Jaw crusher working principle

Today, many industries and production processes use crushed solid materials - stone, concrete, various rocks and even metal. The process of obtaining small fractions from large pieces is called crushing. And special equipment is used to crush stone - crushers.

Crushers can have a variety of designs. They differ in operating principles and are designed based on different diagrams and drawings. One type of crusher is the jaw crusher. We'll talk about its structure further.

Working principle of jaw crusher

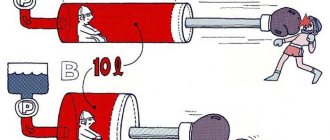

The operating principle of a jaw crusher is that solid materials are crushed by compressing two surfaces - the jaws. One cheek is motionless, it is securely fixed. The second surface is movable; it is set in motion using a special mechanism. If you look at the diagram of a jaw crusher, you can see that the surfaces are located at an angle to each other.

Jaw crusher operating diagram

Technical characteristics suggest the possibility of crushing even large lump materials. The movable cheek makes reciprocating movements. As a result, the angle between the crusher surfaces changes. When the cheeks are retracted to the maximum, large pieces of stone or concrete fall, and small pieces that have already been crushed fall even lower. Thus, during the working cycle in the jaw crusher, it is possible to achieve uniform grinding of solid materials.

Jaw crusher circuit

The design of most jaw crushers suggests the ability to adjust the distance between the working surfaces. Thanks to this, the installation can grind materials with different initial fractions and at the output get crumbs with pieces of different sizes.

Depending on the design of the jaw crusher, it can be used to crush the following fractions:

The linear dimensions of solid pieces for crushing can reach up to 1.5 m. At the same time, for small jaw crushers, the technical specifications provide for crushing to fractions of 1 cm in size.

One of the important characteristics of jaw crushers is the maximum degree of crushing. This technical indicator indicates how many times the crushed pieces will be smaller than the original ones. For a jaw crusher with maximum productivity, the degree of crushing can reach up to eight, although in practice for most installations this figure is from 3 to 6. It is less for machines designed for crushing rocks, but for crushers for concrete and cement it is close to six.

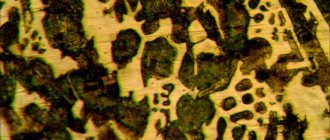

Considering the design and operating principle of jaw crushers, it is clear that the cheeks are subject to the most wear. They usually have a ribbed, corrugated surface, which provides the best crushing of stone, concrete, etc. By regularly updating spare parts for crushers and installing new jaws, you can achieve maximum productivity - and obtain crushed materials of predictable quality.

How does a jaw crusher work?

Such devices crush hard materials by squeezing two parts of the mechanism, called jaws. These are different surfaces, one of which is securely fixed and does not move. The second is movable, launched by a special mechanism. The devices are powerful - with their help you can crush even materials of large fractions. When the movable jaw moves, the pieces are crushed and fall down, the solid material is crushed evenly.

The distance between these surfaces is adjustable. Thanks to this, using such equipment you can grind pieces of different sizes.

One of the important parameters is the highest degree of crushing. This characteristic allows you to understand what size the resulting pieces will be. The degree of crushing in high-performance devices reaches eight. For most installations this figure is slightly lower. It is worth buying a jaw crusher that will meet your needs.

It is also worth paying attention to the cheeks - precisely the part of the device that is subject to the greatest wear. They usually have a ribbed surface, which guarantees rapid grinding of various materials. Their condition must be monitored and replaced if necessary.

Jaw crusher device, operating principle.

A crusher, as you know, is any equipment designed for crushing, that is, mechanical impact on solid materials with the aim of breaking them down and resulting in smaller pieces. The non-standard equipment plant “Machine Industrial Association” designs and manufactures equipment for processing plants and mining and processing plants, including crushers, including jaw crushers.

One of the most important processes in the technology used in the beneficiation of minerals is crushing, and the important equipment involved in this process is crushing equipment or crushers. In this material we will talk about jaw crushers - these are crushers that use compression between special flat surfaces called cheeks to destroy material.

One crushing surface is stationary, and crushing occurs due to the approach of the movable cheek to the stationary one. In this case, the crushing surfaces are located at a slight angle relative to each other and come closer to each other in the lower part.

The moving crushing surface of the jaw crusher performs reciprocating movements, thereby alternately reducing or increasing the gap between the jaws, which leads to the occurrence of large compressive and shear stresses that destroy the material.

Large pieces of crushed material are fed into the working space between the jaws of the crusher under a compressive load, and when the moving jaw approaches the stationary one, they are crushed into smaller pieces. During the removal of the movable cheek from the stationary one, the already crushed pieces of crushed material fall down, and the larger pieces remaining above, in turn, fall to the free space and are crushed again during the next cycle of approach of the movable cheek. By adjusting the width of the gap between the jaws and the frequency of their approach, you can influence the final size of the crushed material at the outlet and the consumption of the crushed product.

Thus, jaw crushers belong to the group of machines with intermittent pressing and free discharge under the influence of gravity of crushed products.

Jaw crushers:

Jaw crushers use the method of compressing the jaws, which are two working surfaces tapering towards the bottom of the structure, one of which is stationary, and the other, mounted on a connecting rod, moves back and forth, which leads to the destruction of raw materials due to the strong stress created by pressure surfaces of the cheeks on both sides onto the material arriving from top to bottom under the force of gravity.

To control the size of the resulting material, the distance of the gap from which the crushed material comes out is adjusted by adjusting the lower edge of the moving jaw.

During intensive work, the working surfaces and elements of crushing equipment can wear out greatly, so spare parts for crushers need to be updated in a timely manner.

Purpose of jaw crushers.

Jaw crushers are universal machines for crushing materials. It is used for crushing rocks of any strength, slag, as well as some metal materials.

Jaw crushers are used in all crushing areas: coarse, medium and fine. The input size of crushed material can reach 1500 mm. The finished product size for small jaw crushers can be 10 mm.

In technological processes of the mining industry, jaw crushers are used mainly for large (1500-350 mm) and medium (350-100 mm) crushing of ferrous and non-ferrous metal ores, coal, shale, non-metallic and other minerals.

Jaw, hammer, roller, cone and rotary crushers.

Crusher is a device for crushing large solid pieces of materials to the desired size using mechanical action (the fraction yield is usually at least 5 mm). To obtain a finer fraction of the material, equipment such as mills is used.

Crushing equipment is a mobile or stationary structure of various types and configurations that can be used for: crushing rocks, construction waste, household waste and other materials.

The description of the various types of crushers below is written in general terms, since each can be divided into subtypes.

Types of crushers

Jaw crushers

Hammer crushers

Roll crushers

Cone crushers

Impact crushers

Design of jaw crushers.

Now let's talk in more detail about the design features of jaw crushers. Despite the wide variety of specific design features, most modern jaw crushers are based on designs developed more than 100 years ago. In the USSR, jaw crushers were produced according to GOST 7084-85, in Russia according to GOST 27412-93.

The basic operating principle of a jaw crusher is quite simple. The crushing chamber is arranged in the shape of a wedge; it is formed by two crushing surfaces, also called “cheeks”. One of the jaws of the crusher is stationary, and the second jaw is mounted on a connecting rod, which ensures the movement of the upper edge of the jaw so that the latter makes a swinging movement.

The material to be crushed is fed into the crushing chamber from above. Due to the wedge-shaped shape of the crushing chamber, pieces of material are initially located along the height of the chamber, depending on their size from top to bottom.

The connecting rod shaft is driven into rotation through a V-belt drive from an electric motor or diesel engine. In the process of bringing the cheeks closer together, during compression, pieces of material are crushed; when the movable cheek moves away (idling), the crushed pieces move down under the influence of gravity. As soon as the size of the pieces reaches a given value (reduced to the size of the outlet), they leave the crushing chamber, and larger pieces are dropped in their place. Then the cycle repeats.

The design of the movable cheek allows for the horizontal position of the lower edge to be adjusted. In this way, the size of the outlet slot is fixed, which determines the maximum size of the crushed material at the exit from the jaw crusher. The side walls of the crushing chamber of the jaw crusher are not involved in the crushing process.

Quality materials must be used to manufacture crushers. Beds are most often made of steel grade 35L or St3. The most worn parts of crushers are the jaws; they are made of 35L steel. The working surface of the cheeks is lined with plates of high-manganese steel 110G13L. The plates have grooves, which makes it easier to crush pieces of ore. The eccentric shaft and the axis of the movable cheek are made of steel 40X, the tension spring is made of steel 60C2, the connecting rod is made of steel 25L, the wedge and slider of the adjusting device are made of steel 25GL. Crackers are also made of high-strength steel. Spacer plates and flywheels of crushers are cast from cast iron grades SCh-18-36 or SCh-24-34.

The design of the jaw crusher must ensure:

- 24-hour operation with stops for maintenance;

- protection of lubricated surfaces from dust;

- start from own drive;

- protection of parts (except for the safety part itself) from damage when non-crushable bodies enter the crushing chamber;

- no emission of crushed material during operation;

- safe access to fastening points for wearing parts, adjustment and lubrication;

- the possibility of attaching individual or standard shelters manufactured by the consumer to the frame for suction of dusty air in the area of loading and unloading materials;

- local and remote control of crusher mechanisms.

The nature of the movement of the movable jaw depends on the kinematic features of the jaw crusher mechanism. During the use of these crushers for processing various materials, a large number of very diverse kinematic schemes of the jaw crusher mechanism have been proposed.

All of them can be divided into two large groups:

- ShchDP is a jaw crusher with a simple movement of the jaw, the trajectories of movement of the points of the movable jaw of which are straight lines or parts of a circular arc. The main method of destruction of pieces in SHDP is crushing.

- ShchDS is a jaw crusher with a complex movement of the jaw; the trajectory of the points of the movable jaw are closed curves, most often ellipses. The main method of destruction of pieces in the ShchDS is crushing and abrasion. ShchDS-I is a jaw crusher with a ratio of the length of the receiving opening to its width of more than 1.6.

- ShchDS-II is a jaw crusher with a complex jaw movement and a ratio of the length of the receiving opening to its width of up to 1.6.

Each of the two main types of jaw crushers has its own advantages and disadvantages.

Types of jaw crushers

This type of technology can have different characteristics. The selection of a suitable crusher option is carried out based on the production tasks, as well as on the basis of the physical properties of the processed composite. In many ways, the latter factor is also determined by the method of extracting the material, as well as its geology.

An important role when choosing jaw crushers is played by the price-quality ratio of this equipment. Based on this, the following types are most widely used:

- Crushers with simple jaw movement;

- Models with complex movement of the shaft and working surface;

- Jaw crusher with roller.

Operating principle of a jaw crusher - application The basic operating principle of a jaw crusher is quite simple. The crushing chamber is arranged in…

Crushers with a simple movement of the movable jaw (SMJ).

The crusher with a simple movement of the movable jaw is installed on a frame, in the side walls of which the main bearings of the eccentric shaft are fixed. A connecting rod is suspended from the eccentric part of the shaft. At the bottom of the connecting rod there are grooves for installing the support blocks of the spacer plates. When the eccentric shaft rotates, the connecting rod receives a rocking motion, which is transmitted to the movable cheek using spacer plates. The cheek receives a pendulum movement centered on the suspension axis. Fixed and movable crushing plates are fixed on the cheeks.

The width of the exit slot is adjusted by installing additional spacers of varying thickness between the stop and the rear wall of the frame, a system of wedges on screws, or replacing the rear spacer plate with a longer or shorter one.

Jaw crushers

Jaw crushers are excellent at processing hard ore and non-metallic materials of medium and large size. Since durable materials are characterized by a high degree of abrasiveness, the main working elements of the crusher: plates, armor - are made of manganese steel. The slabs have a large flat surface, it was this factor that became the basis for the name of the device - cheeks. The jaws of the crusher are driven by an eccentric shaft. Jaw crusher exit slot width

largely determines the output dimensions of crushed material. With the help of simple rocking, the material is crushed by crushing it between the cheeks. More technologically advanced jaw crushers and, accordingly, having a more complex kinematic design can not only perform rocking movements, but also translational ones, i.e. make compound movements, thereby increasing the degree of reduction in material size. You need to understand that the working surface of a jaw crusher wears out quite quickly, especially if it performs complex movements. It is very important not to overload the crusher, since overloading may cause jamming and, accordingly, its emergency stop. Cleaning the jaw crusher after this is not easy, but more and more often a crusher is used for this purpose, installed permanently near the crusher.

As a rule, an industrial jaw crusher can crush from ten to several hundred cubic meters of material per hour.

Crushers with a complex movement of the movable jaw (SMC).

The crusher with complex jaw movement has a specially designed movable jaw. Due to the eccentric fastening of the upper end, the cheek has a complex movement: at the upper support it makes circular movements, and at the bottom, at the unloading end, it makes elliptical movements. As a result, pieces of ore are subjected not only to crushing, but also to abrasive action.

To adjust the width of the exit slot, a device with a vertical adjusting wedge is used, which is raised and lowered by a screw. A casing is provided to prevent the crushed material from flying out. The safety device is usually the spacer plate itself, which breaks when the permissible load is exceeded, preventing failure of more critical and expensive crusher components.

The crushing force of crushers with a complex jaw movement is completely transferred to the eccentric of the crankshaft, so crushers of this type are not manufactured in large sizes and are not used for coarse crushing. Jaw crushers of the ShchDS type are used for crushing relatively small, low-abrasive ores with a high content of clay and moisture. The width of the receiving opening usually does not exceed 600 mm, and the exit slot has a width of 20 to 200 mm.

About the advantages and features of work

Jaw crushers are mobile and can absorb large materials at the input - up to 15 cm. For example, if a jaw crusher SM 741 is used, then at the output it is possible to obtain crushed finished material with a particle size of up to 1 cm.

Quarry jaw crusher

Each subtype of jaw crusher has its own maximum possible crushing classes: coarse, fine and medium. They also differ in their characteristics and other features.

For what purposes is it used?

The crushing movable jaw is used for crushing elements such as basalt, quartzite, granite, as well as concrete, various minerals and slag. It can also be used to grind fragile materials: glass, brick, ceramic waste, coal, etc.

A modern movable jaw has such important characteristics as the maximum dimensions of the receiving mechanism, the angle of material capture, and the dimensions of the outlet opening.

What are they responsible for:

- The receiving mechanism determines the maximum dimensions of the input materials;

- The grip angle is adjusted so that the materials to be crushed fall into the grinding mechanism and do not fall out of the chamber;

- The diameter of the outlet hole allows you to determine the maximum dimensions of the raw material at the outlet.

Operating principle of a jaw crusher (SMD and others)

The principle of operation is simple - the input raw material is crushed by splitting it on two heavy plates of durable metal. One such plate always makes translational movements relative to the second, stationary one.

Working principle of jaw crusher

The plate that is securely fastened and does not move is called the fixed one, and the second is called the movable cheek.

Unprocessed raw materials enter the chamber between the plates from the entrance. Its maximum size depends on the diameter of the inlet. As soon as the pieces are crushed by the cheeks, they will immediately fall into a special hole located below.

Immediately after these processes, the crushed materials go to other production lines - fraction sizing, sorting, etc.

In some device models (for example, jaw crusher SMD 109) both plates are movable. This is done to reduce the load on the shaft bearings and reduce the amplitude vibrations of the metal plates.

Such crushers, according to engineers’ plans, should work much more productively and longer. But these devices have a very complex design and, accordingly, are an order of magnitude higher than their predecessors.

Design and principle of operation of a jaw crusher (video)

Choose a jaw crusher or a cone crusher?

Let's start with a comparative analysis between jaw crusher and cone crusher on the following points: crushing ratio, material hardness, material components, max. input size, performance and price.

| Jaw crusher | Cone Crusher | |

| Degree of crushing | Coarse and medium crushing | Medium and fine crushing |

| Raw material hardness | Average | Tough |

| Inlet size | 125-1200 mm | 35-560 mm |

| Performance | 1-2200 HDTV | 12-2181 HDTV |

The price of a cone crusher is much more expensive, and its performance is stronger than that of a jaw crusher with the same gap. For example, if your material is 250mm in size, you need better performance within an adequate budget, it is better to choose a cone crusher because its capacity can be 85-170t/h, whereas a jaw crusher is only 16-105t/h.

Types of jaw crushers

Today the market offers the following crushing machines:

- With cheeks of “simple movement” regarding the axis. Raw materials are crushed by pressure;

- With cheeks of “complex movement”. In addition to the crushing of raw materials, their erasure also occurs;

- With special rollers.

There are also regular and “mini” units, characterized by their low weight, dimensions and rather serious functionality.

Advantages and disadvantages

The crushing unit has been used for many hundreds of years. During this time, it has undergone a lot of changes, but its advantages and disadvantages have remained virtually unchanged. Let's look at them in more detail.

Design of a simple jaw crusher

Pros:

- ShchD 6 jaw crushers, and any other similar types, have a very simple design and consist of a small number of elements that practically do not wear out. Purchase, maintenance and repair work with such equipment are quite cheap;

- There are mini crushers, which, due to their small size, are usually very simple and easy to assemble and disassemble. This also makes it possible to simply and easily transport them to any location;

- SMD 118 jaw crushers and similar equipment can be used in almost any weather and climatic conditions;

- You can always adjust the dimensions at the outlet of the unit, which is due to the installed hydraulic drive;

- The movable jaw in any crusher has a “gripper” shape, which prevents the unit frame from wearing out too quickly.

Jaw crusher design

Jaw crushers are crushers in which material is crushed using special jaws (flat surfaces). One of the surfaces is motionless. The crushing process is carried out due to the reciprocating movements of the second cheek.

There are separate models in which both cheeks are movable. Such designs significantly simplify the process of rock processing and ensure high quality crushing. The sorting line selects the crushed material into fractions.

Operating principle of jaw crusher

The rock is fed into the cavity, where it is exposed to two fairly massive plates. One of the jaw crusher plates automatically performs a translational-rotational movement, thus contributing to the destruction of the material. The plate that is located in a stationary position is called a fixed cheek, respectively, and the second is called a movable one.

The size of the supplied material is strictly limited by the hole located in the upper part of the structure. Directly when the two cheeks come together, the material is crushed, after which it flows out through the hole located in the lower part. The material is calibrated using the size of the bottom hole. After undergoing appropriate crushing, the material is fed to the central sorting line, where it is further divided according to fraction size. The final product can also be used in multi-fraction form, depending on the need for the technological process and the characteristics of production.

Main characteristics and calculations of jaw crushers

The main technical characteristics of jaw crushing plants include:

the magnitude of the grip angle formed by the fixed and moving surfaces. If the angle is too large, pieces of rock may jump out of the inlet; if the angle is small, the degree of grinding will be insufficient;

dimensions of the receiving opening, on which the size of the supplied material depends;

the dimensions of the outlet, which determine the size of the finished product fractions.

In order for the crusher to best meet production needs, you should first calculate the parameters and the design of the equipment itself. The calculation takes into account the following data:

optimal machine size;

size of pieces of material to be processed;

required dimensions of the finished product.

Calculations allow you to correctly select the width of the inlet and outlet openings, determine the grip angle, rotation speed and stroke of the moving surface.

Working principle of jaw crusher

The crushing process with jaw crushers consists of the following stages:

loading of raw materials. The material to be crushed is fed into a wedge-shaped crushing chamber, due to which large pieces remain at the top, and small pieces are located at the bottom;

splitting up. Rock crushing is carried out using plates with longitudinal corrugation. Small fractions move downwards under the influence of gravity, large fractions are subjected to repeated crushing until the desired size is obtained;

elimination of metal inclusions. Some models are equipped with magnetic separators that remove metal elements from the material;

unloading When the crushed pieces are able to pass through the outlet, they exit the crushing chamber. For prompt unloading, some models are equipped with high-speed belt conveyors.

For crushing high-strength rocks, it is better to use installations in which two jaws are movable.

Design and principle of operation of a jaw crusher

In the video you can see how jaw crushers are designed and the operating features of the equipment.

Reasons for the demand for jaw crushers

The first factor that makes the crusher popular is its simplicity of design. The installation has two main elements - cheeks. These are dimensional metal plates, one of which is fixed motionless, and the second makes a reciprocating movement relative to the first. The splitting of large fractions of ores and other materials occurs during their clamping between elements.

Other reasons for the crusher’s demand are:

- Safety.

Unlike dynamic methods of crushing materials, when a jaw crusher operates, rocks cannot fly out of the working area. The plates are located on two parallel sides of the workpieces, and the machine bed is on the other two. This ensures that the process operator is protected from accidental injury.

- High performance.

The installation is capable of processing up to 1,500 tons of material every hour. Performance depends on the following parameters:

- loading opening size;

- frequency of movement of the movable cheek;

- workpiece grip angle;

- density of the processed rock;

- a given degree of crushing.

This fact is reflected in the third advantage of jaw crushers.

- Variety of designs.

The smallest crushers are with a throat size (loading opening) of 150x100 mm, the largest are with a size of 2100x3000 mm or more. Large machines can crush rock blocks up to 2 cubic meters in volume, have the highest productivity and are used in the primary processing of minerals.

- Ease of maintenance and repair.

This follows from the simplicity of the device design. More often than other nodes, the cheeks wear out. This happens due to the high abrasiveness of the material or when choosing the wrong installation for a particular breed. Machines are gradually being developed to minimize the risk of rapid wear of the plates.

- Innovative technologies.

Manufacturers do not stand still, offering consumers new models of jaw crushers with improved designs. Examples of these are:

- crushers with a hydraulic drive that replaces mechanical connections (first created by the German concern Keppen);

- devices with an increased frequency of movement of plates (principle of impact crushing; ).

- Operational advantages.

These include:

- ease of transportation;

- ease of installation at the workplace;

- resistance to any external conditions;

- the ability to adjust the pharynx and discharge slot (for a number of devices);

- protection of the bed from early wear;

- the presence of a centralized lubrication system.

For what purposes are jaw crushers used?

The scope of application of the installations is wide and involves working with different breeds. Machines are mainly used for crushing crushed stone and gravel.

In the mining industry, machines are in demand for crushing hard rocks. In the construction industry, equipment is used to grind limestone, brick, and hardened concrete. The machines can also easily handle glass and ceramics.

Application area

It is possible to work with different materials. Most often, crushers are used to crush stone and crushed stone. In the construction industry, the unit is used to grind a variety of materials - brick, limestone. This equipment is excellent for grinding coal and old concrete. This technique is also used in cases where there is a need to grind glass.

Such units are simple in design and unpretentious in operation, while being characterized by good performance.

Types of jaw crushers

According to the method of installation and movement, crushing plants can be stationary and mobile (on tracked or wheeled chassis).

According to the design features of the installation, there are:

with a simple movement of the cheek in a circular arc. The material is crushed by crushing;

with a complex trajectory (along an ellipse arc) of a moving surface. Grinding is carried out by abrasion and crushing;

with two movable cheeks moving along a complex trajectory. As in the previous version, crushing occurs by crushing and abrasion.

Depending on the produced fractions of the final product, crushers are classified into three types: fine, medium and coarse crushing.

Cone crushers

Cone crushers are used to process ore and non-metallic materials at the stages of medium and fine crushing. They are especially good at fine crushing, becoming almost universal equipment for crushing durable materials. A cone crusher, like a jaw crusher, has moving and stationary elements - cones. They crush, crumble and building material. Crushing fine abrasive materials with cone crushers is more effective than with jaw crushers. The size of the crushed material is also determined by the diameter of the crushing chamber.

Extremely important when purchasing

or jaw immediately purchase the necessary set of spare parts. Since it is known that the most necessary things are most often not at hand.

Advantages of jaw crushers

Jaw-type crushing units have the following advantages:

high wear resistance reduces the cost of operating and maintaining machines;

easy installation and possibility of transportation due to the small dimensions of the units;

The units maintain efficiency and stability of operation in all weather conditions;

the accuracy and smoothness of adjustment of the slot width is ensured by the scale, and the hydraulic drive is responsible for adjusting the discharge opening;

the enclosing shape of the fixed cheek contributes to a longer period of operation of the equipment;

A continuous supply of oil is ensured by a centralized lubrication system.

The disadvantages include the fact that all jaw installations produce a product with an excess of flakier grains that are not subject to finer crushing, as well as the inability to use crushers for working with elastic and viscous materials: polymers, wood and some alloys.

Types of jaw crushers

The equipment differs in the method of installation on the chassis and the ability to move it into the following types:

Stationary crushers - provide for installation indoors, at production facilities, where it is important to work with large products. Mobile crushers - can be easily transported and work with small stones. Wheel crushers - the equipment is installed on a wheeled chassis and can be moved on a vehicle to a new work site. Track crushers are mounted on a tracked chassis, are heavy and can be transported within the construction site.

Classification according to the method of cheek attachment

According to the method of mounting the jaw, crushers are classified into lower and upper suspension types, which affects the operation of the equipment and the productivity of crushing. In particular, the first type refers to simple elements, the second to complex ones, which will therefore make it possible to regulate the choice of the most optimal system design, unit, in relation to specific types of work performed. The first version of the equipment is easy to maintain and repair, which therefore makes it the optimal solution for frequent use as construction equipment.

Features of classification by technological purpose

If it is necessary to carry out the construction of various objects, the disposal of large-sized material can be carried out using two types of crushing. In particular, this is large, or primary, the second is medium, secondary crushing, which is relevant when it is necessary to create a fraction of the desired type. This equipment has found wide application within production, in industry, where it can be used to obtain minor material. The equipment differs in design and has a complex mechanical chain.

Features of classification according to the kinematic scheme

Jaw crushers differ fundamentally in the existing kinematic diagram of the drive mechanism located as part of the structure of the unit. There are two types of design, the first of which is characterized by simple, the second complex movement. The simple design is distinguished by the ability to crush the material into large fractions, while the second one will allow for a similar operation, only dividing the stone into smaller components. It is worth noting that the simple design is much easier to maintain, which is facilitated by the design feature. Complex units will require the use of special tools and diagnostic equipment. Maintenance is carried out in a shorter time period established by the regulations.