How to stretch a keyway on a shaft.

Browse products for inventors. Link to the store.

Keys are an important part of mechanisms. They provide a reliable connection between shafts and a variety of other objects, including pulleys (as in my case), sprockets, arms and gears. There are many different types of keys, but the simplest and most common is the straight key. For this project I will be punching keys into pulleys that are in the process of being machined. The material is 6061 aluminum and is 3/8" thick with a ø3/8" hole and I will be pulling a 3/32" keyway.

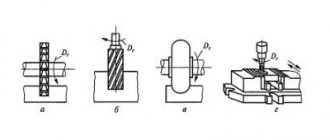

Types of keys

Modern production provides over 20 different types of items. But among them the following most used types in mechanical engineering are distinguished:

- Wedge - used on end installations and are a type of driving keys. This keyed connection is used for shaft diameters of 100 mm or more. Currently they are extremely rare. The reason for this lies in the high probability of overtightening of the unit and displacement of the alignment of the hub and shaft under the influence of one-sided force. It is also difficult to remove the keys.

- Prismatic. The groove dimensions are regulated by GOST 23360-78. They are most in demand in industry due to the optimal ratio of strength and manufacturability. There are two types of them: mortise and embedded. Mortise keys are installed with an interference fit, and embedded keys with a small gap.

- Guide keys. They are distinguished from prismatic ones by the presence of holes for fasteners on the shaft. In addition to transmitting rotation, they serve as an element for guiding parts.

- Segmental keys stand out from the rest due to their increased technology for cutting grooves. The grooves are made using disc cutters, which provides them with greater precision and productivity. The fastening of keys to shafts is also more stable due to deeper cutting into their surface. However, at the same time, all these advantages cause a significant weakening of the shaft. This circumstance, along with the short length of the groove, leads to the appearance of increased stresses, which limit the use of keys to lightly loaded products.

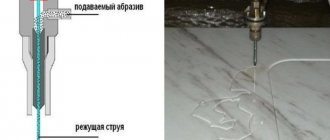

It is worth noting that keyways are made by milling and broaching. The most common way to produce them is with a finger cutter, since this method provides relatively favorable stress distribution and acceptable manufacturability.

Chiseling process

Since the sleeve has its own radius inside, before starting to measure the depth of the groove, it is necessary to cut it off in order to obtain a flat area, which will be the zero reference point.

To do this, using a caliper, I move the cutter inside the bushing along the longitudinal slide, removing the finest metal shavings. After it returns to its original position, I bring the cutting edge closer along the transverse slide to the body of the sleeve by 0.1 mm. Again I make a longitudinal movement along the carriage. I repeat the process until the gutter loses its radius. As soon as he leaves, this will be the zero point for the countdown. Now I start chiseling the keyway. In my case, its depth should be 2.6 mm. Using 0.1mm increments, it would take 26 cuts of the cutter to achieve this depth. After deepening the groove by 2.6 mm, without changing the settings on the dial, you need to make a few more repeated movements of the cutter to clean the plane of small burrs. Next, the sleeve is removed from the cartridge. Its second end is quite rough, but this is easily solved. The boring cutter is again installed in the tool holder, and neat chamfers are removed. After this, the sleeve can be used for its intended purpose. Chiselling on a lathe is a lengthy, although not complicated, process. In my case, the longitudinal movement of the caliper is motorized, so everything is done relatively quickly. It is also possible to make a groove on budget machines with manual drive, but in this case it will take much more time. In a home workshop, without special machines and devices, it is possible to make, perhaps, only the so-called “collective farm” keyway: this is when a joint hole is drilled with an electric drill in a gear or pulley mounted on a shaft with the center on the circumference of the joining of the parts. Then a cylindrical key is inserted into this hole. But such a connection of parts is unreliable - after all, it is not for nothing that it is not in any GOST.

To make “GOST” keyways in parts, I developed a manual tabletop machine (or, one might say, a device), which I have been using for several years now. I think that such a machine can be useful, like me, for home craftsmen, amateur designers, and in a school workshop.

This vertical planing machine-device with a manual drive is similar in design to a drilling machine, and in its operating principle - to a slotting machine.

The entire structure is assembled on a base measuring 350x350x20 mm. It (the base) is also a work table on which there is a stand with all the components necessary for cutting pavements and a support with a three-jaw lathe chuck. The thickness of the base of my machine is 20 mm. At first it was a chipboard (as in the photo), but then I replaced it with a steel one with the same dimensions - the machine became more massive, but also more stable.

Here I will make an explanation: there are other differences in the drawings from the image of the machine in the photographs. The fact is that during operation it became clear that some components and parts would have been better done a little differently. And these improvements are reflected in the drawings.

1—base (steel plate s20); 2 — stand (steel, circle d40); 3 — support flange (steel); 4 — fastening the flange to the base (M12 screw, 3 pcs.); 5—holder (steel); 6 — holder stopper (M12 screw); 7 — lever rod axis (half of an M12 stud with a nut, 2 pcs.); 8—lever rod (steel strip 30×8, 2 pcs.); 9 — articulated connection of the rod with the lever (M12 bolt, 2 pcs.); 10 — lever (steel strip 30×8, 2 pcs.); 11—compression spring; 12 — console; 13 — slider (M12 screw); 14—clamp (M12 screw); 15—mounting the lever on the axle (M12 mount, 2 pcs.); 16 — handle axis (steel, circle 18); 17 — handle (pipe d30x18.5); 18 — mandrel-tool holder (steel, circle d64); 19 — cutter; 20 — stopper (M10 screw); 21—three-jaw lathe chuck: 22—caliper

Near one edge of the base, a stand is fixed by means of a flange - a steel rod with a diameter of 40 mm and a height of 450 mm. A longitudinal groove is cut along the entire rack, and on one of the youngsters there is a groove for joining to the flange. Now it became clear to me that it would be nice to make the rack higher - up to 500 mm - there is often a need when you need to make a groove in long (or high) parts (for example, hubs), and then the console lift is not enough. The flange is a large stepped washer with a central hole for the stand and three evenly spaced holes with a diameter of 12.5 mm for attaching to the base plate. Correspondingly located, but only M12 threaded holes are made in the base table. The stand with its machined end is inserted into the central hole of the flange, and the parts are connected by welding, and after that the flange is screwed to the base.

A holder and a console with a compression spring between them are slidingly mounted on the stand.

The holder is a rectangular parallelepiped with a small height relative to its dimensions in plan, with a central hole for the stand and three M12 threaded holes - two counter blind side ones and one through one at one of the ends. Of course, the definitions of “end” and “side” of such a geometric body are identical, but, I hope, are clear from the drawing. The holder locking screw is screwed into the end hole, and the studs, which serve as the axes of the lever rods, are screwed into the side holes.

The console is a more complicated part. It consists of two hollow cylinders (rack-mount and mandrel), connected to each other by a jumper made of a square steel pipe with dimensions 60x60x2.5 by welding. The body of each cylinder has an M12 threaded hole: in the rack cylinder there is a locking screw for preventing rotation, and in the mandrel cylinder there is a locking screw. In addition, a pair of M12 “half-pins” are welded to the rack cylinder in the middle on opposite sides (you can also use screws with the same thread) - they serve as axes for the tool feed levers.

1—rack cylinder (circle d80); 2—jumper (pipe 60x60x2.5); 3—mandrel cylinder (pipe 80×64); 4—lever axis (M12 pin, cut in half, 2 pcs.)

We must try to perform this operation as accurately as possible, so that later during operation the levers do not warp, the holes in them do not break, and the axes themselves do not wear out. Therefore, before welding them, it is worth performing some technological operations. First, on the rack cylinder it is necessary to mill (or grind off with a file) a pair of diametrically opposite flats measuring 20x20 mm. Holes with a diameter of 4 mm are drilled in the center of the flats on each side. They are then drilled out to a diameter of 6 mm in one installation using a drill of the required length. Axial holes of the same diameter are made in both “half-pins” (screws). After this, a straight piece of wire of the same diameter is inserted into the holes of the cylinder. “Half-pins” are placed on the protruding ends and first grabbed, and after aligning the positions, they are finally welded to the cylinder. At the end of the operation, a piece of wire is knocked out.

The holder on the stand at the required height is secured with a locking screw and serves as a support for the entire tool feed mechanism: a console with a mandrel with a cutting tool fixed in it and a system of levers for its longitudinal feed. The console is lifted and held in the upper position by a spring. The console is kept from rotating on the stand by a fixing screw, the end of which, sharpened to fit the appropriate profile, slides in the longitudinal groove of the stand. Before work, the rubbing surfaces of the parts are coated with a thin layer (like a firearm) of grease.

A mandrel is a part with which a tool or its holder is secured in the console. In my case, the mandrel and tool holder are made of 45 steel as one piece in the shape of a stepped cylinder with a diametrical hole for the cutter near the free thinner end. Here, an M10 threaded hole is drilled in the end - through it, the cutter is secured in the hole of the tool holder with a corresponding screw. On a cylinder of larger diameter, a flat is milled - an M12 fixing screw rests against it, which does not allow the mandrel to rotate when torque from the cutter occurs. The same screw keeps the mandrel from falling out of the console cylinder. But his effort from squeezing the mandrel out of the cylinder during the working stroke may not be enough: for this purpose, a shoulder is left on the mandrel.

Levers and rods are made of steel strip with a cross-section of 30×8 mm. The levers are mounted on the axles of the console's mandrel cylinder, and the rods are mounted on the axis of the holder. Both of them are hingedly fastened together with axle bolts.

Between the upper (free) ends of the levers, the handle axis is inserted and secured - a cylindrical rod with a diameter of 18 mm with an M12 thread on the end grooves. The handle itself, made in the form of a sleeve with a diameter of 30×18 mm, is loosely placed on a lubricated axle. The surface of the bushing is pre-rolled.

A special story about the machine support. Outwardly, it looks like a machine vice. And the workpieces for processing are fixed in a three-jaw chuck from a metal-cutting lathe mounted on the upper movable platform of the support. Using the caliper, the workpiece is fed relative to the cutting tool to the cutting depth. Looking ahead, I note that the cutting depth in one pass is very small - only 0.2 - 0.3 mm.

The support consists of a welded body and a movable table. Although there are several body elements to be welded (5 pieces), they are very simple - almost all (except for the racks) are in the form of rectangular parallelepipeds. The racks are made of equal-flange rolled steel angle 40×40 with a half-cut vertical flange. By the way, the traverses of the body and the cross member of the movable table are holders (bodies) from broken turning cutting tools. Anyone who has a milling machine can easily make the body and platform as one part from a massive blank.

1—hull stand (40×40 corner with a trimmed vertical shelf, 2 pcs.); 2—body platform (steel, sheet s7); 3—front traverse (cutter holder); 4—rear crossbar (cutter holder); 5—movable table (steel, sheet B7); 6—cross member of the movable table (cutter holder); 7-way screw M12; 8—left tie, right not shown (screw M12.2 pcs.); 9—flywheel with handle; 10—cotter pin d3; 11—plate (steel sheet sЗ); 12—fastening the lining to the body (M4 screw, 2 pcs.)

Preliminary approach of workpieces to the cutting tool can be done “manually” by loosening the screws securing its body to the base table and moving the entire support in the grooves (oblong holes).

The platform is moved from the flywheel handle using a lead screw with a conventional M12 thread. There is no matrix nut, as such, in the mechanism. The corresponding threaded hole, along with a pair of guide holes, is made in the cross member under the platform. The guides themselves are a pair of standard long M12 screws. It must be said that the caliper table can be moved up to 60 mm, although for cutting grooves and splines, as a rule, more than 10 mm is not required.

As noted earlier, the depth of cut (feed) when operating the machine is small. To speed up the production of “GOST” keyways, you can use the technology given at the beginning of the article for drilling semicircular “collective farm” grooves, and then use a slotting machine to refine them to a rectangular section.

G. SPIRYAKOV. Chelyabinsk

Typically a lathe is used for boring, tapping, reaming, countersinking and drilling, but their capabilities don't end there. I propose to consider a way to use it to drill out a keyway on the bushing. For this I use a 1K62 screw-cutting lathe.

Preparatory stage

The bushing is installed in a three-jaw chuck. Before performing chiselling, you must first prepare its internal and external chamfer with a boring cutter. They are made only on the side from which the slotting tool will enter. This is a simple process, familiar even to an amateur turner, and therefore does not require separate consideration.

After preparing the chamfers on the machine, you need to set the minimum speed to prevent spindle rotation. On many machines, the jaw chuck can give play under load, so in this case it is necessary to install a spacer. To do this, place a bolt and nut of suitable height under it. When unscrewing it, the length of the stop increases, so it is pressed tightly against the cartridge, thereby eliminating the rolling.

The slotting cutter is lightly clamped in the tool holder. It aligns the bushing in the center, after which it is necessary to make fine adjustments. To do this, it is inserted into the bushing, moving longitudinally with the caliper along the slide. The resulting scratch should run along the bushing hole from one edge to the other. There should not be a section without a scratch in the cut line. If it exists, then this indicates the presence of a distortion. When the cutter is positioned correctly, it must be clamped very tightly, since the load during chiselling is much higher than during standard turning work.

How to make a keyway on a LATHE 1K62

Report Video

Found this content disturbing or inciting religious hatred? email us along with this video url.

Embed Video

Buy a turning cutter https://ali.pub/u2p4b Plates for the cutter https://ali.pub/m3x2z

GROUP https://vk.com/tokarka42 Website https://tokarka42.ru/

Sitting Alone?

Sitting alone and getting bored! The best way to escape the situation is to grab your mobile and go for the Social Media life. Facebook, Twitter, YouTube, etc. they will never let you be bored. The entertainment through the internet has been trendy since social media has developed.the priories of people have been changed, all though social media was created to have an active social gathering. But the results are getting the up-expected opposite. It has been noticed the flavors of relations are getting dull. Especially the young generation, they have used the social media in the way that the concept of socialism has been totally changed. The value of time with family is the most important; this is the main reason that we are facing many family issues. Somewhere social media has lowered the value of real experiences. People may have thousands of friends on Facebook but does not have a single friend in real life. You may like thousands of posts for the social work, but you never worked for the society. You may have liked millions of beautiful places, but you have never been traveled. The reality is the quality of experience is only based on real experience. We strongly promote viewers that vines and funny videos can be entertaining but the ultimate pleasure for the lifetime is based on the real experiences. We advise you that never let social media ruin your real family and social life. Be a good manager is awesome on social media and responsible for your family life. This will help you to balance your responsibilities and enjoyments. Never let yourself isolated from the ultimate great experiences for the lifetime. Good videos can be a source of entertainment, but these videos will never give the memories.

Why PlayTube? PlayTube is one of the most popular video-sharing platforms in the United States. Billions of videos have been uploaded and shared on the platform since it was founded in 2013, ranging from Hollywood movie trailers and music videos to amateur vlogs (video blogs) and videos of cats.

PlayTube in a Nutshell

PlayTube is a video platform that's driven by two types of users: On-Liners (people who watch videos, interact with videos and subscribe to channels) Off-liners (people who have to download them for watch off-line)

Who Uses PlayTube?

Anyone with access to a computer or mobile device and an internet connection can watch PlayTube content. PlayTube is really for everyone. PlayTube is available in nearly every country and over fifty different languages. Although its user base ranges from young to old, PlayTube is particularly popular among younger people who prefer the wide variety of content, interactive components and instant gratification of PlayTube video content over traditional television. Many use it for entertainment purposes, for learning how to do something (tutorials), for keeping up with their favorite artists' latest music videos and so much more.

Getting Started with Watching Videos On PlayTube

There are all sorts of ways you can watch PlayTube videos. They include: Navigating to PlayTube.pk and watching a suggested video or searching for one. Navigating the PlayTube mobile version and watching a suggested video or searching for one. Watching a PlayTube video that was embedded into a post on a social network (like Facebook or Twitter). Watching a PlayTube video that was embedded into a web page or blog post. Watching a PlayTube video by clicking on a link to the video that shared via email, text message, social media, etc.

To get personalized video suggestions, create playlists, comment on other videos and subscribe to channels. There are lots of benefits to subscribing to the mailing list. With a PlayTube subscription, you can: Get personalized recommendations for videos to watch on the home page, based on your viewing history. Subscribe to your favorite channels so you can easily find their latest videos. Receive notifications from channels whenever they upload new videos. Support your favorite creators by interacting with their videos (liking them and leaving comments). Keep track of your video viewing history. Save or download videos to watch later. Create your public or private video playlists.

Finding Videos to Watch on PlayTube There are multiple ways you can find what you want to watch on PlayTube. On the PlayTube platform itself, you can: Browse videos via keyword or keyword phrase using the search field; Find videos in topics and categories; Filter results by date and popularity; Visit the trending topics tab; View the charts rankings for music videos; View or subscribe to the Popular on PlayTube channel; or Check out the Up next videos on the side (web) or bottom (app) of any video page to see related videos.

How to make a keyway on a LATHE 1K62

Report Video

Found this content disturbing or inciting religious hatred? email us along with this video url.

Embed Video

Buy a turning cutter https://ali.pub/u2p4b Plates for the cutter https://ali.pub/m3x2z

GROUP https://vk.com/tokarka42 Website https://tokarka42.ru/

Sitting Alone?

Sitting alone and getting bored! The best way to escape the situation is to grab your mobile and go for the Social Media life. Facebook, Twitter, YouTube, etc. they will never let you be bored. The entertainment through the internet has been trendy since social media has developed.the priories of people have been changed, all though social media was created to have an active social gathering. But the results are getting the up-expected opposite. It has been noticed the flavors of relations are getting dull. Especially the young generation, they have used the social media in the way that the concept of socialism has been totally changed. The value of time with family is the most important; this is the main reason that we are facing many family issues. Somewhere social media has lowered the value of real experiences. People may have thousands of friends on Facebook but does not have a single friend in real life. You may like thousands of posts for the social work, but you never worked for the society. You may have liked millions of beautiful places, but you have never been traveled. The reality is the quality of experience is only based on real experience. We strongly promote viewers that vines and funny videos can be entertaining but the ultimate pleasure for the lifetime is based on the real experiences. We advise you that never let social media ruin your real family and social life. Be a good manager is awesome on social media and responsible for your family life. This will help you to balance your responsibilities and enjoyments. Never let yourself isolated from the ultimate great experiences for the lifetime. Good videos can be a source of entertainment, but these videos will never give the memories.

How to make a keyway on a LATHE 1K62

Report Video

Found this content disturbing or inciting religious hatred? email us along with this video url.

Embed Video

Buy a turning cutter https://ali.pub/u2p4b Plates for the cutter https://ali.pub/m3x2z

GROUP https://vk.com/tokarka42 Website https://tokarka42.ru/

Sitting Alone?

Sitting alone and getting bored! The best way to escape the situation is to grab your mobile and go for the Social Media life. Facebook, Twitter, YouTube, etc. they will never let you be bored. The entertainment through the internet has been trendy since social media has developed.the priories of people have been changed, all though social media was created to have an active social gathering. But the results are getting the up-expected opposite. It has been noticed the flavors of relations are getting dull. Especially the young generation, they have used the social media in the way that the concept of socialism has been totally changed. The value of time with family is the most important; this is the main reason that we are facing many family issues. Somewhere social media has lowered the value of real experiences. People may have thousands of friends on Facebook but does not have a single friend in real life. You may like thousands of posts for the social work, but you never worked for the society. You may have liked millions of beautiful places, but you have never been traveled. The reality is the quality of experience is only based on real experience. We strongly promote viewers that vines and funny videos can be entertaining but the ultimate pleasure for the lifetime is based on the real experiences. We advise you that never let social media ruin your real family and social life. Be a good manager is awesome on social media and responsible for your family life. This will help you to balance your responsibilities and enjoyments. Never let yourself isolated from the ultimate great experiences for the lifetime. Good videos can be a source of entertainment, but these videos will never give the memories.

Why PlayTube? PlayTube is one of the most popular video-sharing platforms in the United States. Billions of videos have been uploaded and shared on the platform since it was founded in 2013, ranging from Hollywood movie trailers and music videos to amateur vlogs (video blogs) and videos of cats.

PlayTube in a Nutshell

PlayTube is a video platform that's driven by two types of users: On-Liners (people who watch videos, interact with videos and subscribe to channels) Off-liners (people who have to download them for watch off-line)

Who Uses PlayTube?

Anyone with access to a computer or mobile device and an internet connection can watch PlayTube content. PlayTube is really for everyone. PlayTube is available in nearly every country and over fifty different languages. Although its user base ranges from young to old, PlayTube is particularly popular among younger people who prefer the wide variety of content, interactive components and instant gratification of PlayTube video content over traditional television. Many use it for entertainment purposes, for learning how to do something (tutorials), for keeping up with their favorite artists' latest music videos and so much more.

Getting Started with Watching Videos On PlayTube

There are all sorts of ways you can watch PlayTube videos. They include: Navigating to PlayTube.pk and watching a suggested video or searching for one. Navigating the PlayTube mobile version and watching a suggested video or searching for one. Watching a PlayTube video that was embedded into a post on a social network (like Facebook or Twitter). Watching a PlayTube video that was embedded into a web page or blog post. Watching a PlayTube video by clicking on a link to the video that shared via email, text message, social media, etc.

To get personalized video suggestions, create playlists, comment on other videos and subscribe to channels. There are lots of benefits to subscribing to the mailing list. With a PlayTube subscription, you can: Get personalized recommendations for videos to watch on the home page, based on your viewing history. Subscribe to your favorite channels so you can easily find their latest videos. Receive notifications from channels whenever they upload new videos. Support your favorite creators by interacting with their videos (liking them and leaving comments). Keep track of your video viewing history. Save or download videos to watch later. Create your public or private video playlists.

Finding Videos to Watch on PlayTube There are multiple ways you can find what you want to watch on PlayTube. On the PlayTube platform itself, you can: Browse videos via keyword or keyword phrase using the search field; Find videos in topics and categories; Filter results by date and popularity; Visit the trending topics tab; View the charts rankings for music videos; View or subscribe to the Popular on PlayTube channel; or Check out the Up next videos on the side (web) or bottom (app) of any video page to see related videos.