Structural steel is a material of special strength and ductility, which provides high resistance to destruction of structures made from it. It is an alloy, certain characteristics of which make it possible to use a multidisciplinary material for the manufacture of industrial mechanisms and building structures.

What is structural steel

Mechanisms and structures used in manufacturing and construction enterprises are subject to high quality and durability requirements. For this reason, the metal for their production must have special technological properties to ensure trouble-free operation in various environmental conditions. These requirements are met by a group of structural steels, the representatives of which are endowed with specified parameters of chemical, physical and mechanical properties.

The composition of structural alloys contains a set of useful additives - iron, manganese, copper, silicon and other elements, but the main parameter that determines all the properties of rolled steel is carbon. Increasing the carbon content in the alloy increases the strength of the metal and the threshold of its cold brittleness, which allows steel structures to withstand harsh climatic conditions, as well as high industrial loads.

At the initial stage of classification, the family of structural alloys is divided into two large categories:

- high-quality carbon steel;

- alloyed quality.

The quality of carbon steels is affected by the content of harmful additives in them:

- phosphorus (P) gives rolled metal the ability to crack and break during mechanical processing (cold);

- sulfur (S) promotes cracking under high pressure during hot working (red heat spectrum).

The use of parts made of carbon metal with a high content of phosphorus and sulfur is justified when it is necessary to increase the degree of machinability of the product by cutting (automatic types of steel).

Marking

Taking into account harmful impurities, the marking of structural alloys is distinguished by some features:

- conglomerates of ordinary quality, containing up to 0.05% of harmful additives, are marked with the designation “St”;

- high-quality metal containing a maximum of 0.035% sulfur-phosphorus impurities is marked “Steel”;

- high-quality metal raw materials containing up to 0.025% impurities are provided with the final letter “A”;

- especially high-quality ones with 0.015% phosphorus and sulfur are marked with the final letter “Ш”.

Based on the scope of application of rolled metal, it can be construction (mainly low-carbon type) and engineering (medium and low-carbon category). Medium-carbon structural steel (0.25-0.55% sulfur) is used in mechanical engineering due to its good combination of mechanical properties after heat treatment. Metal with a low carbon content is used for construction work due to its good weldability and low susceptibility to aging.

Marking and classification of steel by chemical composition

As mentioned earlier, one of the main divisions of this metallic material is based on its chemical composition. The basic components of the material are reinforced concrete and carbon (its concentration is less than 2.14%). Based on the concentration and proportions of additives used, iron accounts for at least half the volume.

Based on the level of carbon content, steel products are divided.

- Low-carbon - carbon no more than 0.25%.

- Medium carbon - from 0.25 to 0.6%.

- High carbon - from 0.6%.

Increasing the carbon component helps to increase metal hardness, but at the same time reduces its strength. To improve the performance of alloys, various chemical elements are added to them, after which they are converted into alloy steels. They come in three types.

- Low alloyed - the volume of additives is less than 2.5%.

- Medium alloyed - 2.5-10%.

- Highly alloyed - can reach 50%.

| steel grade | WITH% | S<= | P<= |

| St 0 | <=0,23 | 0,07 | 0,055 |

| St 1 | 0,06-0,12 | 0,045 | 0,055 |

| St 2 | 0,09-0,15 | 0,045 | 0,055 |

| St. 3 | 0,14-0,22 | 0,045 | 0,055 |

| St. 4 | 0,18-0,27 | 0,045 | 0,055 |

| St. 5 | 0,28-0,37 | 0,045 | 0,055 |

| St. 6 | 0,38-0,49 | 0,045 | 0,055 |

| St. 7 | 0,50-0,62 | 0,045 | 0,055 |

Carbon structural steel

The quality of rolled metal of this type can be ordinary or high. Material of ordinary quality is cheaper due to less purification from harmful components, and is distinguished by a large number of non-metallic impurities.

Gradation by quality indicator

Structural steel of ordinary quality, according to GOST 380-94, is subject to classification into three characteristic groups:

- A – alloys of this group do not require further heat treatment, which helps to preserve the original properties of the original metal. The marking is standard - the letters “St” plus numbers indicating the degree of strength and ductility – St1, St3, etc.

- B – the guaranteed chemical composition of the material of this group is amenable to deoxidation. The marking contains the letter “B” indicating the degree of deoxidation at the end - BST3sp (calm), BSt1kp (boiling). The number represents the percentage of carbon.

- B – a group of high-quality steels with a guaranteed chemical composition that can withstand mechanical processing. Marked with the letters VSt1, VSt3, etc. To produce metal products from this group, additional processing will be required, mainly by welding.

Rolled metal of ordinary high-quality composition is used for the manufacture of parts requiring welding, necessary for working under light load conditions. Structural steel of this type is mainly used in the automotive industry, as well as in the construction industry for mass-produced structures.

Ordinary metal of the appropriate grades is used for the production of nails, wire, and rivets. The structural material is used to produce axles and shafts that operate under light loads, various types of fasteners, and are used to produce shaped rolled products.

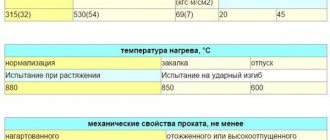

A high-quality type of carbon alloys must comply with GOST 1050-88; the production of alloys requires strict compliance with the parameters of composition, melting, and casting. Requirements for the characteristics of the chemical composition provide for the mandatory content of harmful additives - 0.04% each of sulfur and phosphorus. The marking of improved structural materials is located in the number range 08-85 (Steel08, Steel15, Steel80, etc.).

Restrictions

The carbon content, indicated by a digital index, imposes certain restrictions on the quality and scope of steel products.

| Name | Product properties, scope of application |

| Low carbon | Lightly loaded parts made of this material are characterized by low strength with high ductility and weldability. The products are suitable for cold stamping, excluding heat treatment. The metal alloy is used to produce complex parts for automobiles and critical welded structures. |

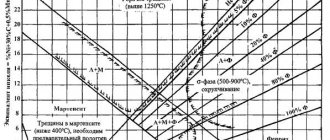

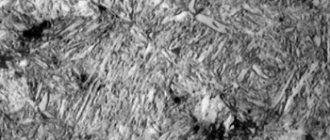

| Medium carbon | Medium-carbon structural steel becomes after improvement by hardening and hot tempering (up to 650°C). These indicators increase the strength of steel parts, but reduce ductility, which allows cutting. High-strength material improved by hardening is used in mechanical engineering |

| High carbon | High carbon materials are characterized by a high percentage of manganese. This type of metal is used to produce products that require increased elasticity and wear resistance (springs, springs). After annealing, the material lends itself well to cutting |

| Quality | Construction material of this category contains an increased proportion of impurities - sulfur-phosphorus, lead additives. High-quality metal is used to produce parts that undergo advanced processing that does not harm metal-cutting tools. This is a class of automatic steels enriched with sulfur, phosphorus, and lead, intended for use on automatic machines |

To increase the wear resistance of metal products, graphitization, cold hardening, and surfacing are used. Such methods of improving the parameters of structural steel make it possible to increase the hardness of the material and its resistance to wear.

Application area

The specific area of application of carbon metal products is determined by its characteristics.

| Structural alloys | Properties of steels, areas of application |

| Mechanical Engineering | Used for automobile production due to its high mechanical properties that extend to the entire material. Machine parts are reliable, resist heavy loads and impacts well, maintaining increased strength |

| Building | Carbon alloys are used to make bridge structures, trusses, and equipment for oil and gas pipelines. The main requirement for structural steels of this type is good weldability with a small volume of alloying components. Alloying with silicon and manganese contributes to increasing strength. |

| Reinforcing | Reinforced concrete structures are reinforced with steel reinforcement, which helps to increase their strength when exposed to loads. This type of metal is represented by rods (smooth, profiled) and wire. Depending on the strength requirements for structures (pre-stressed or unstressed), steel reinforcement is strengthened by heat treatment |

| Spring | The properties of elasticity are used to make spring steel. The main requirement for structural metal is increased fluidity, which is achieved by hardening and tempering at temperatures up to 400°C. This temperature level provides the highest elastic limit value. Structural steels for especially loaded springs are reinforced with the addition of vanadium and chromium |

| Ball bearing | The products are subject to special hardness requirements due to high local loads. For this reason, high-carbon steel is chosen for the production of rolled metal. Ease of hardening at low temperatures and the use of oil is ensured by alloying with chromium; to improve hardening, silicon-manganese elements are introduced |

| Cementable | This type contains 0.1-0.25% carbon, which allows them to be used for the production of products subject to cementation. Parts of the cemented and cyanidated class (bolts, gears, nuts, etc.) are small in size with increased strength due to the introduction of useful additives |

The boiler variety of carbon alloys is produced in the form of boiler sheets of two types - thick-sheet material with a thickness of over 4 mm and a thin-sheet base with a thickness of less than 4 mm. Boiler-type steel is used to make steam boilers (hot water boilers), as well as vessels (steam pipelines, manifolds, pipes) capable of withstanding elevated temperatures (up to 450oC) at high steam pressure. High-quality rolled metal has good weldability and is marked with the letter “K” at the end (12K, 16K, 22K, etc.).

What does steel grade mean and how to determine it

In world practice, there are various steel marking systems. There are no uniform standards for products due to the large number of organizations monitoring and labeling metal products. In Europe, the document EN10027 is in force, which has a similar approach to the Russian one in naming steels.

According to the current Russian standard, alloying elements are designated by Cyrillic letters, and the number indicates the amount of the element as a percentage. The absence of a digital value behind the letter means that the content of the alloying additive is from 0.8% to 1.5%, with the exception of molybdenum and vanadium whose mass fraction is lower. The absence of a number in front of the alloy steel grade means that it contains 1% carbon or more. The designation and interpretation of alloying elements of steels is given in the table

| Item name | Chemical symbol | Designation in the brand | Examples |

| Carbon | C | not specified | |

| Chromium | Cr | X | 40X; 40Х13 |

| Silicon | Si | WITH | 65SG; 30ХГСА |

| Nickel | Ni | N | 45ХН; 12Х18Н10Т-Ш |

| Manganese | Mn | G | 65SG; 30ХГС |

| Tungsten | W | IN | CHVG; Х6ВФ |

| Molybdenum | Mo | M | 12ХМ; 15N2M |

| Cobalt | Co | TO | R10F5K5; R6M5K5 |

| Titanium | Ti | T | 15ХГН2Т; 5ХНТ |

| Vanadium | V | F | 12ХМФ; 12Х8ВФ |

| Aluminum | Al | YU | 38ХМНУА; 36НХТУА |

Chromium in an amount from 1% to 4% improves the hardenability of the alloy, increases its strength and heat resistance. Various parts of mechanisms operating under high loads are made from chromium. Chromium is found in large mass fractions in stainless and heat-resistant samples.

Silicon in an amount of 1% to 1.5% increases the elastic properties of the material and is used for the manufacture of springs and leaf springs. Silicon is often included in the instrumental group.

Nickel in small proportions has a beneficial effect on impact strength and strength, and in large quantities, usually in combination with chromium, it imparts heat-resistant properties and high corrosion resistance.

Manganese content of 1% to 1.5% increases toughness, that is, its ability to withstand shock loads at low temperatures, when the material becomes brittle.

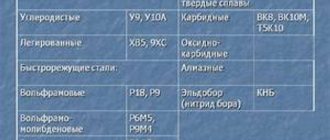

Tungsten dramatically increases red-hardness and wear resistance, which is a necessary property of cutting materials in which it is most widely used. Molybdenum , like tungsten, increases wear resistance and red-hardness, increasing resistance to oxidation at high temperatures.

Cobalt , being in the composition of steel and non-metallic cutting materials, gives them resistance to impact loads at elevated temperatures. The presence of titanium promotes fine graining in the unhardened state and also improves oxidation resistance.

Vanadium , usually combined with chromium, improves strength properties and increases resistance to oxidation at high temperatures. Aluminum increases heat resistance and scale resistance, in addition, like titanium, affecting the extraction of grain size.

Features of alloy alloys

Along with high-quality carbon steels, alloy steel is used for structures in construction, as well as for parts of mechanical engineering and instrument making. Metal alloying (enrichment of the base composition with useful additives) endows finished products with a number of special properties, improves technological, strength, and physicochemical properties.

Additives in the form of manganese, nickel, chromium are introduced one element at a time or in groups. Depending on the percentage of additional components, three groups of steels are distinguished:

- up to 2.5-5% impurities – low-alloy material;

- up to 10% additives – medium alloy metal;

- over 10% of impurities – high-alloy rolled products.

Alloy structural steel is used for the most critical components of mechanisms subjected to particularly heavy loads. To ensure high structural strength, such parts must undergo final heat treatment to guarantee increased strength.

Marking of structural type alloy steels has a complex structure:

- begins with two numbers indicating the percentage composition of carbon;

- a specific alloying element is prescribed with a Russian letter;

- the number following the letter indicates the percentage of this additive;

- the final letter “A” indicates that the steel is high quality.

Benefits of Supplements

The main task of alloying components is to increase the hardenability of the alloy, about 90% of which is ferrite, which is a conglomerate of carbon with alloying elements in solid form. After adding alloying inclusions to the ferrite base, they dissolve, promoting compaction of the ferrite. The alloying process can significantly improve the quality of the final alloy:

- increase strength without subjecting the product to heat treatment;

- increase hardness, toughness, hardenability level;

- enrich with special properties (heat resistance, corrosion resistance).

Different types of additives improve certain properties of structural steel. The introduction of nickel helps to increase impact strength, and in combination with chromium provides the ability for deep hardening. This combination of impurities guarantees a uniform improvement in the properties of the conglomerate over the entire cross-sectional area.

Types of steels and features of marking

Steel is an iron-carbon alloy, the amount of which does not exceed 2.14%. The carbon component is necessary to achieve hardness, but it is extremely important to monitor its concentration. If it exceeds 2.2%, the metal will become very brittle, making it almost impossible to work with.

By adding any alloying elements, the required characteristics can be achieved. It is by combining the type and volume of additives that grades are obtained that have better mechanical properties and resistance to corrosion. Of course, quality indicators can be improved through heat treatment, but the use of alloying additives significantly speeds up this process.

The basic classification criteria are the following indicators.

- Chemical composition.

- Purpose.

- Quality.

- Structure.

- Degree of deoxidation.