Wood is popular in private construction. The material is inexpensive, accessible, and easy to process. Many people prefer to cut the logs themselves. It's cheaper and sometimes better quality. In addition, sawing wood is an exciting hobby. For such a hobby you will need a band sawmill, which you can make yourself.

Homemade circular sawmill

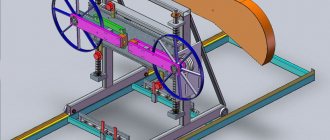

Disc sawmills have received the greatest handicraft use due to their versatility and ease of manufacture. We will make a circular sawmill with our own hands. The most important thing is that we will need a circular saw - a disc larger than 500 mm (the larger the better). The propulsion device is usually an electric motor through a pulley that increases the speed.

1 — main sleeper (steel pipe 80x80x3, 5 pcs); 2 — lining (steel sheet, 40x10x1.22 pcs.); 3 — guide blade (steel channel No. 8, L1750, 4 pcs.); 4 - trolley (telpher carriage); 5 — bottom bracket (steel channel No. 18, 2 pcs); 6 - plate - base (stylish sheet s5); 7 — M20 bolt) (4 pcs.); 8 — Grover washer (4 pcs.); 9 — nut M20 (4 pcs.); 10 — three-phase asynchronous electric motor (220 V, 5 kW, 930 rpm); 11 — upper bracket (steel angle 45×45); 12 — circular saw blade; 13 — protective casing (steel sheet s2); 14 — steel pin (8 pcs.); 15 — circular saw hub (St5); 16 — thrust handle (water and gas pipe 3/4″); 17 — cut-off slab; 18 — thrust gusset (steel sheet s5); 19 — comb (steel angle 45×45, L400); 20 - log; 21 — M30 bolt; 22- split washer; 23 — retaining washer (steel sheet sЗ); 24 — thrust crossbar (steel angle 45×45); 25 — shortened sleeper (steel pipe 80x40x3, 6 pcs.); 26 — overlay for lengthening the blade (steel sheet 250x180x10, 2 pcs.).

A welded frame is prepared, a metal (less often wooden) plate with a slot for the disk is placed on the frame. The gaps between the disk and the plate are minimal. The saw shaft is attached to the plate from below on bearings and a pulley. The electric motor pulley and the saw are connected by belts (reinsurance when the saw jams) - a homemade circular sawmill can work!

one of the options for a homemade circular sawmill

To tension the belt, use the weight of the engine with the addition of weights. Make the supporting platform of the electric motor movable coaxially with the saw shaft, deflecting under weight in the opposite direction. The wheel of a working tractor with a drive to a saw pulley without belts is often used as a propulsion device.

The principles of cutting are the same as in band cutting - we feed the log to the cutting disc. After a disc cut, the surface of the lumber is of higher quality due to the speed of processing. Disc sawmills come in vertical and horizontal types - they are easier to use in mobile installations.

How to make a sawmill from a chainsaw with your own hands: drawings, options

The user needs to arm himself with ready-made drawings and diagrams. You can also watch short video instructions. Next, the place for the future homemade product is prepared. It is best if it is placed under a canopy.

First option

Prepare the following structural parts:

- two channels, the height of which will be 140-180 mm and the length of 8 m.

- two rails for future construction;

- corners, the size of which will be 40x40 mm and 50x100 mm;

- pipe for screed;

- steel sheet, the thickness of which is 4-6 cm and the length is 60 cm;

- hoses;

- pipes with a diameter of 35-40 mm.

Do-it-yourself sawmill from a chainsaw, manufacturing principle

- The base is assembled using rails and angles.

- Holes are drilled along the length of this base every 1-1.5 m. Their diameter should be 14-16 mm.

- The ties are connected to the holes using bolts.

- Stands are created from corners onto which a metal base is attached.

- All elements are welded.

- A movable cart is made: a corner is welded to the metal sheet, and it is placed on rollers. Two corners are installed on the top of the stove, and a chainsaw is placed on them.

- A log retainer is created. For this purpose, movable hoses are attached.

Second design option

This design requires the same set of tools, but it itself has a more elaborate look.

- A saw with a drive is used, which can be purchased in a ready-made version.

- A mechanism for adjusting the thickness of the board is being manufactured. To do this, the metal base is welded to the plate using curved nuts. Lock nuts are installed at the top of the structure to fix the width.

- Mechanism for saw operation. It is necessary to secure the movable ridge with screws when the board is installed between it and the fixed part.

Homemade chainsaw sawmills are quite impressive assistants when working with wood. They should only be used with safety precautions in mind.

A bike with a chainsaw motor

You can install a chainsaw engine on your bike. On such a bicycle moped you can accelerate to 50 km/h, and sometimes even higher. In order to design this transport, you need a chainsaw engine with a power of 1.5 - 2 hp. – this is enough to develop a speed of 30 – 40 km/h. It is clear that you need a container used as a gas pack; you cannot do without wires and a switch to connect the engine ignition, etc.

A bicycle made from a chainsaw consumes a minimal amount of fuel.

Various masters on the Internet tell in detail how to make a motor for a bicycle from a chainsaw.

Safety at work

Having high productivity, sawmills are sources of increased industrial injuries. Many people have heard horror stories about “he turned his head away, but his finger was no longer on his hand.” There are many similar stories and they are all real.

The most reliable method of reducing the number of injuries and accidents when using such equipment is scrupulous compliance with all safety regulations. Before starting work, you need to familiarize yourself in detail with the operating principles and operating instructions of such a device, as well as with the fire safety rules.

The highest level of safety is achieved when the sawmill is equipped with a reverse feed system due to its design.

Purpose and principle of operation

The sawmill is used to produce various lumber (timbers, slats, boards, sleepers) from solid logs. It is used in wood processing plants, sawmills, furniture factories and in the construction industry. This device allows you to:

- Reduce the amount of shavings and other dirt that appears during wood processing.

- Cut short workpieces with a length of 1 m and obtain parts with a thickness of up to 0.2 cm.

- Reduce energy costs.

- Determine the size of the resulting lumber.

- Produce wooden parts with high surface quality with an accuracy of up to 2 mm.

The sawmill has the following advantages:

- Mobility. The woodworking machine can be quickly disassembled and moved to a new location.

- Stability of the structure. The woodworking machine can operate under harsh climatic conditions both indoors and outdoors.

- Ease of use. The sawmill is equipped with many automatic mechanisms that facilitate the process of processing logs. During operation, it does not make unnecessary noise.

The disadvantage of this unit is its high cost. It depends on the type of machine and its technical characteristics. The cost of equipment is also influenced by the manufacturer's brand. The most expensive devices are from Swedish and Canadian manufacturers. Their average cost is 324 thousand rubles. Machine tools produced in Russia cost 135 – 220 thousand rubles.

The sawmill consists of the following elements:

- Bed. It has a U-shape and is assembled from 2 parallel channels. A mobile trolley with a saw element mounted horizontally moves along the bed. Frames and brushes are also attached to it, designed to clean the working surface from sawdust and other industrial debris.

- Saw frame. This part is a device consisting of several welds. At its ends there are driving and driven pulleys. The saw frame moves using metal rollers and an electromechanical drive with driven and driven wheels.

- Guides. They are fixed in the middle part of the saw frame using brackets. Support rollers and log racks are located on the guides.

- Screw mechanism. It is necessary to adjust the thickness of the workpieces being processed. This element helps prevent the log from skewing during processing.

- Clamping device. It is designed to hold the log while sawing. The clamping device consists of a round pipe and clamps in the form of bushings.

- Saw. It acts as the main cutting element of the sawmill. Its average width is 6 cm. The saw is tensioned using a hydraulic or spring mechanism. It allows the operator to adjust the position of the driven pulley and prevents the cutting element from coming off the wheels.

- Tank for cutting fluid. It is used to prevent sawdust from sticking to cutting elements. The tank has valves for supplying liquid.

- Electric motor. It is designed to transmit torque to the pulleys and activate the chain transmission mechanisms that move the saw frame. The average power of the electric motor is 5 kW.

- Remote Control. It is located on the top crossbar of the woodworking machine. Next to the control panel, on the operator’s side, there are measuring instruments for accurately calculating the thickness of the resulting lumber.

The structure of home sawmills is organized in the form of several blocks. This design is easy to manufacture. Its disadvantage is low productivity. Therefore, these machines can only be used in domestic conditions to produce small amounts of lumber. The operating principle of this unit is to cut a log fixed on a special platform with a saw tool located in a horizontal position. The dimensions of the resulting lumber are pre-set by the operator.

Electrical equipment, light, lighting

Residents of small towns or villages are well aware of the role any woodworking equipment plays in their lives, which most likely many have had to use in their work. Nowadays, the construction market is replete with a large number of different models of woodworking equipment, with sawmills being the most popular. All sawmills are divided into frame, disk and band sawmills, which differ in the type of cutting tool. The tire sawmill differs radically from them in its design.

Essential tips and tricks

Since the sawmill is considered a rather dangerous unit of impressive size, before assembling it with your own hands, you need to carefully consider where it will be used. Good for this:

- barn;

- garage;

- an ordinary utility room with a concrete base.

Such a place should be well ventilated, spacious and have sufficient lighting. A place for this device can also be found on the street, but a canopy must be equipped for it.

If the sawmill has an electric motor , then you need to carefully consider the installation of wiring and installation of the necessary switches and machines. If there is a warehouse for finished boards near the place of work, this greatly simplifies the whole process.

When assembling the unit with your own hands, special attention must be paid to its cutting and moving parts, which are considered the most dangerous elements. In general, safety precautions should be observed when operating the device.

After assembling the sawmill and before starting work, be sure to check all fastenings and components, as well as the stability of the structure. The first start of the device is carried out after following all the necessary recommendations.

Thus, making a sawmill with your own hands is not difficult . These devices come in different types and the process of their assembly is presented in the video. You should also definitely use the drawings so as not to make any mistakes. When operating a sawmill, it is necessary to observe safety precautions, because this is a rather dangerous device.