Floor-standing toilets have been out of competition for a long time, but everything is changing. Owners of modern apartments are increasingly choosing hanging models. This pleasure is not cheap, but this is practically the only drawback of this solution. But among the advantages of the design are its excellent design and ease of maintenance.

It is important that the installation of a wall-hung toilet is carried out in accordance with all the rules. We will tell you how and in what sequence the work is carried out, what devices will be needed to attach the bowl. Taking into account our recommendations, you can do everything yourself or supervise the actions of plumbers.

How is the suspended structure constructed?

A home craftsman can easily handle the installation of a wall-mounted model if he understands the distinctive features of its design.

The visible element of such a plumbing fixture is the toilet bowl itself. Its installation on the wall is carried out in two ways: using an installation and on a concrete base. In our article we will look at both options.

A wall-hung toilet model is more expensive than a regular floor-standing version, but you can reduce costs if you install the product yourself

The strengths and weaknesses of the suspended type of plumbing are listed in the article, which describes in detail the varieties and design specifics, and provides guidelines for choosing the optimal model for you personally.

The design of a wall-mounted plumbing fixture can be roughly divided into three main elements, which will be discussed further.

Reliable steel frame (module)

The frame is the main element of the entire structure, which is attached to the floor and wall of the bathroom. It is the frame that supports the cistern and bowl. The quality of subsequent operation of the product depends on its reliability. After putting the toilet into operation, the structure will need to have a sufficient margin of strength to support the weight of an adult.

To secure the frame, you must have a solid base. Plasterboard walls cannot be considered in this capacity. The frame is equipped with a mechanism that allows you to vary the installation height of the toilet bowl in the range of 40-43 cm. To securely fasten the bowl, manufacturers recommend using strong pins made of steel.

In this photo, all three elements of the toilet design are clearly visible: a light blue frame, a gray-blue plastic tank with a flush button and a white bowl

The best models of support frames for hanging plumbing are listed in the article, which we recommend that you read.

Hidden cistern

The hidden fastening of this element, according to supporters of the wall model, is considered one of the advantages of the design. The material for its manufacture is very durable plastic. To prevent condensation from accumulating on the surface, the plastic is treated with styrene.

The tank has a flat shape, distinguished by a technological cutout on one side. This cutout is necessary for the drain key device. This hole has another purpose: it allows you to remove the drain tank fittings when performing repair work.

Another feature of hanging tanks is the economical drainage system that such a model can be equipped with. Depending on the need, the drain dose can be 3 or 6 liters.

The bowl is a visible structural element

The bowl is chosen, as a rule, based on the personal preferences of the users. It is in plain sight and must correspond to the overall interior of the room. In addition, the selected wall-hung toilet should be easy to use.

It is the toilet bowl, as a visible structural element, that should fit organically into the interior of the room: it can even have a square shape

Most buyers prefer an oval-shaped product. Although there are round, rectangular and even square models on sale.

Fastening elements are part of the selected model and are included in its configuration. There is no need to purchase additional hardware for a wall-hung toilet. In addition, among the wall-mounted models there are smart plumbing devices with electronic control and numerous hygienic functions.

Intelligent types of plumbing fixtures with retractable nozzles for washing and drying, deodorizing and other actions need to be connected to a power supply. Their installation is complicated by connecting the power line and setting up the system:

Image gallery

Photo from

Installation of the installation and fixation of the tank

Power line connection in a corrugated pipe

Installing a toilet and masking the installation

Setting up toilet functions after connection

Installation of a frame with a tank in a niche

The complexity of this method is that the installation of the frame in the niche is “non-standard”. The installation instructions from GEBERIT and GROHE do not cover this option, and the kit does not include fasteners for this.

Installation of the frame in a niche proceeds according to the following algorithm:

- Mark the line for installing the legs on the floor, taking into account the installation depth, the location of the water and sewer risers. The markings must be perpendicular to the walls of the niche or in the plane of the adjacent surface.

- The verticals on the walls of the niches are set off from this line.

- Mount reinforced guides of the UA50 profile on the floor, side walls of the niche and ceiling.

- Install the frame into the profile and fasten it to the floor, having previously drilled holes for the dowels.

- Set the height of the legs and the horizontal level of the frame.

- Fasteners (studs or other type of fastening) are made to a specific size to rigidly fix the installation to the “far” wall of the niche. Drill holes for these fasteners and attach the frame.

- Cut a section of the UA profile to the width of the niche. Attach it to the side profiles and frame.

- Install flush and drain fittings for a wall-hung toilet. Install studs to secure the bowl. Connect the tank to the water supply and the drain elbow to the sewer. Temporarily hang the toilet and connect it to the installation. Check the system for leaks and operability.

- Remove the tank, close the flush and drain holes with plugs, and close the toilet studs with protective tubes. Attach plasterboard cut to size to the profiles in two layers.

Careful assessment of pros and cons

When choosing a more modern model, you need to think carefully about whether it makes sense to unconditionally give preference to such a solution or whether you should still prefer the traditional option.

What attracts users to the suspended model and what makes them doubt it?

- Design. The laconic appearance of the product is a definite plus. An elegant bowl that does not touch the floor looks more aesthetically pleasing than the one that is built into it. The panel covering the installation site looks attractive. You can also select a suitable flush key option.

- Compact placement. This statement, by the way, causes controversy among experts. If we talk about the real, and not about the visual effect, then it is small. To install the installation not in a niche, you need about 15 cm. Let's add the thickness of the false wall to this value and make sure that the gain is not as great as we would like.

- Easy to maintain. The absence of a foot makes it easy to clean the space under the toilet. There is no hole in the floor that causes problems with cleaning and could disrupt the overall pattern of the floor covering.

- Repair work. Closed communications are good only if they work properly. In the event of a breakdown, access to them can be very difficult, and restoration of the interior can be expensive. Difficulties may also arise with repairing the tank if it is still needed.

- Psychological aspect of exploitation. The frame of the device is reliable enough to withstand loads of up to 400 kg. But overweight people may experience psychological difficulties when using this plumbing fixture: the fear that the bowl may come off and break. It is very difficult to relax in such a situation.

- Features of installing a wall-hung toilet. Of course, installing a wall model is more difficult than a floor model. To successfully complete your plan, you must either spend additional money by inviting specialists, or energy and time if you decide to do the work yourself.

- Price. A wall model will cost you more than a floor model. This difference in price can be attributed to the cost of the steel installation, so the option of installation on a concrete base can be considered the most budget-friendly.

In fact, apart from a nice appearance, the popular and fashionable model does not have any special advantages. This is rather a matter of taste of the owners. Therefore, if you are on a budget, think again: is the result worth the expected cost?

A wall-hung toilet looks especially impressive when paired with a bidet of the same design: both of these plumbing fixtures successfully complement each other

Niche for installation

A niche is made in the wall for installation if the installation depth of the frame, materials and wall thickness allow such work to be performed. And in addition to the niche in the wall, they also cut channels for water and sewer pipes, which, like the installation, must be installed secretly.

Important. This method is not suitable for load-bearing walls made of bricks (for walls made of reinforced concrete, it is technically impossible to make a niche with your own hands). And if the arch of a niche can be reinforced with an insert made of a metal profile (standard practice for an opening), then this option is not suitable for hidden pipe laying - cutting horizontal channels in a load-bearing wall is prohibited at the regulatory level.

And without horizontal grooves, it is extremely difficult to make hidden wiring - only if the pipes approach the niche from below, and before it are laid in a screed or between the joists of a wooden floor.

For a niche in the wall, there is only one option provided by the manufacturer - for a block installation with an attached toilet.

In addition to this option, they also use a bathroom niche in which the water supply and sewer risers pass. In this case, a frame made of a metal profile is installed in a niche, and a frame installation for a wall-mounted toilet is attached to it.

Preparation for installation work

As always, we advise you to purchase everything you need to complete the job in advance and have it on hand.

So, to install a wall-hung toilet with installation, you need to have:

- steel frame-module complete with a plastic tank (container);

- toilet bowl;

- flush key;

- steel studs for fastening work;

- set of connecting pipes.

Usually, the installation kit includes not only a plastic container, but also a flush key, pipes, adapters and fasteners. As a rule, the kit also includes special material to protect the entire structure, which will be located in the wall of the bathroom, from condensation. The same material reduces the noise level during the period of draining and filling the container with water.

When you buy plumbing fixtures in a store, be sure to check the package and purchase additional items that you need but are not included in the basic set. Please note that the bowl is usually purchased separately. The frame itself and all mounting elements are standardized, so choose the option that you like.

The double flush button not only looks advantageous, but is also a functional element: with its help you can select the flush intensity

Most buyers prefer a double flush button: it allows you to dose the water flow. To perform installation and finishing, you will need moisture-resistant drywall.

Don't forget about the tools. You will need:

- perforator;

- concrete drills;

- roulette;

- pencil for marking;

- spanner wrenches;

- building level;

- knife for working with drywall.

Prepare the work area: remove all unnecessary items. We can start.

Suspended model on a concrete base

A steel frame is expensive. In principle, you can do without it by building a concrete pedestal with your own hands, which will serve as a reliable foundation for the wall-hung toilet. This option is considered the most economical.

The diagram of the model on a concrete base includes: 1 – two rods for fixing the toilet bowl, mounted into the wall; 2 – concrete base; 3 – pipe for draining into the sewer

With this installation method, the drain container can either be mounted into the wall, with the drain button located outside, or placed above the bowl of the plumbing fixture.

Pre-installation procedure

Let's consider the option that is considered the least expensive. Let's prepare everything you need for work:

- concrete M200 - approximately 40 liters;

- boards for making formwork;

- threaded rods (length 50-80 cm, thickness 2 cm) - 2 pieces;

- washers, nuts, screws for woodworking;

- plastic pipe (diameter 11 cm, length 8 cm);

- drain coupling;

- Styrofoam;

- silicone sealant.

I think it’s worth repeating that the wall we have to work with must be permanent.

Step-by-step installation process

We fix rods in the main wall, onto the outlets of which the toilet bowl will then be placed. Let us remind you that we must have a stable and reliable structure that can withstand a weight of 400 kg.

The next step is to install the drain coupling. At this stage, it is necessary to determine the height of the toilet in order to cut the coupling to the appropriate length.

Now we need to install the formwork. In order to mark fastening points on the formwork, you should determine the distance between the holes intended for fastening.

To calculate the length of the rods, you need to add up the thickness of the recess, which is approximately 15 cm, and the distance from the wall to the toilet bowl. To fix the rods in the wall, concrete adhesive is used - a chemical anchor.

This is what the structure looks like ready for the concreting process: the place where the drain will be connected to the toilet bowl is covered with foam plastic

When the formwork is installed and the installation of the pins is completed, the bowl should be installed in the place intended for it. Make sure that the mounting holes match the outlets, and the outlet hole matches the coupling drain.

In twenty-eight days, the monolithic concrete support will be completely ready for installation. Pay attention to the groove in the front of the monolith - there was foam here

The next step is concreting. This must be done by installing foam plastic in the place where the drain hole will be. Remember that the concrete will finally harden only after 28 days.

After this, you can remove the formwork and make sure that in front of us there is a monolithic concrete block with pins coming out of it and an open, fixed coupling. A toilet is mounted to the front of the block, and a tank is placed on the base itself.

This is exactly what a wall-hung toilet will look like after installing the bowl, and its tank will be installed on a concrete base

The procedure for installing a bowl to a concrete base is no different from installing a floor-standing toilet. You need to install the bowl on the pins, tighten the nuts, connect and seal the drain. Lastly, a drain tank is placed on the concrete base.

As you can see, this method of installing a hanging model is much cheaper and easier than working with the installation. But, to be honest, the result is not much different from a floor-standing toilet.

Kinds

There are 2 types of installations:

- Frame . All elements of the device are connected into one structure using a special steel frame and studs. The toilet and tank are attached to it along with the drainage system. Fixation is carried out at four points: 2 on the wall and 2 on the floor.

- The block design requires installation exclusively on reliable and stable walls. The assembly of such a structure is carried out in a special closing niche prepared in advance. Fastening is carried out only on a solid base.

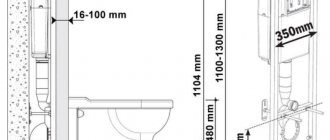

The standard sizes of frame models are (on average):

- width – 50 cm,

- height – 112 cm plus 20 cm retractable supports,

- depth – 15-30 cm.

Block structures are more compact:

- width – 50 cm,

- height – 78-100 cm,

- depth – 10-15 cm.

The height of the module is often of concern to users when installed under a window. The problem can be solved; each manufacturer has a frame kit with a height of 82 cm - this minimum is enough to fit into the given space. Typically, such models provide a frontal and top (on the window sill) location of the flush panel, since in the first option the button will be behind the raised toilet lid, which is not convenient for everyone.

An example of the described installation, the flush button is visible on the window sill.

Depth is also not often a decisive factor, but in this case there is a solution: Tece offers the TECEbox module (8 cm), and Geberit produces the Duofix 111.796.00.1 kit (similar). The Roca and Viega brands have similar lots, but they are a couple of centimeters thicker.

Compactness in some indicators is achieved by increasing others. The TECEboх installation has a width of 64.5 cm, otherwise, with a depth of 8 cm, the volume of the flush tank would have to be reduced. This is what Geberit did - the tank capacity of their ultra-thin module is only 6 liters.

If the standard frame does not fit in width, Geberit comes to the rescue again with a 41 cm model. If you need a narrower one, then you can choose the installation for the Wisa Exellent XS toilet at 38 cm, Ideal Standard at 35 or Migliore Quadra at 30. Please note that all they have an increase in depth.