All photos from the article

If you decide to take up engraving for your own pleasure, you can eventually turn any ordinary thing into a work of art. The process is not difficult, since you only need to trace the drawing yourself using a special tool or use a 3D wood engraver for this.

You can make almost any picture, it just takes persistence and time.

Hand tool for wood engraving

Today we will talk about how to choose the necessary tool for the job, as well as about the process itself.

Features and purpose

The design of the burr is designed to perform the process of milling decorative elements. With its help, part of the wood layer of the required depth is removed. Despite many years of use, the devices are constantly being modernized in order to improve the quality and accuracy of processing. However, the very basis of the design has remained virtually unchanged. It still consists of two parts:

- shank for fastening standard sizes,

- cutting part.

The main feature of a burr is that it is not a power tool, but a dynamic one, which is why it is used with a tool that ensures its rotation.

In the arsenal of engravers and professional woodcarvers, a Dremel, a special drill, is used to ensure the translational movement of the head of the device along the desired path. In domestic conditions, a screwdriver or electric drill works perfectly with its functions.

A wood cutter can be used if necessary for:

- processing the edge part when combining several workpieces due to grooves.

- fittings of fittings to pieces of furniture,

- production of decorative elements of volumetric and complex configurations.

The attachments can be used in operations:

- drilling,

- polishing,

- grinding,

- tongue and groove,

- surface cleaning,

- creating grooves

- final processing of a hole or cavity.

Arsenal of wood carver tools

The main tool for cutting wood, as mentioned above, is a burr. The implementation of such a procedure, during which a layer of the processed material of various depths is removed, is ensured by the rotation of the cutter, as well as its translational movement along the required trajectory. Accordingly, equipment is also required with which the tool used will be driven into rotation. Such equipment, indispensable for an engraver and any woodcarver, is a drill, often called a Dremel.

Dremel produces electric engravers for household and professional grades

The word “Dremel” comes from the name of the German company Dremel, which produces a large range of electrical equipment, in which drills and specialized engravers occupy a significant place. Drill kits from Dremel and other manufacturers already include everything you need to install the tool and get started.

You can also cut wood using cutters using a conventional electric drill or screwdriver, if you equip them with a flexible shaft and a special attachment on it, into which a burr is installed. This simple device is also suitable for an engraver who works with products made of metal and other materials.

Flexible shaft for drill

The quality and attractiveness of the work performed when cutting wood directly depends on the characteristics of the equipment used. Even the experience and knowledge of the person performing such work cannot positively affect the characteristics of the finished product in the absence of appropriate equipment and wood burrs.

Classification

Wood burrs are rotating parts, the entire surface of which is covered with notches.

They come in different shapes:

- cylindrical,

- spiral,

- hyperbolic,

- oval,

- conical,

- spherical.

The most inexpensive products are made of steel. Their service life is shorter than equipment made from carbide materials, whose notched head is often seated on iron cores using brass solder.

Their high cutting performance coupled with good removal allows achieving results in the shortest possible time without clogging the tool. Thanks to the hard alloy, the products retain their properties for a long time when used even in the most difficult conditions. The processing is as smooth and clean as possible, and the chips are powdery.

The processing properties are influenced by the type of tooth cutting, which can be:

- thin,

- large,

- universal,

- ultra-thin.

Using a large-tooth burr allows you to quickly remove a layer of wood without much effort. Their surface is coated with a special multilayer composition, which increases wear resistance.

Manufacturers offer sets of attachments of different designs and prices:

- prefabricated,

- with replaceable edges,

- monolithic.

- terminal

- copying machines,

- edge

- grooved

A set of wood burrs for an engraver is selected depending on:

- quality of material for processing,

- type of work,

- number of revolutions of the rotation device,

- notch configurations.

The product head with a chipbreaker configuration processes material without sticking, producing maximum removal.

Cutters for artistic wood carving

Thanks to carving and burning, real works of art are made from wood. A glance is enough to understand what the master wanted to express.

Artistic carving is an ornament, pattern or design on the surface of wood. The manual carving tool is designed for slots with a depth of 0.5 mm - 2 mm. Laser engraving products are essentially multifunctional 3D printers. The choice of burrs for carving wood depends on the type of operation. For grooves, it is better to use disk cutters; when making cuts of complex configurations, it is better to use shaped attachments.

Wood carving cutters using a drill

instrument.guru > Manual > Working with a wood carving drill for beginners and masters

Carved wood works, made by the hand of a master, attract attention with the filigree of the finish, the subtlety and elegance of the design, and the beauty of the material itself, which has been given a new long life.

The art of wood carving has a long and glorious history, from carved frames in huts in the Russian hinterland to decorative masks from African villages.

Each professional has his own technologies for carved wood processing in order to obtain a highly artistic product, as well as a set of tools for performing this delicate and painstaking work.

- Choosing a drill for wood carving

- Types and purpose of cutters and attachments

- Final finishing of products

- Tips for beginners from professionals

Hard, durable and heavy types of wood - boxwood, ironwood, hopshorn and many others - attract the attention of true professionals with their original structure and beauty, although their processing requires great patience and skill.

Tips for beginners from professionals

- Before starting to carry out the simplest tasks regarding the artistic processing of wood products, it is recommended to take a master class in wood carving from professional carvers and engravers.

These are invaluable and free lessons for those who want to engage in an exciting activity that gives wide scope to the creativity and imagination of a person who wants to acquire knowledge and skills in a previously unknown area. - Drill carving lessons can be found in numerous good video clips on the Internet portal.

You will become familiar with the most important techniques and methods for processing material in hard-to-reach and inconvenient cavities of the intended product using unique means to achieve the goal.

Wood carving drill

Wood carving is one of the oldest types of craft mastered by mankind.

https://www.youtube.com/watch?v=6OFA572u40A

Wooden lace frames in Russian villages and ritual masks of African tribes - each work is unique and bears the imprint of the master’s personality.

Modern woodcarvers are much better equipped than their ancestors - they have accurate and high-performance electrically driven devices at their service.

Wood carving drill

Types of drills

The variety of devices offered on the market comes down to three main types:

- drills for technical purposes;

- micromotors, or engravers for wood carving;

- mini-drills, or compact drills with a flexible drive.

They differ in purpose, size, power, and performance.

The design of both a powerful woodcarving drill and a micromotor is based on two main components: a high-speed electric motor and a replaceable tool mounted in a chuck.

How to choose the right drill

The main criteria to consider when choosing a wood carving drill are as follows:

- engine power;

- revolutions;

- torque;

- weight;

- ergonomics.

Type of tool and material

The use of the type of burrs directly depends on the technological tasks.

With their help you can work not only on wood, plywood, chipboards, but also on other materials:

- metal,

- cast iron,

- plastic,

- bone,

- combined.

When choosing, you need to consider:

- type of work,

- properties of parts materials,

- dimensions of processed elements,

- scope of use.

Professional products include diamond sharpening products. They are excellent for machining very tough boring materials and fine grinding of deep holes.

Recommendations

- You cannot combine an inch collet with a millimeter shank, otherwise the tool will quickly break.

- It is necessary to ensure full contact of the equipment with the surface being processed.

- For better sliding of the head, use special lubricants.

- You cannot put too much pressure on the burr head, because it will overheat and work slower.

- Do not touch the tool shank to the surface of the part.

- It is important to maintain a high rotation speed to avoid unevenness.

How to choose an engraver for manual work

Hand engraving on wood takes a lot of time and requires:

- a set of gravers - steel rods with ends of different shapes,

- punch for drawing dotted lines,

- lamps with lens,

- device for laying the workpiece,

- flat pad with sand.

Manual milling cutters are equipped with so-called finger designs. Thanks to scientific and technological progress, the modern market offers engravers modern types of wood carving tools that operate on electricity. Manufacturers position them as small format drills.

Beginners should pay attention to the main parameters:

- number of spindle revolutions,

- energy consumption level.

The image in the form of a line pattern is obtained after cutting through the wood to the required depth.

Electric tool sets are equipped with:

- ergonomic handle,

- collets,

- milling, corner attachments.

In 99% of cases, the equipment of a hand-held wood engraver consists of:

- classic cutters fixed with a collet or adapter,

- drills with ball-shaped tips,

- brushes for roughing workpieces and finishing,

- set of drills,

- cutting discs.

Engravers are equipped with ultra-thin cutters, which negatively affects the quality of processing of hard workpieces compared to manual milling cutters

How to work as a wood engraver

Carved wood works, made by the hand of a master, attract attention with the filigree of the finish, the subtlety and elegance of the design, and the beauty of the material itself, which has been given a new long life.

The art of wood carving has a long and glorious history, from carved frames in huts in the Russian hinterland to decorative masks from African villages. Each professional has his own technologies for carved wood processing in order to obtain a highly artistic product, as well as a set of tools for performing this delicate and painstaking work.

Hard, durable and heavy types of wood - boxwood, ironwood, hopshorn and many others - attract the attention of true professionals with their original structure and beauty, although their processing requires great patience and skill.

Choosing a drill for wood carving

There are a large number of units that facilitate the work of the carver. Wood carving with a drill for beginners involves choosing the right tool. The success of learning and the rapid acquisition of the necessary skills depends on this. This work requires considerable perseverance, patience and care.

The most important criteria for determining the quality of a device are the spindle speed and the amount of torque. The speed can be from three to thirty thousand revolutions per minute. The cutter holder is made in a collet and more reliable key form.

To ensure high quality work and the most comfortable and safe operation, it is recommended to have two types of engravers.

One should be relatively low speed but have high torque, and the second should be high speed for finishing and polishing parts.

The price range for wood carving drills is quite wide, but a high price is not a guarantee of good quality and reliability. Basically, you need to focus on well-known brands that have proven themselves in the world market as leading manufacturers.

Powerful and reliable engines are produced, for example, by the American company Foredom SR, which supplies its products with a wide range of components for attachments, holders and cutters for engraving.

The Russian brand “Profile” fully meets the requirements for power, reliability and speed, which, combined with an affordable price, makes the device quite attractive.

Professional drills for wood carving are distinguished by a set of specialized attachments and cutters for performing particularly delicate and precise operations that require mastery skills and knowledge of specific technologies. Such machines are also called mini-drills or hand engravers.

You can make an engraver for wood carving yourself, at home. An electric motor from a washing machine with a power of up to 300 watts is suitable for this purpose. You will need to buy a flexible shaft and a set of heads. In addition, it is necessary to have cutters, polishing and grinding attachments of different sizes. It’s good if it is possible to regulate the engine speed.

Types and purpose of cutters and attachments

- The cutter consists of two parts: the shank and the actual working head. The shank is designed to secure the tool in the device clamp. As a rule, collet clamps are produced by the manufacturer under a specific brand, so you need to have a universal set of fastening tips. Depending on the type of technological operations, the most suitable and convenient tools are selected.

- Cutting discs are designed for initial rough processing of the source material in order to prepare the surface for the main work.

- The working surface of the head can be cylindrical, oval or wedge-shaped. The cutter itself is made of tool steel. To grind surfaces, appropriately shaped attachments with an abrasive coating are used. Rubber mixed with grinding powders is used as an abrasive. A more expensive and effective option is a bur coated with diamond chips. As a rule, burs are produced in sets of 6 pieces and have different configurations of the working surface.

A wide variety of dental instruments allows them to be successfully used in artistic carving. High strength and wear resistance will ensure durable and high-quality use of products.

Final finishing of products

To polish surfaces ready for final finishing, felt wheels are used, onto which a special paste is applied to achieve a mirror-like finish.

After the work is completed and the required quality has been achieved, a thin layer of clear varnish is recommended for soft wood types. This will ensure that the model is insulated from moisture and will increase the durability of the product.

After varnishing, you can polish the surface again until a uniform mirror structure is obtained. Hard grades do not require varnishing and allow you to enjoy the natural beauty of the material.

What is laser engraving on wood?

Laser processing is considered the most labor-intensive engraving - this is an innovative way to remove a layer of material. It eliminates deformation because the object or part does not heat up.

But it should be borne in mind that different wood can be processed differently by laser. Laser engraving of wood differs from laser cutting, so precise focusing of the laser beam and the correct selection of optics are required. Experts do not recommend using this method when engraving small elements, and when cutting, take into account the thickness of the workpiece.

A laser, unlike a burr for an engraver, provides a unique opportunity to perform:

- deep relief engraving,

- wooden mosaic

- contactless processing without damaging the wood structure.

- high processing accuracy with minimal cutting width.

The difference between burrs for wood carving and metal cutters

Structurally, cutters for metal are similar to those used for woodworking. But metal processing is characterized by a greater load on the cutting tool, so the equipment is made from materials with a large margin of safety, smaller sharpening angles, and a special tooth configuration. In addition, technologies differ in cutting modes. When processing wood, the rotation speed of the cutter is higher than when processing even soft metal.

In addition, cutters become very hot during metal processing, so they are made of refractory alloys. Woodworking equipment cannot withstand high temperatures.

Wood burrs (cutters) for engravers: types, purpose, features

Wood products, which in our time remain one of the most popular materials, are actively used for home improvement, as well as for decorative purposes.

Previously, in order to make such products, one had to turn to qualified specialists, but now every home craftsman can perform many works on such material independently, using wood burrs and a regular electric drill or screwdriver.

A wood drill is used for milling technological and decorative elements

Burrs for performing decorative work on wood, which also have other names - “cone cutters”, “cone cutters”, are used not only by home craftsmen, but also by qualified specialists - carvers, for whom the manufacture of wood products is the main activity.

Arsenal of wood carver tools

The main tool for cutting wood, as mentioned above, is a burr.

The implementation of such a procedure, during which a layer of the processed material of various depths is removed, is ensured by the rotation of the cutter, as well as its translational movement along the required trajectory.

Accordingly, equipment is also required with which the tool used will be driven into rotation. Such equipment, indispensable for an engraver and any woodcarver, is a drill, often called a Dremel.

Dremel produces electric engravers for household and professional grades

The word “Dremel” comes from the name of the German company Dremel, which produces a large range of electrical equipment, in which drills and specialized engravers occupy a significant place. Drill kits from Dremel and other manufacturers already include everything you need to install the tool and get started.

You can also cut wood using cutters using a conventional electric drill or screwdriver, if you equip them with a flexible shaft and a special attachment on it, into which a burr is installed. This simple device is also suitable for an engraver who works with products made of metal and other materials.

The quality and attractiveness of the work performed when cutting wood directly depends on the characteristics of the equipment used. Even the experience and knowledge of the person performing such work cannot positively affect the characteristics of the finished product in the absence of appropriate equipment and wood burrs.

Types of burrs for woodworking

Metal is predominantly used as a material for the manufacture of burrs, which are used for both cutting wood and engraving on metal, plastic or stone.

Tools made from carbon steel are suitable for processing softer materials.

In order to cut products made from harder wood, it is necessary to use cutters coated with diamond or with a cutting part made of hard alloys.

Naturally, the most inexpensive are burrs made from carbon steel, but their service life is significantly shorter than that of diamond and carbide tools. Carbide cutters not only have an increased service life, but also allow you to effectively process hard wood, as well as the surface of metal products.

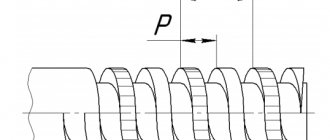

Geometric parameters of the burr

Any burr, regardless of its purpose, consists of two main elements:

- a shank with which the tool is fixed in the equipment used;

- the working part that performs the main work.

The working (or cutting) part of a wood burr can have a different configuration. It is the shape of the cutting part that determines the profile of the groove cut on the surface of the workpiece.

Wood carvers use burrs, the cutting part of which has a conical, oval, semicircular or round shape.

In order to always have the required tool at hand, it is better to immediately purchase a set of cutters, which contains burrs of various sizes and with different shapes of the cutting part.

At the same time, it is better to buy burrs from a trusted manufacturer: they will last much longer and will allow you to cut wood with higher quality.

Wood cutters are available in a variety of teeth, shanks and finishes.

A novice woodcarver should take safety precautions very seriously. Since wood cutting is performed with a burr rotating at high speed, pieces of cut material fly out of the processing area in all directions.

In addition, there are often cases when during such processing not only the cutting teeth of the tool break, but also its entire working head. Such situations are typical for the use of low-quality burrs.

In this regard, in order to protect yourself from injury, all procedures for processing wood products must be performed with protective glasses and gloves.