Main types

There are two main types of barbed wire. Let's take a closer look at them.

Galvanized

Despite all the external similarities, modern barbed wire is not exactly the same as what was patented at the end of the 19th century. To date, about 450 patents have already been issued for it. Collectors of wire fences (it turns out there are such people) count up to 2 thousand different types and samples. Manufacturers' catalogs often mention only 2 dozen main varieties. The simplest option is a single-base corrugated design with spikes throughout.

The thickness of such a product is most often 2.8 mm. This is the option that is usually used in summer cottages and fences around private houses.

Reinforced

Coating with a protective layer of zinc does not always help solve the problems. Sometimes more significant strengthening of the enclosing structure is required. The following options are known:

- Bruno spiral (coils of different diameters);

- flat corrugated tape with a pointed edge;

- “chain-link” with diamond-shaped cells;

- spikes that complement the main fence.

A biaxial (more precisely, two-basic) barbed barrier is also in demand. For the most part, it is made of galvanized metal.

A typical barbed wire texture looks like this.

Products operating under voltage must be designed for a current of 2-10 kV. They are mainly produced for livestock farming and penitentiary use. Returning to tape structures, it is worth pointing out that they can damage significant areas of soft tissue. They are used to protect structures, including those built on frames and supports. And the classic type of barbed wire is used mainly in independent execution.

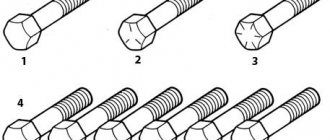

The traditional version is often called “thread”. This is always galvanized material with a thickness of 2.5 to 2.8 mm. Exceeding these limits is strictly not recommended. There are threads made from one wire or from two strands, braided into a “pigtail”. The same distinction is made between spikes. Stamped spikes are used mainly where the maximum degree of security is needed.

The elastic “thread” is relatively strong and has a small cross-section. This material is more resistant to the negative effects of temperature changes. Resistance to mechanical stress is also increased. As a result, “threads” with increased elasticity are used for the construction of large spans. As for the “soft” wire, it is much more convenient when fastening.

However, over time, such a fence weakens and begins to sag intensively. This drawback is especially pronounced with significant spans. The problem is not too significant if you install the wire in small areas. In addition, technologists classify piercing and cutting tape and reinforced “twist” into a special category. Experts consider everything else to be only subspecies of the three main types of barbed wire.

Description

The main purpose of the fence is to stop the movement of an animal or person along a previously chosen route. In the case of cattle, this is leaving the walking area. For people:

- preventing entry into someone else's territory in order to seize property or secrets;

- protection against anti-vandal actions;

- restricting access to areas with substances harmful to health - industrial landfills, reservoirs, etc.;

- fencing an industrial zone with working mechanisms and for solving other similar problems.

In general terms, barbed wire is a wire-tape structure with short, pointed, piercing-cutting edges sticking out in different directions. The latter, digging into the body of an animal or person, create unpleasant irritating sensations. This feeling stops further progress.

Types of structures

The protective product is made of steel. Based on their composition, types of barbed wire are divided into:

- Wire construction. Made in the form of a metal thread (cord):

- Homogeneous. It consists of pieces of wire, parts of which are woven in such a way as to ensure an inextricable connection. The pointed ends are directed to the sides.

Corrugated. The flexible parts are a “pigtail” woven into a strand. Two wires are used. The number of protruding sharp ends in one node increases to four.

According to the degree of hardness, the thorn is divided:

- Soft. Made from annealed wire. It is characterized by increased flexibility, bends easily, and is convenient for installation. It is used for fencing small areas, more often for domestic needs.

- Elastic. Has increased rigidity and strength. Used when there are long spans.

The classic type of barbed wire is produced according to GOST 285-69 standards.

- ASKL is a reinforced twisted razor tape twisted around a load-bearing reinforcing wire. The disadvantage is that the barbed strip can be dismantled quite easily, providing passage.

AKL – reinforced razor tape. The latter is rolled (wrapped lengthwise) on a power flexible rod. The design successfully resists mechanical stress. It is almost impossible to destroy it with a cutting tool. The barbed element is difficult to separate from the flexible power core.

This type of barbed fence has another common name - EGOZA (GYURZA, CONCERTINA).

Installation rules

Vertical supports dug into the ground are fastened in increments of no more than 3 m. These supports are quite sufficient for installing the wire itself; nothing else is required. But increasing the degree of security is only possible with additional tension on the wire in the transverse plane relative to the main strip. Barbed thread can be used in addition to already created protective structures. In this case, it is mounted on top of fences and gates.

Reinforced tape is much more difficult to install. To install it you will need:

- scissors for cutting metal reinforcement;

- Grinder;

- some other tools, which depends on the method of fastening the wire at the support points.

Installation of Egoza wire will be simplified when using special brackets. For flat and spiral models, you can use the same type of brackets. They can be installed in a variety of places. Now they sell brackets in different formats:

- direct;

- L-shaped;

- Y-shaped.

You should prepare the fence yourself with a step between brackets of no more than 2.5-3 m. You need to work not only in protective gloves, but also in thick clothing. Sometimes it makes sense to even wear safety glasses. The shape of the bracket is selected taking into account ease of installation. Before starting work, the area should be marked.

The reference points are fixed using bolts or welding. Then a spiral is mounted on top of the brackets using special brackets. The next step is to stretch the double string along the entire length of the spiral. The spiral itself is aligned, and it is secured using twists of a special pattern.

Finally, the individual parts of the wire fencing are connected using mounting brackets. If the fence is energized, you must warn about this by hanging special signs around the perimeter with clear warning text.

Watch the video below about the production of barbed wire.

What is spiked wire?

If you still don’t understand why barbed wire fencing is called the most effective type of fencing, study the features of this material.

Interesting video about how spiked wire was invented:

Firstly, strong reinforced threads are almost impossible to cut even with wire cutters. No random thief will carry with him a bunch of special devices to overcome such a fence.

Secondly, in different sections of the tape or spiral, the location and frequency of the spikes can change, which makes it possible to further protect the most vulnerable places in the fence.

Well, and finally, pay attention to the fences of various government agencies, prisons, closed facilities - you will see “thorns” almost everywhere, which means that the effectiveness of such a fence has been tested more than once. Such fences usually look quite intimidating

Such fences usually look quite intimidating

pros

The advantages of this material include not only good protective properties. Besides:

- Galvanized options have a long service life (plus or minus 20 years);

- Installing barbed wire on a fence can be done with your own hands;

- This material can be installed on a concrete fence, or on a wooden or plastic one;

- A big plus is the relatively low cost;

- You can install a tape with spikes on an existing fence;

- Such a fence will be as light and breathable as possible.

Of course, when installing razor tape you will have to use protective gloves and fairly durable overalls. The risk of damaging your hands or other parts of the body with such a thread is very high; the wounds remain very unpleasant and “painful”.

What signs can warn of the danger of high voltage? The only disadvantage of razor tape is its unsightly appearance. Many people associate it with a prison fence. But if there is a need to ensure maximum safety on the site, decorative characteristics may fade into the background.

Mounting brackets

To firmly secure the “thorn” to the fence, special brackets are used. They have different shapes, which are used depending on the type of fence and type of wire.

The following options exist:

- straight brackets (vertical or inclined) with brackets, between which wire is stretched in several rows of different densities;

- inclined brackets in the shape of the letter L - the principle of installing razor tape is the same, but thanks to the configuration of the fastenings, the fence becomes even more reliable;

- Y-shaped brackets serve the same purpose; it is especially convenient to attach fidgets to them;

- Semicircular brackets are great for attaching voluminous spiral tapes both to fences and to the surface of the ground.

If you are installing a barb on a residential property, straight brackets will be sufficient. They can be angled to make it impossible to get behind the fence.

Fencing scheme option

Installation of barbed wire on a fence

To install razor tape on a ready-made fence, you will need not only brackets, but also a set of certain tools. Namely:

- welding machine;

- metal staples;

- pliers;

- protective gloves and overalls.

In addition to barbed wire, you can purchase a steel string, which will hold the structure in the desired position and prevent it from sagging over time.

Scheme for using threads to hold the “thorn”

The order of work is as follows:

- Brackets are attached to the top of the fence;

- At a height of about half a meter from the edge of the fence, a steel thread is stretched between the brackets;

- A spiked fidget is wound along this thread in the required position and with sufficient frequency;

- The barb is attached to the brackets using metal brackets.

History of creation

It is impossible to name just one name of the person who invented the barbed defense. But it is quite obvious that the weak restraining ability of ordinary flat wire prompted its creation. It can hardly be considered as a serious barrier for animals on pastures or for criminals in prisons. In 1872, the American farmer G. Rose came up with the idea of attaching boards with sharpened wires to a simple wire fence. The patent was received approximately six months later.

But the modern look of barbed wire was created by Joseph Glidden. He realized that attaching sharp elements to boards was irrational, so he created a metal structure, which without additional devices became a serious obstacle. Wrapping them with metal wire without points helped prevent the spikes from moving.

Important: Glidden did not create his design from scratch, but was based on samples already known at that time, including those proposed in France

Barbed wire also owes a lot to J. Gates. For the first time in the United States, he widely used advanced metal smelting methods, which made it possible to reduce production costs. It was also Gates who carried out an advertising campaign showing that dozens of cows were securely held by a wire fence. Reducing the price of the finished product and bright marketing did their job - soon the “thorn” was bought not only by those who were looking for an effective replacement for a wooden fence around their home. They began to use it in places where the abundance of forests made it possible to build traditional pens, because it turned out to be simpler and more profitable.

Types and applications of steel wire

As you can see, depending on the production method, the use of protective coating, as well as thickness, weight and density, different types of steel wire are produced.

When we talked about the manufacturing process, we mentioned that the finished product is fired. In this case, the output is a flexible product that can be used for knitting, for example, chain-link mesh, bending reinforcement, supports for trees or plants, and so on.

Such wire is usually galvanized due to the nature of its operation - outdoors, with frequent direct exposure to water, high and low temperatures.

- For Chainlink, heat-treated, zinc-coated wire with a diameter of 1.30 to 6.30 mm is used.

- For grape supports, flexible low-carbon steel wire with a rather small nominal cross-section is also used - 2.10-2.30 mm.

- For communication lines, only galvanized steel wire must be used, while the core itself is made of special “T” type steel.

Therefore, both thin and thick wire products are widely used. For some types of fittings it is also important to use rigid, unburnt wire.

And, in conclusion, we can say that we have proven what was said at the beginning: low-carbon steel wire is a truly universal material that is widely used to make completely different products that find their application in many areas of life.

Photo of barbed wire

Vaira Metal mesh Wire Fences and Fidget

- Rabitz

- Lightweight Cossack mesh

- Uzelfix mesh

- Welded mesh

- Masonry mesh for reinforcement from wire VR-1 (armopoyas)

- Cossack masonry mesh

- Expanded mesh

- Woven mesh GOST 3826-82

- Corrugated mesh

- Channeled mesh

- Twisted hexagonal mesh

- Stainless filter mesh

- Brass mesh L-80

- Conveyor woven mesh

- Conveyor woven mesh

- Hinged mesh

- Reinforcing façade fiberglass mesh

- Tensioner for mesh and wire

- Low carbon wire GOST 3282-74

- Egoza

- Metal fences

- Construction nails

- Perforated sheet

- Gabions

Steel fiber

- Lawn mesh

News

Installation of the “thorn”

To protect your dacha, there are 2 options for installing a protective fence:

- On top of or on a regular fence;

- Make a continuous spiked (barbed) fence.

For this we need:

- Barbed wire (preferably reinforced);

- Mounting brackets;

- Electric welding machine;

- Electrodes;

- Hardware (staples);

- Pliers;

- String;

- Protective clothing;

- Mittens.

The brackets are welded to the posts. The barbed wire is stretched and secured with hardware. To prevent it from sagging, the string is stretched. A “thorn” is evenly distributed and secured on top of it.

To make a continuous fence made of barbed wire (which can often be seen in the photo), pillars are dug in at a distance of at least 2 meters from each other. To increase stability, it is better to concrete them or make supports.

To tighten and fix the “thorns”, “eyes” are welded to the posts along the entire length. Their pitch is at least 100 mm. The barbed wire is secured to the “eyes” using hardware (staples).

To increase the protective functions of the fence, voltage can be applied to it. At the same time, you must remember to post a sign warning about this!

Design Features

Barbed wire is a metal thread or a narrow strip with barbs attached to it. The wire is available in several configurations. The material is used both for the construction of a full-fledged fence, and for an additional obstacle on an already installed fence of any type. The thorn is used both for fencing private houses and for protecting industrial facilities.

Initially, the design was invented to protect the territory against animals, and was often used in cattle breeding.

Expert opinion

Vladimir Ulyanov

I have been involved in fences for over 10 years, answering questions and helping people cope with the installation task on their own.

Ask a question to an expert

Such a wire fence does not allow painless passage into the fenced area, since the thorns cling on contact, which leads to large scratches and wounds to the body.

Later, the technology began to be used for fencing against people. The advantages of the design are its low cost, practicality and the ability to install the fence yourself.

Varieties

According to the manufacturing method, the “thorn” is divided into:

Galvanized steel wire with spikes along its entire length. Its thickness is 2.8 mm. It is the simplest protective structure for protecting your property on a farm or country house;

Reinforced (corrugated) tape. It looks like a thin strip of steel with razor-sharp edges. It has 2 varieties - AKL (straight) and ASKL (twisted).

Domestic manufacturers produce various versions of the “thorn” for all household, industrial, strategic and other needs. The most popular and well-known products are under two brands:

- "Egoza";

- "Gyurza."

Types and scope of application

Galvanized wire products can be made from a variety of materials. A steel, aluminum, titanium base is used. In some cases, manufacturers give preference to nickel, zinc, and copper. Suitable alloys are bimetallic or polymetallic.

Thanks to this, the wire has improved qualities and excellent corrosion resistance. It is sold to customers in special skeins of 20-200 kg. Coils of 0.8-1.2 tons are also used.

Galvanized wire is produced using thermal treatment technology or without the use of this method.

The methods of processing the material also differ - soft knitting treatment, thermal or hard treatment without treatment.

If the wire is subjected to thermal hardware action, then it can be used in the manufacture of nails with a diameter of 1-6 mm, chain-link mesh, and in the process of aerial cable fastening. Taking these factors into account, the price of galvanized wire is determined.

The semi-finished product is used in the production of household items - handles for buckets, hangers for hanging clothes, fasteners for drawers.

Sometimes the scope of application expands, and therefore it can be found in the process of reinforcing preparation of power transmission wires. It is used not only for installing cable products, but also for creating staples, key rings, and paper clips.

The material is used in the manufacture of mesh, and also as an element of security systems; in particular, galvanized barbed wire is popular.

There are several other areas of application:

- In welding works.

- For laying communication channels - it has normalized electrical resistance and low elongation. The material is type T steel. Diameter is 1.5-4 mm. The disadvantage is the risk of sagging as a result of heating. The coil of wire is covered with paper with an impermeable effect and a cloth containing chemical fibers.

- In the production of cores that are used in aluminum and steel wires without insulation. Grades for stranded and single-wire cores are used, belonging to types A, B and C, depending on the mechanical properties.

Overview of species

Today several types of products are produced under the name “Egoza”. They all have different external data and characteristics. The simplest type is wire or thread-like, looking like a steel cord. It can be homogeneous, with an inextricable interweaving of elements in the bay and pointed spikes directed to the sides. Corrugated wire of this type is woven in the form of a “pigtail”, which increases its strength characteristics; the number of spikes and strands is doubled.

By composition

Barbed wire is not only round - it can be made in the form of a strip. This “Egoza” has a flat structure, the spikes are located along its edge. Since tape wire is made from a galvanized strip of metal, it is quite easy to cut with special tools. This greatly limits its independent use.

They are divided into 2 categories.

- ASCL. Reinforced tape twisted and wrapped around wire reinforcement. This type is quite popular, but not very reliable - it can be easily dismantled to free up the passage. In this case, the number of thorns increases; externally, the fence looks quite impressive.

- AKL. Razor-reinforced tape in this design is wrapped and rolled in the longitudinal direction on a flexible rod base. The design is resistant to mechanical damage, strong and durable. The standard thickness of the tape is 0.55 mm, the profile is equipped with double-edged and symmetrical spikes.

It is worth considering that according to the standard, Egoza type wire should be made exclusively from galvanized wire and tape of established samples. The core diameter is set to 2.5 mm. The thickness of the tape for combined products varies from 0.5 to 0.55 mm.

By degree of hardness

Considering this characteristic of barbed wire, two main categories can be distinguished.

- Elastic. It provides a high level of strength and rigidity of the material. This variety is intended for creating long-span fencing.

- Soft. For its manufacture, annealed wire is used. It is very flexible and easily takes the desired direction. It is convenient to work with such material when installing complex-shaped, short sections of the fence. Soft wire “Egoza” is easy to use in everyday life.

Volumetric and flat

Barbed wire "Egoza" AKL and ASKL has a tape type of construction. But this brand also produces volumetric and flat fencing. They allow you to quickly deploy the structure on the ground, covering large areas on any type of terrain. Here are the most popular options.

SSB (spiral safety barrier). The volumetric structure is made of AKL or ASKL wire by winding with connection with staples in a checkerboard pattern in 3–5 rows. The finished fence is springy, elastic, voluminous and difficult to overcome. It is almost impossible to push it apart or bite it with tools.

Peculiarities

Egoza barbed wire is a type of security fencing produced by the brand of the same name. The Chelyabinsk plant where it is produced is part of the group. Among his clients are government agencies, nuclear, thermal, electric power facilities, the Ministry of Internal Affairs and the Armed Forces of the Russian Federation. When developing wire, specialists from the Egoza perimeter fencing plant take into account the level of responsibility when protecting objects of special importance and the needs of ordinary citizens who want to ensure reliable protection of their areas.

Flat belt structures have more varied technical characteristics. Thus, for Egoza products, a spiral with a five-rivet fastening of the AKL type, the mass of the coil, depending on its diameter, ranges from 4 to 10 kg. The weight of 1 meter is easy to calculate based on the length of the skein - normally it is 15 m.

The manufacturer produces several types of Egoza brand wire. All products have common features: made from steel or galvanized tape, the presence of sharp spikes. All varieties are highly durable and reliable, have a long service life, and can be mounted either around the perimeter of existing fences or independently, supported on poles.

The main purpose of Egoza wire is to protect objects from unauthorized entry. In livestock grazing areas, it is used to prevent or stop the movement of the animal outside the designated area. In industrial, military, secret, protected facilities, in water and environmental protection zones, in places with limited access, barbed wire acts as a protective barrier, allowing it not to block visibility and access to natural light, as is the case with solid fences.

Depending on the type of product, its installation can be carried out in different ways. Most often this wire is used for:

- creating fences around the perimeter of the roofs;

- fixation on vertical posts (several levels);

- installations on supports with a horizontal tension string for 10–15 sections;

- laying on the ground (quick deployment).

All these features make barbed wire a popular solution for use on various types of objects.

More about Egoza

The EGOZA logo (trademark) belongs to the enterprise of the same name, located in the city of Miass, Chelyabinsk region (next to the Ilmensky Nature Reserve). The Ural company became one of the first developers and pioneers in the implementation of metal security systems in the Russian Federation.

Egoza barbed wire is a prefabricated structure. Includes:

- flexible profile strip of metal with sharp cutting edges;

- power element - steel core.

To produce the tape, galvanized low-carbon steel with a thickness of 0.5–0.55 mm is used. Requirements for metal are set out in GOST 3559-75 or GOST 14918-80. The cutting of shaped parts that form the cutting edges is carried out on a press.

The power element is a zinc-coated wire with a diameter of 2.5 mm (a range of up to 3–4 mm is possible), produced in accordance with GOST 7372-79 “Steel rope wire”, GOST 9850-72 “Galvanized steel wire for wire cores” or GOST 9389-75 “Spring carbon steel wire.” The use of such products is justified by the fact that they are characterized by increased resistance to cutting, biting with a tool or chopping with a chisel (axe). This increases the time it takes to eliminate the obstacle that has arisen in front of the uninvited guest.

Based on fidget fencing, a number of complex products have been developed and introduced into production:

- SBB EGOZA – spiral safety barrier “EGOZA”. It is a spiral (conventionally – 3d format) based on ACL or ASCL. Fixation of adjacent turns is carried out with staples made of tape or iron wire. This ensures enhanced protective functions:

- impossibility of pressing down the unfolded spiral;

the occurrence of serious difficulties when biting or sawing a thorn;

- Such a barrier cannot be overcome by an animal or an unprepared person.

Finished products are formed into coils. The coil diameter is 400, 500, 600, 750, 900 and 1700 mm. The latest size of the fidget is a reinforced fence under its own name SBB “BARS”.

Design Features:

- power element – rod made of spring steel (steel 65G) Ø 4mm;

- tape – galvanized metal strip 0.5–0.55 mm thick;

- spine type – ASCL;

- used to create fences at sensitive facilities.

- increased speed of deployment (collapse) of the fence;