Chemical composition and analogues of steel 20Х23Н18

The properties and scope of application of various grades of stainless steel depend on the ratio of alloying elements. Chemical composition of steel 20Х23Н18 in% according to GOST 5632-72:

- iron (Fe) up to 54;

- chromium (Cr) 22-25;

- nickel (Ni) 17-20;

- manganese (Mn) up to 2;

- silicon (Si) up to 1;

- carbon (C) up to 0.2;

- phosphorus (P) up to 0.035;

- sulfur (S) up to 0.02.

Substitutes: 20Х23Н13, 15Х25Т. The main foreign analogues are brands AISI 310, AISI 310S and AISI 314 (USA).

Product composition

The characteristics of 20x23n18 metal are determined by its composition. High resistance to temperatures is provided by iron and nickel, which are included in the composition. Due to the presence of a certain amount of chromium in the composition, it was possible to achieve high resistance to corrosion, which makes it stainless. Very small, but still there is carbon content in this grade of steel. It is very important to note here that exceeding 0.2% carbon in the composition already indicates that the metal is of poor quality. In addition to the listed substances that give certain characteristics to 20x23n18 metal, there are also such as phosphorus, sulfur, and manganese.

This composition leads to the fact that it is possible to obtain not only a heat-resistant material, but also steel that tolerates moisture well. Nickel in steel indicates that the material has a certain ductility. To obtain such characteristics for 20x23n18 steel, it must be manufactured in an arc furnace. In order to obtain high-quality material of this brand as a result, it is necessary to carry out a complex production process with temperature control at each stage.

Technical characteristics and advantages

Steel 20Х23Н18 has high corrosion resistance in aggressive environments, which is due to a significant proportion of chromium in its composition - more than 22%. Additions of nickel and manganese further increase this parameter and also determine the primary crystalline structure of the alloy in the form of austenite.

Austenitic steels are characterized by the absence of magnetic properties, high ductility and impact toughness. They also do not increase hardness as a result of heat treatment and are used as heat-resistant at temperatures up to 600 °C.

Stainless steel 20Х23Н18 is easy to process, but has limited weldability. Suitable welding methods: manual arc, argon arc, automatic submerged arc, electroslag and resistance. The specific gravity of the material is 7900 kg/m³, hardness HB 10-1=178 MPa, endurance limit 255 MPa.

General information about the material

If we take into account the characteristics, this steel boasts such advantages as: manufacturability of the material, increased ductility, high heat resistance. What is important is that the weldability of this metal is quite high. It is also worth noting that steel 20x23n18 belongs to the austenitic class of metal. The basis for this material is made up of two substances such as nickel and iron.

Sheet steel is made from a complex alloy and austenitic alloy. It must be highly resistant to any aggressive environmental influences. Atmospheric and soil moisture should also not have a significant effect on it. The heat-resistant steel sheet of grade 20x23n18 itself is a very multifunctional and convenient material that allows it to be used in a variety of conditions. Often used to make combustion chambers, the main requirement of which is high temperature resistance.

Scope of application of stainless steel 20Х23Н18

Corrosion-resistant steel 20Х23Н18 is widely used in mechanical engineering, architecture, energy, food and chemical industries. From it they produce:

- Working and guide vanes, forgings and bandages operating at temperatures of 650-700 °C.

- Furnace equipment operating at temperatures of 1000-1050 °C.

- Elements of combustion chambers.

- Medium-loaded parts and advertising structures.

- Pipelines and tanks for chemical reagents, liquid, bulk and vaporous food products.

In the domestic economy, the required material is in demand along with such well-known brands as 12Х18Н10Т and 08Х13.

Steel 20x23n18: characteristics, application, types

The fact is that recently interest in the industrial industry has grown significantly, and methods of high-temperature processing of steel have also begun to be used quite often.

Therefore, heat-resistant stainless steel 20x23n18, the characteristics of which are excellent for these purposes, has become popular.

General information about the material

If we take into account the characteristics, this steel boasts such advantages as: manufacturability of the material, increased ductility, high heat resistance.

What is important is that the weldability of this metal is quite high. It is also worth noting that steel 20x23n18 belongs to the austenitic class of metal.

The basis for this material is made up of two substances such as nickel and iron.

Sheet steel is made from a complex alloy and austenitic alloy. It must be highly resistant to any aggressive environmental influences. Atmospheric and soil moisture should also not have a significant effect on it.

The heat-resistant steel sheet of grade 20x23n18 itself is a very multifunctional and convenient material that allows it to be used in a variety of conditions.

Often used to make combustion chambers, the main requirement of which is high temperature resistance.

Steel classification

Most often, heat-resistant steels are used to produce parts that are simply impossible to obtain in any other way. One of these parts was a blade for gas turbine engines. Most often, st 20x23n18, the characteristics of which allow it to withstand high temperatures well, is ideal. Other important parts are also made from it.

Operations for steel processing

In the industrial sector today, several operations are used to produce elements for gas turbine engines. These include forging, grinding, machining, polishing and precision casting. In order to go through all these stages of processing, it is necessary to use sufficiently high-quality steel.

Read also: Wooden wedges for an ax

You can use a large number of different materials, but the characteristics of steel 20x23n18 indicate that it is most profitable to use it, since it is most suitable for the job. It can also be used in almost any climatic conditions. Thanks to all these qualities, it has become the most common in this field.

This steel is very resistant to high temperatures and also withstands sudden changes in this indicator. Most often it is used in mechanical engineering factories. It is manufactured according to certain state standards, and therefore its quality is guaranteed.

Product composition

The characteristics of 20x23n18 metal are determined by its composition. High resistance to temperatures is provided by iron and nickel, which are included in the composition. Due to the presence of a certain amount of chromium in the composition, it was possible to achieve high resistance to corrosion, which makes it stainless.

Very small, but still there is carbon content in this grade of steel. It is very important to note here that exceeding 0.2% carbon in the composition already indicates that the metal is of poor quality.

In addition to the listed substances that give certain characteristics to 20x23n18 metal, there are also such as phosphorus, sulfur, and manganese.

This composition leads to the fact that it is possible to obtain not only a heat-resistant material, but also steel that tolerates moisture well. Nickel in steel indicates that the material has a certain ductility.

To obtain such characteristics for 20x23n18 steel, it must be manufactured in an arc furnace.

In order to obtain high-quality material of this brand as a result, it is necessary to carry out a complex production process with temperature control at each stage.

Steel production

The production of this product is quite complex. The initial stage should take place at a temperature of 1180 °C. The closer the process is to completion, the lower the temperature should be. It decreases until it reaches a limit of 900 °C.

With this indicator, the operation is completed. At this point the deformation process ends and you can move on to the next stage. There are several ways to heat treat a material. The first method is heating to a temperature of 1100-1150 °C.

The steel is hardened and then undergoes a cooling process in water, oil or air.

In the second method, the metal is heated to a temperature of 1160 °C and increases to 1180 °C. Afterwards you also need to cool the material in water. This will take at least four or five hours.

Use of steel

The use of steel 20x23n18 with characteristics of high resistance to temperature, corrosion and other negative environmental influences determined the direction of use of the material. This steel can be used in almost any industry.

It is used for the manufacture of aircraft parts. Successfully used in the assembly of furnace equipment. Steel can withstand radiation exposure quite well, which led to its use in places where there is an increased rate of this characteristic.

Read also: How to attach a lathe chuck

For example, at nuclear power plants, because it is highly durable and has enormous advantages.

Rolled metal assortment

Stainless steel 20Х23Н18 can be supplied in the form of the following semi-finished products:

- long and shaped rolled products (GOST 5949-75, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006);

- calibrated rod (GOST 8559-75, GOST 8560-78, GOST 7417-75);

- polished rod and silver (GOST 14955-77);

- thick sheets (GOST 7350-77, GOST 19903-74, GOST 19904-90);

- tapes (GOST 4986-79);

- stripes (GOST 4405-75, GOST 103-2006);

- forgings and forged blanks (GOST 1133-71).

Steel 20Х23Н18 heat-resistant, heat-resistant, stainless

Substitutes

- Steel 20Х23Н13,

- Steel 15Х25Т.

Foreign analogues

| UK (BS) | 310S16 |

| USA (UNS) | S31400 (310S) |

| Sweden (SS) | 2361 |

| Japan (JIS) | SUS 310S |

Decoding

According to GOST 5632-2014, the name of steel grades consists of numbers and letter designations of chemical elements:

- The number 20 before the letter designation indicates the maximum mass fraction of carbon in steel in hundredths of a percent, i.e. the maximum carbon content in steel can reach 0.20%.

- The letter X indicates that the steel is alloyed with chromium, the number 23 after the letter indicates that the average chromium content in steel is up to 23%.

- The letter H indicates that the steel is alloyed with nickel, the number 18 after the letter indicates that the average nickel content in the steel is up to 18%.

Type of delivery

- Long products, including shaped steel: GOST 5949-75, GOST 2590-88, GOST 2591-88, GOST 2879-88.

- Calibrated rod GOST 7417-75, GOST 8559-75, GOST 8560-78.

- Polished rod and silver GOST 14955-77.

- Thick sheet GOST 7350-77, GOST 19903-74, GOST 19904-90.

- Tape GOST 4986-79.

- Strip GOST 4405-75, GOST 103-76. Forgings and forged blanks GOST 1133-71.

Characteristics and Application

Steel 20Х23Н18 (symbol EI417) is heat-resistant and heat-resistant of the austenitic class. This steel is smelted in open electric furnaces. Recommended maximum temperature for long-term use (up to 10,000 h), 1000 °C. The temperature at which intensive scale formation begins in an air environment is 1050 °C. In the range of 600-800 °C they are prone to embrittlement due to the formation of the σ phase.

- forgings,

- bandages for work at 650-700 °C,

- combustion chamber parts,

- muffles,

- screens,

- parts of burner devices with operating temperatures up to 1050 °,

- clamps,

- suspensions and other fastening parts for boilers, muffles for operation at temperatures up to 1100 °C,

- Pipes and parts of installations for methane conversion, pyrolysis,

- sheet parts,

- seamless pipes.

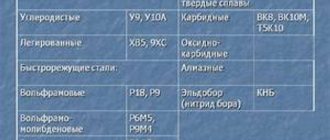

Chemical composition, % (GOST 5632-72)

| C | Si | Mn | Cr | Ni | Ti | S | P | Cu | |||||||

| no more | no more | 0,20 | 1,0 | 2,0 | 22,0-25,0 | 17,0-20,0 | 0,2 | 0,02 | 0,035 | 0,30 | |||||

Chemical composition, % (GOST 5632-2014)

| steel grade | Mass fraction of elements, % | |||||||||||||||||||||||||||||||

| C, carbon | Si, silicon | Mn, magnesium | Cr, chromium | Ni, nickel | Ti, titanium | Al, aluminum | W, tungsten | Mo, molybdenum | Nb, niobium | V, vanadium | Fe, iron | S, sulfur | P, phosphorus | Others | No more | 20Х23Н18 | No more than 0.20 | No more than 1.00 | No more than 2.00 | 22,00-25,00 | 17,00-20,00 | — | — | — | — | — | — | Basic | 0,025 | 0,035 | — | |

NOTE. The sign “-” means that the mass fraction of this element is not standardized or controlled. In steels not alloyed with titanium, the mass fraction of titanium is allowed in accordance with 6.3 GOST 5632-2014.

Recommended mode of heat treatment of steel [1]

Hardening from 1050-1150 °C in air or water.

Mechanical properties

| GOST | Delivery status | Section, mm | σ0.2, MPa | σв, MPa | δ5, % | ψ, % | ||||||||||||||||||

| no less | GOST 5949-75 | Bar. Hardening from 110-1150 °C in air or water | 60 | 196 | 490 | 35 | 50 | GOST 7350-77 | The sheet is hot-rolled or cold-rolled. Quenching from 1030-1130 °C in water (transverse samples) | St. 4 | 264 | 539 | 35 | — | GOST 4986-79 | Cold rolled strip. Quenching from 1050-1080 °C in water or air | Up to 0.2 0.2-2.0 | — — | 580 580 | (19) (38) | — — | |||

Mechanical properties of rods with a cross-section of 38-55 mm, depending on heat exposure and test temperature

| Heat treatment | Heat exposure | tsp, °С | σ0.2, MPa | σв, MPa | δ5, % | ψ, % | KCU, J/cm2 | |||||||||||||||||||||||||||||||||||

| t, °С | τ, h | Quenching at 1180 °C in water; aging at 800°С, 4 h | 650 | 10000 | 20 650 | 330 205 | 590-630 240-390 | 12-18 11-15 | 28 16-21 | 64-69 127 | 700 | 10000 | 20 650 | 320 195 | 510-550 285-330 | 5-6 4-5 | 8-10 5-8 | 15 49 | 800 | 2000 | 20 500 650 800 | 295 195 175 145 | 640 460 390 185 | 26-35 22 14-19 6-8 | 29-42 33-43 23-24 12-16 | 59 — 137-167 — | 800 | 4000 | 20 500 650 800 | 315 195 185 135 | 590-630 470 350 185 | 17-32 18-25 8-12 7-10 | 20-39 29-35 15-17 13-18 | 34 54-59 78-98 — | 800 | 10000 | 20 650 | 275 175 | 580-620 340-370 | 14-28 5-10 | 20-39 20 | 34 73-80 |

Mechanical properties during long-term strength testing

| tsp, °С | Creep limit, MPa | Creep rate, %/h | tsp, °С | Long-term strength limit, MPa | τ, h | |||||||||||||||

| 650 | 53 | 1/100000 | 650 | 113 | 10000 | 700 | 34 | 1/100000 | 700 | 59 | 10000 | 800 | 12 | 1/100000 | 650 | 78 | 100000 | 700 | 34 | 100000 |

Mechanical properties at elevated temperatures

| tsp, °С | σ0.2, MPa | σв, MPa | δ5, % | ψ, % | KCU, J/cm2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rod with a diameter of 38-55 mm. Quenching from 1180 °C in water; aging at 800 °C, 4 h | 20 | 295-320 | 600-660 | 29-35 | 47-54 | 137-186 | 300 | 235 | 520-540 | 25-28 | 45-49 | 147-166 | 400 | 225 | 540 | 24-32 | 39-45 | 147-166 | 500 | 210 | 520-540 | 25-31 | 41-45 | 171 | 600 | 195 | 440 | 24 | 46 | 176 | 700 | 185-195 | 315-330 | 19-24 | 35 | 171 | 800 | 165 | 185-205 | 19-27 | 34 | 176 | Sample with a diameter of 10 mm and a length of 50 mm, rolled. Deformation speed 20 mm/min; strain rate 0.007 1/s | 800 | 215 | 255 | 24 | 67 | — | 900 | 135 | 135 | 37 | 77 | — | 1000 | 64 | 71 | 49 | 77 | — | 1100 | 39 | 44 | 51 | 70 | — | 1200 | 22 | 27 | 27 | 31 | — | ||||||||||

Endurance limit

| σ-1, MPa | Strength characteristics | ||

| 255 | σ0.2 = 590 MPa | 245 | σ0.2 = 290 MPa, σв = 570 MPa; hardness HB 140-200; hardening at 1100 °C in water or air |

Technological properties

| Forging temperature, °C | beginning 1220, end 900. Sections up to 350 mm are cooled in air. |

| Machinability | Kv tv.sp. = 0.4 in the normalized and tempered state at НВ 178 and σв = 610 MPa. |

Characteristics of weldability of steel 20Х23Н18, and technological requirements for it [2]

| Structural class | Steel grades | Weldability characteristics | Technological requirements |

| Austenitic | 20Х23Н18 | Prone to hot cracking | Limitation of heat input |

Electrodes for manual arc welding of steel 20Х23Н18 [2]

| Combination of welded steels of different groups in a welded joint (A + B) | Electrodes | Permissible operating temperature, welding conditions | ||||||||

| A | B | Standard | Type | Brand | Art.3, 16GS, 15G2SF | 20Х23Н18 | GOST 10052 | E-11Х15Н25М6AG2 | EA-395/9 | From minus 40 to 450°C |

| 12ХМ, 10Х2М1, 15Х5М | TU 14-168-23 | 10Х25Н25М3Г2 | ANZHR-3U | Heating 200-300°C, operating temperature from 0 to 525°C | ||||||

| 08X13 | GOST 10052 | E-10Х25Н13Г2, Е-10Х25Н13Г2Б | OZL-6, TsL-9 | Heating to 150-200°C. If there are requirements for MCC up to 350°C (only E-10Х25Н13Г2Б) | ||||||

| 08Х18Н10Т, 10X17H13M3T, 20Х23Ш8 | GOST 10052 | E-08X20N9G2B, E-08X19N10G2B, E-09X19N10G2M2B | TsL-11, TsT-15, NZh-13 | If there are requirements for MCC up to 350°C, higher - after stabilizing annealing | ||||||

NOTE:

- The temperature conditions for the use of welded joints are additionally limited by the conditions of use of the materials being welded.

- In the absence of requirements for MCC, the conditions for the use of welded joints are determined by the conditions for the use of the materials being welded.

- When welding more alloyed alloys with less alloyed alloys and steels, it is recommended to use welding consumables designed for welding more alloyed alloys.

- After “thermal rest” (350-400°C, exposure 3 hours), the time before heat treatment is not limited.

Welding materials for automatic submerged arc welding of steel 20Х23Н18 [2]

| Combination of welded steels of different groups in a welded joint (A + B) | Electrodes | Flux | Permissible operating temperature, welding conditions | ||

| A | B | Standard | Brand | Brand | |

| Art.3, 16GS, 15G2SF | 20Х23Н18 | GOST 2246 | Sv-10X16N25AM6 | AN-26S, AN-18 | From minus 40 to 450°C |

| 12ХМ, 10Х2М1, 15Х5М | TU 14-1-4968 | Sv-08Х25Н40М7 | AN-18 | From 0 to 550°C | |

| 20Х23Н18 | ХН28МДТ | GOST 2246 | Sv-10X16N25AM6 | AN-26S, AN-18 | From minus 60 to 350°C |

| ХН78Т | TU 14-1-4968 | Sv-08Х25Н25М3 | |||

| GOST 2246 | Sv-01Х23Н28М3Д3Т | AN-18 | |||

NOTE:

- The temperature conditions for the use of welded joints are additionally limited by the conditions of use of the materials being welded.

- In the absence of requirements for MCC, the conditions for the use of welded joints are determined by the conditions for the use of the materials being welded.

- Welding flux is supplied in accordance with GOST R 52222.

- When welding more alloyed alloys with less alloyed alloys and steels, it is recommended to use welding consumables designed for welding more alloyed alloys.

- After “thermal rest” (350-400°C, exposure 3 hours), the time before heat treatment is not limited.

Welding materials for gas-shielded welding of steel 20Х23Н18 [2]

| Combination of welded steels of different groups in a welded joint (A + B) | Welding wire | Protective environment | Permissible operating temperature, welding conditions | ||

| A | B | Standard | Brand | ||

| Art.3, 16GS, 15G2SF | 20Х23Н18 | GOST 2246 | Sv-10X16N25AM6 | CO2,Ar | From minus 40 to 450°C |

| 12ХМ, 10Х2М1, 15Х5М | GOST 2246 | Sv-10Х16Н25 AM6 | CO2,Ar | Heating up to 200-300°C, operating temperature from 0 to 525°C | |

| 20Х23Н18 | ХН28МДТ | GOST 2246 | Sv-10X16N25AM6 | Ar | From minus 60 to 350°С, subject to requirements for MCC |

| ХН78Т | TU 14-1-4968 | Sv-08Х25Н25М3 | |||

| GOST 2246 | Sv-01Х23Н28М3Д3Т | ||||

NOTE:

- The temperature conditions for the use of welded joints are additionally limited by the conditions of use of the materials being welded.

- In the absence of requirements for MCC, the conditions for the use of welded joints are determined by the conditions for the use of the materials being welded.

- When welding more alloyed alloys with less alloyed alloys and steels, it is recommended to use welding consumables designed for welding more alloyed alloys.

- After “thermal rest” (350-400°C, exposure 3 hours), the time before heat treatment is not limited.

Corrosion resistance

| Wednesday | t, °С | Corrosion depth, mm/year | |||

| 40% H2SO4 | 20 | 0,1-1,0 | Concentrated H2SO4 | 20 | 0,1 |

Heat resistance

| Wednesday | t, °С | τ, h | Depth, mm/year | Strength group or score | ||||||||

| Air | 650 | 4500 | 0,0027 | 2 | 750 | 1500 | 0,01 | 3 | 800 | — | 0,044 | 4 |

Linear expansion coefficient α*106, K-1

| steel grade | α*106, K-1 at test temperature, °C | 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 | 20Х23Н18 | 14,9 | 15,7 | 16,6 | 17,3 | 17,5 | 17,9 | 17,9 | — | — | — | |||||||||

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 20Х23Н18 | 14 | 16 | — | 19 | — | 22 | — | — | — | — | |||||||||

Specific heat capacity c, J/(kg*K)

| steel grade | s, J/(kg*K), at test temperature, °C | 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 | 20Х23Н18 | 538 | — | — | — | — | — | — | — | — | — | |||||||||

Electrical resistivity ρ nom*m

| Steel grade | At test temperature, °C | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 20Х23Н18 | 1000 | — | — | — | — | — | — | — | — | — | |||||||||

Modulus of normal elasticity E, GPa

| Steel grade | At test temperature, °C | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 20Х23Н18 | 200 | — | — | 182 | 176 | 170 | 160 | 150 | 141 | — | |||||||||

Density ρп kg/cm3

| Steel grade | At test temperature, °C | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 20Х23Н18 | 7900 | — | — | — | 7760 | 7720 | 7670 | 7620 | — | 7540 | |||||||||

Bibliography

- Shlyamnev A.P. Corrosion-resistant, heat-resistant and high-strength steels and alloys 2000

- STO 00220368-011-2007

Find out more

Steel 20X - structural alloy...

Alloyed tool steel 9ХВГ…

Steel 45X structural alloy…

Structural alloy steel 40X2H2MA…

Our offer

The InoxAisa company sells wholesale and retail hot-rolled sheets AISI 310S (20Х23Н18) with a matte surface with a thickness of 1 to 6 mm. Cutting options: 1250x2500, 1250x6000, 1500x3000 and 1500x6000 mm. The average price of products is 3,050 tenge/kg.

You can order sheet metal 20Х23Н18 in our online store or by visiting the InoxAsia office in Almaty. The address, directions, office and warehouse opening hours are presented in the “Contacts” section. Please check the cost and availability of goods by phone or email This email address is being protected from spambots. You must have JavaScript enabled to view it. A flexible system of discounts is provided for wholesale buyers.