The use of dowels in the manufacture of furniture dates back to “Soviet” times. But, despite its “antiquity,” this type of furniture fittings is sometimes used by modern furniture makers. History also knows some individuals who to this day continue to use dowels to connect all furniture components, despite the fact that they live in the age of high technology and the development of Chinese industrial plagiarism of all the latest elements of fittings developed in Europe.

The reason for such “love” for dowels is difficult to explain. The fact is that installing a dowel requires high precision from the master. An error of even a fraction of a millimeter can lead to displacement of parts, which is almost impossible to correct without “sacrifice.” You have to either drill out the hole (which leads to an unreliable connection of the parts), or put a plug in the drilled hole and drill it again (which takes a lot of time and nerves).

In general, we would venture to assume that the craftsmen who continue to work with dowels are either masochists or work in a very cheap market segment (since the only advantage of a dowel is its low cost). Or maybe they live somewhere high in the mountains and work with “grandfather’s” stocks of chipboard and fittings, so they simply don’t know about the existence of confirmations, corners, and even minifixes. Despite our “dislike” for minifixes, the dowel can be classified as an even more “hard” type of fittings in terms of its installation and adjustment.

Nevertheless, we decided to consider the technology of drilling holes for dowels. Let us immediately note that when making furniture with your own hands, you will not have to use dowels everywhere. In our furniture drawings, dowels are used only in those connections where, according to the technology, their use is most optimal. There are few such connections, but, nevertheless, since they are present in the furniture drawings, it means that in order to successfully make furniture with your own hands, you need to consider the issue of drilling holes for the dowel.

Types of dowels

There are many types of fasteners, but they are conventionally divided into groups according to material and shape. Let's consider this issue in more detail.

Material of manufacture

Two types are actively used:

- Wood. Most experts strongly recommend using a wooden tenon when constructing wooden structures. The main advantages when choosing such fasteners are given:

- Even drying. The beam and dowel should be approximately the same humidity. This will allow the shrinkage process to go through with virtually no visible changes;

- Not affected by temperature changes . The tree practically does not change its linear dimensions at different temperatures, so the fastening element will always be in place;

- No rust . Metal rusts over time, which leads to rotting of wooden surfaces in contact with it;

- There is no condensation. With a sharp change in temperature, moisture forms on steel, which is completely useless inside a load-bearing wall.

- The dowel fuses with the wall. After a certain time, the house will become monolithic, the wooden surfaces will be soldered together.

- Metal. This option also applies to a budget fastening method; waste materials (pipes, fittings) are often used. Although experts prefer the previous method, the metal dowel has its advantages:

- The top layers of wood are protected from torsion;

- Durability of the structure.

Form

There are also several main forms:

- Round section. Taking into account the fact that the holes for fastening in the log are made with a drill, the round dowel will provide the maximum contact area, guaranteeing the reliability and durability of the structure;

- Square. It is easier to make such an element; it also costs less. But that's where the positives end. When entering the hole, the edges of the tenon are deformed, and the total contact area remains minimal. Building a house this way is dangerous;

- Narrow rectangle . The easiest option to manufacture. A board of a certain thickness is taken and cut into rectangles. The only advantage is the very small thickness. Suitable for narrow timber, but installation is extremely difficult.

Scope of application

It should be noted that the drilling jig is used almost everywhere where there is a need to regularly drill holes. These areas could be:

- furniture manufacture. When making furniture, it is very often necessary to drill holes for fastening materials, fittings and accessories. The further appearance of the furniture, its presentability and marketability depend on the accuracy and correctness of the hole made;

- construction. When carrying out construction and repair work, it is often necessary to drill walls, pipes and other surfaces. Without templates, this is very difficult to do, and correcting subsequent errors will take a lot of time. Thanks to the templates, all drilled holes will have the desired shape and be at the desired angle;

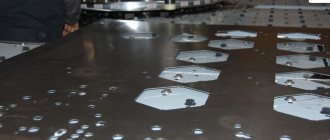

- mechanical engineering. Working without templates here is also quite difficult, since all blanks and parts undergo standardization, that is, they all must have the same dimensions, the same position of some parts, including holes;

- mass production. Stamp production also requires the unification of some components. Templates simplify tasks in this regard. You can be sure that all holes drilled will be the same size and the same slope, or will be directly perpendicular to the surface;

- household. You often have to repair something at home, so the need arises to drill holes in walls, parts or some workpieces, where the particular accuracy of the holes is very critical.

Nowadays, conductors are produced both universal and specialized for specific areas of work. Some are inexpensive, so there is no need to make such products yourself.

We make the dowel with our own hands

This type of fastener is sold in stores, but you can make it at home without much difficulty. The wooden element is made as follows:

- scraps of boards are taken, from which beams measuring 25 by 25 centimeters are cut;

- stakes are made 1.5 times the thickness of the building timber, with a diameter of 2.5 centimeters;

- The corners are cut off with an ax to give a rounded shape.

But the following must be taken into account:

- the wood for fastening must be harder than timber. Nowadays birch is most often used for these purposes;

- the dowel should not differ significantly in humidity from the main structural element;

- It is strictly forbidden to use a dowel with a knot.

Classification of tools

Before you buy a ready-made conductor or make it yourself, you need to decide what problems you will solve with its help and only then you need to select the appropriate option in terms of design and functions.

There are a number of categories of devices that differ in their design and functional features. Here are some of them:

- overhead - such devices are applied to a part that can be processed, then it is attached to it or simply fixed manually. With their help, holes are made in various flat parts, MDF boards or chipboard;

- rotary - these templates are used when processing cylindrical parts. They are equipped with horizontal and vertical axes of rotation, so holes can be made at different angles;

- universal - such devices are suitable for small serial furniture manufacturers, where sometimes quick readjustment of the equipment used is required, they have all the functions necessary for this;

- tiltable - used when the technological procedure is carried out in several planes at once;

- sliding - such conductors do not need to be attached. Simply attach them to the surface area of the workpiece where you want to make a hole;

- fixed - they are more convenient to use, but they limit freedom of action, which is very critical when working with machines where there is only one spindle.

https://youtube.com/watch?v=mtYw_r8OTjU

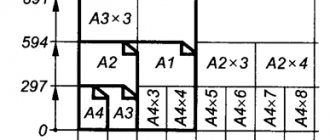

We carry out calculations

Depending on the chosen fastening technology, it is possible to determine with sufficient accuracy the number of dowels and calculate their correct characteristics.

Deciding on the sizes

There are many scientific works that will help determine the diameter of the dowel. But in the professional environment of carpenters and builders, certain rules have already been formed:

- for timber with a thickness of 20 centimeters or less, a dowel with a diameter of 25 millimeters is used;

- a thicker beam is fastened with a tenon measuring 3 centimeters;

- timber thicker than 0.2 meters can be fastened with a 2.5 cm dowel, but subject to the step being reduced to a meter.

Counting the quantity

Even a small sauna will require quite a large number of spikes that need to be purchased or made, which can take a long time. Therefore, it is better to know the number of fasteners in advance.

There are fastening rules:

- the first dowel is inserted at a distance of 20 to 70 centimeters to the corner;

- the step is from one and a half to 2 meters;

- It is necessary to fasten two adjacent logs in height.

Knowing these tricks, the height of the structure, the diameter of the timber, you can easily calculate the number of dowels needed for construction.

Manufacturers of furniture conductors

The following brands of conductors are widely used in the domestic market and have proven themselves well.

Assistant

The furniture jig system of this company is designed for the production of cabinet furniture based on a 32 mm assembly system, suitable for all European fittings. The customer selects the complete set of the system individually for himself, which allows him to save money by choosing only the essentials. The Assistant jig contains modules for marking and drilling holes for guides (roller and ball), tandems, hinges, lifting mechanisms, confirmat, eccentrics, dowels, handles and other holes using the 32 mm system.

Dubel-Profi from KWB

German jig for drilling holes for dowels. The mechanism of the device allows for perfectly accurate positioning of holes with a diameter of 3 to 12 mm. The jig is equipped with a depth gauge and a special stop, which helps to drill at right and oblique angles. Thanks to the rubber pad, the device is convenient to use on smooth and polished surfaces.

Condor

The Condor furniture template is a portable device that is convenient to take with you directly to furniture installation. Thanks to replaceable bushings, the distance between the holes can be adjusted. The tool allows you to make holes for a dowel or confirmat. Milling grooves are installed at distances of 16 or 18 mm, which allows you to work with various materials.

A furniture jig is an indispensable assistant in any furniture production. This inexpensive device will help not only reduce labor costs, but also significantly improve the quality of your products.

Fastening technology

Drilling

A powerful drill is used if it is necessary to make holes directly on the construction site, or a machine if the timber is prepared in advance.

The second method is common in the West and allows you to assemble the structure of almost any house in a few days. But it requires attentiveness, accurate drawing, and professionalism.

The diameter of the drill and the thickness of the dowel must match, and for the upper tiers of the timber the hole should be even two millimeters larger. This eliminates sagging of the supporting structure due to a small vertical load. The hole is made 2 centimeters longer than necessary so that the tenon can move smoothly during shrinkage.

Clogging

Typically a sledgehammer weighing several kilograms is used. The dowel is driven inward below the edge of the beam to the end of the hole; nozzles (usually made of brass) are used for this.

Correct location

The ideal option is when the dowels are arranged in a checkerboard pattern. But a strictly vertical direction along parallel lines is also allowed and does not significantly affect the strength.

A gap of at least thirty centimeters before the start of the opening is recommended. The distance of the fastener to the corner should not exceed 70 centimeters. The step can vary from a meter to 3, depending on the material from which the timber is made (hard varieties require a smaller step).

Features of self-production

When designing a conductor for confirmation, it is necessary to correctly calculate what functions it will have to perform in the future. It should be done for the most commonly used fasteners in the house. If such a device is required by furniture makers for constant work, then it is better to buy a factory model, which is distinguished by great precision. In addition, manufacturers often include additional fasteners, stops and templates in the kit.

The price of such a device for professional use ranges from 400 to 1100 rubles. It depends on the immediate capabilities of a particular unit, the number of holes made, their length, etc. Many people are interested in how to make a furniture jig with their own hands. Drawings with dimensions are a must for novice craftsmen, as they allow you to make a high-quality design on the first try. Similar diagrams can be found on the Internet.

Basically, the conductor has the following elements:

- The basis of the product. It is directly applied to the plane of the furniture, on which the holes will be drilled.

- Guide bushings. A drill goes through them.

- Surface clamping parts. As a rule, they are located at the end of the conductor.

To start designing your own conductor, you need to choose the right corner. It is better to make a non-equal-flanged corner, since it will have much more possibilities, and choose the maximum thickness of the shelf.

Next you need to take care of the correct direction of the sleeve. It can be made from stainless pipe. The length of the sleeve should be at least twice as long as the hole in which it will be located on the angle. The bushing should fit tightly in the hole. The simplest and most common option is a shaft-type landing. A corresponding hole is drilled in the corner to fit the already known diameter of the bushing, and then the fit is made. It is recommended to use a low interference fit.

There are cases when the jig needs to be made for drilling deep holes. Then the bushing is made with a collar. The number of possible holes, their length and the distance between them is selected to suit the specific needs of each master.

Several options can be used to attach the device:

- Spring support. The conductor will adhere to the material being processed using spring force. For these purposes, you can use any flat spring with the required force.

- Fastening to wood using self-tapping screws. Using this method, the jig is pressed and held on the working surface due to friction. This fastening method allows you to use the resulting marks for subsequent centering of the part. When working with chipboard, you need to use this method with great care.

- Clamps with rubber gaskets. This method is dangerous due to possible displacement of the bushing axis. This happens because the weight of the jig increases and the bushings become bent. Therefore, you must first attach the jig to the surface, mark the future hole, and then start drilling.

Read also: Reduction gear on a walk-behind tractor

Advantages and disadvantages

Like any other fastening element, the dowel has a number of positive aspects, as well as disadvantages.

Advantages:

- The spike provides reliable grip and prevents the crown from sagging;

- Provides long-term reliability under bending loads, which nails and bolts cannot boast of;

- Promotes uniform shrinkage of the house. The fastening element moves freely along a vertical plane, preventing horizontal deformations;

- The wooden product is not subject to the formation of moisture and corrosion, excluding the process of rotting;

- Extremely cheap. Even buying ready-made dowels won’t put a big dent in your pocket, allowing you to minimize your budget.

But there are also disadvantages:

- Difficult to install. Absolute vertical position, ideal selection of diameter, implies the presence of decent construction skills;

- Serious quality requirements. The presence of knots or heterogeneity of the material can lead to disastrous consequences;

- Excessive force when driving often leads to cracks in the timber. After which it needs to be changed.