Thanks to technology, achieving the task is not difficult.

For example, polymer wells, which have become an alternative to conventional reinforced concrete products.

Let's find out if they are as good as they say.

Well / Caisson / Septic tank polymer sand with a diameter of 1060 mm price IN STOCK!!!

| Name | Conical transition polymer-sand | Ring polymer sand | Bottom polymer sand | Hatch LPP LO up to (1.5 tons) polymer sand | SET Cone + polymer sand hatch | Caisson / septic tank / prefabricated polymer-sand well with a hatch and a bottom of 9 rings |

| (Only suitable for concrete rings) | ||||||

| Appearance | ||||||

| Overall dimensions,±5mm | 1060x130 | 1060 x 200/250 | 1100 x 30 | Cover diameter: 585 mm | 1050 x 30 | 1060 x 2000 ( height can be changed if desired) |

| External holder diameter: 760 mm | ||||||

| Internal cage diameter: 550 mm | ||||||

| Weight,±1 kg | 50 | 35/38 | 39 | 18 | 40 | 350 |

| Price Moscow Stupino region | 2200 rub. 1995 rub. | 1850 RUR/2090 1670 RUR/1895 | 2100 rub. 1806 rub. | 1000 rub. 890 rub. | 2700 rub. 2310 rub. | 21250 rub. RUB 19,721 |

Laying sections and cutting in pipes

The assembly of well rings can be done both in the pit itself and next to the subsequent descent down of the whole or part of the structure at once. In any case, you can get by with two people. But when lowering an already assembled well into a pit, you will need a tripod with a winch or a crane.

The bottom or starting ring is placed on a sand cushion 15–20 cm thick, previously poured and compacted at the bottom of the pit.

Next, the groove in them is filled with sealant or bitumen mastic and the next part is inserted into it with a comb. So all the other rings are laid one after another, and the neck is installed on top.

Drilling a hole

To insert pipes into the rings of a polymer-sand well, it is enough to use a drill with a crown of the required size.

Polymer sand is quite easy to process. Holes in it for pipeline entries can be made without the use of powerful tools. An ordinary drill with a regular bit for concrete or ceramics is enough. Plus, after such drilling, the edges do not need to be ground or processed in any other way.

To seal the joint between the pipe and the wall, it will be enough to insert a rubber cuff into the hole.

Well / Caisson / Polymer sand septic tank with a diameter of 1610 mm price In stock!

| Name | Polymer sand cone transition | Polymer sand cone adapter for inspection well | Hatch LPP LO up to (1.5 tons) polymer sand | Polymer sand ring | Caisson / septic tank / prefabricated polymer-sand well with a hatch without a bottom made of 9 rings and 2 cones |

| Appearance | |||||

| Overall dimensions,±5mm | 1060 x 130 | 1610 x 150 | Cover diameter: 585 mm | 1610 x 200 | 1610 x 2010 ( height can be changed if desired ) |

| External holder diameter: 760 mm | |||||

| Internal cage diameter: 550 mm | |||||

| Weight,±1 kg | 50 | 84 | 18 | 67 | 757 |

| Price Moscow region Stupino | 2200 rub. 1995 rub. | 2850 rub. 2520 rub. | 1000 rub. 890 rub. | 2850 rub. 2520 rub. | 31,700 rub. RUB 28,085 |

Well / Caisson / Polymer sand septic tank with a diameter of 830 mm price In stock!

| Name | Polymer sand ring | Polymer sand bottom | Hatch LPP LO up to (1.5 tons) polymer sand | Caisson / septic tank / prefabricated polymer-sand well with a hatch and a bottom of 10 rings |

| Appearance | ||||

| Overall dimensions,±5mm | 830 x 200 | 850 x 35 | Cover diameter: 585 mm | 830 x 2060 (height can be changed if desired) |

| External holder diameter: 850 mm | ||||

| Height: 90 mm | ||||

| Weight,±1 kg | 28 | 31 | 20 | 280 |

| Price Moscow region Stupino | 1650 rub. 1155 rub. | 1850 rub. 1785 rub. | 2000 rub. 1785 rub. | 19240 rub. RUB 15,120 |

Do you want to buy polymer sand rings, prefabricated wells, polymer wells, caissons, Tetto assembled septic tanks?

Before you buy polymer sand wells from ANOTHER MANUFACTURER, DO NOT BE LAZY TO COMPARE SAMPLES with ours!!!!

Call us right now - HURRY TO BUY polymer sand rings, caisson, septic tank, prefabricated well AT THE OLD PRICE , raw materials are becoming more expensive!!!

Pressurized cable glands for passing pipes of various diameters through the wall of a polymer well or the bottom of a well are also available for sale. Our pressure seals will ensure the tightness of your caisson, septic tank, or built-up well when organizing the passage through the built-up elements of the pipe well when constructing a well, sewerage, or drainage.

You can order from us the service of making a hole in a prefabricated well element.

We prepare the parts and prepare for excavation work

Before building a caisson, it is necessary to calculate and purchase the number of elements required for its construction.

The heaviest element of the well weighs no more than 60 kg. To unload the car, the efforts of a couple of people will be enough. At the same time, the weight of the entire structure will not exceed a couple of tons; one Gazelle will be enough to transport it from the store.

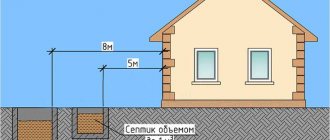

Despite the high strength characteristics, the rings should be covered with boards during transportation and storage. It is better to place the bottom on a pallet or wooden platform. You will have to dig a hole 120–130 cm wide for a polymer sand well. The outer diameter of the rings does not exceed 110 cm. Ten centimeters on the sides is enough to lower the parts into the dug shaft.

Polymer sand well with drainage holes

To make drainage, you can not only remove the bottom, but also drill additional holes in the lower rings.

If the well is made without a bottom, then a gradual excavation of the earth under the lower ring is possible. But with such digging, the pit will have to be dug wider, otherwise it will be inconvenient to work with a shovel. Whether it is worth doing extra work, removing one and a half to two times more soil, is up to the excavator to decide.

DESCRIPTION

The manufacturing company Tetto offers to buy polymer-sand rings for wells, as well as for caissons and septic tanks in a suburban area. Such products will become a profitable and durable alternative to conventional reinforced concrete rings: the new material has a number of operational advantages. We supply our own products in assembled kits to solve a specific problem.

Advantages of using polymer sand rings

Polymer sand wells consist of three main elements: rings of a certain diameter, conical transitions and a bottom that ensures the tightness of the well. For their manufacture, a composite material is used: it consists of a polymer binder base and sand, which is used as a filler. The elements of the well are connected to each other using a tongue-and-groove system - this design ensures the tightness of the connection.

Choosing a polymer well is beneficial due to several important advantages:

- Durability due to low water absorption. The polymer material is not subject to corrosion, it does not absorb water and does not crack over time. This ensures a long period of trouble-free operation.

- Easy to install. If the installation of concrete rings must be carried out using special equipment, lighter polymer rings can be installed manually.

- Sealed connection of elements. This prevents the penetration of surface groundwater into the well or the leakage of untreated wastewater from the septic tank.

- Easy to prepare holes for pipe connections. This task can be accomplished with simple tools at home.

Polymer sand caissons successfully cope with their task. This is a convenient, inexpensive and durable alternative to traditional designs. Concrete rings can be used to assemble a chamber of the required volume; it will be reliably protected from all external influences. A polymer sand septic tank is perfect for a summer house or a country house: the container will reliably protect the soil from the penetration of wastewater. It is easy to install such structures in hard-to-reach places where special equipment cannot be brought.

Ordering products from the manufacturer

The manufacturing company Tetto offers customers to buy a well or other structure made of polymer-sand rings with removal to the site and unloading. Take advantage of a range of services to get rid of unnecessary costs and get the finished result on site faster. The purchased goods are shipped and delivered on all days of the week; you can agree in advance on a convenient delivery time.

When ordering products in Moscow and the Moscow region, no advance payment is required. Cash and non-cash payments are possible, the company offers customers a convenient ordering scheme. In addition to the well elements themselves, there is a wide selection of related products on sale: pressure seals, pipes, bitumen mastic for sealing and much more. The company's consultants will help you select a complete set of necessary elements to quickly prepare a working autonomous water supply or sewerage system.

Order a well or septic tank made of polymer sand rings at a very low cost! Buying directly from the manufacturer will be a profitable solution: you will receive the goods without intermediaries and overpayments. The company has been operating in the capital region for 10 years: it has acquired an excellent reputation, its products have earned positive reviews. Place an order on the website or call the numbers provided for consultation!

Resistance to aggressive substances

Together with water from the ground, aggressive substances reach the surface of the wells, destroying the structure of concrete, and if the well is a sewer, then the reactions of biomass decomposition will “spoil” it from the inside. To make these processes weaker, reinforced concrete rings are lubricated with special antiseptics and waterproofing mastics.

The polymer product is not afraid of aggressive environments. The composite material does not react with substances, therefore it is not afraid of salts, acids and alkalis and does not require additional processing.

ADVANTAGES OF TETTO POLYMER SAND PRECASTIC WELLS OVER COMPETITORS

- All parts of the polymer sand well/caisson/septic tank are made from a high-strength polymer sand composite, which shows excellent technical and operational characteristics in terms of such indicators as work in aggressive environments, resistance to temperature changes, resistance to heavy physical impacts and loads;

- All parts of the polymer sand well/caisson/septic tank have tongue-and-groove locks, which ensure reliable fixation and alignment of the elements together, as well as sealing;

- The products have a low level of water absorption, which is very important for outdoor use, and as a result, they last much longer than concrete ones;

- The elements of the well/septic tank/caisson are perfectly sealed with each other thanks to the connection design;

- Installation and arrangement of a caisson / septic tank / well, loading and unloading operations can be done manually;

- — It is possible to install a septic tank/well/caisson in and in those places where it is not possible to use a truck crane and other lifting equipment, for example under a building, high-voltage lines, trees, etc.;

- — Making holes for pipes and communications, cutting and other processing of our products can be easily done with household power tools at home;

- — It is convenient to install communications directly to the walls of the well - the material is viscous and somewhat reminiscent of wood, the screws fit in and hold very well.

Easy connection to pipeline

When connecting a well to a home water supply system, you have to drill holes or openings in it. This is very difficult to do in reinforced concrete. Often a professional tool is required.

You can cut openings and holes for pipes in polymer sand wells with ordinary household tools, and the edges do not need to be treated with anything.

All openings in the polymer ring are created using household tools. In this case, there is no need to lubricate the edges of the cut piece with any compounds, because the plastic is not afraid of corrosion.

WHY SHOULD YOU CHOOSE PREFABRICATED CAISONS

Today, the well equipment market offers caissons made from various materials, but many of those involved in drilling water wells have already abandoned what they used before and began to use polymer-sand caissons for constructing wells. Let's figure out what are the pros and cons of this or that type of caisson. The advantages of a caisson made of polymer-sand composite include ease of installation. All the elements are so light that even one person can install the caisson, and there have been such cases!!! An important advantage when constructing a well with a caisson will undoubtedly be the ability to select and change the installation depth of the structure. Disputes about the depth of soil freezing within each region do not stop and will never stop, so the opportunity for each owner to choose any multiple of 250 mm installation depth of the caisson will save his nervous system and provide the opportunity for self-realization. The polymer sand caisson is not afraid of frost, moisture or sun. No additional treatment, including waterproofing, is required. The polymer sand caisson provides excellent tightness and protection of the well from groundwater, pollution, dust and freezing. Among other things, polymer sand caisson is a very durable material with good viscosity, which makes it easy to make technological holes for water pipes from a well using household power tools and seal them. Due to the high strength of the polymer-sand composite, the possibility of carelessly damaging or splitting the product during construction of a water well, loading and unloading operations and transportation is excluded.

Nowadays, an important advantage is the low cost of both the caisson itself and the low final cost of installation, loading and unloading work and delivery.

The disadvantage of polymer-sand caissons can be considered the novelty of the material; many are still afraid to use them, however, such fears, as practice shows, are groundless; all caissons produced by our company are installed without problems and are successfully operated by satisfied owners. In the case of a polymer sand caisson, new does not mean bad, new means it simplifies life, saves your effort and money, do it once and forget it.

Metal caissons are expensive, it is a constant struggle against corrosion and, as a result, leaks, difficult installation and expensive delivery. The metal caisson, especially in places where technological holes are made, must be primed and painted, preferably with expensive paint, because Condensation will accumulate in the caisson. You cannot do without a truck crane and trucks. You will definitely have to pay for welding work.

Concrete caissons are again difficult to install and deliver, limited choice of installation depth, require treatment with a waterproofing compound, the fragility of the material and tendency to crumble complicates the installation of technological holes for water pipes.

Plastic caissons are a fairly good option, but the disadvantages are high cost, inconvenient delivery and installation, limited choice of installation , subject to strong compression by soil, there were cases when a plastic caisson was compressed to such an extent that it was impossible to climb into it.

All of the above pros and cons of materials apply equally to their use as septic tanks for sewage, drainage and wastewater.

How to install?

Well installation involves four main steps:

Correct delivery . The weight of one ring is 60 kilograms. Therefore, products can be loaded into the car and unloaded without the use of special equipment. Two or three people are enough for loading and unloading.

For transportation, a wooden platform is placed in the back of a truck, on which the bottom plate (bottom) is placed. The rings are laid out with boards (installation of structural elements on top of each other is allowed).

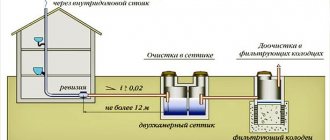

Digging a hole. Shallow mines are completely dug. Deep wells must be dug inside the rings to prevent soil from collapsing. First, the first ring is installed and a recess is made inside it with rings being systematically added on top. With this method of deepening, the slab is not placed in the base - the well is obtained without a polymer bottom.

It is recommended to make a margin of 20-30 centimeters around the entire perimeter to facilitate installation of the structure into the ground.

Assembly can be done both on the surface and inside the pit. If installation is carried out at depth, the parts must be supplied by two people. But the structure assembled on the surface can only be lowered with the help of a crane.

Installation is quite simple:

- the bottom (slab) is placed in the center of the pit;

- the rings are lowered one by one from above (you must ensure that they fit tightly into the grooves);

- the assembly is completed by installing the neck and hatch.

Connecting pipes will not be a problem - the material is quite easy to mechanically influence. However, experts recommend cutting holes on the surface after preliminary marking on the rings. Rubber bushings are inserted into the holes - this material fits tightly to the pipes and does not require additional treatment with sealant. The pipes are connected directly in the trench - they are pushed through a homemade bushing, which is pressed against the pipe according to the principle of a socket bushing and ensures reliable fastening of the pipeline.

The final stage . The gap between the walls of the pit and the well is filled with sand or clay. The backfill is compacted on top. If necessary, an insulated caisson or change house can be built above the well mouth.

OUR ADVANTAGES

- Delivery of orders worth up to 50 thousand rubles is possible - BY CALL Without prepayment, subject to the availability of goods in stock! (For Moscow and Moscow region).

- We help our clients solve the problem of DELIVERY products to the site!!! We can also organize UNLOADING at the site!!!

- Possible shipment and delivery on WEEKENDS and HOLIDAYS (By prior arrangement)!!!!

- We will help you calculate the required amount of materials!

- For 10 years we have been producing and selling products of only ELITE quality and only from HIGH-CLASS raw materials!

- We always meet the agreed deadlines !!!

- We provide a FULL PACKAGE OF DOCUMENTS!!! CASH and NON-CASH PAYMENT !!!

- Can be purchased from ONE piece!!!!

- Before you buy polymer sand products from ANOTHER MANUFACTURER, DO NOT BE LAZY TO COMPARE THE SAMPLES WITH OURS!!!!

- Call us right now - HURRY TO PURCHASE products AT THE OLD PRICE , raw materials are becoming more expensive!!!

INSTALLATION FEATURES OF POLYMER SAND RINGS

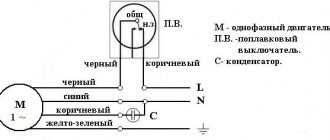

All elements of the well / caisson / septic tank are equipped with locks (tongue and groove) for fixation. To seal the well, coat the joints (locks) with bitumen mastic or a special sealant. The installation of the well can be done manually, without the use of additional equipment. A technological hole for connecting pipes can be made using a hole saw (crown), a jigsaw or a conventional drill with a 5-6 mm drill bit. Please note that during operation, the cutting tool will be subject to increased wear due to the sand in the polymer-sand composite from which our products are made.

Warranty period

Manufacturers provide a guarantee of about 50 years for reinforced concrete products, but indicate that these parameters relate only to basic technical characteristics. Those. the ring will definitely not fall apart or become thinner. But they cannot give a guarantee for the tightness of the joints, so even the most durable factory wells can silt up in a couple of years if the installation was carried out incorrectly.

With polymer sand wells such incidents are excluded. Therefore, manufacturers provide a guarantee of up to 100 years, although plastics in nature decompose over 400 years, and the sand included in the raw material is eternal.

Source: aqua-rmnt.com/kanalizaciya/kanal-kolodcy/polimerpeschanyj-kolodec.html

PHOTO GALLERY

We also offer you: Polymer-sand paving slabs - Polymer-sand tiles - Polymer-sand hatches - Polymer-sand rings: well, caisson, septic tank - Drainage trays with drainage grates - Facade panel and tiles - Basement panel and siding - Caps on the fence post - Lawn grid, eco-parking - Garden decorative fencing for beds, flower beds, flower beds - Flower beds, flowerpots, trash cans - Speed bump - PZK slab - Tactile tiles - Installation, laying, construction - Delivery of polymer-sand products and components

You can buy polymer sand wells, caissons, Tetto septic tanks in cities such as:

Belgorod region, Belgorod, Stary Oskol, Bryansk region, Bryansk, Klintsy, Vladimir region, Vladimir, Kovrov, Murom, Alexandrov, Gus-Khrustalny, Voronezh region, Voronezh, Borisoglebsk, Liski, Rossosh, Ivanovo region, Ivanovo, Kineshma, Shuya, Kaluga region, Kaluga, Obninsk, Kostroma region, Kostroma, Kursk region, Kursk, Zheleznogorsk, Lipetsk region, Lipetsk, Yelets, Moscow, Moscow region, Voskresensk, Chekhov, Stupino, Domodedovo, Vidnoye, Serebryanye Prudy, Moscow region, Balashikha, Zheleznodorozhny , Zhukovsky, Kolomna, Korolev, Krasnogorsk, Lyubertsy, Mytishchi, Odintsovo, Orekhovo-Zuevo, Podolsk, Pushkino, Sergiev Posad, Serpukhov, Khimki, Shchelkovo, Elektrostal, Aprelevka, Bronnitsy, Volokolamsk, Golitsyno, Dzerzhinsky, Zaraysk, Zvenigorod, Istra, Kashira, Kotelniki, Kubinka, Kurovskoye, Lukhovitsy, Mozhaisk, Necklace, Lakes, Protvino, Pushchino, Ruza, Staraya Kupavna, Taldom, Troitsk, Chernogolovka, Shatura, Shcherbinka, Elektrogorsk, Elektrougli, Oryol region, Orel, Livny, Ryazan region, Ryazan , Kasimov, Mikhailov, Smolensk region, Smolensk, Vyazma, Roslavl, Tambov region, Tambov, Michurinsk, Tver region, Tver, Vyshy Volochek, Rzhev, Kimry, Tula region, Tula, Yasnogorsk, Venev, Mordves, Ivankovo, Novomoskovsk, Aleksin, Donskoy, Uzlovaya, Shchekino, Yaroslavl region, Yaroslavl, Rybinsk, Arkhangelsk region, Arkhangelsk, Severodvinsk, Nenets Autonomous Okrug, Naryan-Mar, Vologda region, Vologda, Cherepovets, Kaliningrad region, Kaliningrad, Karelia, Petrozavodsk, Komi Republic, Syktyvkar, Vorkuta , Ukhta, Leningrad region, Vsevolozhsk, Vyborg, Gatchina, Kirishi, Sosnovy Bor, Tikhvin, Murmansk region, Murmansk, Apatity, Severomorsk, Novgorod region, Veliky Novgorod, Borovichi, Pskov region, Pskov, Velikiye Luki, St. Petersburg, Kolpino, Peterhof, Pushkin, Krasnoe Selo, Kronstadt, Zelenogorsk, Sestroretsk, Lomonosov, Pavlovsk, Adygea, Maykop, Astrakhan region, Astrakhan, Volgograd region, Volgograd, Volzhsky, Kamyshin, Kalmykia, Elista, Krasnodar region, Krasnodar, Sochi, Armavir, Novorossiysk, Anapa, Belorechensk, Gelendzhik, Yeisk, Kropotkin, Krymsk, Labinsk, Slavyansk-on-Kuban, Timashevsk, Tikhoretsk, Tuapse, Rostov region, Rostov-on-Don, Taganrog, Bataysk, Volgodonsk, Novocherkassk, Novoshakhtinsk, Shakhty, Azov, Gukovo , Kamensk-Shakhtinsky, Salsk, Republic of Crimea, Alupka, Alushta, Armyansk, Bakhchisaray, Belogorsk, Dzhankoy, Evpatoria, Kerch, Krasnoperekopsk, Saki, Simferopol, Old Crimea, Sudak, Feodosia, Shchelkino, Yalta, Bashkortostan, Ufa, Sterlitamak, Neftekamsk , Oktyabrsky, Salavat, Belebey, Beloretsk, Ishimbay, Kumertau, Meleuz, Sibay, Tuymazy, Kirov region, Kirov, Mari El, Yoshkar-Ola, Volzhsk, Mordovia, Saransk Nizhny Novgorod region, Nizhny Novgorod, Arzamas, Dzerzhinsk, Balakhna, Bor, Vyksa, Kstovo, Pavlovo, Sarov, Orenburg region, Orenburg, Orsk, Buzuluk, Novotroitsk, Penza region, Penza, Zarechny, Kuznetsk, Perm region, Perm, Berezniki, Krasnokamsk, Kungur, Lysva, Solikamsk, Tchaikovsky, Samara region, Samara, Togliatti, Novokuibyshevsk, Syzran, Zhigulevsk, Chapaevsk, Saratov region Saratov, Balakovo, Engels, Balashov, Volsk, Tatarstan, Kazan, Naberezhnye Chelny, Almetyevsk, Nizhnekamsk, Bugulma, Elabuga, Chistopol, Leninogorsk, Udmurt Republic, Izhevsk, Votkinsk, Sarapul, Glazov, Ulyanovsk region, Ulyanovsk, Dimitrovgrad, Chuvashia, Cheboksary, Novocheboksarsk, Dagestan, Makhachkala, Derbent, Kaspiysk, Khasavyurt, Buynaksk, Izberbash, Ingushetia, Nazran, Kabardino-Balkarian Republic, Nalchik, Prokhladny, Karachay-Cherkess Republic, Cherkessk, Stavropol skiy region, Stavropol, Essentuki, Kislovodsk, Nevinnomyssk, Pyatigorsk, Budennovsk, Georgievsk, Mineralnye Vody, Mikhailovsk, Chechen Republic, Grozny, Kurgan region, Kurgan, Shadrinsk, Sverdlovsk region, Yekaterinburg, Nizhny Tagil, Kamensk-Uralsky, Pervouralsk, Asbest, Berezovsky , Verkhnyaya Pyshma, Krasnoturinsk, Lesnoy, Novouralsk, Polevskoy, Revda, Serov, Tyumen region, Tyumen, Ishim, Tobolsk, Khanty-Mansi Autonomous Okrug - Yugra, Nizhnevartovsk, Surgut, Nefteyugansk, Kogalym, Nyagan, Khanty-Mansiysk, Yamalo-Nenets Autonomous Okrug, Novy Urengoy, Noyabrsk, Chelyabinsk region, Chelyabinsk, Magnitogorsk, Zlatoust, Kopeisk, Miass, Ozersk, Troitsk.