Molybdenum (lat. molybdaenum) is a chemical element with atomic number 42 and atomic mass 95.94. Denoted by the symbol Mo. It is a malleable transition metal that is gray with a steely tint when free and turns gray-black when dispersed. About 20 molybdenum minerals have been discovered, but it is not found in free form.

The name of the metal comes from the Greek word “molybdos”, which means “lead”. This name was chosen because the mineral molybdenum has a characteristic luster very similar to that of lead.

In 1778, the Swedish chemist K. Scheele first obtained the mineral molybdenite by calcining molybdic acid. Another Swedish chemist P. Gjelm obtained molybdenum in the form of an impure metal in 1781, and only in 1817 J. Berzelius managed to isolate this element in its pure form.

History and origin of the name

Discovered in 1778 by the Swedish chemist Karl Scheele, who, by calcining molybdic acid, obtained the oxide MoO3.

It was first obtained in the metallic state by P. Guelm in 1782 by reducing the oxide with coal: he obtained molybdenum contaminated with carbon and molybdenum carbide. Pure molybdenum was obtained by J. Berzelius in 1817. The name comes from the Greek. μολυβδος, meaning "lead". It is given because of the external similarity of molybdenite (MoS2), the mineral from which molybdenum oxide was first isolated, with lead luster (PbS). Until the 18th century. Molybdenite was not distinguished from graphite and lead luster; these minerals bore the common name “molybdenum”.

Analysis and synthesis

The new metal and its compounds interested chemists of the 19th century. Pure molybdenum did not change at all during storage; it perfectly resisted the action of moisture and air. But this happened only at low temperatures: as soon as it was heated, it began to react with oxygen; at a temperature of about 500°C it turned into an oxide entirely. This, of course, was upsetting. A metal with good physical and mechanical properties and also refractory lost its metallic properties with relatively little heating. This circumstance (together with the difficulty of obtaining molybdenum metal) long delayed the time when this metal found its first practical application.

Compounds of element No. 42 began to be used much earlier. In 1848, the Russian chemist G.V. Struve, together with the Swede L. Svanberg, studied the properties of molybdic anhydride and the acid it forms. They dissolved MoO3 in a concentrated ammonia solution and added wine alcohol to the resulting solution. A canary-yellow precipitate formed—ammonium molybdate. This salt was destined to play a major role in analytical chemistry.

It was during these years that the science of fertility arose, and it was at this time that, thanks to the work of Liebig and other scientists, agricultural chemistry developed quite rapidly. Special factories began to produce fertilizers containing phosphorus and nitrogen. And we immediately needed reagents with which we could easily and accurately determine the content of these elements in various substances.

The ammonium molybdate obtained by Struve and Svanberg turned out to be an excellent reagent for phosphorus - a reagent that completely precipitates phosphorus from solutions, making it possible to determine its content in any products - fats, metals, ores. The reagent turned out to be so good that today it is readily used in analytical laboratories when it is necessary to determine the phosphorus content in a sample.

Ammonium molybdate has found other uses. It turned out that it has a detrimental effect on microorganisms, and they began to use it as a disinfectant. Initially, silk and cotton fabrics were impregnated with this substance only to extend their service life. But later another feature of the effect of this substance on tissue was discovered.

If a fabric soaked in ammonium molybdate is then pulled through a solution of a reducing agent (tin chloride), then depending on the concentration of the reagents, it turns sky blue or blue. This is generally typical for acidic solutions of molybdic acid salts: under the influence of reducing agents they turn blue. This paint is called molybdenum blue, or mineral indigo. Many recipes have been compiled for dyeing fabrics with molybdenum salts not only blue, but also red, yellow, black, and brown. Wool, fur, leather, wood and rubber were dyed with these salts. Molybdenum compounds were used both for the preparation of varnishes and for painting ceramics. For example, porcelain is colored blue with sodium molybdate, and yellow with the same ammonium molybdate. Orange paint made from molybdate and lead chromate is highly prized.

And molybdenum sulfide, from which pencils were made in ancient times, began to be added to clay, coloring ceramic products yellow or red during firing (depending on the amount of MoS2).

Application

Molybdenum is used to alloy steels as a component of heat-resistant and corrosion-resistant alloys. Molybdenum wire (tape) is used for the manufacture of high-temperature furnaces and electric current inputs in incandescent lamps. Molybdenum compounds - sulfide, oxides, molybdates - are catalysts for chemical reactions, pigments for dyes, and components of glazes. Molybdenum hexafluoride is used when applying metal Mo to various materials, MoS2 is used as a solid high-temperature lubricant. Mo is included in microfertilizers. Radioactive isotopes 93Mo ( T

1/2 = 6.95 h) and 99Mo (

T

1/2 = 66 h) are isotopic indicators.

Molybdenum is one of the few alloying elements that can simultaneously increase the strength, toughness properties of steel and corrosion resistance. Usually, when alloying, along with an increase in hardness, the fragility of the metal also increases. There are known cases of molybdenum being used in the manufacture of edged weapons in Japan in the 11th-13th centuries.

Molybdenum-99 is used to produce technetium-99, which is used in medicine in the diagnosis of cancer and some other diseases. The total world production of molybdenum-99 is about 12,000 curies per week (based on activity on the sixth day), the cost of molybdenum-99 is $46 million per gram ($470 per 1 Ci).

In 2005, world supplies of molybdenum (in terms of pure molybdenum) amounted, according to Sojitz Alloy Division, to 172.2 thousand tons (in 2003 - 144.2 thousand tons). Pure single-crystal molybdenum is used to produce mirrors for high-power gas-dynamic lasers. Molybdenum telluride is a very good thermoelectric material for the production of thermoelectric generators (thermo-emf 780 µV/K). Molybdenum trioxide (molybdenum anhydride) is widely used as a positive electrode in lithium power sources.

Molybdenum is used in high-temperature vacuum resistance furnaces as heating elements and thermal insulation. Molybdenum disilicide is used as heaters in furnaces with an oxidizing atmosphere operating up to 1800 °C.

Hook-holders for the filament body of incandescent lamps, including general-purpose incandescent lamps, are made from molybdenum.

Molybdenum wire with a diameter of 0.05-0.2 mm is used in wire EDM machines for cutting metals with very high accuracy (up to 0.01 mm), including workpieces of large thickness (up to 500 mm). Unlike copper and brass wire, which are used once in such machines, molybdenum wire is reusable (~300-500 meters is enough for 30-80 hours of continuous operation), which somewhat reduces the accuracy of processing, but increases its speed and reduces its cost.

Production, deposits

Molybdenum is a rare metal. In nature, its presence in its pure form is impossible.

Almost two dozen molybdenum-containing minerals are known:

| Mineral | Ore-forming metal content |

| Molybdenite | 57-60% |

| Ferrimolybdite | 40-60% |

| Will command | 48% |

| Wulfenite | 27–46% |

| Zeirigit | Up to 24% |

Other molybdenum-containing ores (chillagite, comosite, kechlinite, jordisite and others) are not of interest for industrial use.

Significant metal deposits belong to:

- USA;

- Chile;

- Canada;

- Kazakhstan;

- Peru;

- China.

The ranking of molybdenum ore production is headed by China, the USA is in second place by a wide margin, and Chile is in third place.

The State Balance of Mineral Reserves of the Russian Federation lists 34 molybdenum deposits.

The origin of molybdenum ores is from skarn, greisen, and hydrothermal deposits.

The content of rare metal in the earth's crust is only 0.02%. But it is necessary for the existence of humans as a biological species. But there is suspiciously a lot of molybdenum in space. Red giants are especially rich in it - old stars, for which “everything is in the past.”

General information:

| 100 | General information | |

| 101 | Name | Molybdenum |

| 102 | Former name | |

| 103 | Latin name | Molybdaenum |

| 104 | English name | Molybdenum |

| 105 | Symbol | Mo |

| 106 | Atomic number (number in table) | 42 |

| 107 | Type | Metal |

| 108 | Group | Transitional, heavy metal |

| 109 | Open | Karl Wilhelm Scheele, Sweden, 1778 |

| 110 | Opening year | 1778 |

| 111 | Appearance, etc. | Shiny silver-white metal |

| 112 | Origin | Natural material |

| 113 | Modifications | |

| 114 | Allotropic modifications | |

| 115 | Temperature and other conditions for the transition of allotropic modifications into each other | |

| 116 | Bose-Einstein condensate | |

| 117 | 2D materials | |

| 118 | Content in the atmosphere and air (by mass) | 0 % |

| 119 | Content in the earth's crust (by mass) | 0,00011 % |

| 120 | Content in seas and oceans (by mass) | 1,0·10-6 % |

| 121 | Content in the Universe and space (by mass) | 5,0·10-7 % |

| 122 | Abundance in the Sun (by mass) | 9,0·10-7 % |

| 123 | Content in meteorites (by mass) | 0,00012 % |

| 124 | Content in the human body (by weight) | 0,00001 % |

Physical properties

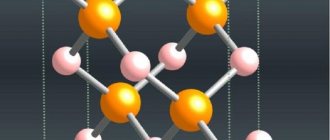

Molybdenum is a light gray metal with a body-centered cubic lattice of the α-Fe type (a = 3.14 Å; z = 2; space group Im3m), paramagnetic. Mechanical properties, as with most metals, are determined by the purity of the metal and previous mechanical and thermal treatment (the purer the metal, the softer it is). Has an extremely low coefficient of thermal expansion.

Physical and mechanical properties

Property Meaning

| Atomic number | 42 |

| Atomic mass | 95,94 |

| Unit cell parameter, nm | 0,31470 |

| Atomic diameter, nm | 0,272 |

| Density at 20°C, g/cm3 | 10,2 |

| Melting point, °C | 2610 |

| Boiling point, °C | 4612 |

| Heat of fusion, kJ/mol: | 28 |

| Heat of evaporation, kJ/mol: | 590 |

| Molar volume, cm³/mol: | 9,4 |

| Specific heat capacity, J/(g K) | 0,256 |

| Thermal conductivity, W/(m K) | 142 |

| Linear expansion coefficient, 10-6 K-1 | 4,9 |

| Electrical resistance, µOhm cm | 5,70 |

| Young's modulus, GPa | 336,3 |

| Shear modulus, GPa | 122 |

| Poisson's ratio | 0,30 |

| Hardness, HB | 125 |

| Spark color | Short yellow intermittent beam of sparks |

| Group of metals | Refractory metal |

Chemical properties

Molybdenum, the chemical properties of which are given below, has the following characteristics:

- valence radius - 130·10-12 m;

- ionic radius - (+6e) 62 (+4e) 70·10-12 m;

- electrical negativity - 2.15;

- electric potential – 0;

- valence during oxidation - 2-3-4-5-6

- molybdenum valence – 6;

- oxidation onset temperature - 400°C;

- oxidation to MoO3 at a temperature of - 600°C and above;

- reaction with hydrogen is neutral;

- reaction temperature with chlorine – 250°C;

- reaction temperature with fluorine – room temperature;

- reaction temperature with sulfur – 440°C;

- reaction temperature with nitrogen is 1500°C.

With oxygen, the element forms two main oxides:

- MoO3 – white crystalline form

- MoO2 is silver in color.

Molybdenum MoS2

Solubility properties of molybdenum in chemical solutions: soluble in alkalis and acids when heated. This helps to obtain various compounds or purify it.

Where is molybdenum used?

In history, the very first use of molybdenum was recorded in Japan back in the 10-13th century. There is a possibility that in those distant times, this metal served as a material for the manufacture of edged weapons.

Today the molybdenum industry is a fairly developed industry. And, in addition to the fact that pure molybdenum and its alloys continue to be produced at present, there are also many grades of it, each of which is intended for specific purposes. The most famous brands of molybdenum:

- MP is pure molybdenum without additives. This brand is used to produce tungsten filament holders, incandescent filaments, and generator lamp anodes.

- MChVP is pure molybdenum without additives, produced by vacuum melting.

- MRN - molybdenum for various purposes, does not contain additives, includes a larger number of impurities compared to the MCh and MChVP brands. Intended for use in the production of high-temperature heaters, screens, electrical inputs into vacuum devices and installations.

- MK - contains a silicon-alkaline additive.

- CM - zirconium and/or titanium are used as an additive.

- MR is an alloy of molybdenum and rhenium.

- MV is an alloy of molybdenum and tungsten.

Thus, after centuries, molybdenum has become an indispensable component in many industrial sectors. It applies:

- as an alloying element of steel;

- in the production of heat-resistant alloys, which aviation, rocket and nuclear technology cannot do without;

- for the production of alloys with anti-corrosion properties;

- during the production of parts for electric vacuum devices, filaments of incandescent lamps;

- for the manufacture of turbine blades;

- in power nuclear reactors;

- as lubricants and as a hydrogenation catalyst;

- in the production of paints and varnishes;

- in the chemical and petroleum industries, as well as in metallurgy.

Grades of molybdenum and its alloys

Molybdenum alloys are more often used in industry than pure metal. Among them are:

- metal with a purity of 99.96%, which is used for the production of electronic devices, is labeled MCH;

- metal obtained by melting under vacuum is marked molybdenum MChVP;

- for the production of wire used in light sources, metal under the MRN brand is used, where its content is 99.92%;

- when adding an additive, silicon alkali, molybdenum is marked MK;

- zirconium (Zr) or titanium (Ti) is introduced into Mo - grade CM;

- with the introduction of rhenium - MR;

- tungsten with Mo – MV.

Electricity and radio engineering

The filaments of conventional electric lamps are made of tungsten, which is more refractory than all other metals and gives the greatest light output. But if you solder a tungsten filament into a glass rod in the center of a light bulb, it will soon crack due to thermal expansion of the filament.

When the physical properties of molybdenum were studied, they found that it has a negligible coefficient of thermal expansion. When heated from 25 to 500° C, the dimensions of the molybdenum part will increase by only 0.0000055 of the original value. And even when heated to 1200°C, molybdenum hardly expands. Therefore, tungsten filaments began to be suspended on molybdenum hooks soldered into glass. Subsequently, molybdenum played an even greater role in electric vacuum technology. Electric current is supplied to vacuum devices through molybdenum rods, soldered into a special glass that has the same coefficient of thermal expansion as molybdenum (this glass is called molybdenum glass).

Application of alloys with molybdenum

When niobium, titanium and other super-strong metals are added to molybdenum, the heat resistance of the alloys increases. This composition can be used to create parts for gas turbines and combustion chambers in rocketry.

In alloys containing a large amount of molybdenum (17-28%), corrosion resistance increases. They are not afraid even of interaction with any acid (except hydrofluoric acid).

The refractory properties of molybdenum and its use in the creation of special pipes are of great importance in nuclear energy. Such products can withstand the effects of molten lithium. It acts as a coolant in uranium reactors. In addition, molybdenum itself, in the form of the Mo-99 isotope, has found use as an indicator in the nuclear industry.

Due to the refractoriness of molybdenum, it is used to create molds for casting parts from copper, aluminum and zinc. The high strength of the metal allows processes to be carried out under high pressure.

Heat-resistant alloys

The technology of ultra-high-speed and space flights poses the task of metallurgists to obtain increasingly heat-resistant materials. Strength at high temperatures depends primarily on the type of crystal lattice and, of course, on the chemical nature of the material. The operating temperature limit for titanium alloys is 550-600° C, molybdenum alloys - 860, and titanium-molybdenum alloys - 1500° C!

How can we explain such a significant jump? Its reason is in the structure of the crystal lattice. Foreign atoms are introduced into the body-centered structure of molybdenum, this time titanium atoms. The result is a so-called interstitial solid solution, the structure of which can be represented as follows. Atoms of molybdenum, the base metal, are located at the corners of the cube, and atoms of the added metal, titanium, are located in the centers of these cubes. Instead of a body-centered crystal lattice, a face-centered one appears, in which the processes of softening under the influence of temperatures occur much less rapidly.

This purposeful change in the crystal structure of metals is one of the basic principles of alloying.

Another reason for such a sharp increase in heat resistance lies in the fact that very dissimilar metals are fused - molybdenum and titanium. This is a general rule: the greater the difference between the atoms of the alloying metal and the base metal, the stronger the bonds formed. The metallic bond is, as it were, complemented by the chemical one.

Alloying, however, is not the last word in solving the problem of heat-resistant alloys. Already in our time, the extraordinary properties of threadlike crystals, or “whiskers,” have been discovered. Their strength, compared to metals commonly used in technology, is amazingly high. This is explained by the fact that the crystalline structure of the whiskers is practically free of defects, and the technology of ultra-high-speed flights takes the whiskers into service, creating composite heat-resistant materials with their help. One of these materials is aluminum oxide reinforced with molybdenum whiskers, the other is technical titanium stuffed with the same reinforcement. Compared to conventional titanium, this material can last 1000 times longer under harsh conditions.

What can be opposed to a fiery tornado that hits a spaceship upon entering the dense layers of the atmosphere? First of all, heat-protective coating and cooling. Yes, cooling, similar in principle to cooling car engines using radiators. Only more energy-intensive processes must work here. A lot of heat is needed to evaporate substances, but even more for sublimation - transfer from a solid state directly to a gaseous state. At high temperatures, molybdenum, tungsten, and gold can sublimate. Coating the bow of the ship with molybdenum or other of the listed (more expensive) metals will significantly weaken the force of the firestorm through which the spacecraft's return vehicle must pass.

Other industries

The lion's share of products made from molybdenum and metal alloys is taken by manufacturers of radio and electric lamps, radio electronics.

There is enough material for other purposes:

- Molds, machine parts for injection molding of alloys.

- Electrovacuum production (X-ray tubes).

- Positive electrode of lithium-based current sources.

- Shells of nuclear reactor parts.

- Heaters for electric furnaces operating in harsh conditions.

- The outer layer of the “nose” segment of the body of supersonic aircraft.

- Electrodes for glass melting.

- Catalysis of chemical reactions.

- Varnishes, paints for porcelain, textiles, furs.

These products are created on the basis of natural compounds and metal alloys.

The newest area of application of molybdenum is space technology.

Assortment: components of rocket (ion, plasma) engines; skin of descent vehicles; heat exchangers. Here, the properties of molybdenum are corrected by alloys with niobium and tantalum.

Pure crystalline Mo is used as a component of mirrors for special purpose lasers.

Microdoses of metal are added to agricultural fertilizers.

Crystal lattice of molybdenum:

| 500 | Crystal cell | |

| 511 | Crystal grid #1 | |

| 512 | Lattice structure | Cubic body-centered |

| 513 | Lattice parameters | 3.147 Å |

| 514 | c/a ratio | |

| 515 | Debye temperature | 450 K |

| 516 | Name of space symmetry group | Im_ 3m |

| 517 | Symmetry space group number | 229 |

Advantages/disadvantages

- Advantages:

- has a high melting point, and therefore heat resistance;

- because the density of this metal (10200 kg/m3) is almost two times less than the density of tungsten (19300 kg/m3), then molybdenum-based alloys have significantly greater specific strength (at temperatures below 1370 °C);

- has a high elastic modulus;

- low temperature coefficient of expansion;

- has good heat resistance;

- small cross section for thermal neutron capture;

- Molybdenum is characterized by high corrosion resistance. This metal is stable in most alkaline solutions, as well as in sulfuric, hydrochloric and hydrofluoric acids at different temperatures and concentrations.

- Flaws:

- has little scale;

- high fragility of welds;

- low plasticity at low temperatures;

- work hardening can be used only up to 700-800 °C; at higher temperatures, softening occurs due to return.

Biological role

The physiological significance of molybdenum for the animal and human body was first demonstrated in 1953, with the discovery of the influence of this element on the activity of the enzyme xanthine oxidase. Molybdenum promotes (makes it more effective) the work of antioxidants, including vitamin C. An important component of the tissue respiration system. Strengthens the synthesis of amino acids, improves nitrogen accumulation. Molybdenum is part of a number of enzymes (aldehyde oxidase, sulfite oxidase, xanthine oxidase, etc.) that perform important physiological functions, in particular, the regulation of uric acid metabolism. Molybdenum enzymes catalyze the hydroxylation of various substrates. Aldehyde oxidase oxidizes and neutralizes various pyrimidines, purines, and pteridines. Xanthine oxidase catalyzes the conversion of hypoxanthines to xanthines, and xanthines to uric acid. Sulfite oxidase catalyzes the conversion of sulfite to sulfate.

A lack of molybdenum in the body is accompanied by a decrease in the content of xanthine oxidase in tissues. With a lack of molybdenum, anabolic processes suffer, and a weakening of the immune system is observed. Ammonium thiomolybdate (soluble molybdenum salt) is a copper antagonist and disrupts its utilization in the body.

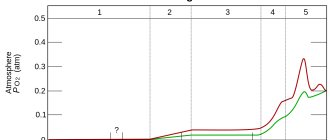

Nitrogen cycle

Molybdenum is part of the active site of nitrogenase, an enzyme for fixing atmospheric nitrogen (common in bacteria and archaea).

Microelement

Micro amounts of molybdenum are necessary for the normal development of organisms; it is used as part of microelement nutrition, in particular, for berry crops.

Affects reproduction (in plants).

Molybdenum Processing

Processing of molybdenum is difficult due to its low viscosity at low temperatures. It also has low ductility, so the following methods are used for its processing:

- hot deformation:

- forging;

- rolling;

- broach;

- heat treatment;

- mechanical restoration.

When processing small workpieces, crimping machines are used. Large billets are rolled on small mills or shaped on broaching machines.

Appearance of molybdenum

If there is a need for machining by cutting, then machining of molybdenum is carried out with a tool made from high-speed steel grades. The sharpening of tool corners during turning should correspond to the sharpening angles for machining cast iron.

The heat treatment of molybdenum is characterized by high hardenability due to its content in steels. The hardening carried out increases the hardness and wear resistance of critical parts.

Being in nature

The occurrence of free molybdenum in nature has not been recorded. But two dozen minerals based on it have been identified. The most notable: molybdenite, molybdite, wulfenite.

Molybdenite from Australia

In the earth's crust the element is distributed evenly. Also found in rivers, seas, fossils of organic origin (plant ash, coal, oil). However, the total mass content of the metal is hundredths of a percent.

World reserves of molybdenum are estimated at 11.5 million tons.

Australia and both Americas (USA, Canada, Mexico, Chile) have large deposits. In Europe – Russia and Norway.

Mining is carried out using closed or open-pit methods.

Metal discovered in space. Its concentrations are off the charts in systems with a central star - a red (super) giant and a neutron star inside it.

Molybdenum Products

The industry produces a wide variety of products. The most common are molybdenum wire, molybdenum rods, molybdenum powder, rod, sheet. Molybdenum rods, as well as wire and tape, are used for the manufacture of heaters for high-temperature electric furnaces. In addition, rods are used for the manufacture of bushings for electric vacuum devices. The wire has found application in the production of high-temperature thermocouples, incandescent lamps, receiving-amplifier and generator lamps, and X-ray tubes. The sheets are used as a structural material for the production of products in the aviation and space industries. Molybdenum powder acts as an alloying additive to various steels and alloys. It is also the starting material for the production of compact molybdenum.

Application: from light bulb to rocket

- Most molybdenum products are consumed by radio electronics.

- The use of metal in rocket technology is increasing: for lining reentry rockets and capsules, in rocket engine nozzles, in solid fuel rockets.

- Molybdenum wire is used for the production of thermocouples, incandescent lamps, and heaters for high-temperature electric furnaces.

- Molybdenum tapes and wires are in demand in the lighting industry; they are used to make electrodes for melting glass.

- The use of molybdenum and its alloys is widespread in nuclear energy, in the production of cooling pipelines, and shells of fuel assemblies.

- More than 2/3 of the produced metal is used in metallurgy, as an alloying additive to steel.

- Molybdenum sulfide is an excellent high-temperature lubricant for parts, it is used to coat bullets, and it is used in the production of ceramics as an additive to clay (to produce blue or red colors).

We recommend: BARIUM - from Chinese blue to fluoroscopy

Metal forming is simpler than similar processing of tungsten.

Molybdenum alloys

Two alloys based on this metal are used: tungsten (MV) and rhenium (MR).

Alloys of molybdenum with tungsten are necessary to increase the heat resistance of the former. At the same time, deformability deteriorates and specific gravity increases. Such alloys contain from 48% tungsten and from 49 to 51% molybdenum, the rest are impurities. MV is refractory, has high strength and corrosion resistance. Used to make thin wire that is rolled into coils or coils.

Rhenium is necessary to increase the ductility of molybdenum. MR alloys contain more than 50% rhenium and about 47% molybdenum. They are also used to produce thin wire, which is used in special instrument making.

Main grades of molybdenum

The industry uses pure molybdenum and with various additives. Among the most common are the following brands:

Production stages:

- The concentrate is subjected to oxidative roasting at a temperature of 600 ⁰C. The output is molybdenum oxide, which contains a significant amount of impurities.

- The oxide is purified from impurities by distilling or leaching the cinder and further neutralization.

- Molybdenum metal powder is produced from pure oxide in a tube furnace. For this process, a current of dry hydrogen is used.

- The powder is turned into metal. Typically, one of two methods is used for this - smelting or powder metallurgy.

To obtain ferromolybdenum, a reduction reaction is used to reduce molybdenite concentrate, which is preliminarily roasted.

Molybdenum in the human body

Molybdenum is one of the microelements necessary for humans. It is found mainly in the bones, kidneys and liver, as well as in the brain, thyroid and pancreas, and adrenal glands.

The role and functions of molybdenum for the body:

The daily requirement for molybdenum ranges from 70 to 300 mcg, depending on body weight. In case of microelement deficiency in the body and diseases caused by it, the daily norm increases.

Obtaining molybdenum

The raw materials from which metallic molybdenum is produced are molybdenum concentrates. They contain about 50% of this element. They also contain: sulfur ~ 30%, silicon oxide (up to 9%) and about 20% of other impurities.

The concentrate is pre-fired for additional oxidation. The process is carried out in two types of furnaces: multi-hearth or fluidized bed. Firing temperature 570 °C - 600 °C. The result is cinder - MoO3 and impurities.

In the next step, impurities are removed to obtain pure molybdenum oxide. Two methods are used:

- Sublimation at a temperature of 950 °C - 1100 °C.

- Chemical leaching. The essence of the method is that when interacting with ammonia water, impurities of copper and iron are eliminated and molybdenum carbide is obtained, which is crystallized by evaporation or neutralization. Next, the carbide is heated and maintained at temperatures up to 500°C. The output is pure MoO3 oxide, in which the impurity content is only 0.05%.

Molybdenum production is based on the reduction of MoO3. The process is carried out in two stages:

- In a tube furnace at a temperature of 550°C - 700°C, oxygen atoms are separated in a flow of dry hydrogen.

- Then the temperature rises to 900°C - 1000°C and final recovery occurs. The resulting metal is in powder form.

To obtain a monolithic metal, powder is melted or sintered. Melting is used when producing workpieces weighing more than 500 kg. The process is carried out in arc furnaces with a cooled crucible, into which a consumable electrode is supplied from previously sintered rods.

Obtaining molybdenum

Powder sintering is pressing in a hydrogen atmosphere at high pressure (2000-3000 atmospheres) and temperature (1000°C - 1200°C). The resulting bars are subjected to sintering at high temperatures equal to 2200°C - 2400°C. Subsequently, molybdenum is given the required shape through pressure treatment - forging, rolling, broaching.

Ferromolybdenum, which contains up to 60-70% molybdenum and the rest is iron, is widely used in industry. It is obtained by introducing molybdenum additives into steel. The alloy is produced by reducing cinder with iron silicate with the addition of steel filings and ferrous ore.

Daily norm of molybdenum

Depending on many indicators, the body requires molybdenum in different quantities. Adults require an average of 70 to 250 mcg per day, but this varies depending on age, gender, health status and lifestyle.

Children need a minimum of 15 mcg of metal each day, taking into account the child's physical activity and weight.

Women need a minimum of 70 mcg of molybdenum per day. Moreover, pregnancy and breastfeeding are not indicators for increasing the dosage.

Men also need a minimum of 70 mcg of the element per day. This amount is sufficient to prevent the occurrence of diseases that can be caused by a lack of molybdenum, as well as to increase potency.

Elderly people over 75 years old need to reduce the dosage of the element by a quarter (the maximum dose should not exceed 200 mcg).

Molybdenum deficiency

Deficiency of the substance is rare, but still a phenomenon encountered in the practice of doctors. It can be recognized by the following symptoms:

- increased nervous excitability;

- rapid heartbeat;

- decreased activity of enzymes that contain this metal;

- decreased clarity of vision, poor vision at dusk.

With a long-term shortage of the substance, serious consequences can occur:

- stopping normal brain development;

- insufficient metabolism of nitrogen, cysteine;

- increased risk of developing esophageal cancer;

- mental retardation;

- reducing the amount of secreted uric acid and inorganic sulfate compounds;

- poor eyesight;

- disturbance in the body's elimination of sulfates;

- slow catabolism of methionine;

- formation of urolithiasis;

- accumulation of copper compounds in the body with subsequent poisoning;

- reduced breakdown of cellulose;

- slower growth and development in children.

What causes an element deficiency? There may be several main reasons:

- long-term intravenous nutrition in people with impaired functioning of the gastrointestinal tract or during a long stay in intensive care;

- a very strict vegetarian diet without a balanced diet;

- problems in the intestines with impaired absorption;

- frequent stress and anxiety, which increases the body’s need for sulfite oxidase;

- high concentrations of tungsten in the blood.

Signs of element deficiency can be eliminated after introducing a sufficient amount of products containing molybdenum or special preparations into the diet.

Properties of the molybdenum atom:

| 200 | Properties of the atom | |

| 201 | Atomic mass (molar mass) | 95.96(2) amu (g/mol) |

| 202 | Electronic configuration | 1s2 2s2 2p6 3s2 3p6 3d10 4s2 4p6 4d5 5s1 |

| 203 | Electronic shell | K2 L8 M18 N13 O1 P0 Q0 R0 |

| 204 | Atomic radius (calculated) | 190 pm |

| 205 | Empirical atomic radius* | 154 pm |

| 206 | Covalent radius* | 154 pm |

| 207 | Ion radius (crystalline) | Mo3+ 83 (6) pm, Mo4+ 79 (6) pm Mo5+ 75 (6) pm, Mo6+ 73 (6) pm (in parentheses the coordination number is indicated - a characteristic that determines the number of nearest particles (ions or atoms) in a molecule or crystal) |

| 208 | Van der Waals radius | |

| 209 | Electrons, Protons, Neutrons | 42 electrons, 42 protons, 54 neutrons |

| 210 | Family (block) | d-family element |

| 211 | Period in the periodic table | 5 |

| 212 | Group on the periodic table | 6th group (according to the old classification - a secondary subgroup of the 6th group) |

| 213 | Emission spectrum |