Fatty elements contained in wastewater can block the pipe, causing a blockage. Fatty acids tend to cause metal corrosion and destroy pipelines, causing the sewer system to become unusable.

Grease traps for sewers, which are installed in the riser to the point where used water is discharged, will help solve this problem. In this material we will talk about the design features of these devices, their types and features that you need to pay attention to when choosing a grease trap for your home.

Design and principle of operation of the device

The main function of a grease trap is to filter sewage from grease, oil and solids that pollute the environment.

The equipment consists of a number of elements, these are:

- compartment of the device in which fat and oil are collected;

- a flask of 2-3 compartments, designed for settling wastewater;

- outlet pipeline connected to the sewer system;

- inlet pipe;

- airtight removable lid that prevents the occurrence of unpleasant odors.

The sewer grease separator consists of a one-piece sealed housing with a lid. The removable cover allows for preventive maintenance or manual cleaning of the tank when necessary.

There are 2 pipes connected to the body - inlet and outlet. The tank is divided into 2 or 3 compartments, which communicate with each other and are designed to separate oil, fat, and solids.

From the last compartment, defatted and treated wastewater is discharged into the sewer pipeline.

The simplest, inexpensive grease trap models have 1 chamber and are installed under the sink

Any model of grease trap for sewerage works on the principle of gravity. Particles of fat and oil accumulate on the surface of the filter, since they are much lighter than water.

Then they fall into a special settling tank, from where they are easily removed manually, using special equipment or special equipment.

Special enzymes are usually added to the device to break down accumulated fat. They allow you to significantly increase the time between cleaning the device.

Main types

Devices of this type are classified according to the principle of cleaning; it can be performed in three ways:

- Mechanical. This most common option was described above, its main disadvantages are:

- during operation, it is necessary to regularly clean the device from the accumulation of fats;

- low efficiency and level of purification; some impurities still remain in the wastewater.

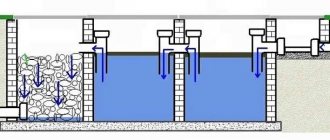

- Gravitational. The design of such separators and the operating principle are similar to the previous type (see Fig. 3), the only difference is in the cleaning process. The effluent is given time to settle (about a day), which allows almost all impurities to collect near the surface. Often, these devices use special chemical reagents that bind fatty impurities, forming heavy conglomerates from them that precipitate.

The principle of operation of the Evo Stok gravity grease trap.

Such devices have a much higher cleaning percentage, approximately 98%, but they also have characteristic disadvantages:

- manual cleaning and subsequent disposal of fat is required;

- In the precipitated organic matter, the process of decay may begin, which manifests itself in the form of an unpleasant odor.

- Biological. Such separators are called biological destructors. The difference from previous types also lies in the cleaning technology. It is produced by adding biological products (special cultures of microorganisms), which, feeding on fat, convert it into a neutral sediment.

Tablets for the Custom GT grease trap

The advantages of this method are obvious: after the grease decomposes, there is no unpleasant odor and the cleaning process is less difficult.

Concluding the topic about the types of grease traps, we should mention devices for ventilation systems, for example, a kitchen hood, which also has special devices for separating fats.

Grease traps in kitchen hoods: a – grille filters; b – labyrinth type

Passing through the filters, fat vapors settle on them, which reduces contamination of duct ventilation systems.

Purpose and advantages of grease traps

More complex models of grease traps are used in large enterprises and are designed to effectively purify wastewater from solid particles, fat-containing and oil impurities.

According to sanitary standards in meat and dairy production and in public catering establishments, the installation of grease collection equipment in the sewer system is mandatory.

Industrial devices are installed at the outlet of a treatment structure that performs primary wastewater treatment.

Installing a grease trap will protect the sewer system of any catering establishment or production facility from contamination with fat and oil inclusions

Industrial devices are developed by manufacturers to ensure that clean water, purified from foreign impurities, enters the sewer system by separating and further removing the fatty component of the waste mass.

Installing a grease trap will help prevent sewerage failure due to the effects of grease deposits. It also protects the environment from the release of harmful impurities that can cause irreparable damage to the environment.

Such separators are indispensable not only in production, but also in everyday life. They reliably protect sewer pipes from the occurrence of grease valves or blockages. At the 1st stage, the device receives household water and separates fat and oil accumulations.

At the 2nd stage, the final separation of fat deposits and the removal of effectively purified water into the sewer system is observed. The device traps non-emulsified fats and removes them from wastewater.

A grease trap installed under the sink is often used in home kitchens, cafes, restaurants, pastry shops and fast food establishments.

The use of grease removal equipment has a number of advantages:

- Equipment tightness . Due to the tightness of the housing, the possibility of foreign liquid entering the filter is excluded.

- Practicality and versatility . Installation of various additional devices is possible. The sensor for the accumulation of harmful substances is in particular demand.

- No unpleasant odors . Due to the tightness of the housing, odors that usually arise during the breakdown of fats do not penetrate into the room.

- Easy to install . Installing indoor grease traps does not require any special skills and is carried out in 4 stages.

- Ease of maintenance. Cleaning most models of grease traps does not require much effort; it can be done manually using available tools.

- Reasonable price . The devices have a low price compared to other types of filters.

In addition to these advantages, the device that collects fat also has a long service life. All equipment is made of high-quality and wear-resistant materials, which guarantees its durability.

An important advantage of using a grease trap is the preservation of the environment, which is especially important in modern times.

Care and maintenance of the device

If the grease trap is used heavily, grease removal operations may need to be performed every couple of weeks. The accumulation of contaminants is monitored by opening the top lid of the container. The fat clot that has accumulated in the upper part of the container must be removed. For this purpose, a special cage is suitable, which is included in the factory configuration of some devices. You can also use a suitable-sized ladle or an ordinary mug. Food fat mixed with dirt to form a clot is quite dense, so it easily collects like foam from the surface of a liquid and is thrown into the trash.

To ensure that the grease trap unit installed under the sink does not create emergency problems, and also works effectively for at least the period stated by the manufacturer, it requires simple annual maintenance. To do this, it is disconnected from the siphon supply and sewer lines and thoroughly washed to get rid of heavy bottom sediments.

Types of grease traps by purpose

Equipment for household purposes is installed under the sink in residential buildings, apartments and small catering establishments - bars, restaurants, cafes, confectionery shops and canteens.

There are 2 main types of fat traps:

- household appliance;

- industrial.

They are mandatory elements of the sewerage systems of restaurant-type establishments. The devices filter the grease that forms after washing dirty dishes.

Household grease traps are cleaned manually and used with a liquid flow rate of up to 1.5 cubic meters per hour. Industrial grease traps are installed in industries whose wastewater contains a significant amount of fat, oil and other foreign impurities.

The use of an industrial device for catching grease is mandatory in large enterprises if the water flow is more than 2 cubic meters per hour. Their cleaning is carried out automatically - using special mechanisms.

How to choose the right grease trap?

Each buyer independently chooses a grease trap model depending on the requirements for the device and financial capabilities. Regardless of the model you like, it will be possible to solve the current problem of the accumulation of fat and oil impurities, which can lead to clogging of the sewer system.

Grease traps by installation type

There are several criteria for choosing a special grease trap.

According to the installation method, separators are divided into 2 types:

- installed outdoors;

- used indoors.

There are separate models for each installation method. It is rare to find “mixed” solutions that are installed both outdoors and indoors.

Grease traps of any type are installed in the sewer system. In catering establishments and in the meat, dairy and fish processing industries, the use of separators for separating fat is a prerequisite.

Devices intended for indoor use are easy to install and affordable

Household grease separators can be installed in various ways:

- in a separate room;

- under plumbing fixtures;

- in the basement.

The choice of the optimal option depends on several criteria: the dimensions of the equipment and the ease of use.

Outdoor grease traps are made from more durable materials, as they must effectively resist external soil pressure.

Installation of such a fat separator is a complex and multi-step process. At the first stage, earthworks are carried out, then the site is concreted, and only then can we proceed to installation.

Therefore, to install grease traps, they usually turn to specialized companies.

The throughput capacity of outdoor grease separators is much greater than that of grease separators installed indoors

What material is the equipment made from?

The body of grease traps can be made of plastic, fiberglass or stainless steel.

Plastic grease traps are characterized by the following properties: attractive appearance and low throughput. They are mainly intended for domestic use, so they are installed indoors.

Advantages of plastic fat separators:

- Environmental friendliness of the material . Plastic is considered safe for the environment and people.

- Practicality . The material allows manufacturers to produce devices of standard sizes and tailored to individual customer requirements.

- Easy to maintain . Equipment can be cleaned manually using available tools.

- Durability . Plastic has a long service life; the device can last up to 30 years.

For the correct operation of grease traps, it is recommended to use a fat and oil deposit level sensor or other additional devices

Plastic fat separators are distinguished by their aesthetic appearance and compactness. They can be installed in premises of any purpose

Fiberglass is made from glass fiber and a polymer binder. Fiberglass grease traps have excellent strength characteristics. Due to this, they can be installed both indoors and outdoors.

The main advantages of a fat separator made of reliable fiberglass:

- Resistance to aggressive environments . The devices are resistant to extreme weather conditions and harmful chemicals.

- Increased strength . Grease traps made of fiberglass have proven themselves to be durable and reliable equipment.

- Light weight and easy to care for. Fiberglass grease separators are easy to clean.

The design of fiberglass grease traps can be horizontal or vertical

The fat layer accumulates inside the device to a certain level and is easily pumped out through the hatch

Fat separation equipment made of durable stainless steel is the most expensive among different models. It can be installed outdoors and indoors.

Some manufacturers make separators for fat impurities from galvanized steel. The quality characteristics of such devices are lower than those of stainless steel devices.

A stainless steel fat separator installed indoors looks aesthetically pleasing. The equipment not only effectively performs its direct functions, but also stylishly decorates the interior

Grease traps made of stainless steel are distinguished by high hygienic properties, excellent performance characteristics, and a long service life. It is also worth noting the high anti-corrosion qualities of stainless steel separators.

Image gallery

Photo from

Plastic grease trap for sink

Industrial grease trap made of fiberglass

Stainless steel separator

Homemade bucket separator

Conclusion

A grease trap under the sink is a very useful thing. I guarantee you that after installing such a unit, you will forget for a long time about such an unpleasant phenomenon as clogged pipes, because it collects not only fat, but also coarse-grained contaminants. In the photos and videos in this article I presented additional material on sewer separators. If you have any questions, welcome to the comments, I will help as best I can.

Grease trap under sink with two baths.

Performance properties of separators

Grease traps vary significantly in power and performance. Devices with a capacity of 0.1 to 2 l/s are considered household equipment.

All devices with a capacity of more than 2 l/s belong to industrial devices. Fat separators provide effective wastewater treatment from fats up to 20 mg/l.

Full operation of the fat separator is possible if the performance of the device corresponds to the amount of wastewater coming from the sewage system

The performance of the equipment must correspond to the amount of sewage entering the device or be higher than this value.

Grease traps also differ in how they are cleaned. There is equipment:

- manual cleaning;

- mechanized cleaning.

In most cases, grease separators are manually cleaned with low throughput, intended by the manufacturer for indoor installation.

They are under constant control; filters are cleaned manually using available means.

Grease traps for mechanized cleaning are, most often, industrial fat separators, characterized by high productivity. Typically, devices are equipped with sensors that signal the need for cleaning.

The cleaning procedure is carried out using pumps or specialized vehicles.

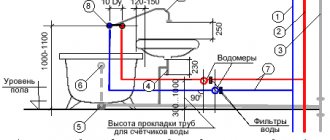

Equipment installation technology

The installation process of a fat separator can be carried out in various ways. It is necessary to choose the optimal type of installation depending on the type and characteristics of the grease trap. Let's consider several options for installing separators.

Installation of an outdoor grease trap

The installation procedure for an industrial grease trap is complex and time-consuming. Therefore, most trap buyers prefer to entrust the installation of equipment to specialists.

In order to carry out the installation yourself, it is necessary to carry out a number of preparatory work:

- We select a place for installation . When choosing, you should take into account the layout of the site, as well as the possibility of performing landscaping work in the future.

- We determine the size of the pit for mounting the device - its depth should be such that the grease trap cover is approximately 4 cm higher than the surface of the ground.

- We dig a hole . At the very bottom we will equip a solid formwork into which we will pour a mixture of sand and cement. For sandy soils and loams, a solution prepared in a ratio of 1:5 is optimal.

- We wait until the solution hardens , at least 14 days.

When the preparation of the base for installation is completed, you can proceed directly to the installation of the equipment. To do this, we install the grease trap body on a concrete base and securely fasten the device to the hinges embedded in a homemade concrete slab during the pouring period. If you forgot to install the hinges, they can be secured with anchor bolts.

Now we are constructing unique plywood walls around the equipment installed in the pit. This process is necessary to prevent soil shedding. If you plan to operate the separator in a cold climate, then it must be covered with heat-insulating material. Mineral wool or polystyrene foam is suitable for this.

All that remains is to connect the grease trap to the communication networks. To do this, the outlet pipe of the equipment must be connected to the drainage system. The joints must be treated with sealant. And we connect the inlet pipe of the device to the sewer pipe. Coat the joints of the elements with sealant.

We fill all the free space created between around the grease trap body with soil. Usually backfilling is used, during which the soil dug out from this place during the hole digging stage must be filled into the opening.

We must not forget about the need to install a fan riser. It is required to remove excess gases accumulated in the sewer system. If there is a large load on the wastewater disposal system, it is better to install several risers at once. The fat accumulation sensor, which is installed inside the equipment, will warn you about the need for a cleaning procedure.

Outdoor grease traps are often cleaned by specialists from specialized companies using pumps or special equipment

It is recommended that the installation and installation of industrial grease traps be carried out with the assistance of professional installers. They must have permits to carry out the full range of work.

Also, professional specialists have the necessary construction equipment for installation, so they can perform the necessary procedures for stable and long-term operation of the equipment.

Installing a grease trap indoors

Installing a household separator under a sink is a simpler process than installing equipment outside. To do this, you first need to choose the optimal location for installing the equipment.

It should be located on an easily accessible, hard and as level surface as possible, close to plumbing equipment.

It remains to perform a number of sequential actions:

- We bring the outlet pipe of the equipment into the sewerage system. At the connection point you need to install a rubber gasket, which comes with the device.

- We connect the inlet pipe of the trap to the outlet pipe of the sanitary equipment or to the pipeline (at the junction of the sink and washing equipment), not forgetting to install a special gasket.

- We fill the grease trap with the required amount of water to check the device for leaks.

If the test is successful, you can install the lid on the grease trap. Once the cover is installed, the installation of the equipment can be considered complete.

Image gallery

Photo from

Step 1 - Disconnecting the Flexible Sewer Hose

Step 2 - connecting the grease trap and drain

Step 3 - connecting the grease trap to a flexible hose

Step 4 - connecting the device to the sewer

For more information on how to choose and install a grease trap under a sink, read this material.

TOP 7 best grease traps for sinks

Let's look at the best devices included in our rating:

- Biofor Economy 0.5-40;

- Alta-M-In 0.5-25;

- Onyx 0.5-15;

- Aqua Mini (0.3-20);

- EVO STOK 0.5-25;

- PU-0.5-0.25 series “Standard”;

- Thermite 0.5-25.

Biofor Economy 0.5-40

The model is made of HDPE polyethylene, solid cast, and consists of two chambers. Separates wastewater into fats, clean water and solid sludge. Peak discharge 40 liters, device weight only 8 kg. Perfect for home use, thanks to its compact size it fits easily under the sink.

| Performance | 0.5 m3/h |

| Nozzles diameter | 50 mm |

| Peak reset | 40 l |

| Dimensions | 460x370x400 |

| Selection by sinks | 2 sinks, 2 mixers |

| Weight | 8 kg |

| Operating temperature | 1-80 degrees |

Price from 4900 to 5450 rubles.

pros

- one-piece body;

- easy to maintain;

- good separation;

- excellent performance;

- takes up little space.

Minuses

- not detected.

A plumber friend advised me to install a grease trap under the sink. With its purchase, the unpleasant smell disappeared, and we already forgot about the fact that the water does not drain well. And this saves time, money and effort.

grease trap for sink Biofor Economy 0.5-40

Alta-M-In 0.5-25

The grease trap is made of plastic, effectively purifies wastewater from vegetable and animal fats, and is installed under the sink before the drain enters the sewerage pipeline. Such a device can be used for more than 50 years, as guaranteed by the manufacturer.

| Performance | 0.5 m3/h |

| Peak reset | 25 l |

| Dimensions | 500x350x400 mm |

| Nozzles diameter | 50 mm |

| Weight | 8 kg |

Cost from 8990 to 9450 rubles.

pros

- innovative design technology increases cleaning efficiency;

- the design is well thought out;

- providing easy access to fat storage;

- low installation and installation costs;

- simplicity of the device;

- environmental friendliness;

- modern polymer materials;

- long shelf life.

Minuses

- high price;

- Sometimes there are defects in production, the body is cast crookedly, and therefore there is a lack of tightness, where the lid is and leaks.

- material plastic.

If you want to get rid of the unpleasant smell in the kitchen once and for all, we recommend purchasing this grease trap model. We have a large family, we have to cook and cook a lot, but we don’t have time to constantly look at what else has flown into the pipes. An excellent way out of this situation. And my nerves are calmer.

grease trap for sink Alta-M-In 0.5-25

Onyx 0.5-15

The model consists of two compartments. In the first, water and large solid sediments settle. Particles from the oil, growing in layers, rise up to the surface. In the second compartment, additional treatment takes place and discharges into the sewer. Entry height 200 mm, exit height 170 mm.

| Performance | 0.5 m3/h |

| Peak reset | 15 l |

| Dimensions | 300x300x300 mm |

| Nozzles diameter | 50 mm |

| Weight | 5 kg |

Cost from 7000 to 8000 rubles.

pros

- food grade polypropylene material;

- UV-resistant plastic;

- can be cleaned either using special equipment or manually;

- complies with sanitary standards;

- maximum wastewater temperature up to 75 degrees;

- easy access to the drive;

- the device is designed for 50 years;

- compact dimensions;

- very easy to install.

Minuses

- cube shape;

- It is recommended to install a fat level sensor;

- high price.

I bought a grease trap for the first time. I didn’t know how to choose and choose. I contacted the manager and they recommended this model to me. We have been using it for more than a year and have had no problems; at the same time, cleaning costs have decreased. We recommend for purchase.

grease trap for sink Onyx 0.5-15

Aqua Mini (0.3-20)

It is a container with built-in partitions and an external plastic thickness of 8 mm, which ensures structural strength. Made from homogeneous food grade blue polypropylene. Entry height 275 mm, exit height 255 mm. The material is UV resistant and the product weighs only 2.7 kg, which is important during installation.

| Performance | 0.3 m3/h |

| Peak reset | 20 l |

| Dimensions | 320x260x320 mm |

| Weight | 2.7 kg |

| Nozzles diameter | 50 mm |

Price from 3515 to 3700 rubles.

pros

- stainless steel adjustable locks;

- affordable;

- can be installed on your own;

- built-in grease trap pipes;

- high quality cleaning;

- non-volatile operating mode, no connection to the electrical network required;

- easy to maintain;

- light weight.

Minuses

- 1 year warranty;

- rarely found on sale;

- daily visual monitoring of the operation of the device as it is used.

We live in a private house, and power outages occur frequently. And kebabs, grilling, salads and get-togethers are commonplace for us. Well, and a mountain of dishes accordingly. In order not to torment either ourselves or our guests, and also to bother with the sewer system less often, we purchased a miniature grease trap. We are pleased with the results of our work and the price of our little helper.

grease trap for sink Aqua Mini (0.3-20)

EVO STOCK 0.5-25

The model will ideally fit under the sink in a spacious kitchen of a private house; it is intended for only one sink with minimal discharge of grease-containing wastewater. Withstands room temperatures from five to forty degrees Celsius, as well as wastewater temperatures up to 70 degrees. The material is heat-resistant inert plastic.

| Performance | 0.5 m3/h |

| Peak reset | 25 l |

| Pipes with radius | 25 mm |

| Dimensions(LxWxH) | 420x320x370 mm |

| Weight | 8 kg |

Prices range from 8,000 to 10,950 rubles.

pros

- tightness (each product undergoes a special test);

- pleasant appearance;

- cleaning technology is based on the laws of gravity and the ability of fat and oil droplets to merge - coalescence;

- made in Russia;

- resistance to corrosion and detergents;

- environmental friendliness;

- simplicity and ease of maintenance;

- The material is high quality engineering plastic.

Minuses

- square shape;

- the price is decent.

We purchased a grease trap from the EVO STOK brand. We focused on compactness and reasonable price. They were chosen with special care, because size sometimes has special meaning. Specialists helped with installation and advice on how to extend its service life. We were pleased with the results.

grease trap for sink EVO STOK 0.5-25

PU-0.5-0.25 series “Standard”

It is used both in small enterprises and at home. The tightness of the product is ensured by a tightly closed lid with a rubber seal and convenient latches. Polypropylene ensures reliability and durability. The kit includes special separation plates, two pipes and a distribution pocket and cover.

| Performance | 0.5 m3/h |

| Peak reset | 25 l |

| Nozzle diameter | 50 mm |

| Dimensions(LxWxH) | 420x320x370 mm |

| Weight | 7 kg |

Cost from 8208 to 9120 rubles.

pros

- versatility (suitable for both the dining room and home);

- tightness;

- compact dimensions;

- modern and environmentally friendly materials;

- manufacturer Russia.

Minuses

- warranty period is only 3 years;

- for more efficient work, it is recommended to use additional biological products that decompose organic matter into simple and safe substances;

- cubic shape.

A neighbor showed off the know-how in her kitchen in her spare time. They say that there will be no blockages, and the unpleasant smell will disappear without a trace. I decided not to think for a long time and went with my husband to the store. After consulting a specialist, we looked at this invention and purchased it. Now I’ve been happy with my purchase for exactly six months now, and all the foreign odors have evaporated somewhere.

grease trap for sink PU-0.5-0.25 Standard series

Termite 0.5-25

Installed under or next to the sink. It features a sealed design and is made without welds. Universal in its functionality. Designed for a number of washes from one to two. Made from LDPE polymer, which has a service life of up to 50 years. The height of the inlet pipe is 190 mm, the outlet pipe is 180 mm. The durable case is closed with four metal locks.

| Performance | 0.5 m3/h |

| Peak reset | 25 l |

| Dimensions(LxWxH) | 450x350x395 mm |

| Weight | 7 kg |

| Pipes with diameter | 50 mm |

Cost from 4300 to 4600 rubles.

pros

- withstands temperatures from 1 to 80 degrees Celsius;

- made using rotational plastic molding technology;

- suitable for 1-2 sinks;

- seamless container;

- non-volatile;

- the design provides for the installation of an additional tray;

- ease of installation and maintenance;

- small sizes.

Minuses

- daily visual inspection must be carried out;

- clean by hand.

I own a small cafe on the ground floor of a high-rise building. I installed this grease trap and I don’t worry anymore. Easy to install, easy to clean. The SES doesn’t ask unnecessary questions, and residents don’t complain that I’m clogging their pipes. Everyone is happy. Beauty!

grease trap for sink Termite 0.5-25

Review of popular grease trap manufacturers

The modern market offers a wide range of fat separators made by foreign and domestic manufacturers. It should be noted that there are no significant differences in the equipment of different companies.

Devices of any brand work on the same principle - they function due to the force of gravity. Many manufacturers offer additional equipment in addition to traps, such as a stand.

The stand is designed for use with grease traps that are installed directly under the sink in restaurants, canteens, cafes and cutting shops of large supermarkets

When choosing the optimal model, you should focus on the purpose of the grease trap, as well as the prestige and reputation of the manufacturer.

Grease traps from the following companies are in particular demand:

- Helyx;

- Wavin Labko;

- Evo Stock;

- flotenk;

- UE "Polymerkonstruktsiya"

Helyx is a popular manufacturer that produces mainly industrial vertical and horizontal grease traps. The separator is used as the initial treatment system.

It is installed at the site of industrial sewage discharge, which contains contaminated and greasy wastewater.

Wavin Labko is a Finnish developer and manufacturer of innovative electronic fat accumulation meters and traps made of fiberglass and polyethylene.

Wavin-Labko's EuroREK grease traps are used in restaurants, cafes, canteens, gas stations, meat processing plants and slaughterhouses.

The Russian manufacturer Evo Stok produces equipment for various purposes from heat-resistant reinforced plastic that is resistant to corrosion.

The devices are equipped with hermetic seals that effectively prevent unpleasant odors from entering the room.

Flotenk produces industrial and household devices from durable fiberglass reinforced plastic .

The advantages of grease traps from Flotenk are aesthetics, the presence of a level alarm, a degree of purification of up to 50 mg/l, and durability. The manufacturer produces vertical and horizontal grease traps.

The grease catcher from Polymerkonstruktsiya Unitary Enterprise is a container made of a spiral pipe, with inlet and outlet pipes.

The outlet pipe is located at a considerable depth, which prevents fat from leaking through.