Milling operations are the processing of materials using a cutter. Large enterprises usually use machines that combine boring, drilling, marking and other functions. All kinds of methods and approaches support work in any direction and from different angles. In addition, the machines allow the processing of several workpieces mounted on one surface at once. Processing with several cutters at once is also common. In this article we will look at the main milling methods

.

Basic milling methods

Method for simultaneous milling of a group of workpieces

This milling method allows you to process workpieces much faster than usual. In this case, single milling can be carried out, but only for large-sized products.

The group milling method is based on the fact that various products are distributed depending on which machines should process them: milling, turning, drilling, turret, and so on.

Within this milling method, parts that are combined into one group are processed according to a common scheme. A properly developed scheme, taking into account the characteristics of individual products, allows processing to be carried out in compliance with the rules and methods of the established technological process.

Multiple milling method

This milling method can be implemented in two forms: sequential and parallel.

With the parallel milling method, the same cutter processes rows of workpieces. Or, in more complex situations, several cutters do this work.

With the sequential milling method, conveyor processing is carried out. The workpieces are lined up in a row so that they can one by one fall onto the work table under the cutter.

Positional milling method

This milling method is one of the most effective in operation. There are several varieties of it:

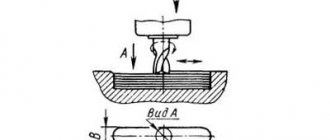

- The pendulum milling method is when workpieces are fed in two directions at once without any rotating devices. This allows you to combine the time spent on installing/removing the workpiece from the machine.

- A milling method that uses repeat tables. They can be either universal or specially designed for certain industries.

Continuous milling method

This milling method is used with special equipment. For example, such equipment is a round table that can rotate without interruption. There are other options, in particular, vertical milling machines. The essence of the method is that there is a continuous supply of workpieces under the cutters.

Development of metal milling technology

Initially, turning and milling of metal was carried out manually. The craftsmen worked with homemade devices and ordinary tools. Because of this, productivity was low, and the output was a lot of defective parts. Even experienced metalworkers found it difficult to produce a part with the exact dimensions and shape.

With the development of technology, machines began to appear that operated using electric motors. With their help, it was possible to process workpieces more accurately and quickly. Metal processing became much easier, and technology continued to develop. Gradually, conventional machines began to be equipped with CNC systems. Today, professional equipment works independently after setting up the program. For production, it is enough for one operator to set up the program and control the operation of the machine.

https://youtube.com/watch?v=UTUzUZlNK3Q

What are the different types of cutters?

There are many cutters available for a wide variety of routing methods. For various purposes, materials such as diamonds, steel, special types of ceramics and others are used in the manufacture of a cutting edge. It is only important to choose correctly which type of cutters is suitable for a particular milling method, as well as determine the method by which the workpieces will be fed. Among such methods, we can highlight, for example, translational-rotational and helical. Next, we will briefly consider which products are intended for what purposes and methods.

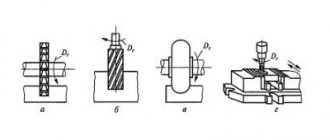

Let's consider what classifications of cutters exist based on the needs of milling methods:

- by the material of their cutting elements;

- by the location of the cutting parts of the teeth;

- by type of teeth sharpening;

- in the direction of the teeth (helical, inclined, etc.);

- by product design (composite, one-piece, prefabricated);

- according to the type of fastening of the cutting elements.

Considering the variety of classifications of tools for milling, it is quite problematic, and there is no need to present them within the framework of this article. We use the most common classification - according to the shape and function of cutters. This will allow not only to list existing products, but also to mention the milling methods in which they are used.

Cylindrical

This type of cutter has two types. The first is distinguished by straight teeth, and the second by screw teeth. In this case, straight teeth are used for simple milling methods, while screw teeth are considered a more universal tool that allows processing in rather complex cases.

It should be mentioned that sometimes it is advisable to use twin cylindrical cutters. This is due to the fact that the angle of the cutting edge does not exceed 450 degrees, which means it has limitations in its use. With the dual milling method, the cutting parts are able to cover the place where the halves of the tool meet.

Disk

Have the following functions:

- cutting grooves;

- sampling of metal in small areas;

- cutting material;

- chamfering;

- some other possibilities.

A distinctive feature of this type of cutter is the ability to use it for various types of milling. This is achieved due to the fact that the cutting edges can be on either one or both sides of the product. In this case, different tooth sizes are possible. Large ones are needed for pre-processing, and small ones for finishing stages of work. This type of cutter is operated under not the most convenient conditions, including strong vibration and difficulties in removing chips from metal products.

Varieties:

- cutting;

- slotted;

- grooved;

- end

They are used to process workpieces that have a flat or stepped surface. The most popular milling method in this case is perpendicular.

A distinctive feature of such parts is the frequency of the teeth at the point where the cutter comes into contact with the workpiece. This allows the material to be processed very quickly and evenly. There are cutting edges on the end part. This contributes to a clean surface if the work is carried out on a milling machine.

Worm

Used for specific milling methods. As a rule, metal is processed by rolling. The cutter touches the workpiece pointwise.

Varieties:

- right and left directions of turns;

- single-pass and multi-pass;

- monolithic and prefabricated;

- with ground teeth and with unground teeth.

End

These products are designed for milling methods such as shouldering, slotting and similar procedures.

Varieties:

- cylindrical or conical shank;

- large teeth for initial (preliminary) and small teeth for final processing of the workpiece;

- monolithic products or having soldered cutting elements.

Roughing

These cutters are used for milling methods such as processing alloys - the results of forging or casting.

Keyed

They are one of the variations of end mills. Used for metal milling methods such as T-profile cutting. A distinctive feature is the presence of two teeth in the middle and end of the tool. The distance between the teeth determines the sampling parameters.

Cut-off

Required for those milling methods that involve cutting the workpiece - not necessarily full, sectorial is also possible. It should be noted that the cutting edge does not meet on the end side.

Varieties:

- with fine teeth;

- with medium teeth;

- with large teeth.

Fine to medium tooth tools are required for most methods of milling steel or cast iron. Large teeth will be required in more complex cases, for example, for processing light alloys (magnesium, aluminum, etc.).

Dear readers!

If you have any questions about development and production:

➜ housings for electronic equipment;

➜ housings for LED displays and monitors;

➜ shielding structures for electronic devices.

Call: +7(495)642-51-25

or leave a request. We will answer all your questions! It's absolutely free!

Features of turning and milling processing

Although milling and turning can produce similar results, there are significant differences between the two operations in terms of process technology. In both methods, chips are removed and grooves and holes are made. But the working units of a turning and milling machine are radically different.

Mechanical turning equipment is one of the first technical devices invented. During processing, the workpiece rotates, and the tool with cutting surfaces carries out a forward feed motion. Lathes are used in the manufacture of:

- disks,

- shafts,

- bushings,

- axes,

- couplings,

- nuts, etc.

The equipment carries out trimming, turning, cutting, boring. The combination of rotational and translational motion makes it possible to effectively process various types of surfaces: threaded, cylindrical, conical, shaped, etc. The accuracy of dimensions and configurations is ensured by the use of special instruments: bore gauge, micrometer, caliper. Turning is used to create parts made of steel, aluminum, lead, and polymers.

Milling machines appeared later, at the beginning of the 19th century. During processing, the workpiece is securely fixed, and rotational movements are performed by the working cutting tool. Horizontal and vertical type devices and universal designs are used in production. This allows processing to be done at any desired angle. Using milling, various parts are made, cuts and grooves are produced, and surfaces are processed. Various types of machines perform milling:

- end,

- terminal,

- shaped.

Milling can be used for workpieces made of different materials. The equipment works with several types of working tools. There are cutters for steel parts, hard and soft alloys, ceramic workpieces, etc. A large number of operations are due to a wide range of tools: keyed, disk, end, cylindrical.

In the manufacture of parts with complex configurations, it is often necessary to use both types of work. In order to simplify processes and optimize production, combined machines were designed that perform turning and milling operations.

Methods for milling inclined surfaces and shoulders

Many milling methods involve machining shoulders and grooves. As a rule, such work is carried out on machines. What are grooves and ledges?

ledge

- This is a recess that has two flat surfaces perpendicular to each other. Due to this, a step is obtained.

Groove

is a recess that can have a variety of surfaces: triangular, square, rectangular, etc. At the same time, there are many options for grooves: open, closed, through, etc.

Various milling methods involving the processing of grooves and ledges have all sorts of technical requirements for products. The list of these requirements depends on the specifics of production, its goals, etc. Often the choice of milling method itself is dictated by the characteristics of the workpieces, the quality of their surface, production tasks and many other factors.

Milling methods offer various options for creating and processing grooves and shoulders. For example, you can use a set of cutters or a disc end mill. It should be noted separately that in the case of shoulders, end mills are often used.

Milling grooves and shoulders with disc cutters

Disc cutters are used for milling techniques such as slotting, shouldering and flat surfaces.

The teeth on disc slot cutters are usually located exclusively on a cylindrical element and are designed for relatively simple routing methods. For example, they allow you to create grooves of small depth in workpieces.

Another popular variety of this type of cutter is three-sided. It also has teeth on the end surfaces. This arrangement allows the use of more complex milling methods, in particular, the creation of grooves deeper than in the previous version. In addition, this type of cutter makes it possible to produce cleaner work.

Three-sided cutters have a number of advantages over simpler types of this tool. Their distinctive feature is the teeth, which have a constantly changing direction of the grooves. The teeth tilt in different directions. This allows the cutting forces to be balanced due to their opposing effect on the cutter and the product. In addition, this type of cutter has teeth on both ends, which allows for a variety of milling methods.

However, three-sided disk cutters also have a number of disadvantages. First of all, it is worth mentioning the reduction in width after regrinding. If cutters of their halves are used, having the same thickness, then the original size can be restored. But this will require a gasket, which should be placed between the halves. The most popular material for such a gasket is foil.

Disc cutters with insert knives with plates are created in two versions:

- according to GOST 5348 - 69 (a) - three-sided, used for milling methods such as processing of product grooves;

- according to GOST 6469 (b) - double-sided, used for milling methods such as processing planes and shoulders.

Insert knives are inserted into the body due to corrugations on the axis and a special wedge having an angle of 5 degrees. This fastening method allows you to compensate for layers that wear out during operation. Thus, you can return the tool to its original form in two ways:

- if the diameter is worn, replace the knives in the grooves;

- when worn along the width - by extending the cutting elements.

The knives in three-sided cutters, alternating directions, are tilted at an angle of 10 degrees.

The knives in double-sided cutters tilt at an angle of 10 degrees in one direction, but on different tools it can be either left or right.

The three-sided disk cutter can be used in various milling methods due to a number of advantages. It retains its size better and allows for quick processing of ledges and grooves.

Types of milling work

A wide range of existing cutters allows processing materials of varying complexity and configuration, at any angle. All types of processes can be divided into several groups:

- Working with flat surfaces. Roughing and finishing cleaning of non-volumetric planes having a horizontal, vertical or inclined position is carried out.

- Processing of bulk shaped blanks and parts. Volumetric cleaning is carried out, giving objects a certain shape.

- Separation. The parts are divided into several parts and excess material is cut off.

- Modular finishing. It is based on the formation of the required profile of the existing workpiece, the design of grooves, grooves, teeth, and shaped recesses.

For each individual method, a separate milling fixture is most often used. Particularly complex workpieces are processed using a set of cutters. Thus, milling of wide surfaces is carried out using a set of tools that have multi-directional helical teeth in order to reduce axial forces.

Machine tools

The milling work required determines the equipment required, including the type of machine on which it will be performed.

Horizontal milling machines are designed for processing horizontal planes and shaped surfaces, manufacturing gears, and designing some profile objects. Their design determines the horizontal fastening of the tool, most often a cylindrical, disk or end mill.

The same types of work, but with distinctive features, can be performed by a vertical milling machine. A special feature is the vertical mounting of the tool and, therefore, the predominant use of face, end and modular cutters.

Universal milling machines have additional devices for rotating the table in 3 planes, which allows you to work with horizontal, vertical and shaped surfaces.

In the mass production of parts with the same profile, copy milling installations are used, which make it possible to produce repeating patterns or indentations on a plane with increased accuracy.

The equipment of the future is CNC machines. They ensure the execution of a programmed set of actions, mainly for artistic milling or non-serial production of parts. End, face and modular cutters with different numbers of cutting edges are used.

Milling is work on a special cutting machine, which ensures the working stroke of the tool and the feed of the workpiece.

CNC metal milling

Despite the apparent simplicity of the technology, milling is a very complex operation, the success of which depends on the qualifications of the performers. Therefore, since the invention of the first milling machine (mid-19th century), the search for an automatic control mechanism for this unit has not stopped.

A compromise solution was a special device that connects the movable spindle to the template using a system of levers and rocker arms. This device synchronized the route of movement of the cutter with the contours of the template. As a result, with the help of this prototype of a numerical control (CNC) system, it was possible to mechanize some operations.

But the price of milling metal according to a template turned out to be too high. After all, the cost of a template is comparable to the wages of a semi-skilled miller, but high quality remains unattainable.

The already mentioned numerical control system changed everything. A system of automatic control of feed and spindle speed and work table feed was added to the standard components of the machine. Moreover, the plane above the table was considered as a three-dimensional space with its own coordinate grid, along which the cutter was moved, moving the spindle and the table with the part.

As a result, CNC milling metal processing began to produce results that no living milling operator could demonstrate. Moreover, CNC machines turned out to be beyond competition, both in terms of productivity and processing quality. And only thanks to these devices was multidimensional - 3D metal milling, which involves simultaneous processing of a workpiece on several spindles operating in different planes, mastered.

Accompanying phenomena

Milling is a chip removal process that is characterized by increased thermal effects and mechanical stress that can negatively impact tooling capabilities and finishes. Some phenomena that influence the results of milling work:

- Chip sticking and shrinkage. The sticking of metal on the cutting surface and its pressing spoils the finishing process and the knives themselves. This is more relevant for soft materials.

- Hardening. An increase in hardness, a decrease in strength and ductility of the surface layer of a part is a side effect of plastic deformation, which is removed by subsequent heat treatment.

- Friction, increased heat in the working area, vibration are factors that reduce the performance of the cutter.

To prevent side effects, it is necessary to use additional technologies and means.