Types of single-lever mixers and their design

Despite the external similarity, there are two types of rotary or single-lever faucets - with a cartridge (cartridge) and ball - with a ball inside. You can repair any of them, but to do this you must first disassemble them. And so that you can not only disassemble, but also assemble, it is advisable to become familiar with the internal structure of each.

The design may be different, the structure remains the same

Cartridge mixer: structure

Cartridge mixers are so named because their shut-off and control mechanism is hidden in a special cartridge flask. In more expensive faucet models, the cartridge body is made of ceramic, in cheaper ones - from plastic. The good thing about these models is that they are easy to repair, but it is not always easy to achieve the required pressure with them - you need tighter control of the handle. But changing the water temperature is very easy - with a slight movement of the hand.

The structure of a single-lever faucet with a cartridge is simple. If you go from top to bottom:

- Switch with fixing screw.

- Locking (clamping) nut.

- Cartridge. The water flows are mixed in it, and the same device shuts off the water.

- The mixer body, which has a “seat” for the cartridge.

- Fasteners, studs and gaskets to ensure tightness.

- Spout (gander). It can be a separate part - in rotary models for the kitchen or part of the body - for sinks in the bathroom.

- If the spout is separate, gaskets are also installed below and there is also part of the body.

What does a single lever mixer with cartridge consist of?

The cartridge itself contains several (usually 4) ceramic or metal disks of a special shape. A rod is welded to the upper disk. By changing the position of the rod, we change the position of the plates relative to each other, changing the amount of water passing through the holes in the plates.

In order for the faucet/mixer to work normally, the plates are ground very tightly. For this reason, cartridge single-lever faucets are very demanding on water quality. Foreign fragments getting between the plates causes the faucet to leak or stop working altogether. To avoid this, some manufacturers install filters on the incoming pipes. But, it is better to install filters on the water supply and get clean water that can be safely supplied to household appliances.

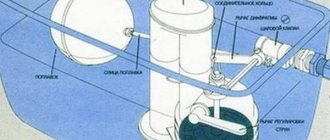

Single lever ball mixer

It got its name from the element in which the water is mixed - a ball with cavities. The ball is usually metal, hollow inside. Its outer part is polished to a shine. The ball has three holes - two for the entry of cold and hot water, one for the exit of already mixed water. A rod is attached to the ball, which fits into a cavity in the handle. This rod with a rigidly attached ball changes the temperature of the water and its pressure.

The structure of a single-lever mixer with a ball water mixing mechanism

It is easier to adjust the parameters with such a device - the parts are well lapped, the handle moves easily. Mixers with a ball mechanism are less critical to the presence of mechanical impurities, but do not respond very well to the presence of hardness salts and excess iron. So for normal operation, pre-filtration is required here too.

Design

A single-lever bath mixer is structurally different from a double-valve one. It has only one lever handle, with which you can regulate the temperature and water pressure in the tap. This type of faucet is also known as one-armed bandit, ball, joint, joystick. It performs three main functions: mixing water at the optimal temperature, forming a jet and changing its power. The mechanism of its action is quite simple:

- By turning the handle horizontally, you can change the water temperature from cold to hot.

Single lever mixer - By raising or lowering the lever in the vertical direction, you can adjust the flow power. The higher the handle position, the more powerful the jet.

Please note that a single-lever faucet consists of the following structural elements: a rotary handle, a faucet cover, a spout with a faucet body, an internal chamber or cartridge, as well as several gaskets and seals.

How to disassemble and repair a faucet with a cartridge

Repairing a single-lever cartridge faucet often involves reassembling and cleaning the O-rings. Salts are deposited on them, debris and dirt accumulate, which is why the faucet begins to leak. To eliminate this nuisance, the mixer is disassembled, all parts are wiped of dirt (with soapy warm water), rinsed, dried, and put back in place.

Sequence of installation of parts in a cartridge single-lever mixer

Let's figure out how to disassemble a faucet with a cartridge. First, turn off the water, and then the procedure is as follows:

- Remove the decorative plug located on the handle. Just pry it out with a screwdriver.

- The mounting screw is hidden behind it. We unscrew it with a hex key and take it out.

First, unscrew the fixing screw

- Now pull up the shift lever.

- Next, a decorative washer is screwed onto the body or simply installed. We're filming it.

- Unscrew the clamping nut. It has a large diameter, so you may need an adjustable wrench or a set of open-end wrenches.

- We take out the cartridge. Let's examine it.

- Below are gaskets, fasteners and studs. You need to remember exactly the order in which they are laid out. Sometimes it even matters which side they are laid on. Therefore, be careful when disassembling.

That's all. The single lever mixer with cartridge was disassembled. As you can see, there are not many details. The main working part is the cartridge. It is in it, inside, that mixing occurs.

Replacing the cartridge

The cartridge itself has a sealing gasket - a rubber seat at the bottom, which ensures a tight fit to the body. Over time, the rubber loses its elasticity and water begins to leak out. If this is the problem, you can first try to clean this ring from the salts and deposits that have formed on it. Place the cleaned part in place and check the work. If the leak does not stop, you will have to replace the cartridge.

Cartridges for “one-arm” faucets

Cartridges for mixers have different diameters, and the inlets and outlets in the lower part are located differently. Therefore, if you need to replace it, first you disassemble the mixer, get the treasured part and go to the store or market with it. You must choose exactly the same model without any deviations. At home, install the cartridge into the housing, turn it slightly until you feel that it “sits” in place. Next is assembly, it goes in reverse order.

First install the clamp nut. Actually, at this stage you can check how the new cartridge works. Turn on the water, adjust the temperature and pressure with the stem. To make it more convenient, you can put a handle on the rod. If everything is fine, continue assembly.

Main signs of malfunctions

The mixer is a structurally complex piece of plumbing equipment. Its operation and service life are influenced by many factors. The main signs of faucet failure include:

- Difficulty moving the lever or rotating the valves . It may also be difficult to adjust the flow parameters: adjusting the temperature and pressure. Such manifestations occur when the mechanical components of the mixer wear out due to the ingress of small solid inclusions or the formation of dense limescale;

- water leaking from under the control lever or valves . Such a breakdown can be caused by a number of reasons: failure of the cartridge, a small crack in the housing, insufficient tightening of the threaded couplings (nuts), wear of the seals on the crane axle boxes;

- low pressure in the kitchen tap without a similar problem at other water intake points . Most often, the cause of such a malfunction is overgrowing or clogging of the aerator mesh. Also, a decrease in pressure can be caused by poor passage of supply pipes (hoses), overgrowing of channels in the mixer, pinching of gaskets on the supply;

- formation of a puddle at the base of the mixer . Its cause may be wear of the sealing rings in the rotating block or the appearance of a crack in the housing;

- constant leakage . A trickle of water regularly drips or flows from the spout when the tap is closed. With a high degree of probability, we can say that the ceramic parts of the valve part or seals have worn out.

We disassemble and repair a single-lever ball mixer

The single-lever ball mixer was invented a little over 40 years ago. Its design is simple and reliable - there is nothing to break. If problems arise, it is only due to poor quality water - dirt particles settle on the rubber saddles on which the ball rests. The contact deteriorates, water leaks out and the faucet begins to leak.

How to disassemble a single lever ball mixer

Some ball valves are also available with a cartridge. Only inside the cartridge there are not plates, but a ball. Disassembly of this type is no different from that described above. All the difference is hidden inside the flask. There are also other types of taps. In them, the locking ball is installed directly into the rubber seat. There are some minor differences here.

The faucet lever is removed in the same way - first remove the plug, then unscrew the screw with a hexagon. Pull the lever up and remove it. Afterwards the steps are very simple and similar to those described above:

- We unscrew the cap, preferably by hand, since it is usually made of thin metal and is easy to bend.

- We unscrew the clamping nut, there is a washer under it, remove it too.

- Access to the ball has opened. Pull the rod and take out the ball.

- Under the ball there are two saddles, with springs so that the elastic bands are pressed more tightly to the ball.

That's it, sorted it out. Next comes the repair of the single-lever mixer. In theory, the problem is that deposits have accumulated at the contact point between the ball and the seat. They need to be removed - carefully clean and wipe. There may be problems with the springs. Dirt sometimes accumulates on them too, but more often they simply lose their elasticity.

The third source of problems is the ball itself. In general, it should be made of stainless steel; accordingly, it only needs to be cleaned of deposits. In reality, this is not always the case - cheap faucets have appeared even with plastic balls or made of cheap metal. In this case, peeling of the surface or other similar troubles may occur. Such a locking element will no longer work normally. It needs to be replaced. You also go to the store with the ball and select a replacement of the appropriate size. Assembling the mixer in the reverse order: springs from the seat, the seat is out of place, there is a ball on it, etc. When assembling the entire structure, carefully center everything - misalignment will lead to rapid wear and the tap will leak again.

Advantages and disadvantages

Many homeowners pay attention to the single-lever mixer, because its design, repair, and installation are simple, but at the same time very effective and functional. These more modern devices differ from two-valve ones not only in their more aesthetic appearance. They are also very convenient to use; they allow you to more accurately and quickly adjust the water temperature and reduce its consumption. But they also have disadvantages:

- Demanding on water quality. Single-lever faucets, due to the nature of their design, are very sensitive to impurities contained in tap water. Due to its poor quality, they often become clogged and then stop working. Models with ceramic cartridges especially suffer from this problem.

- Low maintainability. It is almost impossible to repair a single-lever faucet with your own hands; you can only replace some of its parts, for example, seals or the entire cartridge.

Remember! To increase the service life of a single-lever mixer, you can improve the quality of tap water by installing a special filter, as well as perform timely preventive maintenance of the device.

Repair of a single lever faucet with swivel spout

Faucets with a swivel spout are installed on sinks in the kitchen or bathroom. Periodically it starts leaking from under it. In this case, the locking mechanism is not to blame; it’s just that the gaskets have lost their elasticity or the lubricant has dried out.

Repair of a single-lever mixer with a movable spout

In this case, disassemble the mixer as described above, then remove it by pulling the spout up. Remove all old gaskets. If they are stuck, you can use a flathead screwdriver or even a knife blade. You have to remove them, but they are still replaceable. Use the removed gaskets to select new ones. It is advisable that they be made of silicone, not rubber. Silicone is more elastic, retains its properties longer, and tolerates contact with water better.

Lubricate the new gaskets with plumbing silicone grease and install them in place. Reinstall the spout. It must be pressed down well so that it rests against the union nut on the mixer body. Next is the assembly of the rest of the mechanism.

Problems during operation

Even high-quality plumbing fixtures fail over time. The service life of the faucet depends on the material from which it is made, the quality of the tap water and the intensity of use. The most common problems that arise when using single-lever models are:

- Cracks on the device body. They arise due to poor quality material and installation errors.

- Aerator clogged. The cause of this malfunction is the poor quality of tap water.

- Wear of rubber gaskets. Seals are consumables; they wear out over time due to the high intensity of use of the device.

Important! No matter how high the quality of the faucet, it needs preventive maintenance. Even if no problems arise during operation, you need to disassemble the device once every 2 years, clean it, and replace the gaskets. After all, even a small speck that gets under the seal can cause a leak.

Causes of faucet breakdowns

To begin repairing a faucet, you need to know the common problems and malfunctions of faucets that may arise during operation.

The second reason may be that old materials are used in production, for example, if you use rubber for a gasket, then such a gasket will last less time than a silicone one. An important point is that the silicone gasket is less deformed and does not collapse due to drying out.

The most common reason in our time is hard and dirty water that flows through pipes. This water forms deposits in faucets and contributes to the destruction of seals and other parts of the device. This reason also contributes to the corrosion of metals.

These were the reasons for faucet breakdowns, and now we need to look at specific faults that may occur.