During the construction of residential buildings and other structures, everyone is faced with the need to correctly calculate and install floors. The ceiling is a horizontal structure located inside the building, which divides it vertically into adjacent rooms (floors, attic, etc.). In addition, this structure is load-bearing, since it takes all the loads coming from furniture, people, equipment and the ceiling itself and transfers them either to the walls or to the columns (depending on the type of structure).

Types of floors

According to their purpose, floors can be divided into:

- basement - separates the first floor of a building from the ground floor or basement

- interfloor - aimed at separating the floors of a building from each other

- attics. The first ones. From the name of the second type it follows that they. The latter separate the attic space from the residential building.

Depending on the design features of the ceiling, they can be divided into tile and beam:

- Tiled floors are most often installed in large stone houses using reinforced concrete slabs.

- Beam floors are used in the construction of low-rise residential buildings. Metal or wooden beams can be used for their installation.

How to choose the right channel?

When choosing the right product, it is important to correctly calculate the length, width and weight of the product. So, if you need to make beam floors, you should carefully measure the width of the shelves, which will correspond to the length of the beams. And the length of the beams must match the dimensions of the floor.

Such manipulations with calculations are quite complex, so it is easy to make mistakes. It is advisable to contact a company where experienced consultants will select the most suitable option.

is the first supplier of channels from the manufacturer. We deliver throughout Tyumen and the region, and also provide construction services. Call now!

Channel for floors

Let's take a closer look at structures made from channel beams for flooring as a load-bearing base. They are the ones who bear the entire load falling on the floors of the second floor. If U-shaped rolled products are used to install the ceiling, then the following points must be taken into account:

- the channel must be laid vertically, since the moment of resistance of the section in this direction is several times higher than the value of the moment in the opposite direction

- The laying scheme is as follows: from the middle of the ceiling, the profile should be turned in the opposite direction, since the center of gravity of the channel does not belong to its wall

This laying scheme is necessary to compensate for tangential stresses. It should be remembered that ceiling channels are subject to bending stresses.

The scope of use of channels is wide

They are used wherever it is necessary to make a structure as stable as possible and increase its resistance to significant loads. Channels are most often used in the following industries:

Construction (including architectural) - as reinforcement for roofs and walls, for strengthening concrete and load-bearing structures, in the construction of frames of residential and industrial buildings, for creating floors and reinforcing walls, for finishing.- Heavy engineering, automobile, carriage and shipbuilding. Most often in these industries, U-shaped channels are used as elements that can withstand heavy loads. For example, they strengthen beams on which cranes move.

- Machine tool industry. The channel is a hot-rolled profile with optimal technical parameters. It has high strength and ability to withstand vibration. It is suitable for use as frame elements and motor mounts

Steel profiles are also used in the construction of bridges and in the reconstruction of buildings. In fact, without this product it is impossible to build or restore any residential or industrial facility. To choose the right channel for a specific task, you need to take into account the steel grade and standard size of the product.

How are channels obtained?

The production technology of this type of profile is strictly regulated by GOST. The main raw materials are structural high-carbon and low-carbon steel, as well as steels with alloying elements. The channel manufacturing process includes several stages:

- the rectangular workpiece is heated to the required temperature and fed to the rolling mill;

- the workpiece is crimped by rotating shafts - first its central part, it is given an M shape;

- the channel is leveled and sent to a calibration machine, where the profile receives the exact size.

The process of producing channels is labor-intensive, but thanks to high productivity and excellent quality of the finished product, the demand for this type of rolled metal is growing rapidly.

Calculation of channel bending for floors

How to calculate and select the size of a channel - on the page “Moments of resistance of a channel according to GOST”

Let us calculate the channel for the ceiling based on the following conditions. There is a room measuring 6x8 m. The pitch of the floor channel beams is p = 2 m. It is logical to assume that the channel should be laid along a short wall, which will reduce the maximum bending moment acting on it. The standard load per square meter will be 540 kg/m2, and the calculated load will be 624 kg/m2 (according to SNiP, taking into account the reliability factors for each component of the load). Let the ceiling channel on each side rest on a wall 150 mm long. Then the working length of the channel will be:

- L = l+2/3∙lоп∙2 = 6+2/3∙0.15∙2 = 6.2 m

The load per linear meter of channel will be (normative and calculated, respectively):

- qн = 540∙р = 540∙2 = 1080 kg/m = 10.8 kN

- qр = 540∙р = 624∙2 = 1248 kg/m = 12.48 kN

The maximum moment in the channel section will be equal (for standard and design load):

- Mn = qn∙L2/8 = 10.8∙6.22/8 = 51.9 kN∙m

- Мр = qр∙L2/8 = 12.48∙6.22/8 = 60 kN∙m

Let us determine the required moment of resistance of the section using the expression:

- Wtr = Мр/(γ∙Ry)∙1000, where

Ry = 240 MPa – resistance of steel C245, calculated γ = 1 – operating conditions coefficient

Then Wtr = 60/(1∙240)∙1000 = 250 cm3

How much can a channel weigh?

| Channel number | Weight of 1 meter in kg | Meters per ton |

| 5 | 4,84 | 206,6 |

| 6,5 | 5,9 | 169,5 |

| 8 | 7,05 | 141,8 |

| 10 | 8,59 | 116,4 |

| 12 | 10,4 | 96,2 |

| 14 | 12,3 | 81,3 |

| 16 | 14,2 | 70,4 |

| 18 | 16,3 | 61,3 |

| 20 | 18,4 | 54,3 |

| 22 | 21 | 47,6 |

| 24 | 24 | 41,7 |

| 30 | 31,8 | 31,4 |

Selection of cross-section and checking for channel rigidity

Using the reference book (see GOST 8240-97 or GOST 8278-83), we select a channel profile that has a moment of resistance greater than the design one. In this case, a 27P channel is suitable, Wx = 310 cm3, Ix = 4180 cm4. Next, it is necessary to check the strength and bending rigidity of the channel (deflection of the whip).

Test of strength:

- σ = Мр/(γ∙Wx)∙1000 = 60∙1000/(1∙310) = 193 MPa< Ry = 240 MPa, which confirms the strength condition

Test for rigidity, channel bending where the relative deflection f/L must be less than 1/150 and is determined by the expression:

- f/L = Mn∙L/(10∙E∙Ix) = 60∙103∙620/(10∙2.1∙105∙4180) = 1/236<1/150

The rigidity condition is ensured. Consequently, this channel can be used for ceilings according to the described scheme. The channel number can be reduced if the rods are laid in smaller increments.

Source

When creating or expanding openings of various types - windows, doors, their high-quality strengthening is important. Installing a channel is the most popular way to strengthen such structures. It is widely used for load-bearing structures made of reinforced concrete and brick. As soon as the steel frame is installed, the entire load, which was previously taken by the remote parts of the partitions, is transferred to the channel.

Such reinforcement has a positive effect on the structure: it is protected from destruction and cracking. The height of the channel edges is from 5 to 40 mm - this is expressed by the number on the marking. A distinctive characteristic of the product is its U-shaped format. Metal products have resistance to bending and compression, and can withstand significant loads of building elements. They give any metal structure additional stability and reliability. Products are manufactured in accordance with GOST 8240-89

.

Other types of rolled metal

Other types of rolled metal can be used in construction and industry: profiled, galvanized, cold- and hot-rolled sheets, steel strips, angles, circles, fittings, round and profile pipes, squares and I-beams. All of the listed types of rolled metal are used to create reliable, functional and high-strength structures. In addition, various types of rolled metal guarantee the external aesthetics and long service life of these structures.

In conclusion, it remains to add that rolled steel can be relevant for residential, industrial, administrative and road construction, machine tool and shipbuilding, the agricultural sector, the aviation industry, instrument making, etc.

How are openings strengthened with channels?

To create a metal frame, accurate measurement results and a carefully made opening are required. If these conditions are met successfully, then the channel is fastened quickly, easily, comfortably - there is no dust, dirt, or unnecessary noise. Another bonus is that the interior partitions remain intact. Here is a brief example of work on decorating an opening with a metal profile:

- Before cutting the opening, specialists install safety racks, which will strengthen the structure and take the load from it during the installation period;

- the boundaries of the future opening are marked;

- next - dismantling the wall elements;

- After this, the opening is strengthened with a steel beam.

The channel element is mounted from racks located vertically. They frame the edges of the free space. Metal strips in a horizontal format are welded to the walls. The structure is attached to the partition using bolts and anchors. In some cases, with chemical anchors, which are capsules with glue. They are inserted into drilled holes.

Next, anchor bolts are placed, which break the adhesive mixture, causing a chemical reaction. The introduced mixture hardens, after which the anchors are tightened with nuts. This connection has high reliability, it is durable, and there is no need for further repair work. The distance between fasteners is calculated individually for each project. Calculations are made by engineers based on a technical report. Each stage of work is described in detail in the design documentation.

Product classification and scope

The characteristics of rolled metal products are greatly influenced by the manufacturing method and configuration of the product. On this basis, products are divided into hot-rolled, special and bent. The first and last options are universal and are used in all areas of construction. Special ones are most often intended for carriage building.

Regular hot rolled

Popular type of shaped profile. It is used for reinforcing and stiffening frames and other load-bearing structures .

The part is manufactured using hot rolling technology. The steel billet is heated and rolled through a rolling mill, where it is given a U-shape. The weight of a channel is higher than that of a bent one, for example, the accuracy of the shapes is lower. Thick blocks of this type are quite difficult to connect, but due to their thickness and configuration, such structures can withstand high loads. At the same time, the material consumption of the profile is lower than that of a solid rod. Alloy steel is used for manufacturing . This means that no additional restrictions need to be observed when welding channels.

They produce several types of hot-rolled profiles - 5 series .

- Series P is a model with parallel shelves. The most popular option. Available in lengths from 2 to 12 m, however, upon request, beams of any measured or unmeasured length are supplied. Products with parallel edges are the most massive. The weight of 1 linear meter ranges from 4.84 to 48.28 kg.

- Series U - in this profile, the shelves are located parallel to each other, if you evaluate the outer sides of the part. However, inside the shelves have a slope due to different thicknesses of the edges and the junction with the wall. The slope is smooth, has a certain radius of curvature, which is regulated by GOST. It ranges from 6 to 15 mm. In this case, the mass of a channel with sloped flanges coincides with its analogue from the P series, provided the wall thickness and dimensions are the same. The slope is small: the maximum value reaches 10%.

- Series E – economical. It received this name due to its lower material consumption. This is achieved by rounding parallel shelves without reducing the thickness. But with these dimensions, the lightest channel of the P series weighs 4.84 kg, and the E series - 4.79 kg. When using rolled metal in construction work, this difference results in big savings.

- Series L – lightweight. Option with parallel rounded shelves and reduced wall and shelf thickness. The assortment of the lightweight model is represented by only 9 options. Compared to the P or U series, such elements can withstand less load.

- Series C – highly specialized. Its dimensions correspond to industry demands and are more specific. This includes, for example, an option intended for carriage building. In this profile, the upper shelf is bent and differs in width from the other by 6–10%.

Valera

The voice of the construction guru

Ask a Question

The main area of application of hot-rolled channel is construction. It is used for the construction of building frames, strengthening structures, and when laying pipelines. Since the U-shaped beam is very resistant to vibration, it is actively used in machine tool construction. Rolled metal is also in demand in the construction of cars and heavy equipment.

Bent

A bent channel is inferior in strength to a hot-rolled one.

A bent channel or “correct” channel received its name not because of its shape, but because of its manufacturing technology . Its configuration is somewhat different from the usual one. The parallel edges are rounded not only from the inside, but also from the outside.

For such an element, rolled cold-rolled or hot-rolled steel - regular, carbon structural and low-alloy. The characteristics of the resulting profile depend on the characteristics of the raw materials. The most durable and dimensionally accurate channels are made from cold-rolled carbon steel.

Channels are produced on profile bending machines . The steel strip is fed to the mill, where it is cold formed into a U-shape.

A bent profile is inferior in strength to a hot-rolled one . At the same time, it is noticeably superior in resistance to deformation and is used to strengthen structures subject to high tensile and compressive loads.

There are 4 types of bent profile:

- B – the edges of the shelves are inclined inward;

- P – shelves are exactly parallel to each other;

- L – lightweight channel with a thinner wall and parallel edges;

- C – special beam.

Bent channel is produced both according to GOST and in accordance with technical specifications. Channel dimensions may be far from standard.

Equal shelf - an option in which the width of the shelves is the same. Regulated by GOST 8278-83. Made from different grades of steel. The length of the bent profile with equal edges reaches from 3 to 11.8 m. Unmeasured and multiple measured lengths can be produced.

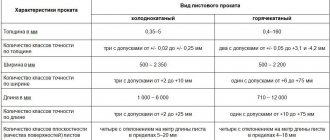

Bent steel profiles are available in standard, high and high precision. The class requirements are higher here. Deviations for increased accuracy for shelf heights up to 15 cm are only 1.5 mm.

Unequal - regulated by GOST/82821-80. Most often made from boiling carbon steel because it provides a tensile strength of over 460. However, the channel can also be made from alloy steel if it has the same characteristics.

The length range for unequal options is the same as for equal options. They are distinguished by the distance between the shelves, the so-called step.

How is an opening made in a brick wall?

Before starting work, a horizontal jumper consisting of two channels is installed. This is necessary so that the brickwork remains intact. The wall is chipped over the constructed openings on both sides. U-shaped metal profiles are inserted into the resulting niches.

Insertion methods:

- One of the not the best ways to install a channel into a wall is to use a product with sloping shelves that overlap the opening. Due to the formed empty space, the channel begins to slip over time and the structure loses strength. As a rule, this solution is used by non-professionals or in cases where there are no other materials to strengthen the wall.

- A more sophisticated way of mounting the U channel into the surface is flush. In this case, the structure holds firmly and does not lose its qualities during operation. Due to friction and pressure, the probability of losing the connection is close to zero. The disadvantage of this design is that it is very difficult to create - this will require special tools and precise measurements.

- One of the most common methods of strengthening an opening is to use a product with parallel shelves and overlap installation. The popularity of this method is due to minimal labor costs - the wall does not need jewelry cutting. In addition, such a connection has sufficient strength to prevent shedding and cracks in the opening.

- Finally, the strongest and highest quality of all possible installation options is the use of a P channel with flush mounting. This method is aesthetic, its results are subsequently easily processed by finishing. The downside is that it is expensive, since you will need to use a diamond saw.

The free spaces between the metal and the brick are rubbed with cement-sand mortar. Source

Types of loads and channels

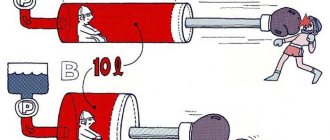

View A.

"Canopy over the entrance." This type includes beams with rigid embeddings. The load is usually applied evenly. These could be canopies over entrances. Welding is used for their manufacture. They are made of two channels attached to the wall, and the space is filled with reinforced concrete.

View B.

“Interfloor slabs” Rigidly fixed single-span beams, the load on which is distributed evenly. Usually these are floor beams between floors.

Species C.

"Hinged balcony support." The beams have two supports with a cantilever, the load is distributed evenly between them, but they extend beyond the outer walls. This is necessary to create support for the balcony slabs.

View D.

"Under two jumpers." These are single-span hinged-supported beams on which two concentrated forces act. Usually these are lintels on which another pair of floor beams rests.

Species E.

"Under one jumper." These are single-span hinged-supported beams where one force is concentrated. Usually these are lintels on which one beam of another floor rests.

After it has been clarified what type of channel this channel belongs to and where the main load will go, a calculation formula is selected.

Types of channels

Manufacturers offer hundreds of channel options, varying in shelf sizes and widths, configurations, types of production, and steel grades.

According to the production method, the channel is distinguished:

- hot rolled;

- cold rolled.

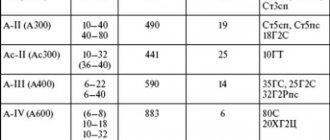

Hot rolled steel is produced in a special rolling mill under high temperatures. This is a durable, inexpensive material, which is divided into different types according to accuracy and strength:

- marked A - a product of high precision and durability;

- with marking B - normal accuracy and strength.

A cold-rolled channel is produced by bending a steel strip on special equipment; it is distinguished by higher dimensional accuracy and surface smoothness from a hot-rolled channel, and is somewhat more expensive due to a more complex production process. Cold-rolled steel has a “U” shape, unlike hot-rolled steel, the corners are rounded, which is explained by the peculiarities of production.

The shape of the channels comes with different angles of inclination of the shelves:

- parallel;

- inclined.

A channel with inclined flanges is used in more critical designs; it weighs more and can withstand greater loads.

Channel assortment

Despite the difference in configuration, the U-shaped profile is used in similar works and often has very similar parameters. The dimensions of the channel, for example, series P or U, are almost the same. The wall thickness in the L series is smaller, as is the weight of the product.

Dimensions of hot rolled channels:

Legend and notes:

Dimensions of bent channels:

Marking and decoding

Rolled metal has an alphanumeric designation that reflects the dimensions of the product, the type of steel used, and the series.

The marking begins with the word “Channel”, indicating the type of metal profile, then indicates:

- the first digit indicates the height of the wall in cm;

- the next letter denotes the series - P, U, L;

- The accuracy class is separated by a hyphen: B – normal, B – increased;

- a small letter “a” can be placed between the first number and the letter - it indicates that the width and thickness of the edge has been increased;

- GOST regulating products of this type.

Example of marking

A bent profile is marked differently:

- the first dimensions to be indicated are the wall height, edge width and thickness for an equal-flange channel, and the wall height, thickness and width of each flange for an unequal-flange channel;

- the second letter indicates the accuracy class: A – high, B – increased, C – normal;

- the corresponding GOST products are indicated;

- after the fraction sign, the grade of steel from which the channel is made and GOST regulating its characteristics are given.

Advantages of hot rolled steel channel

The main advantage is the shape in the form of the letter “P”. Thanks to it, the product gains its advantages, which are in demand in various fields of construction, mechanical engineering and carriage building:

- rigidity and strength, which allows it to withstand significant mechanical loads;

- versatility;

- the possibility of erecting metal structures even without welding. Channels can be disassembled and folded like a construction set;

- the center of gravity is shifted towards the ends of the shelves;

- resistance to deformation, including bending and tearing loads. Therefore, hot-rolled channel is excellent for the construction of even heavy metal structures, even those that play a load-bearing role;

- light weight and ease of installation;

- the peculiarity of the product manufacturing technology eliminates the possibility of the appearance of “weak points” that could provoke destruction;

- high weldability rates;

- high performance properties.

During production, hot-rolled channel is subjected to thermal effects. In this case, recrystallization occurs in the crystal lattice of the material, and after that, annealing occurs, which reduces internal stress. Annealing also increases the plasticity and viscosity of the material, so it becomes more amenable to machining.

Hot rolled models made of stainless steel are resistant to corrosion. This feature makes their use more preferable than, for example, cast iron products. They require additional treatment with a primer, placement inside a concrete pour, as well as the use of other protective agents, which implies additional costs. And even this is not complete protection against corrosion, since the protective coating may crack or peel off over time, and in this place the metal will be corroded by rust. Therefore, if it is necessary to use a metal structure erected using a channel in conditions of high humidity or temperature changes (outdoors), you should give preference to stainless steel products.

Another technical feature is that it is not very weldable. Therefore, in cases where welded structures that do not play a load-bearing role are needed, it is better to choose a channel made by cold rolling.

Channels, like other metal products, must be stored in specially equipped places. Before transporting them, they are tied with steel wire and then transported on trucks. Products are shipped by weight or footage.

What are channels made of?

The most durable and rigid is a stainless steel channel. It has high anti-corrosion properties and can easily serve for decades without a hint of rust. For production, steel grades are used: AISI 304 or its domestic analogue 12Х18Н10, as well as acid-resistant molybdenum steel AISI 316.