Stainless steel is an excellent material, not only in terms of internal qualities, but also in external ones. This is what made him so popular. Yes, stainless steel is more expensive, however, given its characteristics, cost is not an obstacle to the widespread use of, for example, stainless pipes, about which so many videos have been shot.

Stainless steel pipes

Such products very often have to be connected to each other, and welding is most often used for this. The performance properties of the products will depend on the quality of its execution. And here you need to understand, if you do welding with your own hands, that the connection of stainless pipes differs from the connection of products made of carbon steel.

The differences relate to low thermal conductivity (70 percent lower), low melting point (100 degrees lower) and high electrical resistance (about 6 times higher).

Of all the possible welding methods for connecting stainless steel pipes, the following are used:

- Laser;

- Spot;

- Pulse arc. Occurs in an inert gas environment with a consumable electrode;

- Electric arc. If the wall thickness is more than 1 cm, it is performed under flux;

- Plasma. The thickness of the metal does not matter;

- Manual arc. The thickness of the product can start from 1.5 mm. A tungsten electrode in an inert gas is used to weld stainless steel.

Any of the presented technologies allows you to obtain a high-quality connection. However, the choice depends on the conditions of use, type of product, and so on.

Stainless pipe welding technology

Technology and features

As with welding carbon steels, stainless steels also need to be prepared by machining the edges. You can use flux cutting or compressed arc. The edges also need to be degreased.

Taking into account the often need to obtain a high-quality “commercial” weld, the area of the base metal near the seam should be covered with a protective coating. Otherwise, splashes of molten metal will fall on the surface.

Each fusion method can be used to connect such parts, however, it has certain characteristics, as noted above.

Manual arc welding

Manual arc welding involves creating the desired chemical composition of the weld metal. Therefore, the electrode coating (its composition) can be adjusted to obtain the required amount of ferrite in the weld. And this prevents the formation of hot cracks, and also achieves high corrosion resistance.

You should also use special equipment to reduce the waste of alloying elements. For example, supporting a short arc without performing transverse oscillations of the electrode.

Due to the composition of the electrode coating, the current must be constant and of reverse polarity. In the opposite case, we obtain arc instability. The current strength in the vertical and ceiling positions is reduced by 30 percent; it directly depends on the selected electrode diameter, multiplied by a coefficient.

It is better to perform welding with minimal melting of the base metal and the formation of small cross-section beads. Before the process, it is better to calcinate the electrodes to reduce the likelihood of pores due to the presence of hydrogen.

Welding stainless steel with ferrous metal

Welding products from different types of metals is accompanied by the following problems: different melting temperatures, different physical and chemical properties. The most common methods for welding corrosion-resistant steels and ferrous metals are:

1. Welding using coated electrodes is carried out with direct current of reverse polarity. It is recommended to choose consumables designed for dissimilar steels. You can also use highly alloyed electrodes, which allow you to obtain a high-strength connection. The amount of tension is selected depending on the width and depth of the seam. When performing work, you should pay attention to the following nuances:

- the connection point must be uniform;

- cooling should occur without forced influence;

- to prevent the molten additive from flowing out of the weld area, welding should be carried out in lower, horizontal or inclined spatial positions;

- Differences in the properties of metals can cause the weld to rust.

2. Welding with tungsten electrodes is less in demand due to the higher cost of this type of welding materials.

Other features of welding these materials are presented in the article “Welding stainless steel with electrodes.”

Submerged arc welding

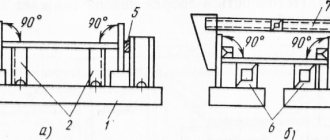

Submerged arc welding has been successfully used to connect stainless pipes with wall thicknesses from 3 to 50 mm. Characterized by more stable properties and composition of the metal in the weld. At the same time, corrosion resistance improves, since a smooth transition to the base metal and the formation of fine flakes on the surface of the weld are observed.

The seam

Cutting edges is only needed when the wall thickness is more than 1.2 cm, which reduces the labor intensity of the process, in contrast to manual arc cutting, when edges need to be prepared already at a thickness of 4 mm.

However, with this method it is more difficult to retain the ferrite phase in the weld metal. The rollers are also made of small cross-section wire with a diameter of about 3 mm, and the electrode extension should be halved from the standard values.

Fluxes should be calcined before welding to reduce the waste of alloying elements. After the process, remaining flux and slag must be removed.

Welding stainless steel with an electrode

Stainless steel has been serving humanity well for over a hundred years, touching all areas of life for each of us. This material is used to create bolts, fasteners, tanks, fittings, cans, tools and much more. And in order to manufacture or repair the necessary parts, manual arc welding of stainless steel with an electrode using an inverter is most often used. Read in detail about the features of the method, advantages and disadvantages, as well as “surprises” that beginners can expect during MMA welding in our article.

Content

- What is the essence of the method of welding stainless steel with a conventional electrode?

- Where is stainless steel RDS used?

- Obvious pros and cons of the stainless steel RDS method

- Is it possible to weld stainless steel with an electrode at home?

- What you need to weld stainless steel using the MMA method

- What types of metals can be welded with a stainless steel electrode?

- What electrodes to use for manual arc welding of stainless steel

- What models of welding inverters are suitable for welding stainless steel with an electrode?

- Features and useful tips

- Treatment of stainless steel after electrode welding

What is the method of welding stainless steel with an electrode using an RDS inverter?

RDS of a stainless steel electrode is a process in which the electrode coating, which melts during the melting of the rod, creates a gas-slag protection. This is a crust of slag that isolates the arc zone and weld pool from the surrounding air (oxygen contained in the air rapidly oxidizes the molten metal and significantly reduces the quality of welding). The welded joint is created by the molten metal of the part and the metal of the electrode rod (and the metal from the electrode coating). In international practice, this technology is briefly called MMA (Manual Metal Arc) welding.

Where is the RDS welding method most often used?

You can use inverter welding of stainless steel in all spatial positions, but not every experienced welder can lay high-quality vertical seams.

- Manual arc welding with coated electrodes is rationally used for short seams in small-scale production of parts. When installing metal structures, the use of this welding technology is recommended for a small amount of work.

- RDS of stainless steel with coated electrodes has found application for tack welding when assembling structures for welding and, if necessary, correcting defects in small areas of the seam.

- Surfacing can also be performed using a similar method.

Conclusion : Thus, MMA welding is more often used for small volumes of production and for personal household purposes; the method is used for welding pipes, metal structures, stainless steel containers or tanks and other products in dachas, garages, etc.

Pros and cons of the method

When compared with other welding methods, such as TIG welding, MIG/MAG gas shielded welding, submerged arc welding, manual welding of MMA stainless steel has the following advantages:

- equipment for welding by this method is simple, inexpensive and mostly compact;

- RDS is used for welding most ferrous and non-ferrous metals and various alloys of almost any thickness;

- no need to use additional flux or gas protection;

- this welding method is suitable for hard-to-reach areas due to the small dimensions of individual models of welding inverters;

The disadvantages of this method include:

- the need to get rid of slag after creating a seam;

- due to the fact that the welding current constantly flows along the entire length of the electrode, it is necessary to limit the maximum permissible current due to the problem of overheating of the electrode and destruction of the coating;

- slow welding speed.

Conclusion : There are not many advantages of the method, but they all lie in the simplicity of MMA welding and its versatility, which makes the technology so popular.

How to cook stainless steel with an inverter at home and is it possible?

Many people are interested in whether it is possible to cook stainless steel with an inverter at home, and what they should pay special attention to.

- Before you start welding stainless steel products, you need to carefully process and prepare the surfaces for further work. The pre-treatment process is identical to that carried out with low-carbon steels:

- the surface of the product is cleaned of dirt,

- the edges and surface are treated with a solvent (gasoline or acetone), such treatment will make it possible to get rid of fat, the presence of which leads to a deterioration in the stability of the arc,

- The surface to be welded is treated with an anti-spatter agent.

The difference is that the welded joint must have a gap that can ensure optimal shrinkage.

- Stainless steel is welded using reverse polarity current. When carrying out work, you should try to melt the seam less.

- Electrodes with large diameters are, as a rule, not used. The need to use them appears only when welding thick surfaces. You can select an electrode for metals of different thicknesses, including thin sheet steel, using Table 1 below. An incorrectly selected electrode will cause poor sealing of the seam; microcracks, cavities and pores will form in it. They are obtained due to the boiling of the metal.

- When welding stainless steel, the current should be 20% lower than for welding low-alloy steels. For an inverter used in everyday life and private construction, a range of 60-160 A is sufficient. Smooth adjustment will make it possible to more accurately select the welding current and improve the quality of the seam. The optimal values of welding current are given in Table 1 and are determined by the thickness of the material being welded.

- After the weld is formed, a cooling procedure must be performed to maintain the resistance of high-alloy steel to corrosive processes. Cooling is carried out using copper pads. In the case of austenitic steel, cooling using water is possible.

Conclusion : Thus, welding stainless steel requires the performer to have certain experience and skills, as well as knowledge of the ratio of metal thickness, current values and electrode diameter. A beginner should not immediately expect an ideal result.

What is needed to weld stainless steel with an inverter?

To weld stainless steel yourself with an inverter, you will need the following:

- welding inverter;

- electrodes;

- solvent;

- steel brush;

- protective equipment: mask, gloves, suit.

The necessary components are alligator clips for grounding, electrode holders, as well as a power and grounding cable. Sometimes these components are included with the inverter, but most often you have to buy them in addition. The optimal cable length should be at least 2 meters.

Many people ask what electrodes to use to cook stainless steel. An important condition for the welding process to be successful is the choice of the optimal ratio of the thickness of the metal and the electrode used.

Table 1.

| Thickness of welded metal, mm | 1-3 | 3-4 | 4-5 | 5-6 | 6-8 | 8-10 | 12-15 | 15-18 |

| Recommended welding current values, A | 20-60 | 50-90 | 60-100 | 80-120 | 110-150 | 140-180 | 180-220 | 220-260 |

| Welding electrode diameter, mm | 1,0-1,5 | 1,6-2,0 | 2,0-2,4 | 2,5-3,1 | 3,2-3,9 | 4,0-4,9 | 5,0-5,9 | 6.0 or more |

What types of metals (steel) can be welded with stainless steel with an inverter and the features of welding such metals?

Manual arc welding of stainless steel with an inverter is a universal technological process used for welding non-ferrous and ferrous metals and various alloys of any thickness (from 1 mm to 100 mm), but, as a rule, the thickness range ranges from 3 to 20 mm.

Under certain operating conditions of the structure, as well as when using specific grades of electrodes, it is possible to weld different groups of stainless steels: heat-resistant, corrosion-resistant and heat-resistant steels. The values for the most commonly welded stainless steel, austenitic steels, are presented in the table.

Table 2.

| steel grade | Working conditions | Electrode brand | Electrode type | α phase content (%) and weld structure | |

| Heat-resistant steels | |||||

| Х25Н38ВТ ХН75МБТУ | Heat | EA-981-15 | E-09Х15Н25М6Г2Ф | Austenitic | |

| 20Х20Х14С2 20Х25Н20С2 30Х18Н25С2 | Temperatures up to 900-1100°C Temperatures up to 1050°C; heat resistance and heat resistance | OZL OZL-9-1 | E-12Х24Н14С2 E-28Х24Н16Г6 | 3-10% Austenitic-carbide | |

| Corrosion-resistant steels | |||||

| 08Х18Н10 | Aggressive environments; resistance to intergranular corrosion | TsL-11 | E-04Х20Н9 | 2,5-7,0 | |

| 12Х18Н10Т 08Х22Н6Т | Temperature up to 600oC; liquid media; resistance to intergranular corrosion | L38M | E 07Х20Н9 E-08Х19Н10Г2Б E-02Х10Н9Б | 3-5 | |

| 10X17NIM2T 08Х18Н19Б 08Х21Н6М2Т | Temperature up to 700 °C; resistance to intergranular corrosion | SL-28 | E-08Х19Н10Г2MB E-09Х19Н10Г2М2Б | 4-5 | |

| 10Х17Н13МЗТ | Resistance to intergranular corrosion | NZh-13 | E-09Х19НУГ2М2Б | 4-8 | |

| Heat-resistant steels | |||||

| 20Х20Х14С2 20Х25Н20С2 30Х18Н25С2 | Temperatures up to 900-1100°C Temperatures up to 1050°C; heat resistance and heat resistance | OZL OZL-9-1 | E-12Х24Н14С2 E-28Х24Н16Г6 | 3-10% Austenitic-carbide | |

| Х25Н38ВТ ХН75МБТУ | Heat | EA-981-15 | E-09Х15Н25М6Г2Ф | Austenitic | |

What electrodes should be used for welding stainless steel?

For manual arc welding of stainless steel, there are two main types of electrodes.

- with the main coating (SEZ ZIO-8 d4.0, SEZ TsT-15 d5.0, ESAB FILARC 88S d3.2) which are used only on direct current with reverse polarity (“+” on the electrode), where the main coating is most often calcium and magnesium carbonates;

- with rutile coating (Lincoln Electric Omnia 46 D3.0, Mezhgosmetiz Omnia 46 d3.0, ESAB OK 46.00 d3.0) mainly made of titanium dioxide, which are used if it is necessary to weld on alternating current and direct current of reverse polarity. They ensure arc stability and reduce the amount of spatter during welding.

The answer to the question of which electrodes to use to weld stainless steel depends on what type of steel needs to be welded. Table 2 shows the optimal grades of electrodes depending on the type and grade of the metal being welded.

What models of welding machines are best suited for welding stainless steel?

When choosing an inverter for RDS, you need to consider the following points:

- Operating temperature range (as some models are not capable of operating at low temperatures in open air conditions).

- Power and welding current of the unit. For domestic use, an inverter that produces 180A output is sufficient. More professional welders produce more than 200A.

- Possible deviations of at least ± 20% of the network voltage from the nominal parameter without harming the quality of welding.

It is also important to have additional functions, the most popular of which are: Hotstart, Arcforce, Antistick

Our website presents modern welders from well-known manufacturers that have successfully proven themselves in the welding equipment market. Depending on the required voltage, you can choose:

- models of welding inverters for RDS (MMA welding) for 220V mains voltage,

- models of welding inverters for RDS (MMA welding) for a mains voltage of 380V.

The Tiberis assortment includes budget units suitable for work at home.

- For voltage 220V Svarog PRO ARC 160 (Z211S), Svarog PRO ARC 180, Svarog TECH ARC 205B (Z203), PATON VDI-200P.

- For operation under 380V mains voltage, these are inverters such as Svarog ARC 315 (R14), BRIMA ARC 250 (380V).

And sophisticated multifunctional premium-class installations for professional welding.

- For 220V voltage these are EWM Pico 162, Lincoln Electric Invertec 170S, KEMPPI Minarc 150.

- For operation under 380V voltage these are Lincoln Electric Invertec 270-SX, EWM Pico 220 CEL Puls, Kemppi Minarc 220.

Conclusion : The choice of a specific welding inverter model depends on the existing work task, working conditions and financial capabilities of the performer. In Tiberis you can easily select the device that suits you in all respects.

Features of welding stainless steel with an electrode using manual arc welding

Anyone who has not encountered this method of welding asks how to weld stainless steel with an electrode. The principle of welding stainless steel by electric welding is that the arc is excited between the electrode and the plane of the product being welded.

- It is necessary to attach a ground cable (-) to the surface to be welded, which comes out of the welding machine.

- The second cable (+) with the electrode must be brought closer to the surface to be welded, as a result of which a welding arc is formed.

- For the reliability of the process, it is worth remembering that the optimal distance between the tip of the electrode (which must also be chosen correctly in accordance with the thickness of the metal) and the element being welded is in the range from 2 to 6 mm. Due to the influence of high temperatures, the metal melts, and then the groove formed during the action of the arc on the surface of the metal being welded is filled.

- The electrode must be at the correct angle during welding. This will provide control over the welding process. The tilt angle should be approximately 80 degrees. The tilt should be towards the arc. The arc occurs due to the fact that the electrode touches the surface of the metal being welded or due to impacts with medium force on the surface being welded.

- The current strength also needs to be selected correctly. The discrepancy between this value and the thickness of the metal will not lead to a positive result. If the current is weak, the electrode will constantly fade and the welding process will not be effective. If the current is too high, the metal will burn through. Recommended values for this parameter are given in Table 1.

Conclusion : The MMA welding process is not particularly complicated, although it requires some care from the performer.

Processing stainless steel after welding with an inverter

After welding, stainless steel must be processed. Ignoring such manipulations can lead to negative consequences: corrosion and a decrease in the quality of the product.

The technology for processing stainless steel products after MMA welding includes:

- mechanical cleaning of the weld seam, this operation improves the appearance of the product and is performed with hard steel brushes;

- sandblasting, after which the seam looks even more aesthetically pleasing;

- grinding to achieve uniformity and smoothness of the weld surface. To grind the weld after welding stainless steel, abrasive materials based on zirconium, aluminum oxide or ceramic artificial mineral are used. It is not recommended to use products containing corundum, as it promotes corrosion.

But all such measures are only preliminary processing of the product, since they only affect the appearance of the part. To reliably protect the welding site from destruction, it is necessary to resort to passivation and etching.

Passivation is the application of a special substance to the welding site, under the influence of which a protective film of chromium oxide appears on the metal surface.

Pickling is the treatment of the welding site with chemically active agents (special liquids or acids). Acids destroy scale, which can cause rust.

Only after chemical treatment is carried out does the welding zone reliably resist corrosive processes.

Conclusion : Treatment of the seam after welding will improve the quality of the work done and extend the durability of the part being welded, reducing the risk of corrosion.

See also:

- Catalog of electrodes for welding stainless steel

- Catalog of household welding inverters