack, the product can be repaired at home at minimal cost. This quality is the main advantage when choosing a cutter.

When figuring out how to properly assemble cutters on a walk-behind tractor, many owners wonder about the design of soil rippers. The basis of these parts may well be car springs, which are bent and then welded to the main pipe at the desired angle.

Purpose and features

“Crow's feet” are one of the most popular types of cutters, which are designed to ensure high-quality plowing of the land on the site. This element is a small axis on which knives are placed. It is they who create the effect of cutting the earth, plowing it in a similar way. It should be noted that when using a walk-behind tractor with similar cutters in a dacha area, not only the soil can be processed, but also the plants on it. Therefore, many summer residents use this unit to control weeds.

The peculiarity of “crow's feet” is that they do not come apart into parts, but are distinguished by a cast construction. During the production process, exclusively carbon steel is used, which ensures the reliability and durability of the unit.

Another advantage of the element is its triangular shape, which guarantees excellent soil mixing. This configuration is extremely relevant, given the strength of solid soil.

Crow's feet are simply irreplaceable when cultivating areas where the soil lies in a large lump.

Most summer residents use walk-behind tractors with similar cutters to cultivate the area where potatoes will be planted. Some believe that such finishing can even protect the future harvest from the Colorado potato beetle.

If you plan to use the attachment not only for cultivating the ground, but also for destroying weeds, then the edges of the knives will need to be sharpened first, since initially they are quite dull.