3.5.1.

Installer's claws must comply with the requirements of TU 34-09-10147 - 88 and are intended for work on wooden and wooden with reinforced concrete stepson supports of power transmission and communication lines, on reinforced concrete supports of overhead power lines (VL) 0.4 - 10 and 35 kV, as well as on cylindrical reinforced concrete supports with a diameter of 250 mm of a 10 kV overhead line.

3.5.2.

Installer's manholes are designed for climbing onto rectangular reinforced concrete supports of 0.4 and 10 kV overhead lines, universal manholes are designed for climbing onto unified reinforced concrete cylindrical and conical supports of 35 - 500 kV overhead lines.

3.5.3.

Metal parts of claws and manholes should not have dents, cracks, breaks, burrs, or sharp edges. Welding areas must be level, smooth, without cavities or other defects. Removable tenons must not be knocked down or beveled.

3.5.4.

The fastening straps are made of two layers of leather, soaked in fat and stretched. The thickness of the belts must be at least 3 mm. Belts are stitched with machine stitching, linen thread or other threads of equivalent strength.

3.5.5.

Seam lines should be even, well tightened and without loops. The beginning and ends of the lines must be secured.

3.5.6.

Buckles must have a frame, the joints of which are welded, or the buckle must be stamped.

The rollers should have tightly butting edges and rotate freely.

3.5.7.

The pin of the buckle must be blunt, extend beyond the middle of the outer wall of the buckle and not protrude along the length of the buckle.

3.5.8.

The pin should be made of steel wire.

3.5.9.

Buckles must have a protective and decorative coating and are sewn to the belt using linen thread or other threads of equal strength.

3.5.10.

By order of the workshop or area in the organization, persons responsible for the good condition of the claws and manholes must be appointed.

3.5.11.

Claws and manholes must withstand a static load of 1765 N (180 kgf) without permanent deformation.

3.5.12.

The service life of claws and manholes (except for spikes) is 5 years.

3.5.13.

On the foot of the claw, the hole should be applied:

a) manufacturer's trademark;

c) date of manufacture.

3.5.14.

Before climbing onto the support, you must carefully inspect the claws and manholes and make sure that their test date has not expired and that the components and parts are in good working order. Particular attention should be paid to the strength of the welds, the integrity of the carbide inserts of the studs, the integrity of the firmware of the belts and the reliability of the buckles, the presence of lock nuts and cotter pins and the reliability of fastening the end of the double spring band to the drum of the worm mechanism, as well as the reliability of fixation of the tip of the cable loop of universal manholes in socket of the mechanism body, the serviceability of which is checked by rotating the handle of the worm mechanism.

3.5.15.

The use of claws and manholes that have blunted or broken spikes is not permitted.

3.5.16.

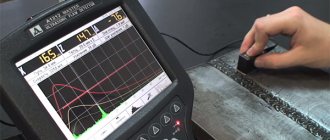

Claws and manholes are subjected to periodic static tests at least once every 6 months.

Requirements for personal protective equipment against falls from height

Personal protective equipment against falls from height includes:

a) safety belts (hereinafter referred to as belts) that meet the requirements of GOST R 50849 - 96, GOST 12.4.184 - 95;

b) safety semi-automatic steeplejack devices type PVU-2;

c) catchers with a vertical rope or other devices;

d) safety ropes that meet the requirements of GOST 12.4.107-82;

e) construction helmets that meet the requirements of GOST 12.4.087-84.

Personal protective equipment against falls from height, both domestic and purchased abroad, must have quality certificates.

Fitter's claws (fitter's manholes, crampons) are devices used by electricians and high-rise workers to safely climb concrete and wooden power line supports and trees. Despite the widespread use of specialized automobile towers and telescopic lifts, mounting claws still have a very large list of situations in which their use is more appropriate and convenient: when space is cramped and there is no possibility for equipment to approach power lines, when hydraulic mechanisms break down or fail lift at the work site.

Legislative framework of the Russian Federation

Free consultation

Federal legislation

- home

- “INDUSTRY RULES FOR OCCUPATIONAL SAFETY DURING MAINTENANCE AND REPAIR OF SIGNALING, CENTRALIZATION AND INTERLOCKING DEVICES ON FEDERAL RAILWAY TRANSPORT. POT RO-13153-TSSh-877-02" (approved by the Ministry of Railways of the Russian Federation on February 19, 2002)

| Name of document | “INDUSTRY RULES FOR OCCUPATIONAL SAFETY DURING MAINTENANCE AND REPAIR OF SIGNALING, CENTRALIZATION AND INTERLOCKING DEVICES ON FEDERAL RAILWAY TRANSPORT. POT RO-13153-TSSh-877-02" (approved by the Ministry of Railways of the Russian Federation on February 19, 2002) |

| Document type | rules |

| Receiving authority | MPS RF |

| Document Number | POT RO-13153-TSSh-877-02 |

| Acceptance date | 01.01.1970 |

| Revision date | 19.02.2002 |

| Date of registration with the Ministry of Justice | 01.01.1970 |

| Status | valid |

| Publication |

|

| Navigator | Notes |

Monter's claws and manholes

4.2.24. Assembly claws must comply with the requirements of TU 34-09-10147-88. The claws are designed to work on wooden and wooden with reinforced concrete stepson supports of power transmission and communication lines, on reinforced concrete supports of overhead power lines (OHT) 0.4 - 10 and 35 kV, as well as on cylindrical reinforced concrete supports with a diameter of 250 mm of 10 kV overhead power lines.

4.2.25. Metal parts of claws and manholes should not have dents, cracks, breaks, burrs, or sharp edges. Welding areas must be level, smooth, without cavities or other defects.

Removable tenons must not be knocked down or beveled.

4.2.26. By order of the workshop or area in the organization, persons responsible for the good condition of the claws and manholes must be appointed.

4.2.27. Claws and manholes must withstand a static load of 1765 N (180 kgf) without permanent deformation.

4.2.28. The service life of claws and manholes (except for spikes) is 5 years.

On the foot of the claw, the hole should be applied:

a) manufacturer's trademark;

c) date of manufacture.

4.2.29. The use of claws and manholes that have blunted or broken spikes is not permitted.

Design and principle of operation

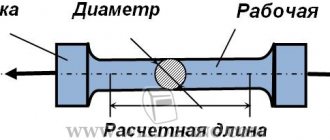

The simplest manholes for concrete supports consist of 2 elements for attaching to shoes, each of which consists of the following main components:

- Oval foot support with transverse reinforcements;

- 2 straps holding the foot on the platform;

- “Sickle” is a rectangular grip with 4 conical spikes attached at an angle of approximately 600 to the supporting platform.

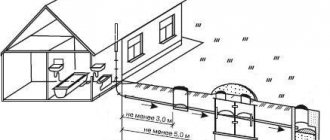

Climbing onto a reinforced concrete pole using a similar device occurs as follows:

- The electrician securely fixes the manholes on his shoes using belts;

- Approaching the pillar, he grabs it with the grips of each of the elements of the claws;

- The electrician climbs the pole, thanks to the fact that the claw grips, which he alternately rearranges in the vertical plane, located at an angle to the supporting platforms, bite into the concrete with their spikes and prevent slipping.

Using a similar principle, electrical claws designed for this type of support help you climb onto a wooden pole. Their only differences from the crampons used for concrete pillars are the semicircular shape of the grips and softer spikes.

Claw-holes for concrete, metal, round and polyhedral supports of overhead lines and communications

Professional claw-claws are equipped with a convenient screw mechanism for adjusting the width of the aluminum footrest base with rubber pads and tanned chrome straps.

Reliable adhesion to the reinforced concrete support is provided by profiled, arched, steel paws covered with rubber, anti-slip hoses.

Carabelli Srl's manhole claws are made from high-strength materials, thanks to which they do not bend under weight and do not slide off the poles.

Adjustable claws model 3005

| Dimensions | Ø SUPPORT | Weight, kg | |

| min. Ø, cm | Max. Ø, cm | ||

| 1 | 9 | 22 | 6,5 |

| 2 | 14 | 27 | 6,7 |

| 3 | 16 | 33 | 7,1 |

| 3S | 14 | 30 | 7,1 |

| 4 | 26 | 40 | 7,4 |

| 5 | 28 | 46 | 7,7 |

Non-adjustable claws model 3020

| Dimensions | Ø SUPPORT | Weight, kg | |

| min. Ø, cm | Max. Ø, cm | ||

| 1 | 8 | 16 | 4,2 |

| 2 | 12 | 20 | 4,3 |

| 3 | 16 | 24 | 4,5 |

| 4 | 18 | 28 | 4,7 |

| 5 | 22 | 34 | 5,1 |

carabelli-cis.com

Types of climbing cats

Depending on the design and purpose, all such devices are divided into claws for concrete pillars, manholes for wooden supports, dart climbers (devices used for climbing trees).

Manholes, claw-holes for reinforced concrete pillars

This is the most common type of these devices, widely used by modern electricians and installers.

They consist of two oval support platforms with fastening straps for legs and rectangular grips up to 190-200 mm long, having 2 conical spikes on each of the short sides.

Claws for wooden posts

Less common and less commonly used by modern electricians, manholes have one significant difference from the previous ones - their grips have a semicircular shape with a diameter of up to 220-315 mm and 5 spikes on each. The most famous model of such a device is the KM 1 brand claws.

Tree frogs

Tree climbers have claws for climbing tree trunks. They are a curved “L”-shaped splint with a semicircular casing for the shin and a sharp triangular spike located on the outer part and a belt for fixing the foot. A similar device is used by high-altitude tree trimmers and hunters.

Areas of application of KLM2

Lazy claws marked KLM 2 are the most popular and widespread device. They are used for lifting reinforced concrete trapezoidal or rectangular supports with a diameter of up to 190 mm.

On a note. There is also a universal type of these devices, which has grips that allow you to climb most modern power transmission towers.

The most famous model of such manholes is LU-2.

Structure

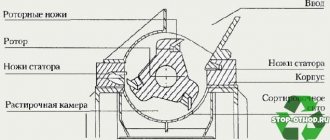

Monter's manholes (claws) are a design of two main parts:

The hook has the shape of a trapezoid or rectangle. For strong adhesion to the support, it is equipped with teeth and self-adjusting spikes. The belts are made of genuine leather, sewn in two layers. The total weight of the structure is from three to five kilograms.

The laz works using momentum: different levels of spikes allow the hooks to be more firmly fixed under the influence of a person’s weight. The more weight, the better the grip. The gravity of the body, whatever it may be, will create the necessary moment of momentum, allowing you to maintain the required mass.

Rules for using claws

The procedure for using manholes consists of the following manipulations:

- When working on power lines, you must have the appropriate education and permission to repair such communications;

- When working on power lines, you must take care in advance to de-energize them;

- Before starting work, be sure to check the integrity of the retaining belts, support platforms for the feet, grips and the spikes located on them;

- It is advisable to work together - this is necessary so that in the event of an electric shock when working on an unpowered line or falling from a height if the technique of using claws is not followed, the second person can promptly provide first aid and call doctors.

Safety during work

Both the installer and the other person using the claws must adhere to the following safety rules:

- In order to minimize the risk of falling, it is necessary to use a safety (safety) belt, with which the worker must fasten himself to the pole;

- To avoid electric shock and head injuries, it is imperative to use a protective helmet, special dielectric gloves, and overalls;

- The shoes to which the manholes are fastened must fit tightly on the feet: before putting on the manholes, they are carefully laced or fastened;

- Before you start lifting, be sure to check the stability of the support.

When using tree climbers, be sure to have a safety rope attached to a strong branch.

Equipment operating conditions

The use of manholes is permitted subject to the following conditions:

- Integrity of all elements: metal frame, support platforms, grips, holding belts;

- Mandatory verification of manholes - such equipment must be verified every two years in specialized laboratories. During the verification, the values of the strength characteristics of the main manhole structures declared are determined, and a conclusion is issued on the safety of using such equipment. The verified equipment must have a stamp indicating the date of verification;

- It is undesirable to use manholes of dubious origin: those that do not have manufacturer logos or initial verification marks;

- Requires appropriate education or training in the use of such equipment;

- Absence of foreign elements - for the safe use of factory models of manholes, it is prohibited to independently modernize them, replace structural elements and spikes with homemade ones.

All the details of working with manholes are described in special instructions for electricians and high-rise installers.

Defects in mounting claws

The main defects that can be found in an electrician's claws include the following:

- Cracks – such damage includes a violation of the integrity of the metal structures of the supporting platform, grip;

- Burrs are sharp edges of cracks in metal parts that, in contact with belts, can cause damage;

- Tears and fraying of retaining belts - with prolonged use, the material of the belts, gradually losing strength, begins to tear and separate into fibers, which is visually manifested in the form of terryness and clearly visible transverse tears;

- Deformation and reduction in the strength of the studs - caused by natural fatigue of the metal, this defect manifests itself in the partial or complete loss of this element of its main functions.

Note! If one of the above-described defects is detected in factory-made models, experts recommend not to repair them yourself, but to take them to a specialized workshop for repairs. It is prohibited to use such installation equipment even with minimal damage.

Selection rules

To make the right choice of claws, you need to have some knowledge in this area. When choosing a device, you should pay attention to the following nuances:

Product price. In this case, it is worth remembering that cheaper versions of the claws may use insufficiently high-quality metal, as a result of which the device will be unreliable and dangerous. Focus on medium or high price, which guarantees quality.

Manufacturer. As you know, it is better to trust proven and well-known manufacturers.

Quality. Products must comply with current GOST or TU and have quality certificates. Upon external inspection, no defects or unevenness of the seams should be noticeable. The thickness of the belts must be at least 0.3 mm, the stitches must be even and securely fixed.

Proper storage conditions

After each use, the claws must be cleaned of dirt, rust, concrete dust or crumbs.

Claws for climbing poles should be stored suspended (on hooks or special hangers), in well-ventilated, dry areas out of the reach of children and pets.

Another advantage of such equipment for installers and electricians is the possibility of making it yourself - on the Internet you can easily find both a visual drawing and video instructions for assembling claws from scrap materials with your own hands.

Product selection criteria

Smooth-haired cats lead a very active lifestyle and love to climb trees and claw at each other. A sharpener for them can be made from thin twigs that are equipped with bark. Fluffy cats are less active and more phlegmatic. They are not characterized by high activity and have no desire to climb branches. For such cats, you need to make a stable sharpener with a resting area.

Do not place the product near your sleeping area. Home safety is important for a cat , and he will not tolerate unnecessary objects near the house. This arrangement will cause anxiety in the cat; most likely, he will move away from such a complex.

The exception is cats of wild breeds. A Siamese, Bengal, or Abyssinian cat will be quite happy with a complex in which there will be a house and a sharpener. In nature, they live in trees, and therefore such close proximity of two favorite places is the norm for them. Experts advise making a bench and inspection platform on a pole. It must be branched enough to allow the animal to move around the scratching post. If it is not possible to buy a wooden pole, then you can build such a tree from cardboard tubes.