To cut grooves for electrical wiring in brick and concrete partitions, use a special tool with abrasive wheels or a circular saw.

To renovate an apartment, you can make a wall chaser attachment for an angle grinder, which will reduce costs. It is necessary to consider a method for removing dust generated during operation, as well as the design of the piercing depth regulator.

General concept of wall chaser

To lay electrical and telecommunication wiring or water supply or heating pipes in main walls made of brick, blocks or monolithic concrete, it is necessary to cut grooves (grooves, or grooves) of rectangular cross-section.

The width and depth of the channel depend on the diameter of the lines, and sharp protrusions that could damage the insulation or pierce the pipe body are not allowed on the bottom.

When manually scraping, the time spent on repairs increases, and the resulting grooves have uneven dimensions. To improve quality, use an electric tool.

Purpose

The wall chaser is designed for semi-automatic cutting of grooves in main walls and partitions. The master must manually move the tool in accordance with the marking lines.

The channel has the correct geometric dimensions and uniform depth. The electric drive allows you to reduce the time spent on preparatory work. The equipment is capable of cutting steel reinforcement and stones present in the structure of reinforced concrete walls.

Device

Factory-made equipment consists of the following parts:

- metal base with a sight and rollers for moving along the surface;

- AC electric motor covered with a plastic casing;

- 2 discs with the ability to adjust the gap between the cutting edges;

- covers made of plastic or silumin with a hole for connecting a vacuum cleaner;

- handles for holding and moving the tool.

Principle of operation

After adjusting the width and depth of the groove, the wall chaser is connected to the network, and then the start button is pressed. The electric motor spins the gears of the gearbox and the cutting tool, rigidly mounted on the toe of the secondary shaft.

After the edges touch the surface, sawing of concrete or brick begins. The operator guides the equipment manually, aligning the sight with the marking line.

Dust and small stones are captured by a protective shield and then poured onto the floor of the room or removed through a flexible hose connected to a construction vacuum cleaner.

Tool effectiveness and application advantages

The equipment allows you to cut grooves in vertical and horizontal directions in walls made of any material and having external decorative finishing.

The discs are covered with a shield that prevents injury to the operator from cutting edges, flying stones and fragments of reinforcement.

After cutting is completed, it is necessary to knock out the central part of the groove with a chisel, saturate the concrete or brickwork with soil, lay cables or pipes, and then carefully seal the grooves with gypsum plaster.

Advantages of using an electric fine cutting tool:

- reducing time spent on work;

- reducing the amount of finishing material for sealing grooves having a uniform cross-section;

- cutting to the required depth in 1 pass;

- reduced noise level compared to a rotary hammer;

- reduction of dust emissions into the room (when using a waste removal system);

- minimum level of vibrations transmitted to the partitions.

Work rules

You should not start gating before preparatory work has been completed. At the stage of drawing up the diagram, the quantity is correctly calculated and the location of the elements of the electrical network is chosen. The presence of each point must be necessary. It is not practical to place a large number of sockets on one side. You need to take into account the material of the wall and choose the right disc for the grinder.

Norms and restrictions

When gating a wall, the following requirements should be taken into account:

- The depth of the channel should be 2-3 cm, width - 3 cm.

- The maximum distance between the power point and the distribution box is 3 m. The grooves are laid vertically or horizontally. The parallelism of distribution is assessed by the building level. The cable cannot be shortened by laying it at an angle. This also applies to the wave method. The exception is attic rooms with sloping ceilings.

- The distance between the groove and the window or doorway must exceed 10 cm. A distance of 15 cm must be left from the horizontal channel to the floor slab. A distance of 40 cm must remain between the gas or heating pipe and the groove.

- You cannot make channels in internal load-bearing walls. A groove of the required depth does not affect the external walls, but the partition may collapse.

- Gating of reinforced concrete slabs is excluded. This procedure violates their integrity and load-bearing capacity.

- When gating the ceiling, they try to make a channel of minimal length.

- It is forbidden to make recesses in the floor covering. It is recommended to hide the wiring in a concrete screed. However, this method cannot be called optimal. Replacing a burnt-out cable will take a lot of time and effort.

Main types

Equipment is usually divided into categories:

- with electric drive for processing hard materials;

- with manual rotation of the cutting tool (used for walls made of foamed concrete);

- with installation on an angle grinder (grinder).

Manual

The hand-held device is a curved metal pipe with an additional handle, equipped with a double steel cutter, secured with a bolt and nut.

The operator presses on the tool and simultaneously pulls it along the surface being processed. The equipment is designed for occasional processing of soft building materials (for example, cellular aerated concrete). The product is not used for cutting brick or concrete partitions.

Electric

The power drive allows you to work with hard materials and increases productivity. A tool with a pair of rotating parts allows you to produce grooves of different widths, and a moving platform allows for depth adjustment.

There is simplified electrical equipment with 1 disk, which allows you to make fines and cut concrete blocks, tiles or metal profiles.

What are the walls like in houses and apartments?

When choosing a gating technology, you need to find out what material the building is built from.

Wood

It is undesirable to make channels in such material, but sometimes it is impossible to do without this action. The security of the cables and the fire safety of the wiring depend on the correct execution of the work. The best solution is to avoid gating in wood in favor of external installation or the use of cable ducts.

Concrete

Walls made of durable material are difficult to machine. It is recommended to make the channels with a wall chaser (shaving cutter). If such a tool is not available, you can use a grinder with a stone disc. In this case, gating takes more time and effort.

Aerated concrete

Difficulties in forming channels in soft material rarely occur. It is recommended to use a grinder with a diamond wheel or a wall chaser. You can replace them with a homemade device that looks like a bent metal pipe with a protrusion for recesses on one side and a handle on the other. When using an angle grinder, a lot of dust arises, so you should take care of a device for quickly removing it.

Brick

Working with masonry cannot be called simple, because the material is resistant to mechanical stress. Hidden wiring is rarely done in brick houses. Most often, the cable is fixed on top of the masonry, after which it is sealed with a layer of plaster. The latter should have a thickness of more than 3 cm, which is sufficient for standard cables.

If it is necessary to groove bricks, the same device is used as for forming channels in concrete.

Drywall

The sheet is too thin, so it is impossible to groove it. The wire is hidden under a plasterboard structure, attaching it to a metal frame. The only possible option is to create seats for sockets and switches using a hammer drill.

Popular models

There are several manufacturers of equipment with electric drive for cutting fines on the Russian market. To reduce production costs and logistics costs, the tool is produced in China.

A number of companies declared as Russian (for example, Interskol or Fiolent) also widely use Chinese components for assembly.

"Interskol PD-125/1400E"

The equipment is equipped with an electric motor with a power of 1400 W. The rotation speed of discs with a diameter of 125 mm reaches 9500 rpm.

The adjustment mechanism allows you to cut furrows to a depth of up to 30 mm, and the width is smoothly adjustable in the range from 3 to 29 mm. The engine is equipped with a smooth acceleration system and protection against unintentional starting and overheating; the casing is designed for switching a vacuum cleaner.

Advantages:

- low price;

- stepless adjustments.

Flaws:

- poor quality of materials and workmanship;

- lack of power to cut fines of maximum size.

Makita SG150

The Makita SG150 design uses a 1800 W motor designed to drive a tool with a diameter of 150 mm. It is possible to cut furrows with a width from 7 to 35 mm and a depth of up to 45 mm.

The no-load rotation speed reaches 7800 rpm. When cutting, the speed drops (there is no support system provided). The tool comes in a plastic case. It is possible to reinstall the side handle and switch the vacuum cleaner.

Advantages:

- high power;

- low noise level;

- high reliability of the electric motor and gearbox;

- overload alert.

Flaws:

- inconvenient tool mounting nut;

- handles designed for horizontal cutting from right to left;

- dust emission through furrows;

- heavy weight.

Bosch GNF 35 CA

The equipment with a 1400-watt motor is designed to cut furrows up to 39 mm wide and 35 mm deep. The lid has a connector for a flexible hose connected to a construction vacuum cleaner. There are 4 rollers installed on the plate, and ergonomic handles reduce the load on the operator’s hands during long-term work.

Advantages:

- high quality workmanship;

- thoughtful ergonomics of the handle;

- light weight;

- protection against accidental activation.

Flaws:

- inconvenient location of the power button;

- insufficient power;

- high cost of spare parts;

- poor protection against dust emissions.

"Fiolent"

The B1-30 furrow machine is equipped with a 1100 W motor that rotates discs with a diameter of 125 mm at a frequency of 6200 rpm. There is a function to support speed under load, the groove width reaches 30 mm.

The gear housing is made of aluminum alloy to ensure heat dissipation. The engine is equipped with ventilation slots to prevent dust from accumulating inside the casing.

Method No. 2. Electric wall chaser

An electrically powered tool is much more effective for cutting a groove in a wall. Therefore, for durable surfaces and large volumes of work, it is much more convenient to use a ready-made tool for making an electric wall chaser. The most suitable option for an electric tool is a regular grinder, which lacks one more working disk to function in wall chaser mode.

This issue can be solved in practice quite simply:

- Purchase two identical discs for concrete and an additional nut for tightening;

- First, install one disk on the angle grinder and tighten the original nut, as when working normally with an angle grinder;

Rice. 5: install the first disc on the grinder - Place the second disc on top of the nut on the shaft;

Install a second drive - Press the second disk with another nut;

Rice. 7: press the second disc with the nut - The electric wall chaser is ready for use.

It should be noted that in some models of angle grinders the length of the shaft may be very short, so after installing the second disk there will not be enough space to tighten the nut. In such situations, it is necessary to install a piece of pipe or a washer separating the discs between the discs instead of the clamping nut. This will significantly reduce the width of the groove, but will allow you to secure both disks at the same time. If there is a sufficient length of the shaft, you can use such shims to increase the width of the groove, for example, for water pipes or for several cables.

Rice. 8. groove width

The only drawback of such a home-made tool will be the huge amount of dust when digging grooves in the wall, since the angle grinder, unlike a wall chaser, is equipped with a shield only from flying particles. Therefore, when working for long periods of time, you will need to protect your eyes and respiratory organs. To do this, you can use either a respirator in combination with safety glasses, or a special casing in combination with an industrial vacuum cleaner. The first option is the simplest, but dust will settle throughout the room and create a number of difficulties; for the second, you will need a construction vacuum cleaner and a dust collection cover.

Homemade casing for a wall chaser.

Due to the fact that the original casing for a wall chaser costs a lot, it is much more profitable to make it yourself from scrap materials. Structurally, a homemade casing must have an outlet for connecting a hose from a vacuum cleaner. A conventional vacuum cleaner will not cope with such a volume of debris and its fractions; as a result, the bag or flask will fill up too quickly, and the motor may break down from fine dust. Therefore, you will need to rent such a device or convert an existing one.

The simplest way to make such an attachment for a wall chaser is a plastic bottle, in which the bottom is cut off, and a vacuum cleaner hose is connected in place of the lid. Such a device will not last long, but it should be enough for you to work in one room. If you need a wall chaser for your entire apartment or house, make a more durable and reliable metal casing.

For a metal casing you will need a steel sheet 1 - 2mm thick. Grinder with a diamond blade, welding or bolts with sealant (depending on the convenient method of fastening). If the metal is too thin and it will not be possible to weld it, then it is better to connect the parts of the nozzle with bolts and treat the seams with sealant. Since the welded structure is more reliable, we will consider this option in detail.

The entire process of making a homemade nozzle for a wall chaser consists of the following steps:

- Draw a drawing of the future casing for the wall chaser, you can make a pattern for cutting out the side elements;

- Cut out two side parts, in one of which make a hole for the grinder shaft;

Rice. 9: side plate with hole - Using a metal strip, connect the two parts by welding; file any unevenness in the seams so as not to injure yourself during work;

Rice. 10: using a strip, weld the side parts - Weld a pipe with a diameter suitable for connecting a vacuum cleaner to the outer edge of the wall chaser nozzle;

Rice. 11: weld the pipe - Weld two metal bars along the edges of the wall chaser attachment and make holes in them for attaching the casing to the grinder;

Rice. 12: Weld the clamp - Weld a clamp on two clamps to a separate triangular metal sheet, as shown in the figure - it is designed to grip the angle grinder and allows you to adjust the groove depth.

The attachment for the wall chaser is ready, you can connect it to the previously assembled device and use it for chase. The only thing you should pay attention to is the need to simultaneously turn on both the wall chaser and the vacuum cleaner. If the vacuum cleaner is not equipped with an outlet on the body, then you will need to use a portable extension cord with at least two outlets; you can buy it in a store or make it yourself.

Preparatory activities

Since factory-made wall chasers have a price of 5.5 thousand rubles. (budget models, professional-level equipment will cost 50-60 thousand rubles), then for home repairs they use homemade attachments for a grinding machine.

The grinder must have a motor with a power of at least 1500 W, since installing a double disk increases the load on the drive.

Required tools and materials

To make the device you will need:

- Scraps or a piece of carbon steel sheet with a thickness of 1.5 to 3 mm, required for the shield. Constructions made of plastic or plywood should not be used due to low mechanical strength and insufficient resistance to the effects of a flow of heated dust.

- Steel tube suitable for connecting a vacuum cleaner arm (directly or through an adapter).

- Tool for cutting workpieces, drilling holes and cleaning welds.

- Welding inverter and protective mask.

- Measuring and drawing tools.

Drawings and diagrams of nozzles for chipping

The angle grinder has a standard protective screen, which is used as a template for marking workpieces. The master can develop sketch drawings of the nozzle, focusing on the power of the electric motor, the dimensions of the grinder and the diameter of the cutting tool.

When manufacturing the device, the increase in the weight of the wall chaser should be taken into account. Heavy equipment is difficult to hold horizontally when cutting long furrows.

Detailed instructions on how to make an attachment for an angle grinder with your own hands

Manufacturing algorithm:

- Mark the contours of the internal partition of the nozzle on a sheet of metal, using the standard casing from the machine as a template.

- Make blanks for the mounting clamp. Some craftsmen retain the factory screen with standard fasteners, to which they weld a plate to reduce the overhang of the cutting tool.

- Cut the workpiece and cut windows for installation on the tool body.

- By analogy, prepare the blank outer wall of the nozzle.

- Cut a rectangular plate of the outer part of the protective screen, which has an increased length. The excess is needed to form the abutment surface.

- Connect the parts at points using resistance welding, and then completely weld the seams. It is permissible to install a stud on the outer part of the cover used for mounting the auxiliary handle.

- Bend the protruding corners of the outer part of the nozzle at a right angle.

- Clean the joints with an abrasive tool.

- Cut a hole on the outer part of the nozzle into which to install a dust removal tube for welding.

- Degrease the surfaces and coat with impact-resistant paint.

- Mount the attachment on a grinding machine with installed diamond discs, using the standard mount on the internal partition for fixation.

- Connect the vacuum cleaner hose to the tube (for example, through a layer of masking tape to seal the joint), and then make a test cut.

How to make a wall chaser from an angle grinder

Such a power tool as a wall chaser, in its appearance and operating principle, is very similar to angle grinders (grinders). In such tools, diamond wheels are used as cutting elements. However, unlike angle grinders, furrow machines are equipped not with one, but with two saw wheels arranged in pairs in relation to each other.

However, for use at home, a simple furrow maker can be made independently from a simple grinder. For this you will need the following materials:

- diamond discs (2 pieces);

- nuts (necessary for fixing the wheels on the angle grinder);

- a special protective casing equipped with a dust removal pipe (can be made independently from a metal sheet).

In this case, it is necessary to adapt the angle grinder for the simultaneous use of two cutting discs. To do this, install one disk on it and tighten it with a nut. Then, on top of the first one, you need to install a second saw blade on the tightened nut and also secure it with a nut.

It is worth considering the fact that some models of angle grinders are equipped with a short shaft. Therefore, in this case, after installing the second cutting wheel, there will not be enough space to tighten the second locking nut. In such a situation, you can install not a clamping nut directly between the cutting discs, but an ordinary washer . This will significantly save the length of the angle grinder shaft for further fixing the second circle using a clamping nut.

Between the cutting wheels installed on the grinder, you can place special bushings. Due to this, the distance between them will change, which will accordingly affect the width of the grooves made on the surface of the walls.

The nuances of making a protective dust cover

When making a protective screen, it is possible to adjust the cutting depth. The case consists of a hinged support plate and an attachment, which is attached to the body of the angle grinder.

Cotter pins or locking rings are used to secure the axle. A semicircular plate with a slot for a bolt is provided on the base, and 1 or 2 springs are installed on the rear edge.

Some craftsmen attach plastic rollers to the bottom of the sole, which reduce the effort when moving the tool along a concrete or plastered surface.

Manual wall chaser

If using an electric wall chaser is not practical, you can use a manual analogue. This type of device is a suitable option for small private buildings, since its cost is much lower.

An indisputable advantage is the fact that the manual type of the device is almost silent. It is not as dusty as electric. This product consists of a metal pipe, and handles are attached to the side. On one side of the pipe there is a cutting part that cuts into the aerated concrete mechanically.

In the construction industry, there are two types of manual wall chasers:

- devices that are used on horizontal surfaces;

- for processing vertical surfaces.

Both options are used for the same purpose. Their differences are only in the shape and location of the elements on the base that make up the tool.

A manual wall chaser for horizontal surfaces is equipped with a curved handle. While for a tool for vertical processing, this handle has a flat shape. These types of handle shapes are specially created. In order to be able to process the surface as best as possible without much effort.

Operating and safety rules

When using a homemade device:

- It is forbidden to turn on and operate the angle grinder with a missing or damaged protective screen. It is not allowed to install cutting tools with dimensions exceeding the permissible limits (the diameter is indicated in the passport and on the tool body).

- It is necessary to take into account the permissible rotation speed and the suitability of the tool for the material being processed (for example, it is not allowed to saw concrete slabs with discs designed for steel structures).

- It is not allowed to use cutting tools with defects and use low-quality consumables.

- The rotation should be directed as the tool moves along the wall surface.

- It is necessary to take into account the correspondence of power to the width and depth of the furrow. For example, when cutting a groove with a depth of 35-40 mm and a width of 45-50 mm, a motor with a power of at least 1500 W is required.

- Do not force the diamond blades into the wall before cutting. To reduce the load on the power drive, you need to immerse the tool in concrete smoothly. The operator will then move the angle grinder along the marking line.

- Safety glasses, gloves and a respirator must be used. The installed nozzle and dust removal system do not provide complete protection of the operator from flying concrete fragments.

- Installation of new discs is allowed only after disconnecting the grinder from the AC power supply.

- Avoid overloading or overheating the electric motor of the tool (some of the equipment is equipped with protective bimetallic fuses that break the power circuit if the temperature of the windings increases excessively). The appearance of a smell of burnt insulation and increased sparking of the collector unit indicate a malfunction of the angle grinder.

Installing two discs on the grinder shaft

The standard grinder is designed to install 1 diamond blade. To install the second element, use an extended shaft (available from some equipment manufacturers or ordered from a workshop) or a special nut.

The adapter is screwed onto the standard axle; to attach the second tool, a short shaft with a thread for fixation is provided on the bushing. To make channels up to 10 mm wide, craftsmen separate the cutting elements with washers (no additional nuts are required).

When using a double disk, the load on the gearbox bearings and the electric motor increases, which leads to accelerated failure of the grinder.

An additional disadvantage is misalignment, which leads to vibration. It should be taken into account that the adapter nut provides a fixed distance between the cutting edges, so you will need to purchase or make several bushings to make grooves of different widths.

What is needed to make a wall chaser?

The factory wall chaser has an almost identical design as the homemade one from an angle grinder. Here, too, the main element cutting concrete and brick are two diamond discs, which are spaced apart from each other at the distance required for cutting the grooves.

In the case of making a wall chaser from a grinder, the width of the cut can be adjusted with a nut, using one or two to place between the discs. The only limitation in this case is the length of the shaft on the grinder for mounting disks. However, as practice shows, the length of the shaft is enough to make a wall chaser.

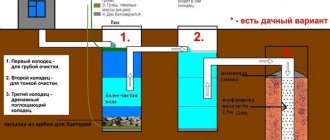

Now it remains to solve the issue of dust removal. And here the sewer outlet from pipe 50 comes to the rescue. By making a slot in the outlet for the disks so that they can rotate normally and screwing the outlet to the bottom of the angle grinder, you can connect a pipe or flexible hose from a vacuum cleaner to it.