The quality of the work it produces directly depends on the sharpness of the blade. A dull or deformed tip does not perform its functions and can not only ruin the cutting process, but also injure the operator. Throughout the development of all bladed weapons, sharpeners were invented that could restore the original quality of the cutting edge. The further progress developed, the more high-tech sharpening stones became, and the amount of time that needed to be spent on work was reduced. Models with a motor at the heart of the design are considered the most powerful and efficient. Their range of functions includes straightening a bent edge, removing chips and nicks, grinding, cleaning, and restoring the original sharpness. However, the turning process requires practical or at least theoretical preparation. Unlike manual abrasive bars, where a sharp change in the angle of the blade will not have a critical effect on it, on automated models any mistake can lead to damage to the product. We will explain how a knife sharpening machine works, how to properly sharpen knives on a machine, how to achieve maximum efficiency and avoid the most common mistakes.

How to sharpen knives on a machine correctly

Before you learn how to properly sharpen knives on a machine, you need to become more familiar with its design. Since all motor models are divided into automatic and semi-automatic, instructions for their use will vary.

Figure 1. Wheels for sharpening knives: abrasive and felt

However, the operating principle remains the same:

- The electric motor rotates the axis on which a circle with a special coating is installed. For turning it is crystalline abrasive grains of various sizes, for grinding it is felt (Figure 1). The coarser the crystals on the wheel, the more severe dullness they can handle. It is prohibited to use coarse grain for thin, soft or partially dull blades - complete deformation will follow. The use of small crystals for a completely dull tip will also be ineffective;

- The rotation speed of the axis is selected by the operator himself, depending on the type of steel and the degree of dullness. If you choose the wrong mode, you can overheat the product and inevitably damage it under the influence of temperature;

This is where the similarities between automatic and semi-automatic devices end.

Figure 2. Options for professional knife sharpening machines

A professional automatic knife sharpening machine (Figure 2) operates according to the following algorithm:

- A motor and abrasive wheels of different grain sizes are built into a maximally closed casing with an opening (or several openings) for the blade. The system is designed in such a way that the inclination of the grinding wheel can change depending on the impact on the guides themselves. The operator inserts the product into the opening, and the guides automatically adjust the required angle;

- Since the turning inclination is individual for each tip, such devices imply the ability to adjust down to the millimeter;

- Most devices have several speed or time modes, so you need to know the characteristics of the gun in advance. By choosing too intense a mode, you can also deform the tip.

Figure 3. Typical “Epaper”

A manual machine (Figure 3) for sharpening knives (aka “emery”) requires an integrated approach to the entire process:

- Turning is carried out by applying the edge to a rotating wheel; precise inclination must be maintained. Otherwise, you can either grind off a significant layer of metal, or completely change the slope of the processing, which will ruin the blade;

- The attachment with grain is also selected according to the characteristics of the implement. For kitchen or travel models, fine sandpaper is sufficient, for working tools (for example, shoemakers) – medium sandpaper. Axes and other household and garden tools are sharpened using the coarse fraction;

- To ensure that the process proceeds smoothly, at first it is recommended to work with a partner who will monitor the uniformity and accuracy of the operator’s movements. Even an untrained person can act as an assistant: he only needs to concentrate on the work. At a more professional level, the operator copes independently;

- It is recommended to work in plastic safety glasses and closed clothing to prevent crumbs or sparks from touching soft or mucous tissues. Neglecting safety precautions when working with the machine is strictly prohibited.

Sharpening or straightening knives?

Before moving on to the instructions on how to sharpen knives on a sharpening machine correctly, you need to determine what kind of care the blade of your tool needs - sharpening or sharpening. What is it for? The fact is that for different types of deformation, the principles of care will also differ. For example, when bending an edge, one nozzle and one speed are used, when removing chips, a completely different disk and different settings are used. Using standard bent edge turning techniques, you can cut off too much metal. Therefore, it is recommended to edit the gun first. Among the mechanical analogues, musat is used to eliminate wavy irregularities and curves - a round oblong file with a handle (Figure 4). However, if you have a machine, processing with hand tools is too energy-intensive.

Figure 4. Variant of the Musat file

Editing is carried out at minimum speed:

- The wave-bent metal is removed completely under the base. It will be impossible to bend it back. It is worth considering that cutting the deformed layer must be done with pinpoint precision, so as not to double the time of further processing and not accidentally shorten the length of the blade;

- Based on the initial edge angle, further work is carried out.

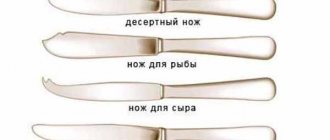

Types of knives and their descriptions

Before you start sharpening a knife, it is worth finding out what metal it was made of. After all, each type of this material has its own care characteristics that the owner of the blade needs to know (Figure 1).

Figure 1. Types of blades by blade material

There are these types of knives:

- Carbon steel:

These are the most affordable in terms of pricing and are made from an alloy of iron and carbon. Blades made of this material are easy to sharpen and remain sharp for a long time. The disadvantage of carbon steel knives is the occurrence of oxidation of the blade due to contact with food or an acidic environment, which causes stains and rust to appear on the metal. The resulting changes on the blade will cause the products to acquire a brighter metallic taste. Once the plaque formation process is complete, oxidation will be complete. - Low-carbon stainless metal:

It is composed of an alloy of iron, carbon and chromium, and in some cases may contain molybdenum or cobalt. Products made from this metal are resistant to corrosion and at the same time are inferior in hardness to knives made of carbon steel. - Made from high-carbon stainless metal:

they belong to a higher class, since the base of such metal products contains a lot of carbon and the addition of vanadium or cobalt. The high quality of the metal alloy protects against corrosion and does not require frequent sharpening. - Damascus steel knives:

most often made as edged weapons, but there may also be kitchen options. A Damascus knife is made from a multi-layer blade that contains various high-quality metal alloys. The high level of quality of these knives made them very expensive, which may be the main disadvantage of these products. - Ceramic knives:

have gained great popularity due to their high sharpness and the absence of the need for frequent sharpening. However, against the backdrop of advantages, there are also negative aspects of ceramic knives, namely fragility (can break if dropped from a height) and poor resistance to fracture.

How to sharpen knives on an emery machine

An electric sharpener, which is based on an emery disc, is used both at home for sharpening cutting edges and in production (Figure 5). The machine is used for sharpening jointing knives, countersinks, dies, drills, spatulas, hand scythes, household and travel blades, scissors and even screwdrivers.

The main requirement for the operator’s work is accuracy and adherence to the algorithm.

Figure 5. Electric grinder in production

How to sharpen knives on a sharpening machine:

- The standard set of sandpaper includes two abrasive discs of different grain sizes. At the first stage of processing, large grains should be used to give the primary shape and sharpness. Finishing is carried out on small crystals. If the blade is made of thin metal, then it is recommended not to use large crystals at all;

- The RPM for most tools should be up to 150 rpm. This value is the maximum, so you can reduce it if you have doubts about the speed;

- The point is made exclusively on the side of the abrasive nozzle. First, the blade is installed parallel to a special stand, then tilted at the required angle (Figure 6). For thin kitchen blades this value will be up to 20 degrees, for tourist and shoe blades - up to 35 or 40 degrees;

- The width of the approach (the transition from the “body” of the blade to the tip) should be 2-3 millimeters. A larger value of 4-5 millimeters is used for rough tools such as an ax or garden shears;

- During the entire process, it is necessary to make smooth and symmetrical movements, barely touching the disk and moving the blade from side to side with the same amplitude. This is necessary for uniform turning;

- To prevent the tool from overheating, if it is impossible to reduce the engine speed, it should be cooled regularly. A container of cold running water will suffice for cooling.

Figure 6. Sharpening a knife: parallel and at an angle

Electric knife sharpeners

An automatic electric knife sharpening machine does not require special care. Previously, such models were used in public catering places - canteens, cafes and restaurants and were a bulky structure. Over time, their dimensions began to decrease, and now they are compact devices with connectors for different types of blades. The entire system is hidden under a plastic or metal casing, thereby increasing the safety factor.

Figure 7. Sharpening a knife on an automatic machine

Let's look at how to properly sharpen knives on an automatic machine (Figure 7):

- First, the point is inserted into the opening for rough processing, brought to the end and fixed between the plates. Since the device is equipped with guides, the disks will be positioned at the required angle as soon as the product is inserted into the slot;

- Then you should turn on the device, selecting standard or individual mode, depending on the provided functionality;

- Sharpening is done by lightly pressing the tip and moving it with the same movements in one direction. It is forbidden to drive first towards yourself, then away from yourself, since nicks will appear in the best case, and the edge will deteriorate in the worst case;

- After initial processing, the tool is inserted into a second slot with fine-grained discs, where it undergoes final grinding and finishing.

Is it possible to sharpen a knife without a stone?

It happens that a knife needs urgent sharpening, but there are no suitable tools. But don’t worry, you can solve the problem in the following ways:

- sharpen a dull knife on the blade of another cutting device;

- sharpen on the raw edges of the bottom of a plate or mug;

- sand the blade with sandpaper, processing only one side;

- take any stone that you find on the street and sharpen it in the same way as you do with a whetstone.

This will allow you to briefly sharpen a dull device, but such methods cannot be called full-fledged sharpening. Remember that it is better to reserve these measures for extreme cases and not to use them constantly, otherwise the blades will quickly become unusable.

How to sharpen knives on a machine with an abrasive wheel

Another way to sharpen knives on a machine correctly is to use a grinder with a granular disk attachment (Figure 8). This method is popular among both professionals and amateurs, since there is no need to buy a separate device for turning.

Figure 8. Sharpening knives using a grinder

Turning on an angle grinder is carried out according to the same algorithm as on emery.

It is enough to fix the device vertically on the surface and install a medium or fine abrasive nozzle. Since the grinder produces over 11,000 rpm at its lowest power, it should be handled very carefully.

Using a sharpener for straightening cutting devices

A separate operation that accompanies the process of sharpening tools is the editing of cutting devices. Its goal is to give the blade an ideal sharpness, subject to the obligatory preservation of the sharpening angles. The steel is also polished at this stage.

Editing is the most critical part of the work, during which mistakes are most often made. This is due to the fact that a thin part of the metal is exposed to the abrasive. As a result, the risk of overheating or damage increases significantly.

Therefore, it is recommended to edit a tool, as opposed to sharpening, by directing the blade along the rotation of the grinding wheel. The abrasive used is fine-grained and only at low speeds.

But for beginners, it is still recommended to edit the cutting tool using a ceramic stone or fine-grained sandpaper.

By following these recommendations, you can maintain your cutting tool in perfect condition at no extra cost. The main thing to remember is that any sharpening method, especially using an electric sharpener, requires mandatory compliance with safety requirements.