Being actually the initial link in the chain of obtaining products from hard alloys, the mixture plays an important role in this process.

The properties of the final product depend on its quality, the main ones being mechanical strength and hardness. Currently, almost the entire drilling rig, as well as a significant part of the cutting tool, is made entirely or partially using these materials. You can buy carbide mixtures from MTK Metotechnika. Ordering through the website is available on the pricing page. It is also possible to leave a request via email and telephone.

You can learn more about brands, as well as production methods and areas of application of these products on this page in the relevant sections.

Characteristics and markings

Compounds obtained using a relatively new technological method do not change their characteristics even at very high temperatures - above 1000 degrees. They also do not deform under significant mechanical loads. This is ensured by the fact that they are created from refractory metals with the addition of less durable cobalt, which gives the composition bending strength so that the product does not have the brittleness of titanium and does not break.

The first feature we pay attention to is pressing. Powdered tungsten, titanium and tantalum carbides are mixed with fine cobalt particles. Alloying elements are added, for example, chromium. Then, under the influence of high pressure and ultra-high temperatures, thermal sintering is carried out.

Marking of hard alloys is carried out on the basis of state standards. It includes numbers and letters.

Examples of steel grades

Let's present the most popular connections. They are used in various types of industries. The proportions of the components are responsible for the characteristics.

VK2

The tungsten content is dominant, so its letter appears in front. There is only 2% cobalt – this is what the figure tells us. Apart from alloying additives and impurities, which amount to a hundredth of a percent, the remaining 98% belongs to W.

VK6M

This is an analogue - a tungsten-cobalt set with a high content of the latter - not 2, but 6% cobalt. But here there is a specification on the application - tools for processing refractory steels should be made from such material.

T5K10

When there are three elements of components, instead of two, then the most common one, which is the bulk, may not be written. A priori, the basis of the alloy is tungsten. And what is next to the numbers are the minor components - 5% titanium and 10% cobalt.

T14K8

Similar content, but different percentages. An increase in titanium inclusion imparts strength, but also brittleness.

TT7K12

Analogue, but with the addition of tantalum. Composition: W – 71%; Ti – 17%; Co – 12%; Ta – less than 1%, as an impurity.

In addition to classical substances, molybdenum and nickel are also added. The resulting materials acquire the properties of the indicated elements. These are expensive metals used for special parts in aircraft and mechanical engineering.

Decoding letters in grades of hard sintered alloys

In addition to indicating which ingredient is included in the compound and in what percentage, there is also a letter indication of use. This classification was carried out by an international organization called ISO. This made it possible to unify the labeling of domestic and foreign analogues. The letter is usually placed at the end of the abbreviation.

N

A sharpened object from this brand can be used to process hardened steel. It is harder and stronger than ordinary metals.

TO

Suitable for cast iron. The large amount of carbon combined with iron makes it less ductile, so cutting with another tool may result in chips and cracks.

M

Stainless steel is usually processed. It contains the maximum content of alloying additives, including chromium.

N

Used in metal processing of non-ferrous compounds.

P

For plastic materials with high viscosity. When you cut them, the shavings come out draining. They “merge” down from the incisor, which negatively affects the result.

S

Ideal for substances that have increased heat resistance. What is relevant here is that carbide tools are even less susceptible to high temperatures.

Classification of hard alloys by groups

This is a fairly large area of metallurgy, which includes all tungsten carbide compounds obtained by the above method. Therefore, they are divided into categories on several grounds.

According to the composition of chemical elements

This happens most often. The focus is on the percentage content of various metallic substances and non-metals. This is logical, because a knowledgeable person will evaluate the main characteristics and strength qualities based on this indicator.

Almost everyone in the group is tungsten. But since this is an expensive and rather scarce component, they are now creating a new group of tungsten-free ones - ceramites. They contain titanium carbides and titanium carbonitrides, which are bound by a base of nickel and molybdenum.

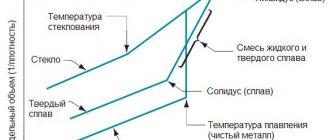

According to production technology

We previously described the most common cooking process. But at this moment, two methods are actively used in the metallurgical industry. It is worth noting that depending on which of them is used, the characteristic features of the result obtained also change. Alloys are distinguished:

Sintered. Thermal sintering is used, and powders are used as materials. The fact that all metals are in crushed form increases miscibility, speeds up the diffusion process, making the final ingot as monolithic as possible. It is important to note that such workpieces are not amenable to any metalworking, but only to grinding and processing with laser, ultrasound, etching in acids, but not cutting, not mechanical methods. Cast. Production methods: melting and casting. This is quite expensive, since the components generally have a fairly high melting point. But the result is very good - a monolithic, whole block, which you can no longer be afraid to process using all known methods - cutting, hardening, annealing, aging, etc. They are mainly used for surfacing on a tool or part of a part that wears out quickly.

By area of application of hard alloys and their properties

Here the classification that we have already given within the framework of labeling will be relevant. These are exactly the letters that are placed at the end of the abbreviation on the stamp. Thus, they are most often used to make metalworking tools because they produce:

- durable - no defects remain during contact with any other metal;

- wear-resistant - which is very important for expensive cutters;

- heat-resistant - direct friction produces a very high temperature.

If we are talking about a material obtained by casting, then another application option is surfacing. That is, part of the part is covered with the molten mixture in order to improve the characteristics of the working element as a whole.

The industry does not end its requests here. The more needs there are, the wider the range of compounds - a new recipe is smelted, which is classified according to a new definition. Below we will talk in more detail about the application of hard steels.

Tungsten compounds

Tungsten is the most refractory metal in the entire periodic table. It is for this reason that it is actively used in metallurgy. Mainly in brands like VK6, VK3M, which are very popular, the content of this substance is overwhelming - 94%, 97% and even more.

Let's give an example on VK8 - it is very often used to make cutters. They are very durable, so much so that they process cast iron without any problems or difficulties. In this case, the method is chipless.

Titanium-tungsten containing types of hard alloys

The name already shows that in addition to tungsten (the base), titanium plays an active role here, but not only. Cobalt usually plays an important role. What kind of instrumental composition is obtained from brands such as T5K10? For metalworking at high speed. They are also capable of processing metals with increased strength and heat resistance. For example: this could be a wear-resistant cutter for hardened steel.

Application

Mixtures of VK, TK, TTK serve as initial raw materials for the production of hard alloys supplied in the form of bars and plates.

For example, VK8 powder is used to produce the hard alloy of the same name. To obtain the semi-finished products described above, powder metallurgy methods are used. The basic technological chain is as follows: molding -> pressing -> sintering.

Hard alloys of the VK group are actively used in the manufacture of drilling and cutting tools. Grades VK8, VK6 are used to produce cutters, drills, milling cutters and other tools intended for machining workpieces. Carbide inserts VK8, VK6 have also found application in industry.

Materials belonging to the TK, TTK groups are mainly used for the manufacture of cutting tools used for various stages of mechanical processing of products (roughing, semi-finishing, finishing turning, milling, countersinking, etc.).

Characteristics

Properties depend on several factors. No two brands are completely identical.

First, let's look at exactly what characteristic features are categorized.

Name and percentage of chemical elements

Everything is simple here. The alloy is characterized into groups of 4 different composition qualities - this is “VK”, that is, with tungsten carbide and cobalt; titanium tungsten; titanium-tantalum tungsten and with wear-resistant coatings. It’s already clear from the name which substance has the priority amount. This is how the characteristics are determined.

Physical and mechanical properties

Perhaps the most important. We will list them in more detail and analyze them below; now we will point out that all compounds, without exception, are manufactured according to a recipe approved by GOST. The domestic standard corresponds to international ones, so you can calculate all the technical qualities of each brand. After we list their average values, we present a short table.

Features of technological processes for obtaining

Depending on whether powder pressing or casting was taken as a basis, characteristic features are determined. For example, about sintered materials, every specialist knows that an important indicator is the size of the carbide grains. The smaller it is, the more monolithic the result will be. It also influences what metalworking methods can be used and where the material will then be used.

Physical and mechanical characteristics

Of course, it is quite difficult to say average values, because too many things influence what the result will be. Below we will provide more precise tabular data from the official document, but first we will imagine what properties are generally evaluated and why.

Allowable strength

This is the resistance of the metal to any mechanical influence from the outside. That is, there is no deformation left on the surface after a collision with other parts. And this is very accurately said about carbide materials.

Measurements are taken using bending. The pressure exerted on the workpiece varies from 1200 MPa for VK2 to 2150 MPa for VK25.

Hardness

This is the ratio of the load to the surface area that is deformed under the influence of an indenter - that is, a cone or ball that is pressed into the sample as an experiment. It is measured in HRA and reaches up to 91, which is very high compared to steel.

Realizable thermal conductivity

This is the ability to conduct and retain heat from a hotter part to a colder part. The process continues until an energy balance is established. The average is about 51 W/(m×C).

Density of hard alloys

This indicator means how much mass per unit volume. In simpler terms, this is how tightly particles of a substance are pressed against each other. And since metals are, in principle, very heavy and practically do not contain voids, their density is very high. The characteristic fluctuates in the range of 14.9 – 15.2 g/cm3.

Heat resistance

Any material is destroyed under the influence of significant temperatures, but the limit that the compositions can withstand is different for everyone.

In this case, the sample can withstand up to 1200 degrees.

Corrosion resistance

Rust resistance is mainly provided by alloying additives. Some brands have added chromium, just like stainless steel, which increases the indicator.

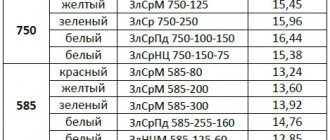

Now we present a summary table, note that the data is taken from the GOST document.

| Labeling (we take the most popular) | Bending strength, MPa | Thermal conductivity, W/(m °C) | Hardness, HRA | Density, g/cm3 |

| VK2 | 1200 | 51 | 91,5 | 15,1 |

| VK4 | 1500 | 50,3 | 89,5 | 14,9 |

| VK6 | 1550 | 62,8 | 88,5 | 15 |

| VK8 | 1700 | 50,2 | 87,5 | 14,8 |

| VK10 | 1800 | 67 | 87 | 14,6 |

| T5K10 | 1450 | 20,9 | 88,5 | 13,1 |

| TT7K12 | 1700 | –– | 87 | 13,3 |

| TT8K6 | 1350 | –– | 90,5 | 13,3 |

| TN-20 | 1000 | –– | 89,5 | 5,8 |

Areas of use

The use of the material has long gone beyond tool making, although this remains the main area of work with carbide workpieces. Let's explain why - when cutting or other metalworking processes, a lot of heat is released, which has a detrimental effect on the cutting edge. In this case, this influence is virtually invisible due to the heat resistance.

You also need to take into account increased strength - the tool set will retain its integrity for a long time, will remain without chips, etc. Therefore, below we will list more specifically those areas in which production takes place.

Metal cutting tool

Everything is simple here - they make drills, cutters, cutters, reamers, taps of various diameters, with different numbers of passes, cutting edge angles, etc.

The use of a relatively specific workpiece is usually determined by markings - some are intended for metalworking of one material, others - for a second.

Separate parts of meters

These are various compasses, calipers, with which you can make very accurate measurements. The stronger the steel from which they are made, the more accurate results can be achieved because there will be minimal natural wear and tear during use.

Brands, stamps

During hot or cold stamping, punches and dies are used, which, under the influence of pressure, must bend the workpiece. Of course, it is important that they are stronger than the workpiece. In this sense, hard alloys are an excellent option.

Accessories for cutting in metal

Artistic cutting, as well as die stamping, often uses special sharp cutting edges that, when pressed, cut into sheet steel and cut out a part.

Elements of machines for drawing and rolling

These can be shafts, profiles and guides. And also pressure beams.

Equipment for mining equipment

Rocks are often as hard as metals.

Let's compare diamond - it is difficult to find a material of natural origin stronger than it. Therefore, these tools are used when drilling, drilling and other procedures.

Bearing parts

The use of the substance increases the wear resistance of components.

Spraying on steel housings

Even a thin layer improves mechanical properties.

Equipment for ore processing plants

This is the primary processing of minerals. During the process, knives with increased strength properties are also required.

In the article we talked about the properties of hard alloys and the features of their manufacture and application. Let's watch the video to understand the topic in more detail:

To clarify the information you are interested in and purchase Russian-made metal band sawing machines, contact the managers by phone 8 (908) 135-59-82;;. They will answer all your questions.

Material VK8 Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells VK8 material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, VK8 material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.