Zinc or Zincum is element 30 of Mendeleev's periodic table of chemical elements and is designated by the symbol Zn. It is mainly used in the creation of deformed semi-finished products and as part of various types of mixtures. In its pure form, it looks like a brittle metal of a bluish-silver color; it quickly oxidizes and becomes covered with a protective film (oxide), due to which it noticeably tarnishes.

It is mined in Kazakhstan, Australia, Iran and Bolivia. Due to the difficulties in identifying the metal, it is often called "blende" .

Where to find zinc at home

Metals and alloys have become so integral to our lives that sometimes we don’t even think about them.

Back in the millennia BC, man's first acquaintance with nuggets occurred. A lot of time has passed since then, and every year metal processing has only improved. A metal such as zinc played a big role in this. Alloys based on it are used in many industries. In this article we will look at zinc alloys and their role in our lives. Search data for your request:

Wait for the search to complete in all databases. Upon completion, a link will appear to access the found materials.

Go to search results >>>

WATCH THE VIDEO ON THE TOPIC: Where to get zinc at home.

Zinc casting alloys

Pure or technical zinc is well processed by rolling, stamping and other metal processing methods. It can be processed both cold and heated to 170 degrees. The density of zinc is 7.13 kg per cubic decimeter. In addition, zinc has a low melting point - 420 degrees Celsius. The metallurgical industry produces several grades of zinc, which differ from each other in the set of impurities. The following set of letters and numbers is used to mark zinc alloys. The letter C, indicating that the material is zinc. Then the letters A, M or others are indicated, which indicate the names of the impurities A - aluminum, M - copper, etc. on the third there are numbers indicating the percentage of the impurity.

Zinc casting alloys

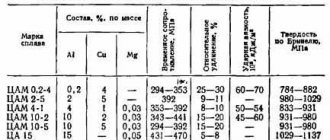

TsA4 alloys are used for zinc casting, TsAM4-1 are used for injection molding and many others. The composition and mechanical parameters of antifriction alloys are defined in GOST 21437-95.

One of the peculiarities of the use of zinc alloys is that secondary melting of this material leads to their loss of fluidity.

Features of the galvanizing procedure and the main methods of metal protection

Confidentiality Rules. Chemists Forum Chemists Forum Skip. We need a piece of zinc for exchange and sale of reagents, equipment and everything related to laboratory chemistry. Needed to protect iron from corrosion. To come back to the beginning. True, there are not pieces, but plaques half a centimeter in diameter, two or three millimeters thick [Post made via Android]. In my opinion, the corrosion protection zone from a piece of zinc is about fifteen centimeters in radius from the point of attachment.

Then a merciless struggle of potentials begins. I’m ready to donate one piece of 90 grams for a holy cause. But in general, it’s easier for you to find a granular one and cast it into the desired shape. God is not on the side of large battalions, but of those who shoot better - attributed to Voltaire. The zinc in the battery cups is quite pure, and the batteries themselves are cheap. Zinc, however, is thin, but it can be melted down, or you can simply change it more often.

I can offer a couple more options: – buy a thin flat galvanized steel sheet and screw it to the bottom in several places with stainless steel screws. However, this topic is already beyond the scope. It's much more effective! Last edited by ximi Mon Oct 28, pm, edited 1 time in total. Even imported ones do not have all their bottoms galvanized. Magnesium is also good in general. I'm not sure about aluminum anymore. I don’t want to melt anything down, to be honest. On the one hand, when damaged, galvanized water buckets corrode more slowly than enameled ones; on the other hand, a section of a freshly sawn galvanized gas pipe, thrown into the grass with dew, becomes covered with fresh rust overnight - both cases - personal observations, although it’s possible , the metal was different.

IMHO, zinc only protects small damage near it, so screwing large plates without applying potential to them will not be effective.

But I live far away. Krasnoyarsk region. I can send it by mail. Who is currently at the conference Currently this forum is being viewed by: no registered users and 1 guest.

Basic methods of zinc casting

In non-ferrous metallurgy, several technologies for producing castings are used, and this somewhat complicates the work of the technologist in terms of determining how the part will be manufactured. Before making a final choice in favor of one technology or another, you need to understand the following:

Centrifugal casting method

- The chosen casting method must guarantee that the resulting parts will fully meet the requirements of regulatory, technical and working documentation. All parameters included in the part will be observed, and allowances for machining should not exceed the norms defined in the relevant standards.

- The technical process must have appropriate productivity and efficiency.

- The use of the selected process must be based on the operation of existing equipment and fixtures.

Zinc sand casting method

To produce castings from zinc alloys, the following main types of casting are used, and their features must be taken into account. For example, casting in sand or metal molds is the most common and, probably, economical method of obtaining the necessary blanks. But it is necessary to take into account that after casting in sand, additional surface treatment will be required, since its quality leaves much to be desired. When producing small batches of parts, it makes sense to think about die casting. But in this case, the high cost of equipment may become an obstacle.

Centrifugal casting

The result of constant improvement of foundry technologies was the emergence of machines for performing centrifugal casting. The principle of this method of producing castings is simple - the melt is fed into molds rotating around its axis, under the influence of centrifugal force it is “smeared” over the mold and after a predetermined time the finished product will be formed. This technology makes it possible to smelt products without air bubbles.

There are horizontal and vertical machines. They are used to produce large-sized castings. The use of equipment of this class is justified from an economic point of view when organizing mass production.

This technology makes it possible to produce hollow castings without the need to use additional devices, such as rods. The casting obtained using this technology has a dense and fine-grained material structure. However, the equipment to perform work using this technology is quite expensive. In addition, for a number of reasons, in particular, due to the low flexibility of the shape, defects in the form of cracks may appear.

Injection molding

Die casting of zinc alloys is based on the following principle - the melt is fed into the mold under pressure from 7 to 700 MPa.

Its level depends on the composition of the alloy and the characteristics of the future part. Using existing equipment, it is possible to produce parts weighing from several grams to tens of kilograms. Advantages and disadvantages of casting technology Among the many casting technologies used for working with zinc alloys, the following are used:

Chill casting

Guarantees the production of workpieces with high surface quality; as a rule, such parts do not require machining operations. But the mold has a high price due to the high labor intensity of its production.

A high cooling rate leads to a decrease in the fluidity of the melt and this can lead to the appearance of various types of defects. The virtual absence of gas permeability of the mold leads to the fact that the gases generated during the casting process remain in the workpiece. Die casting of zinc alloys makes it possible to produce complex products with minimized wall dimensions. The quality of the resulting product allows us to avoid further machining. This type of casting is distinguished by its level of productivity. However, expensive equipment is required to ensure it. In addition, there are restrictions on the overall dimensions of cast parts.

Do-it-yourself galvanizing of metal - an overview of suitable methods

You have all probably encountered such a phenomenon as rust. There are many ways to combat it: chemical, mechanical, electrochemical. Once, having cleaned and painted over a chip on my car, I was surprised to see rust in this place a few months later. I decided to buy a converter and apply it, read a lot of information on this subject and found an interesting post on Drive2. Buy hydrochloric acid or its more affordable version, in Ukraine - this is a detergent for bathtubs and toilets “Santry”, you can use its analogue based on this acid, you can use orthophosphoric acid or a converter based on it, but then the process of dissolving zinc in acid will take longer , under no circumstances use sulfuric acid or electrolyte for the battery, it is also there - the process will take a long time and the acid will never “overwhelm completely”. You need to buy zinc, the simplest option is 5 zinc batteries will be enough, they are already rare, but the cheapest ones are usually with zinc.

Zinc anti-friction alloys

Antifriction materials are most widespread. They are used as castings, as well as after machining. These materials are distinguished by anti-friction parameters and fairly high strength. They are used to replace bronze, parts from which operate at temperatures not exceeding 100 degrees Celsius.

Microstructure of zinc antifriction alloys

If the temperature is higher than this, the alloy becomes excessively soft and gradually the top layer of the zinc part will appear on the surface of the shaft. Alloys of this class are used to produce all-metal or bimetallic materials. Of the zinc-based alloys, the most widely used alloys are TsAM1 and TsAM 4-1; they contain up to 4% aluminum and 1% copper. In addition, brands such as TsAM 10, consisting of 5% aluminum and 10% copper, are used to produce castings. It is distinguished by high mechanical and antifriction properties. This material is widely used for motorcycle parts. Its technical properties make it possible to use it in the production of plain bearings. The TsAM 4-1 alloy stands apart. This material is used to produce parts of various configurations and purposes in the automotive industry. The composition of this material is standardized by GOST 19424-97. In accordance with its requirements, the composition of this alloy, in addition to aluminum and copper, may include:

- silicon, not more than 0.13%;

- magnesium, not more than 0.06%;

- iron, not more than 0.005%;

- lead, not more than 0.01%;

- tin, not more than 0.012%;

- cadmium, not more than 0.004%.

Electroplating at home.

Welcome, Guest. Please login or register. Did not receive your activation email? Pages: [ 1 ] 2 I encountered a problem where to get reliably pure zinc. I don't want to buy on eBay. There's a gram there and the price is decent. But I need a quarter of a gram.

The group of auxiliary metals used in orthopedic dentistry and denture technology is united according to the principle of their purpose and application. Auxiliary metals include copper, aluminum, lead, zinc, tin, bismuth, cadmium, antimony, and magnesium. Auxiliary metals are used to make alloys.

Where is zinc used in everyday life? And how can we determine that it is zinc and not some alloy of zinc with other metals? You won't be able to get zinc from them. The easiest way to get it is in batteries, where the index L is indicated. It has a zinc cup under the outer plastic wrapper. You can determine zinc in the following way: dip it in hydrochloric acid.

Zinc is widely used in production, mainly to protect the surface of iron products from corrosion - the surface is galvanized, but it is impossible to separate it from the surface of iron at home. But in widely used batteries, zinc is often used as an anode, located under an outer iron or polymer shell. Therefore, all that remains is to find a used battery, disassemble it, only on the street, and the zink is in your hands. Be careful when searching for batteries, do not open Lithium batteries - they are explosive. I don't think the steel body could have melted instantly. My scales are excellent.

Protection of metal surfaces from corrosion is always relevant, regardless of production volumes. It is also necessary in private households. Such protection significantly extends the service life of products and makes their use reliable.

Types of alloys

The following zinc alloys are used in industry for casting:

- Zn-Al system – TsA4, TsA15, etc.;

- Zn-Cu system – TsM 1, TsAMO, etc.;

- Zn-Al-Cu system – TsAM 4-1, TsAM 10-4;

- Zn-Al-Me system – CPU2, CPU3, etc.

The alloys listed are used for injection molding. They are used to produce castings of complex shapes, and the wall thickness can be 0.6 mm. The same alloys can be used for casting in chill molds or sand molds. Zinc casting alloys must meet the following requirement - a minimum amount of impurities, namely in alloys, the content of lead, iron and some others must be minimized.

Download - Where to get zinc at home.

Vladimir Maxim

Video comments

Good afternoon, it’s clear where it is, but how to extract it from it? Thanks for the video, like it!

Don’t confuse it with tsam, otherwise you’ll give me some advice. people can do refining. The carburetor is definitely made of 80% high-grade zinc and the cables too. and the rest is slag

I have zinc from electroplating. no shit, he's not like a pen. and why look for zinc acid is not clear. the price of soldering acid is 150 rubles per half liter.

I thought the hangers were made of aluminum or duralumin.

- ⇥ Autoplay

How to distinguish TsAM metal

Don't rush to throw away your old meat grinder.

Gallium is a metal that melts in the hand.

how to make a hand sewing machine for leather with your own hands // Hand sewing machine for leather

Battery chemistry

Dimexide. Exposure. Spark plug.

•Gold in Radio Tubes from Televisions•

Auto LIFE HACKS. Every DRIVER NEEDS THIS!

OBTAINING PURE ZINC. Zinc purity 98%.

How to solder aluminum with a conventional turbo torch.

We galvanize rust spots using electrolysis. Part 2.

Zinc coating. Electroplating at home. [ChemistryToday]

Zinc, where to find, where to get.

Everyone has their own fashion and hobbies, and therefore sometimes it’s very nice to find like-minded people, appreciate their stamp collection or skill in a certain game. Here are collected various videos that are dedicated to one or another hobby. It doesn’t matter whether you like chess, tennis, or collecting wild, untamed animals under your roof - here you will be able to find good video content to your liking.

Properties of zinc alloys

Products made from zinc alloys are used in various industries and households. For example, when assembling automotive equipment, zinc alloys are used in the manufacture of some body parts, filters and many others. The electrical industry uses zinc to produce brush holders. Alloys made from this material have high ductility. And this property allows it to be used to produce castings of complex shapes with thin walls. Zinc casting alloys do not react chemically with the metal of the mold and do not stick to its surface. The parameters of these materials allow the production of threaded parts.

Properties of zinc alloys

Meanwhile, the mechanical properties of zinc and its alloys are characterized by the fact that the tensile strength lies in the range of 20 - 38 kgf per square meter, and the Brinell hardness is 65 - 110 units. Castings made of zinc alloys have low surface roughness and dimensional accuracy. The workpieces obtained by injection molding are well processed by pressure and cutting. Meanwhile, zinc alloys have a high density - 7 kg per decimeter, and this is comparable to steel. They do not have very high resistance to corrosion. The presence of substances such as lead, cadmium and some others in the alloy results in accelerated aging processes. It is accompanied by a decrease in mechanical parameters and a change in the volume of the casting. In addition, alloys made from these materials are characterized by increased porosity.

To improve the strength properties and give zinc alloys good corrosion resistance, magnesium is introduced into their composition; its concentration should not exceed 0.1%. In addition to this, fairly traditional methods are also used - nickel plating, cadmium plating, etc. The properties of the alloy are determined by the presence of certain substances in the alloy composition.

Why is zinc needed?

Zinc is essential for human health. It participates in the Discovery of human zinc deficiency: its impact on human health and disease in the synthesis of about 300 enzymes that regulate brain activity, cell growth, metabolism and digestion. In addition, zinc protects against cardiovascular diseases, supports the immune system, promotes tissue repair, and improves vision.

Since this substance does not accumulate in the body, it is recommended that men consume 11 mg of zinc daily, women - 8 mg, pregnant women - 11 mg per day, and lactating women - 12 mg. .

A lack of zinc leads to frequent colds, brittle nails and hair loss, irritability, poor coordination and rashes. Let's figure out what you should include in your diet to avoid this.

Currently reading