Vacuum presses for veneering, veneering, laminating, as well as creating bent products are actively used in furniture production. Such installations are successfully used in the manufacture of doors, modular systems, for facades made of wood of various shapes, and even in the production of musical instruments. Using vacuum-type presses, it is possible to apply MDF, chipboard and other finishing materials onto panels as tightly as possible. Due to the vacuum created, there are no air gaps between the products, which results in the highest quality gluing and processing.

Press device

Let's look at the design of a vacuum press using the example of the Master Compact model, which is very popular today. It consists of:

- Heating system. Special lamps are used as heating elements, the type of which differs depending on the scale of production. High-quality heaters provide heating to the required temperature in 2 minutes;

- Desktop. The design of this element allows for cladding for flat or, conversely, radius elements, the height of which can be 300 mm or more. As a rule, tables are made of high-quality aluminum, the thickness of which is at least 6 mm. The table should provide convenient access to the workpiece from all four sides;

- Lifting systems. As a rule, this is a spring-lever mechanism of the thermal module, which is capable of compensating for the weight of the so-called heating cap itself. In this case, when unloading and loading workpieces, the operator does not need to spend a lot of effort;

- Thermomodule. This is a closed device that must protect the workpiece from any environmental influences and changes in temperature or pressure level. Otherwise, it may affect the quality of the future product. Often thermal modules are equipped with viewing windows, allowing the operator to control the entire process of applying film to a wooden workpiece;

- Vacuum pump. The Master Compact press is equipped with a German Busch pump, which has a capacity of 40 m3/h. However, the system can also use other vacuum pumps, each of which differs in its operating principle and characteristics of the pressure created inside the working chamber;

- Control systems. It is a control panel that can switch to manual or automatic mode. For example, the Master Compact system uses a three-phase inverter power controller, which allows you to smoothly change heating rates. This is a very useful option, as it ensures that the object is not deformed due to heating of the film at different intensities. The control system is also responsible for monitoring the heating element in case it fails or begins to malfunction;

- Membranes. Most often used when processing so-called breathable materials. It presses the film and allows you to cover even complex, bent furniture elements with film;

- Pin systems. Thanks to the presence of such a module, there is no need to prepare supports for the workpiece. This significantly speeds up the work process and simplifies the operator’s task. However, such systems are not installed in all vacuum presses, so before purchasing you need to check the availability of this module or order it additionally if the design involves integration;

- Mobile stand. It is very convenient for rolls of film material. In the Master Compact model, such a rack allows you to install 6 rolls at once, after which the press automatically begins to use them one by one. This also speeds up and simplifies the processing process;

- Knife. Typically, presses are equipped with specialized knives for removing excess film after processing;

Press device

Membrane vacuum press

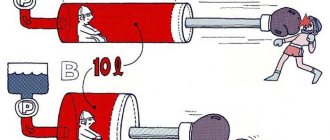

A membrane-vacuum press is most often used for veneering wood blanks and, if necessary, covering complex-shaped or embossed parts with film. Thanks to the membrane, it is possible to achieve the most effective adhesion of the cladding to the product. The process of maximum pressing is carried out under the influence of elevated temperatures and direct vacuum.

Thanks to high pressure, it is possible to significantly increase the productivity of the units. The operating principle of such systems is quite simple:

- First, the wooden blank is lubricated with an adhesive composition and a film or veneer is applied to it;

- At the next stage, the workpiece with the film applied to it is pressed using a special heat-resistant membrane;

- The membrane is heated, after which air begins to be pumped out of it using vacuum equipment;

- The film or veneer is firmly glued to the product due to high pressure;

- The workpiece is cooled.

Membrane vacuum press

If a large installation is used for work, then this allows processing within 140 cm. If the room is quite small, then it is more profitable to use an installation with a special lifting module for heating. In this case, the press is located not horizontally, but vertically, which allows significant savings on space, but does not reduce the productivity of the installation.

After veneering or laminating using this method, the parts can be safely cut into smaller elements, drilled holes in them, or carried out other measures. In this case, the edges of the film will not come off, since they are reliably pressed with the main part and are practically one whole with it.

Multi-span machines

These units do not differ in operating principle from the previous ones, but their structure is more complex and their dimensions are larger. They are equipped with several hydraulic devices, located one above the other (in several tiers).

Thanks to this structure, several plates are processed on the machine at once, which significantly increases productivity. The price of such equipment is an order of magnitude higher than that of single-span equipment. In addition, to install this press you will need a fairly large room.

Post-processing of furniture blanks

As a rule, after gluing the film, some of the material remains on the edges of the workpiece. Therefore, as a rule, such elements are called semi-finished products, which require a number of additional procedures.

As a rule, additional processing uses a special mechanical-type trimming press, a horizontal or vertical band saw, a grinding, milling and drilling machine. Various power tools are also used for work.

Post-processing of furniture blanks

Veneering machines in production line

According to the characteristics, the hot press acts as equipment that is part of a complete line of devices for woodworking and furniture production. After the fiberboard or MDF boards have been veneered, they are sent for further processing. The next stage is finishing trimming the edges and gluing the end parts. There are special machines for this. Thanks to some features of such devices, it is possible to cover not only straight, but also rounded corners.

Features of veneer equipment

The veneering process significantly increases the cost of the finished product. In this case, units of different levels of automation can be used.

There are vacuum installations for small private workshops, and there are also stationary production units that are suitable for mass production of furniture.

Features of veneer equipment

If light loads are expected, it is recommended to purchase manual control models. They are cheaper due to the mechanical control principle. But for industrial use, the best option would be automated systems that independently control technological processes.

Vacuum presses also differ in the parameters of the main modules, which are responsible for heating the system. For example, in models for industrial production, quartz-halogen heating elements are often installed. They are able to provide fairly fast heating, subject to economical energy consumption. More portable, lower-capacity units usually use IR lamps.

If you intend to process products with more complex shapes, then it is better to give preference to thermal vacuum type units, since classic presses are more suitable for veneering even products with simple geometry.

Silicone and rubber membranes for presses

During processing of the workpiece, displacement of the membrane may occur if it is made of low-quality material. This element also acts as a seal, so it is subject to rather strict requirements.

The best membranes are considered to be rubber and silicone products. The first option is optimal if the process of hot and cold pressing is carried out; if necessary, apply veneer or a special film to the workpiece. Silicone membranes are more elastic, so they are often used to work at elevated temperatures, when the characteristics of this material become most advantageous. Also, silicone seals are universal, as they are suitable for different substrates and provide more economical consumption of finishing material.

Silicone and rubber membranes for presses

It is also worth considering that membranes are consumable elements of the system. Even if all equipment operating rules are followed, the membrane is not able to withstand more than 3000 processing cycles. If the press is used to work with chipboard and MDF, then in this case additional glue is used, which is also applied to the membrane itself to ensure tighter bonding.

What to look for when purchasing

Purchasing specialized equipment is a serious, expensive business, so selecting a machine requires careful study of the characteristics. Among the features that require increased attention are the following:

- number of hydraulic devices (directly affects performance);

- working surface dimensions;

- maximum heating temperature;

- dimensions and weight of equipment.

Many European and Russian companies are engaged in the production of such machines. Most manufacturers include a photo of a hot press, which makes the choice much easier. You can see some samples in the article.

In other words, a hot veneer press is an extremely important link in the furniture production line. The presented models differ in volume, performance, appearance and cost, so you need to take the purchase extremely seriously. At the same time, taking into account the advice of experts, it will be quite simple to decide on a suitable model.